ASTM D36/D36M-14

(Test Method)Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus)

Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus)

SIGNIFICANCE AND USE

4.1 Bitumens are viscoelastic materials without sharply defined melting points; they gradually become softer and less viscous as the temperature rises. For this reason, softening points must be determined by an arbitrary and closely defined method if results are to be reproducible.

4.2 The softening point is useful in the classification of bitumens, as one element in establishing the uniformity of shipments or sources of supply, and is indicative of the tendency of the material to flow at elevated temperatures encountered in service.

SCOPE

1.1 This test method covers the determination of the softening point of bitumen in the range from 30 to 157°C [86 to 315°F] using the ring-and-ball apparatus immersed in distilled water [30 to 80°C] or USP glycerin (above 80 to 157°C).

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D36/D36M − 14

StandardTest Method for

1

Softening Point of Bitumen (Ring-and-Ball Apparatus)

This standard is issued under the fixed designation D36/D36M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Summary of Test Method

3.1 Two horizontal disks of bitumen, cast in shouldered

1.1 This test method covers the determination of the soft-

brass rings, are heated at a controlled rate in a liquid bath while

ening point of bitumen in the range from 30 to 157°C [86 to

each supports a steel ball.The softening point is reported as the

315°F] using the ring-and-ball apparatus immersed in distilled

mean of the temperatures at which the two disks soften enough

water [30 to 80°C] or USP glycerin (above 80 to 157°C).

to allow each ball, enveloped in bitumen, to fall a distance of

1.2 The values stated in either SI units or inch-pound units

25 mm [1.0 in.].

are to be regarded separately as standard. The values stated in

each system may not be exact equivalents; therefore, each

4. Significance and Use

system shall be used independently of the other. Combining

4.1 Bitumens are viscoelastic materials without sharply

values from the two systems may result in non-conformance

defined melting points; they gradually become softer and less

with the standard.

viscous as the temperature rises. For this reason, softening

1.3 This standard does not purport to address all of the

points must be determined by an arbitrary and closely defined

safety concerns, if any, associated with its use. It is the

method if results are to be reproducible.

responsibility of the user of this standard to establish appro-

4.2 The softening point is useful in the classification of

priate safety and health practices and determine the applica-

bitumens, as one element in establishing the uniformity of

bility of regulatory limitations prior to use.

shipments or sources of supply, and is indicative of the

tendency of the material to flow at elevated temperatures

2. Referenced Documents

encountered in service.

2

2.1 ASTM Standards:

C670 Practice for Preparing Precision and Bias Statements

5. Apparatus

for Test Methods for Construction Materials

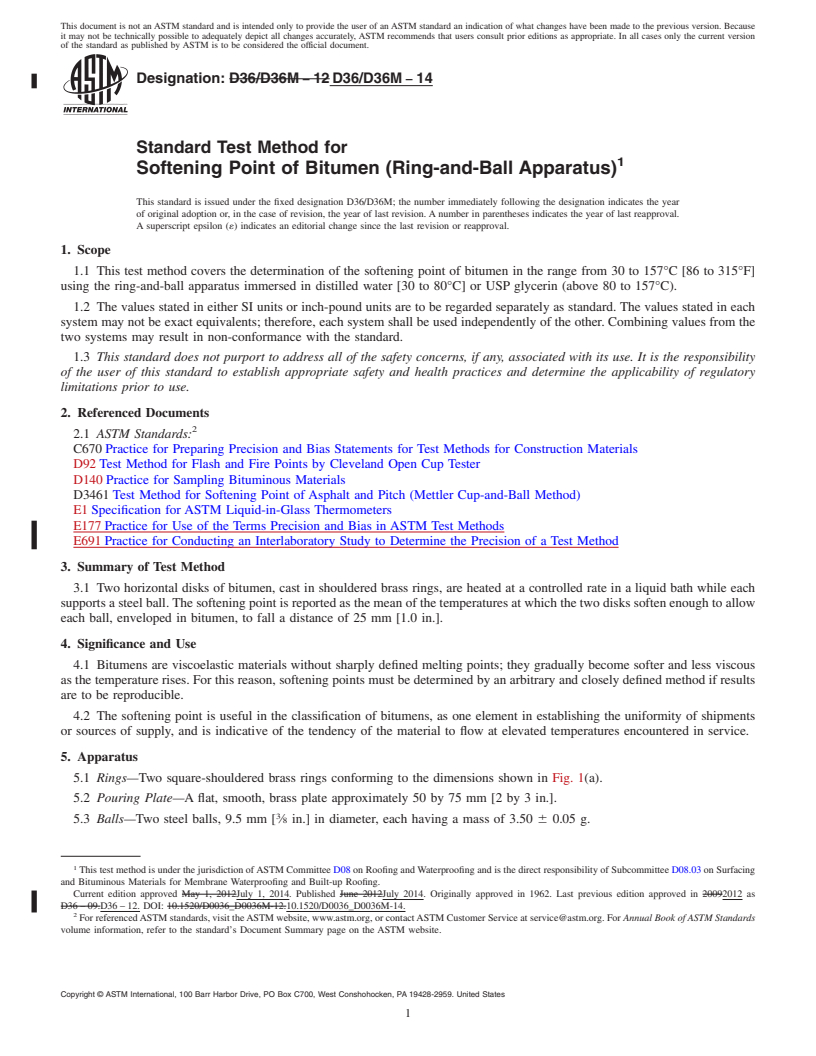

5.1 Rings—Two square-shouldered brass rings conforming

D92 Test Method for Flash and Fire Points by Cleveland

to the dimensions shown in Fig. 1(a).

Open Cup Tester

D140 Practice for Sampling Bituminous Materials

5.2 Pouring Plate—A flat, smooth, brass plate approxi-

D3461 Test Method for Softening Point ofAsphalt and Pitch

mately 50 by 75 mm [2 by 3 in.].

(Mettler Cup-and-Ball Method)

3

5.3 Balls—Two steel balls, 9.5 mm [ ⁄8 in.] in diameter, each

E1 Specification for ASTM Liquid-in-Glass Thermometers

having a mass of 3.50 6 0.05 g.

E177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods 5.4 Ball-Centering Guides—Two brass guides for centering

E691 Practice for Conducting an Interlaboratory Study to

the steel balls, one for each ring, conforming to the general

Determine the Precision of a Test Method

shape and dimensions shown in Fig. 1 (b).

5.5 Bath—A glass vessel, capable of being heated, not less

than 85 mm in inside diameter and not less than 120 mm in

1

This test method is under the jurisdiction ofASTM Committee D08 on Roofing

depth from the bottom of the flare.

and Waterproofing and is the direct responsibility of Subcommittee D08.03 on

Surfacing and Bituminous Materials for Membrane Waterproofing and Built-up

NOTE 1—An 800-mL, low-form Griffin beaker of heat-resistant glass

Roofing.

meets this requirement.

Current edition approved July 1, 2014. Published July 2014. Originally approved

5.6 Ring Holder and Assembly—A brass holder designed to

in 1962. Last previous edition approved in 2012 as D36 – 12. DOI: 10.1520/D0036

_D0036M-14.

support the two rings in a horizontal position, conforming to

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

the shape and dimensions shown in Fig. 1 (c), supported in the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

assembly illustrated in Fig. 1 (d).The bottom of the shouldered

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. rings in the ring holder shall be 25 mm [1.0 in.] above the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D36/D36M − 14

NOTE 1—All dimensions are in millimetres (60.3 mm except where noted).

FIG. 1 Shouldered Ring, Ball-Centering Guide, Ring Holder, and Assembly of Apparatus Showing Two Ring

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D36/D36M − 12 D36/D36M − 14

Standard Test Method for

1

Softening Point of Bitumen (Ring-and-Ball Apparatus)

This standard is issued under the fixed designation D36/D36M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the softening point of bitumen in the range from 30 to 157°C [86 to 315°F]

using the ring-and-ball apparatus immersed in distilled water [30 to 80°C] or USP glycerin (above 80 to 157°C).

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C670 Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials

D92 Test Method for Flash and Fire Points by Cleveland Open Cup Tester

D140 Practice for Sampling Bituminous Materials

D3461 Test Method for Softening Point of Asphalt and Pitch (Mettler Cup-and-Ball Method)

E1 Specification for ASTM Liquid-in-Glass Thermometers

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Summary of Test Method

3.1 Two horizontal disks of bitumen, cast in shouldered brass rings, are heated at a controlled rate in a liquid bath while each

supports a steel ball. The softening point is reported as the mean of the temperatures at which the two disks soften enough to allow

each ball, enveloped in bitumen, to fall a distance of 25 mm [1.0 in.].

4. Significance and Use

4.1 Bitumens are viscoelastic materials without sharply defined melting points; they gradually become softer and less viscous

as the temperature rises. For this reason, softening points must be determined by an arbitrary and closely defined method if results

are to be reproducible.

4.2 The softening point is useful in the classification of bitumens, as one element in establishing the uniformity of shipments

or sources of supply, and is indicative of the tendency of the material to flow at elevated temperatures encountered in service.

5. Apparatus

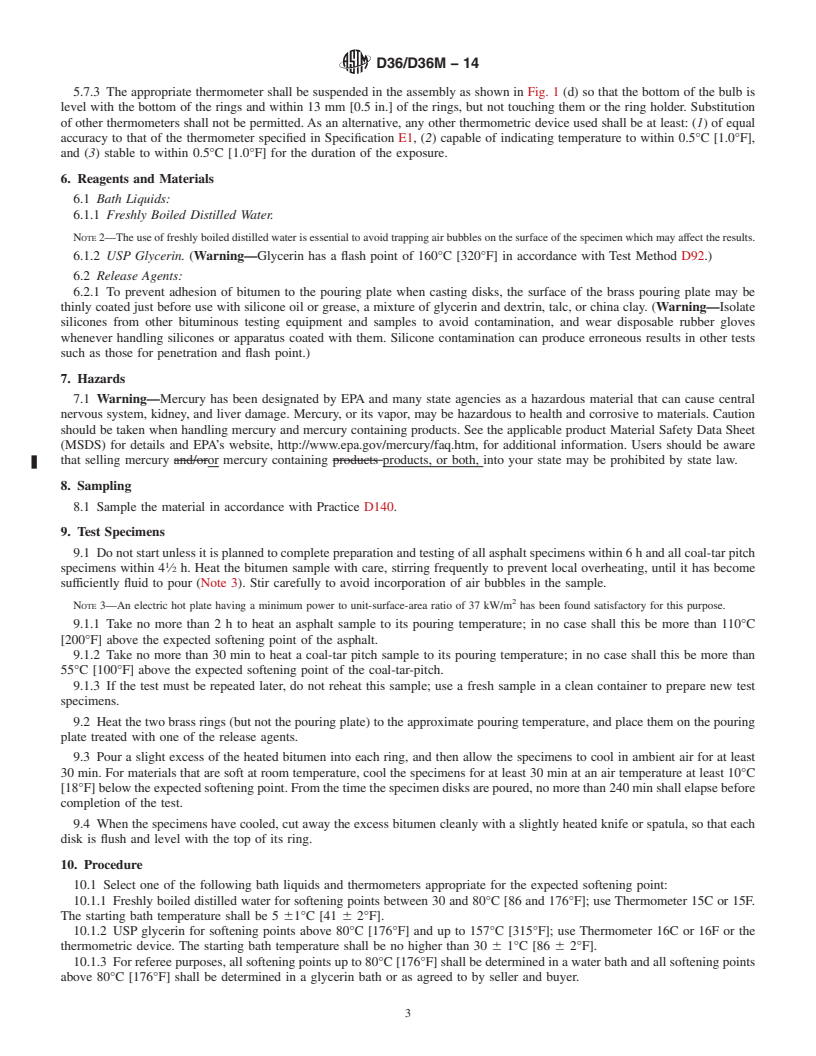

5.1 Rings—Two square-shouldered brass rings conforming to the dimensions shown in Fig. 1(a).

5.2 Pouring Plate—A flat, smooth, brass plate approximately 50 by 75 mm [2 by 3 in.].

3

5.3 Balls—Two steel balls, 9.5 mm [ ⁄8 in.] in diameter, each having a mass of 3.50 6 0.05 g.

1

This test method is under the jurisdiction of ASTM Committee D08 on Roofing and Waterproofing and is the direct responsibility of Subcommittee D08.03 on Surfacing

and Bituminous Materials for Membrane Waterproofing and Built-up Roofing.

Current edition approved May 1, 2012July 1, 2014. Published June 2012July 2014. Originally approved in 1962. Last previous edition approved in 20092012 as

D36 – 09.D36 – 12. DOI: 10.1520/D0036_D0036M-12.10.1520/D0036_D0036M-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D36/D36M − 14

NOTE 1—All dimensions are in millimetres (60.3 mm except where noted).

FIG. 1 Shouldered Ring, Ball-Centering Guide, Ring Holder, and Assembly of Apparatus Showing Two Rings

5.4 Ball-Centering Guides—Two brass guides for centering the steel balls, one for each ring, conforming to the general shape

and dimensions shown in Fig. 1 (b).

5.5 Bath—A glass vessel, capable of being heated, not less than 85 mm in inside diameter and not less than 120 mm in depth

from the bottom of the flare.

NOTE 1—An 800-mL, low-form Griffin beaker of hea

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.