ASTM F1488-03

(Specification)Standard Specification for Coextruded Composite Pipe

Standard Specification for Coextruded Composite Pipe

ABSTRACT

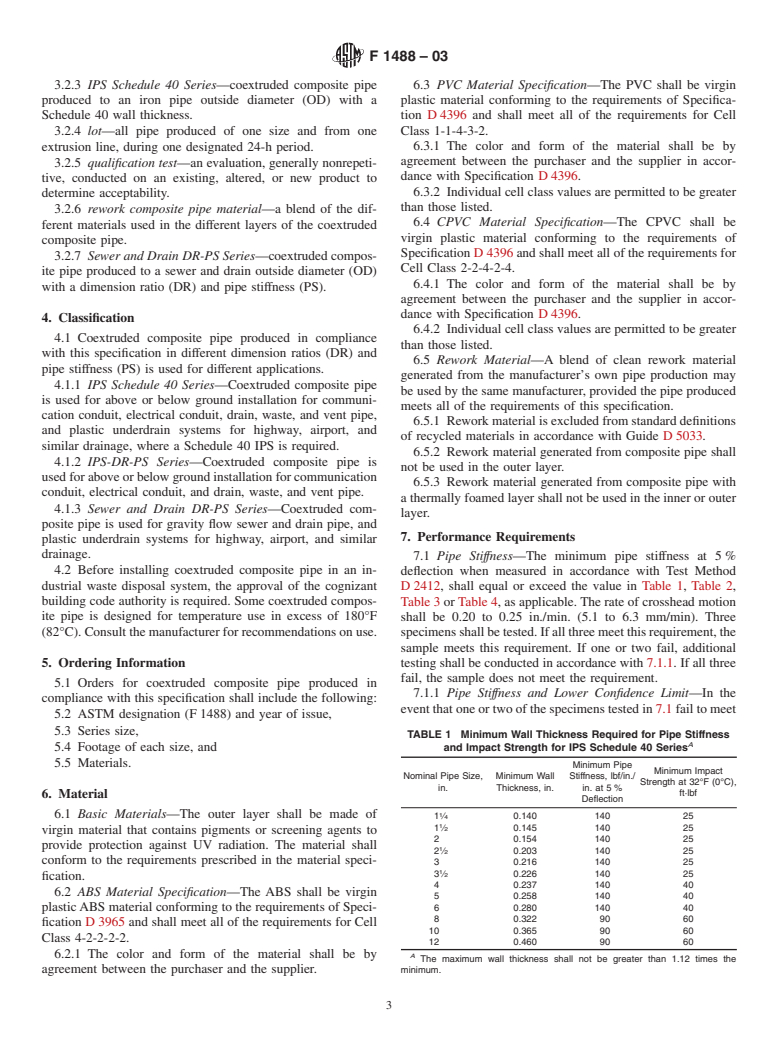

This specification covers coextruded composite pipe, produced by a coextrusion die system, in which the concentric layers are formed and combined before exiting the die. Coextruded composite pipe conforming to the requirements prescribed are used for different applications: IPS Schedule 40 Series-coextruded composite pipe is used for above or below ground installation for communication conduit, electrical conduit, drain, waste, and vent pipe, and plastic underdrain systems for highway, airport, and similar drainage, where a Schedule 40 IPS is required; IPS-DR-PS Series-coextruded composite pipe is used for above or below ground installation for communication conduit, electrical conduit, and drain, waste, and vent pipe; and Sewer and Drain DR-PS Series-coextruded composite pipe is used for gravity flow sewer and drain pipe, and plastic underdrain systems for highway, airport, and similar drainage. The pipe stiffness, impact resistance, and bond strength shall be tested to meet the requirements prescribed.

SCOPE

1.1 This specification covers coextruded composite pipe, produced by a coextrusion die system, in which the concentric layers are formed and combined before exiting the die.

1.1.1 Materials listed in the material section are permitted to be used in any layer of the coextruded composite pipe. When coextruded composite pipe is produced with three layers, the middle layer is permitted to be solid or thermally foamed.

1.1.2 The function of this specification is to provide standardization of product, to produce technical data, and to serve as a purchasing guide.

1.2 Compounds that do not meet the requirements of the material section are excluded.

1.3 The coextruded composite pipe is permitted to be perforated in accordance with any specified standard or by agreement between the purchaser and the supplier.

1.4 The coextruded composite pipe is permitted to be belled for joining by solvent cementing or belled for joining by an elastomeric seal (gaskets), in accordance with any specified standard or by agreement between the purchaser and the supplier.

1.5 Recommendations for storage, joining, installation, and rationale are listed in Appendixes X1, X2, X3, and X4, respectively.

1.6 The values stated in inch-pound units are to be regarded as the standard. A companion standard written in SI units is under development.

1.7 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of this specification.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—Related specifications are as follows: D 2661, D 2665, D 2729, D 2750, D 2751, D 2949, D 3034, F 512, F 628, F 758, F 789, and F 891.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 1488 – 03

Standard Specification for

1

Coextruded Composite Pipe

This standard is issued under the fixed designation F 1488; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This specification covers coextruded composite pipe, 2.1 The following standards contain provisions which,

produced by a coextrusion die system, in which the concentric thoughreferencedinthisspecification,constituteprovisionsof

layers are formed and combined before exiting the die. this specification. All standards are subject to revision and

1.1.1 Materialslistedinthematerialsectionarepermittedto parties using this specification shall reference the most recent

be used in any layer of the coextruded composite pipe. When edition of the standards listed as follows.

coextruded composite pipe is produced with three layers, the 2.2 ASTM Standards:

2

middle layer is permitted to be solid or thermally foamed. D618 Practice for Conditioning Plastics for Testing

1.1.2 The function of this specification is to provide stan- D696 Test Method for Coefficient of Linear Thermal Ex-

dardization of product, to produce technical data, and to serve pansion of Plastics Between −30°C and 30°C with a

2

as a purchasing guide. Vitreous Silica Dilatometer

2

1.2 Compounds that do not meet the requirements of the D883 Terminology Relating to Plastics

material section are excluded. D1600 Terminology for Abbreviated Terms Relating to

2

1.3 The coextruded composite pipe is permitted to be Plastics

3

perforated in accordance with any specified standard or by D1898 Practice for Sampling of Plastics

2

agreement between the purchaser and the supplier. D1972 Practice for Generic Marking of Plastic Products

1.4 Thecoextrudedcompositepipeispermittedtobebelled D2122 Test Method for Determining Dimensions of Ther-

4

for joining by solvent cementing or belled for joining by an moplastic Pipe and Fittings

elastomeric seal (gaskets), in accordance with any specified D2235 Specification for Solvent Cement for Acrylonitrile-

4

standard or by agreement between the purchaser and the Butadiene-Styrene (ABS) Plastic Pipe and Fittings

supplier. D2321 Practice for Underground Installation of Thermo-

1.5 Recommendations for storage, joining, installation, and plastic Pipe for Sewers and Other Gravity-Flow Applica-

4

rationale are listed in Appendixes X1, X2, X3, and X4, tions

respectively. D2412 TestMethodforDeterminationofExternalLoading

4

1.6 The values stated in inch-pound units are to be regarded Characteristics of Plastic Pipe by Parallel-Plate Loading

as the standard. A companion standard written in SI units is D2444 Test Method for Determination Impact Resistance

under development. of Thermoplastic Pipe and Fittings by Means of a Tup

4

1.7 Thetextofthisspecificationreferencesnotes,footnotes, (Falling Weight)

and appendixes which provide explanatory material. These D2564 Specification for Solvent Cements for Poly(Vinyl

4

notesandfootnotes(excludingthoseintablesandfigures)shall Chloride) (PVC) Plastic Piping Systems

not be considered as requirements of this specification. D2661 Specification for Acrylonitrile-Butadiene-Styrene

1.8 This standard does not purport to address all of the (ABS) Schedule 40 Plastic Drain, Waste, and Vent Pipe

4

safety concerns, if any, associated with its use. It is the and Fittings

responsibility of the user of this standard to establish appro- D2665 Specification for Poly(Vinyl Chloride) (PVC) Plas-

4

priate safety and health practices and determine the applica- tic Drain, Waste, and Vent Pipe and Fittings

bility of regulatory limitations prior to use. D 2729 Specification for Poly(Vinyl Chloride) (PVC)

4

Sewer Pipe and Fittings

NOTE 1—Related specifications are as follows: D 2661, D 2665,

D2750 Specification for Acrylonitrile-Butadiene-Styrene

D2729, D2750, D2751, D2949, D3034, F512, F628, F758, F789,

5

(ABS) Plastic Utilities Conduit and Fittings

and F891.

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

2

Piping Systems and is the direct responsibility of Subcommittee F17.11 on Annual Book of ASTM Standards, Vol 08.01.

3

Composite. Discontinued. See 1997 Annual Book of ASTM Standards , Vol 08.01.

4

Current edition approvedAug. 10, 2003. Published September 2003. Originally Annual Book of ASTM Standards, Vol 08.04.

´1 5

approved in 1994. Last previous edition approved in 2000 as F 1488–00 . Discontinued. See 1997 Annual Book of ASTM Standards , Vol 08.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.