ASTM D4350-00(2005)

(Test Method)Standard Test Method for Corrosivity Index of Plastics and Fillers

Standard Test Method for Corrosivity Index of Plastics and Fillers

SIGNIFICANCE AND USE

This test method provides a means for comparing the corrosive potential of plastics and fillers in humid atmospheres.

This test method is intended for use in research and evaluation.

SCOPE

1.1 This test method is designed for use in obtaining the specific conductance of a water extract of plastics and fillers. The magnitude of this conductance may be taken as an index of the likelihood that, in a humid atmosphere, metal surfaces in contact with these materials may become corroded due to galvanic action or direct chemical attack; this is called the corrosivity index. Note 1There is no similar or equivalent ISO standard.

1.2 The values stated in SI units are to be regarded as standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4350 −00(Reapproved 2005)

Standard Test Method for

Corrosivity Index of Plastics and Fillers

This standard is issued under the fixed designation D4350; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope time. The specific resistance of each of the solutions extracted

from the test specimens is measured by using the specified

1.1 This test method is designed for use in obtaining the

conductivity cell. The specific conductance is calculated from

specific conductance of a water extract of plastics and fillers.

the data and is called the corrosivity index of the material.

The magnitude of this conductance may be taken as an index

ofthelikelihoodthat,inahumidatmosphere,metalsurfacesin

4. Significance and Use

contact with these materials may become corroded due to

4.1 This test method provides a means for comparing the

galvanic action or direct chemical attack; this is called the

corrosivity index. corrosivepotentialofplasticsandfillersinhumidatmospheres.

4.2 This test method is intended for use in research and

NOTE 1—There is no similar or equivalent ISO standard.

evaluation.

1.2 The values stated in SI units are to be regarded as

standard.

5. Apparatus

1.3 This standard does not purport to address all of the

5.1 Conductance Bridge, Wheatstone type, with a range

safety concerns, if any, associated with its use. It is the

from 1 to 250 000-Ω measured resistance, a built-in

responsibility of the user of this standard to establish appro-

potentiometer, a 1000 6 50-cycles per second oscillator, and a

priate safety and health practices and determine the applica-

sensitive null point indicator. The bridge shall be capable of

bility of regulatory limitations prior to use. Specific precau-

measuring resistance with an accuracy of 62%.

tionary statements are given in Section 7.

5.2 Conductivity Cell, dip-type, micro, for solutions of

2. Referenced Documents

medium conductance. The cell should have a cell constant of

−1

2.1 ASTM Standards:

approximately 1.0 cm . The borosilicate glass shall have a

D618Practice for Conditioning Plastics for Testing

maximum outside tube diameter of 12.7 mm, overall length of

D1193Specification for Reagent Water

177.8 mm, chamber inside diameter of 9.5 mm, and chamber

E1Specification for ASTM Liquid-in-Glass Thermometers

depth of 50.8 mm.

E11Specification forWovenWireTest Sieve Cloth andTest

5.3 Drill, electric, capable of holding a 10.54-mm drill bit,

Sieves

and rotating at 500-r/min maximum speed.

E145Specification for Gravity-Convection and Forced-

5.4 Mill,suchaslaboratoryWileycuttingmillorequivalent.

Ventilation Ovens

E691Practice for Conducting an Interlaboratory Study to

5.5 Sieves, standard (alternative) sieve designations 425 µm

Determine the Precision of a Test Method

(No. 40), and 250 µm (No. 60) in accordance with Specifica-

tion E11.

3. Summary of Test Method

5.6 Analytical Balance, capable of determining mass to the

3.1 Specimensofplasticsorfillersareimmersedindistilled

nearest 1.0 mg.

water and exposed to specified conditions of temperature and

5.7 Oven, forced-ventilation type, with uniformity of tem-

ThistestmethodisunderthejurisdictionofASTMCommitteeD20onPlastics

perature within 61% of the differential between oven and

and is the direct responsibility of Subcommittee D20.16 on Thermosetting Materi-

als.

Current edition approved Nov. 1, 2005. Published January 2006. Originally

approved in 1984. Last previous edition approved in 2000 as D4350-00. DOI: The sole source of supply of the conductivity cell (Model No. 3403) known to

10.1520/D4350-00R05. the committee at this time is Yellow Springs Instrument Co., Inc., P.O. Box 279,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or YellowSprings,OH45387.Ifyouareawareofalternativesuppliers,pleaseprovide

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM this information toASTM International Headquarters. Your comments will receive

Standards volume information, refer to the standard’s Document Summary page on careful consideration at a meeting of the responsible technical committee, which

the ASTM website. you may attend.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4350−00 (2005)

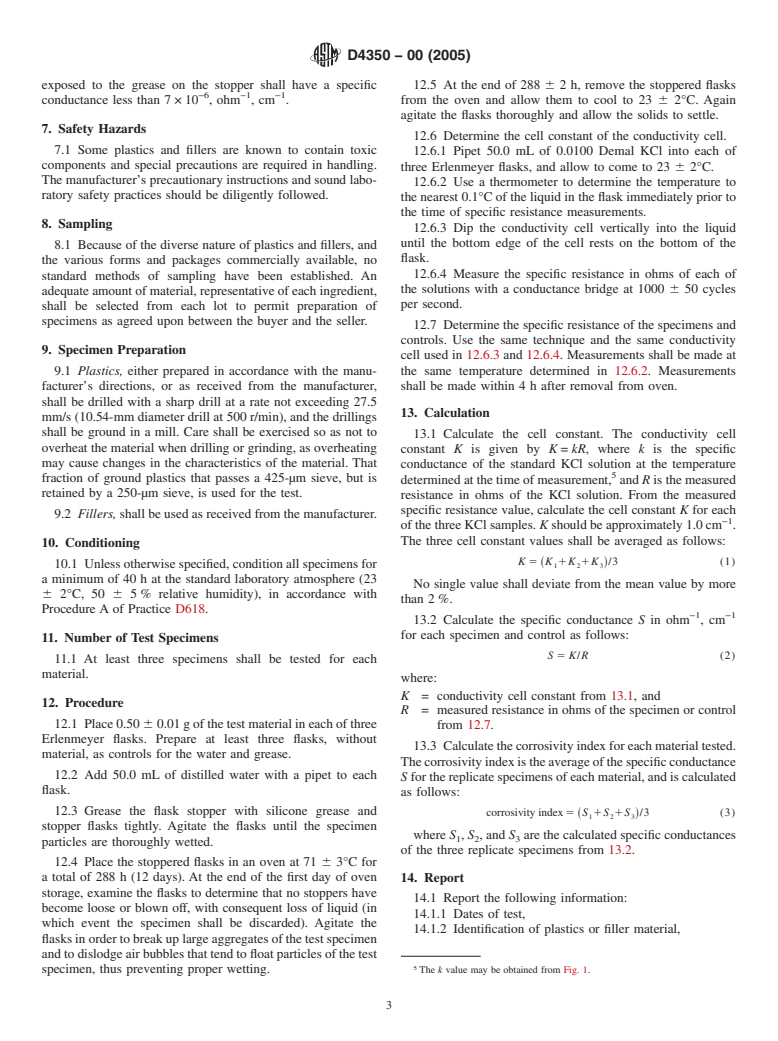

FIG. 1 Specific Conductance of 0.0100 Demal KCl

ambienttemperature,witharateofventilationof100to200air at 23 6 2°C, the water shall have a calculated specific

−6 −1 −1

changesperhour,inaccordancewithSpecificationE145,Type conductance of less than 2.0×10 , ohm ,cm .

IIA.

6.2 Potassium Chloride Solution, consisting of 0.7453 g of

5.8 Thermometer, solid-stem, precision,ASTM No. 63C, in reagent grade potassium chloride, previously dried at 105 6

accordance with Specification E1. 3°Cforatleast24h,dissolvedin1000gofdistilledwater.The

solution shall be stored in a borosilicate glass stoppered bottle.

5.9 Chemical Glassware:

Thespecificconductanceofthis0.0100DemalKClsolutionis

5.9.1 Borosilicate Glass Flask, nominally 1000-mL size,

−1 −1 −1 −1

0.0007736 ohm ,cm at 0°C, 0.0012205 ohm ,cm at

with ground glass stopper.

−1 −1 4

18°C, and 0.0014087 ohm ,cm at 25°C. This specific

5.9.2 Borosilicate Glass Erlenmeyer Flask, 65-mL actual

conductance versus temperature is plotted in Fig. 1.

capacity to bottom of stopper (nominally 50-mL size), with

ground glass stopper No. 19. 6.3 Grease,silicone,notsolubleinwaternorcontainingany

5.9.3 Pipet, volumetric, 50-mL capacity, calibrated “to de- water-soluble constituents. In the control specimens, water

liver.”

6. Reagents and Materials SpecificconductancevaluesarebasedontheworkofJones,G.,andBradshaw,

B. C., J. Amer. Chem. Soc., 55 (1933) 1780. For more detailed information on the

6.1 Distilled Water, Type III, reagent water as defined in

use of Demal KCl, see“ Electrolyte Solutions,” by Robinson, R.A., and Stokes, R.

Specification D1193. When stored in borosilicate glass bottles H., Academic Press, Inc., New York, 1955, pp. 94–96.

D4350−00 (2005)

exposed to the grease on the stopper shall have a specific 12.5 At the end of 288 6 2 h, remove the stoppered flasks

−6 −1 −1

conductance less than 7×10 , ohm ,cm . from the oven and allow them to cool to 23 6 2°C. Again

agitate the flasks thoroughly and allow the solids to settle.

7. Safety Hazards

12.6 Determine the cell constant of the conductivity cell.

7.1 Some plastics and fillers are known to contain toxic

12.6.1 Pipet 50.0 mL of 0.0100 Demal KCl into each of

components and special precautions are required in handling.

three Erlenmeyer flasks, and allow to come to 23 6 2°C.

Themanufacturer’sprecautionaryinstructionsandsoundlabo-

12.6.2 Use a thermometer to determine the temperature to

ratory safety practices should be diligently followed.

thenearest0.1°Coftheliquidintheflaskimmediatelypriorto

the time of specific resistance measurements.

8. Sampling

12.6.3 Dip the conductivity cell vertically into the liquid

until the bottom edge of the cell rests on the bottom of the

8.1 Because of the diverse nature of plastics and fillers, and

flask.

the various forms and packages commercially available, no

12.6.4 Meas

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.