ASTM D1527-99(2005)

(Specification)Standard Specification for Acrylonitrile-Butadiene-Styrene (ABS) Plastic Pipe, Schedules 40 and 80 (Withdrawn 2014)

Standard Specification for Acrylonitrile-Butadiene-Styrene (ABS) Plastic Pipe, Schedules 40 and 80 (Withdrawn 2014)

ABSTRACT

This specification covers acrylonitrile-butadiene-styrene (ABS) plastic pipe produced by single extrusion or simultaneous multiple coextrusion, in Schedule 40 and 80 sizes and pressure-rated for water. Included are criteria for classifying ABS plastic pipe materials and ABS plastic pipe, a system of nomenclature for ABS plastic pipe, and requirements and test methods for materials, workmanship, dimensions, sustained pressure, burst pressure, and extrusion quality. The pipe shall be homogeneous throughout and free of visible cracks, holes, foreign inclusions, or other defects. It shall be as uniform as commercially practicable in color, opacity, density, and other physical properties. The pipe shall not fail, balloon, burst, or weep upon sustained and burst pressure testing in water.

SCOPE

1.1 This specification covers acrylonitrile-butadienestyrene (ABS) pipe produced by single extrusion or simultaneous multiple coextrusion, in Schedule 40 and 80 sizes and pressure-rated for water (see Appendix). Included are criteria for classifying ABS plastic pipe materials and ABS plastic pipe, a system of nomenclature for ABS plastic pipe, and requirements and test methods for materials, workmanship, dimensions, sustained pressure, burst pressure, and extrusion quality. Methods of marking are also given.

1.2 The products covered by this specification are intended for use with the distribution of pressurized liquids only, which are chemically compatible with the piping materials. Due to inherent hazards associated with testing components and systems with compressed air or other compressed gases some manufacturers do not allow pneumatic testing of their products. Consult with specific product/component manufacturers for their specific testing procedures prior to pneumatic testing.

Note 1—Pressurized (compressed) air or other compressed gases contain large amounts of stored energy which present serious saftey hazards should a system fail for any reason.

1.3 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information purposes only.

1.5 The following safety hazards caveat pertains only to the test method portion, Section 7, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This specification covers acrylonitrile-butadienestyrene (ABS) pipe produced by single extrusion or simultaneous multiple coextrusion, in Schedule 40 and 80 sizes and pressure-rated for water (see Appendix). Included are criteria for classifying ABS plastic pipe materials and ABS plastic pipe, a system of nomenclature for ABS plastic pipe, and requirements and test methods for materials, workmanship, dimensions, sustained pressure, burst pressure, and extrusion quality. Methods of marking are also given.

Formerly under the jurisdiction of Committee F17 on Plastic Piping Systems, this specification was withdrawn in November 2013. This standard is being withdrawn without replacement due to its limited use by industry.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1527 −99(Reapproved 2005) An American National Standard

Standard Specification for

Acrylonitrile-Butadiene-Styrene (ABS) Plastic Pipe,

Schedules 40 and 80

This standard is issued under the fixed designation D1527; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

1.1 This specification covers acrylonitrile-butadienestyrene 2.1 ASTM Standards:

(ABS) pipe produced by single extrusion or simultaneous D618 Practice for Conditioning Plastics for Testing

multiplecoextrusion,inSchedule40and80sizesandpressure- D1598 Test Method for Time-to-Failure of Plastic Pipe

rated for water (see Appendix). Included are criteria for Under Constant Internal Pressure

classifyingABS plastic pipe materials andABS plastic pipe, a D1599 Test Method for Resistance to Short-Time Hydraulic

systemofnomenclatureforABSplasticpipe,andrequirements Pressure of Plastic Pipe, Tubing, and Fittings

and test methods for materials, workmanship, dimensions, D1600 Terminology forAbbreviatedTerms Relating to Plas-

sustained pressure, burst pressure, and extrusion quality. Meth- tics

ods of marking are also given. D2122 Test Method for Determining Dimensions of Ther-

moplastic Pipe and Fittings

1.2 The products covered by this specification are intended

D2837 Test Method for Obtaining Hydrostatic Design Basis

for use with the distribution of pressurized liquids only, which

forThermoplasticPipeMaterialsorPressureDesignBasis

are chemically compatible with the piping materials. Due to

for Thermoplastic Pipe Products

inherent hazards associated with testing components and sys-

D3965 ClassificationSystemandBasisforSpecificationsfor

tems with compressed air or other compressed gases some

Rigid Acrylonitrile-Butadiene-Styrene (ABS) Materials

manufacturersdonotallowpneumatictestingoftheirproducts.

for Pipe and Fittings

Consult with specific product/component manufacturers for

F412 Terminology Relating to Plastic Piping Systems

their specific testing procedures prior to pneumatic testing.

2.2 Federal Standard:

NOTE 1—Pressurized (compressed) air or other compressed gases

contain large amounts of stored energy which present serious saftey Fed. Std. No. 123 Marking for Shipments (Civil Agencies)

hazards should a system fail for any reason.

2.3 Military Standard:

1.3 The text of this specification references notes, footnotes, MIL-STD-129 Marking for Shipment and Storage

and appendixes which provide explanatory material. These

2.4 NSF Standards:

notesandfootnotes(excludingthoseintablesandfigures)shall Standard No. 14 for Plastic Piping Components and Related

not be considered as requirements of the specification.

Materials

Standard No. 61 for Drinking Water System Components—

1.4 The values stated in inch-pound units are to be regarded

Health Effects

as the standard. The values given in parentheses are provided

for information purposes only.

3. Terminology

1.5 The following safety hazards caveat pertains only to the

3.1 Definitions—Definitions are in accordance with Termi-

test method portion, Section 7, of this specification. This

nology F412. Abbreviations are in accordance with Terminol-

standard does not purport to address all of the safety concerns,

ogy D1600, unless otherwise indicated. The abbreviation for

if any, associated with its use. It is the responsibility of the user

acrylonitrile-butadiene-styrene plastic is ABS.

of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

tions prior to use.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

This specification is under the jurisdiction ofASTM Committee F17 on Plastic the ASTM website.

Piping Systems and is the direct responsibility of Subcommittee F17.61 on Water. AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Current edition approved Aug. 1, 2005. Published August 2005. Originally Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

´1 4

approved in 1958. Last previous edition approved in 1999 as D1527 – 99 . DOI: Available from the National Sanitation Foundation, P.O. Box 1468,AnnArbor,

10.1520/D1527-99R05. MI 48106.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1527−99 (2005)

TABLE 1 Outside Diameters and Tolerances for ABS Plastic Pipe

3.2 Definitions of Terms Specific to This Standard:

Schedules 40 and 80, in.

3.2.1 acrylonitrile-butadiene-styrene (ABS) pipe and fitting

plastics —plastics containing polymers or blends of polymers, Tolerances

or both, in which the minimum butadiene content is 6 %, the For Max and Min Diameter (Out-

of-Roundness)

minimum acrylonitrile content is 15 %, the minimum styrene

Average

Nominal

Schedule 40 Schedule 40

Outside

For Average

or substituted styrene content, or both, is 15 %, and the

Pipe Size

sizes 3 ⁄2 in. and sizes 3 in. and

Diameter

Diameter

maximum content of all other monomers is not more than 5 %,

over, Schedule less, Schedule

80 sizes 8 in. 80 sizes 6 in.

and lubricants, stabilizers, and colorants.

and over and less

3.2.2 hydrostatic design stress—the estimated maximum

tensile stress the material is capable of withstanding continu- 1

⁄8 0.405 60.004 60.015 60.008

⁄4 0.540 60.004 60.015 60.008

ously with a high degree of certainty that failure of the pipe

⁄8 0.675 60.004 60.015 60.008

will not occur. This stress is circumferential when internal

⁄2 0.840 60.004 60.015 60.008

hydrostatic water pressure is applied. 3

⁄4 1.050 60.004 60.015 60.010

1 1.315 60.005 60.015 60.010

3.2.3 pressure rating (PR)—the estimated maximum water

1 ⁄4 1.660 60.005 60.015 60.012

pressure the pipe is capable of withstanding continuously with 1

1 ⁄2 1.900 60.006 60.030 60.012

2 2.375 60.006 60.030 60.012

a high degree of certainty that failure of the pipe will not occur.

2 ⁄2 2.875 60.007 60.030 60.015

3.2.4 relation between dimensions, hydrostatic design

3 3.500 60.008 60.030 60.015

3 ⁄2 4.000 60.008 60.050 60.015

stress, and pressure rating—thefollowingexpressionisusedin

4 4.500 60.009 60.050 60.015

this specification to relate dimensions, hydrostatic design

5 5.563 60.010 60.050 60.030

stress, and pressure rating:

6 6.625 60.011 60.050 60.035

8 8.625 60.015 60.075 60.045

2 S/P5~ D /t!21 (1)

O

10 10.750 60.015 60.075 60.050

12 12.750 60.015 60.075 60.060

where:

S = hydrostatic design stress, psi (or MPa),

P = pressure rating, psi (or MPa),

TABLE 2 Wall Thicknesses and Tolerances for ABS Plastic Pipe

D = average outside diameter, in. (or mm), and

Schedules 40 and 80, in.

O

t = minimum wall thickness, in. (or mm).

A

Wall Thickness

Nominal

3.2.5 standard thermoplastic pipe materials designation

Pipe Schedule 40 Schedule 80

code—the pipe materials designation code shall consist of the Size

Min Tolerance Min Tolerance

abbreviation ABS for the type of plastic, followed by the

ASTM type and grade (see Table X1.1) and the hydrostatic ⁄8 0.068 +0.020 0.095 +0.020

⁄4 0.088 +0.020 0.119 +0.020

design stress in units of 100 psi with any decimal figures

⁄8 0.091 +0.020 0.126 +0.020

dropped. When the design stress code contains less than two

⁄2 0.109 +0.020 0.147 +0.020

⁄4 0.113 +0.020 0.154 +0.020

figures, a cipher shall be used before the number. Thus a

1 0.133 +0.020 0.179 +0.021

complete material code shall consist of three letters and four

1 ⁄4 0.140 +0.020 0.191 +0.023

figures for ABS plastic pipe materials (see 6.3). 1

1 ⁄2 0.145 +0.020 0.200 +0.024

2 0.154 +0.020 0.218 +0.026

2 ⁄2 0.203 +0.024 0.276 +0.033

4. Pipe Classification

3 0.216 +0.026 0.300 +0.036

3 ⁄2 0.226 +0.027 0.318 +0.038

4.1 General—This specification coversABS pipe, produced

4 0.237 +0.028 0.337 +0.040

by single extrusion or simultaneous multiple coextrusion from

5 0.258 +0.031 0.375 +0.045

three ABS plastic pipe materials in Schedule 40 and 80 sizes.

6 0.280 +0.034 0.432 +0.052

8 0.322 +0.039 0.500 +0.060

Pipe produced by simultaneous multiple coextrusion shall be

10 0.365 +0.044 0.593 +0.071

classified “CoeX.”

12 0.406 +0.049 0.687 +0.082

A

The minimum is the lowest wall thickness of the pipe at any cross section.The

5. Requirements

maximum permitted wall thickness, at any cross section, is the minimum wall

thickness plus the stated tolerance. All tolerances are on the plus side of the

5.1 Workmanship—The pipe shall be homogeneous

minimum requirement.

throughout and free of visible cracks, holes, foreign inclusions,

or other defects. The pipe shall be as uniform as commercially

practicable in color, opacity, density, and other physical prop- 5.2.3 Thickness of Outer Layer—For pipe produced by

erties. simultaneous multiple coextrusion, that is, pipe containing two

ormoreconcentriclayers,theouterlayershallbeatleast0.020

5.2 Dimensions and Tolerances:

in. (0.50 mm) thick.

5.2.1 Outside Diameters—The outside diameters and toler-

5.2.4 Wall Thickness Range—The wall thickness range shall

ances shall be as shown in Table 1 when measured in

be within 12 % when measured in accordance with 7.4 and

accordance with 7.4 and 7.4.1.

7.4.3.

5.2.2 Wall Thickness—The wall thicknesses and tolerances

shall be as shown in Table 2 when measured in accordance 5.3 Bond—For pipe produced by simultaneous multiple

with 7.4 and 7.4.2. coextrusion, the bond between the layers shall be strong and

D1527−99 (2005)

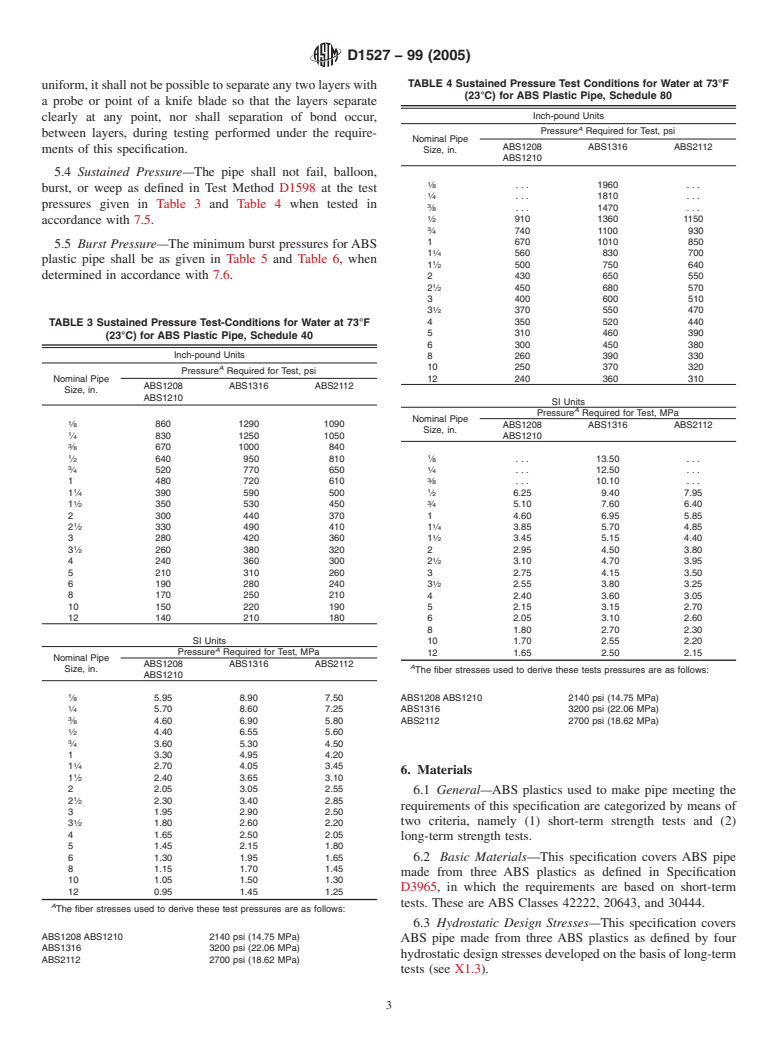

TABLE 4 Sustained Pressure Test Conditions for Water at 73°F

uniform, it shall not be possible to separate any two layers with

(23°C) for ABS Plastic Pipe, Schedule 80

a probe or point of a knife blade so that the layers separate

Inch-pound Units

clearly at any point, nor shall separation of bond occur,

A

Pressure Required for Test, psi

between layers, during testing performed under the require-

Nominal Pipe

ABS1208 ABS1316 ABS2112

ments of this specification.

Size, in.

ABS1210

5.4 Sustained Pressure—The pipe shall not fail, balloon,

⁄8 . . . 1960 . . .

burst, or weep as defined in Test Method D1598 at the test

⁄4 . . . 1810 . . .

pressures given in Table 3 and Table 4 when tested in 3

⁄8 . . . 1470 . . .

⁄2 910 1360 1150

accordance with 7.5.

⁄4 740 1100 930

1 670 1010 850

5.5 Burst Pressure—The minimum burst pressures forABS

1 ⁄4 560 830 700

plastic pipe shall be as given in Table 5 and Table 6, when

1 ⁄2 500 750 640

determined in accordance with 7.6. 2 430 650 550

2 ⁄2 450 680 570

3 400 600 510

3 ⁄2 370 550 470

TABLE 3 Sustained Pressure Test-Conditions for Water at 73°F 4 350 520 440

5 310 460 390

(23°C) for ABS Plastic Pipe, Schedule 40

6 300 450 380

Inch-pound Units 8 260 390 330

A 10 250 370 320

Pressure Required for Test, psi

Nominal Pipe 12 240 360 310

ABS1208 ABS1316 ABS2112

Size, in.

ABS1210

SI Units

A

Pressure Required for Test, MPa

Nominal Pipe

⁄8 860 1290 1090

ABS1208 ABS1316 ABS2112

Size, in.

⁄4 830 1250 1050 ABS1210

⁄8 670 1000 840

1 1

⁄2 640 950 810 ⁄8 . 13.50 .

3 1

⁄4 520 770 650 ⁄4 . 12.50 .

1 480 720 610 ⁄8 . 10.10 .

1 1

1 ⁄4 390 590 500 ⁄2 6.25 9.40 7.95

1 ⁄2 350 530 450 ⁄4 5.10 7.60 6.40

2 300 440 370 1 4.60 6.95 5.85

1 1

2 ⁄2 330 490 410

1 ⁄4 3.85 5.70 4.85

3 280 420 360 1 ⁄2 3.45 5.15 4.40

3 ⁄2 260 380 320 2 2.95 4.50 3.80

4 240 360 300 2 ⁄2 3.10 4.70 3.95

5 210 310 260 3 2.75 4.15 3.50

6 190 280 240 3 ⁄2 2.55 3.80 3.25

8 170 250 210 4 2.40 3.60 3.05

10 150 220 190 5 2.15 3.15 2.70

12 140 210 180 6 2.05 3.10 2.60

8 1.80 2.70 2.30

SI Units 10 1.70 2.55 2.20

A

Pressure Required for Test, MPa 12 1.65 2.50 2.15

Nominal Pipe

ABS1208 ABS1316 ABS2112

A

Size, in. The fiber stresses used to derive these tests pressures are as follows:

ABS1210

⁄8 5.95 8.90 7.50 ABS1208 ABS1210 2140 psi (14.75 MPa)

⁄4 5.70 8.60 7.25 ABS1316 3200 psi (22.06 MPa)

⁄8 4.60 6.90 5.80 ABS2112 2700 psi (18.62 MPa)

⁄2 4.40 6.55 5.60

⁄4 3.60 5.30 4.50

1 3.30 4.95 4.20

1 ⁄4 2.70 4.05 3.45

6. Materials

1 ⁄2 2.40 3.65 3.10

2 2.05 3.05 2.55

6.1 General—ABS plastics used to make pipe meeting the

2 ⁄2 2.30 3.40 2.85

requirements of this specification are categorized by means of

3 1.95 2.90 2.50

two criteria, namely (1) short-term strength tests and (2)

3 ⁄2 1.80 2.60 2.20

4 1.65 2.50 2.05

long-term strength tests.

5 1.45 2.15 1.80

6 1.30 1.95 1.65 6.2 Basic Materials—This specification covers ABS pipe

8 1.15 1.70 1.45

made from three ABS plastics as defined in Specification

10 1.05 1.50 1.30

D3965, in which the requirements are based on short-term

12 0.95 1.45 1.25

tests. These are ABS Classes 42222, 20643, and 30444.

A

The fiber stresses used to derive these test pressures are as follows:

6.3 Hydrostatic Design Stresses—This specification covers

ABS1208 ABS1210 2140 psi (14.75 MPa)

ABS pipe made from three ABS plastics as defined by four

ABS1316 3200 psi (22.06 MPa)

hydrostatic design stresses developed on the basis of long-term

ABS2112 2700 psi (18.62 MPa)

tests (see X1.3).

D1527−99 (2005)

TABLE 5 Burst Pressure Requirements for Water at 73°F (23°C) TABLE 6 Burst Pressure Requirements for Water at 73°F (23°C)

for ABS Plastic Pipe, Schedule 40 for ABS Plastic Pipe, Schedule 80

Inch-pound Units Inch-pound Units

A A

Minimum Burst Pressure, psi Minimum Burst Pressures, psi

Nominal Pipe Nominal Pipe

ABS1208 ABS1316 ABS2112 ABS1208 ABS1316 ABS2112

Size, in. Size, in.

ABS1210 ABS1210

1 1

⁄8 2110 2420 2660 ⁄8 . . . 3680 . . .

1 1

⁄4 2040 2340 2570 ⁄4 . . . 3390 . . .

3 3

⁄8 1630 1870 2060 ⁄8 . . . 2750 . . .

1 1

⁄2 1560 1790 1970 ⁄2 2220 2550 2800

3 3

⁄4 1260 1450 1590 ⁄4 1800 2060 2270

1 1180 1350 1490 1 1650 1890 2080

1 1

1 ⁄4 970 1110 1220 1 ⁄4 1360 1560 1720

1 1

1 ⁄2 870 990 1090 1 ⁄2 1230 1410 1550

2 730 830 920 2 1060 1210 1330

1 1

2 ⁄2 800 910 1000 2 ⁄2 1110 1270 1400

3 690 790 870 3 980 1120 1240

1 1

3 ⁄2 630 720 790 3 ⁄2 910 1020 1140

4 580 670 730 4 850 970 1070

5 510 580 640 5 760 870 950

6 460 530 580 6 730 840 920

8 410 470 510 8 640 740 810

10 370 420 460 10 610 700 770

12 340 390 430 12 600 680 750

SI Units SI Units

A A

Minimum Burst Pressures, MPa Minimum Burst Pressures, MPa

Nominal Pipe

ABS1208 ABS1316 ABS2112 Nominal Pipe ABS1208 ABS1316 ABS2112

Size, in.

ABS1210 Size, in. ABS1210

1 1

⁄8 14.6 16.7 18.3 ⁄8 . 25.4 .

1 1

⁄4 14.1 16.1 17.7 ⁄4 . 23.4 .

3 3

⁄8 11.2 12.9 14.2 ⁄8 . 19.0 .

1 1

⁄2 10.8 12.3 13.6 ⁄2 15.3 17.6 19.3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.