ASTM F3203-19(2023)

(Test Method)Standard Test Method for Determination of Gel Content of Crosslinked Polyethylene (PEX) Pipes and Tubing

Standard Test Method for Determination of Gel Content of Crosslinked Polyethylene (PEX) Pipes and Tubing

SIGNIFICANCE AND USE

5.1 Many important properties of crosslinked ethylene plastics vary with the gel content. Hence, determination of the gel content provides a basis for controlling production processes and a means of establishing the quality of finished products.

5.2 Extraction tests permit verification of the proper gel content of any given crosslinked ethylene plastic and they also permit comparison between different crosslinked ethylene plastics, including those containing fillers, provided that, for the latter, the following conditions are met:

5.2.1 The filler is not soluble in the solvent used in this method at the extraction temperature.

5.2.2 The amount of filler present in the compound either is known or can be determined.

5.2.3 Sufficient crosslinking has been achieved to prevent migration of filler during the extraction. It has been found that, at gel content above 30 %, the solvent remains clear and free of filler.

5.3 Since some oxidative degradation of the material and solvent may occur at the reflux temperature of the solvents, a suitable antioxidant is added to the solvent to inhibit such degradation.

5.4 This test method is normally used for specimens consisting of an equal representation of the entire cross section of the product, but may also be used to examine specific portions of a product for differences in extent of cross-linking when compared to either a product standard or another sample.

5.5 This test method is intended for testing crosslinked polyethylene compounds that are not hygroscopic. If compounds that are hygroscopic are tested using this method, specimen conditioning before and after extraction is required.

5.6 This test method differs from Test Methods D2765, ISO 10147 and Test Method D7567 which also describe procedures for determining the gel content of crosslinked polyethylene. It allows for the use of naphthenic hydrocarbon blend, isoparaffin solvent, or light aromatic solvent naptha as alternatives to xylenes. Xylenes a...

SCOPE

1.1 The gel content of pipe and tubing produced from crosslinked polyethylene plastics as described in Specification F876 and other pipe or tubing standards is determined by extracting with solvents such as xylenes. A test method for quantitative determination of gel content is described herein. The method is applicable to PEX pipe and tubing of all densities, including those containing fillers, and provides correction for the inert fillers present in some of those compounds.

1.2 Continuous extraction (see definition in Section 3) is used in this method to test the gel content of crosslinked polyethylene specimens. Continuous extraction when used for testing gel content has the advantages of decreased cost of testing, increased accuracy and consistency of results, and decreased test time. This is because extraction with a pure solvent is more efficient than extraction with a partially saturated solvent.

1.3 While extraction tests may be made on articles of any shape, this test method is applicable for determining the gel content of crosslinked polyethylene pipes and tubing.

1.4 This test method makes use of xylenes or alternative solvents. Alternative solvents either have lower toxicity than xylenes or allow decreased extraction times. The alternative solvents are also potentially beneficial from an economic and environmental viewpoint. Xylenes are used for referee tests.

1.5 The values stated in SI units are to be regarded as standard. The inch-pound units in brackets are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standard...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3203 − 19 (Reapproved 2023)

Standard Test Method for

Determination of Gel Content of Crosslinked Polyethylene

(PEX) Pipes and Tubing

This standard is issued under the fixed designation F3203; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.7 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 The gel content of pipe and tubing produced from

ization established in the Decision on Principles for the

crosslinked polyethylene plastics as described in Specification

Development of International Standards, Guides and Recom-

F876 and other pipe or tubing standards is determined by

mendations issued by the World Trade Organization Technical

extracting with solvents such as xylenes. A test method for

Barriers to Trade (TBT) Committee.

quantitative determination of gel content is described herein.

The method is applicable to PEX pipe and tubing of all

2. Referenced Documents

densities, including those containing fillers, and provides

correction for the inert fillers present in some of those 2.1 ASTM Standards:

compounds. D883 Terminology Relating to Plastics

D1603 Test Method for Carbon Black Content in Olefin

1.2 Continuous extraction (see definition in Section 3) is

Plastics

used in this method to test the gel content of crosslinked

D2765 Test Methods for Determination of Gel Content and

polyethylene specimens. Continuous extraction when used for

Swell Ratio of Crosslinked Ethylene Plastics

testing gel content has the advantages of decreased cost of

D7567 Test Method for Determining Gel Content in Cross-

testing, increased accuracy and consistency of results, and

linked Ethylene Plastics Using Pressurized Liquid Extrac-

decreased test time. This is because extraction with a pure

tion (Withdrawn 2015)

solvent is more efficient than extraction with a partially

E177 Practice for Use of the Terms Precision and Bias in

saturated solvent.

ASTM Test Methods

1.3 While extraction tests may be made on articles of any

E691 Practice for Conducting an Interlaboratory Study to

shape, this test method is applicable for determining the gel

Determine the Precision of a Test Method

content of crosslinked polyethylene pipes and tubing.

F876 Specification for Crosslinked Polyethylene (PEX) Tub-

1.4 This test method makes use of xylenes or alternative ing

solvents. Alternative solvents either have lower toxicity than

2.2 ISO Standard:

xylenes or allow decreased extraction times. The alternative

ISO 10147 Pipes and Fittings Made of Crosslinked Polyeth-

solvents are also potentially beneficial from an economic and

ylene (Pe-X) – Estimation of the Degree of Crosslinking

environmental viewpoint. Xylenes are used for referee tests.

by Determination of the Gel Content

1.5 The values stated in SI units are to be regarded as

3. Terminology

standard. The inch-pound units in brackets are for information

only.

3.1 Terms as shown in Terminology D883 are applicable to

1.6 This standard does not purport to address all of the this test method.

safety concerns, if any, associated with its use. It is the

3.2 Definitions of Terms Specific to This Standard:

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

This test method is under the jurisdiction of ASTM Committee F17 on Plastic the ASTM website.

Piping Systems and is the direct responsibility of Subcommittee F17.40 on Test The last approved version of this historical standard is referenced on

Methods. www.astm.org.

Current edition approved July 1, 2023. Published July 2023. Originally approved Available from International Organization for Standardization (ISO), ISO

in 2018. Last previous edition approved in 2019 as F3202–19. DOI: 10.1520/ Central Secretariat, BIBC II, Chemin de Blandonnet 8, CP 401, 1214 Vernier,

F3203–19R23 Geneva, Switzerland, http://www.iso.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F3203 − 19 (2023)

3.2.1 continuous extractor, n—test apparatus for performing 5.2.3 Sufficient crosslinking has been achieved to prevent

a continuous extraction. migration of filler during the extraction. It has been found that,

at gel content above 30 %, the solvent remains clear and free of

3.2.1.1 Discussion—Soxhlet, Knofler-Bohm, and Kum-

filler.

agawa extractors are examples of continuous extractors. A

continuous extractor has three main components which are a

5.3 Since some oxidative degradation of the material and

boiling flask or vessel for the solvent, a condenser, and a

solvent may occur at the reflux temperature of the solvents, a

siphon cup. There are various designs for the siphon cup; the

suitable antioxidant is added to the solvent to inhibit such

Soxhlet, Knofler-Bohm, and Kumagawa designs are the most

degradation.

common.

5.4 This test method is normally used for specimens con-

3.2.2 continuous extraction, n—an extraction performed in a

sisting of an equal representation of the entire cross section of

continuous extractor where a solvent (normally xylenes) is

the product, but may also be used to examine specific portions

heated in a vessel and boils forming vapors, the vapors rise and

of a product for differences in extent of cross-linking when

condense on a condenser to form droplets, the droplets fall into

compared to either a product standard or another sample.

a cup where one or more specimens are placed, there the

5.5 This test method is intended for testing crosslinked

solvent in the cup dissolves some of the un-crosslinked

polyethylene compounds that are not hygroscopic. If com-

polyethylene in the specimens, and when the cup holding the

pounds that are hygroscopic are tested using this method,

specimens is filled with solvent, the solvent now containing

specimen conditioning before and after extraction is required.

some of the un-crosslinked polyethylene drains out through a

5.6 This test method differs from Test Methods D2765, ISO

siphon tube back into the vessel where it started. The solvent

10147 and Test Method D7567 which also describe procedures

and the sample specimens in the cup are kept warm by solvent

for determining the gel content of crosslinked polyethylene. It

vapor rising toward the condenser. The extraction steps repeat

allows for the use of naphthenic hydrocarbon blend, isoparaffin

automatically and continuously as long as heat is applied to the

solvent, or light aromatic solvent naptha as alternatives to

vessel holding the solvent. Because only the solvent evaporates

xylenes. Xylenes are the only solvent allowed to be used for

and not the material dissolved in it, the concentration of

referee tests. The preferred method of sample preparation in

un-crosslinked polyethylene in the boiling solvent increases,

this test method is to use a lathe to create thin ribbons of PEX

while the concentration of un-crosslinked polyethylene in the

material. This standard requires the use of a continuous

specimens continually decreases.

extractor in order to provide consistent results and to allow for

3.2.3 gel content, n—the percentage by mass of polymer

reliable solvent re-use. Specialized specimen holders are used

insoluble in a specified solvent after extraction under the

to minimize variability resulting from loss of specimen par-

specified conditions.

ticles.

NOTE 1—Pressurized extraction techniques have been found to yield

4. Summary of Test Method

useful results in a shorter time frame, however not all grades of PEX

tolerate the elevated extraction temperatures without substantial degrada-

4.1 Specimens of the crosslinked ethylene plastic are

tion. For this reason pressurized extraction techniques are recommended

prepared, weighed and then extracted using a heated extraction

for control tests only if it is possible to determine that the crosslinked

solvent in a continuous extractor for the time designated by the

matrix of the PEX does not break down at the temperature of extraction

procedure. After extraction, the specimens are removed from

the continuous extractor, dried, and weighed as directed. The

6. Conditioning

gel content is calculated using the final and initial specimen

6.1 Conditioning—Conditioning of the test specimens is not

weights as directed in the calculations section of this test

required, unless specified by the manufacturer of the material

method.

being sampled.

5. Significance and Use 6.2 Test Conditions—Test conditions do not affect results,

with the exception of atmospheric pressure. Conduct tests in a

5.1 Many important properties of crosslinked ethylene plas-

laboratory with atmospheric pressure greater than 80 kPa (less

tics vary with the gel content. Hence, determination of the gel

than 6000 ft above average sea level).

content provides a basis for controlling production processes

NOTE 2—The altitude above sea level of the lab will influence the

and a means of establishing the quality of finished products.

atmospheric pressure, which in turn will affect the boiling temperature of

5.2 Extraction tests permit verification of the proper gel the solvent used and the rate at which it will be able to extract

un-crosslinked polyethylene from the matrix.

content of any given crosslinked ethylene plastic and they also

permit comparison between different crosslinked ethylene

7. Apparatus

plastics, including those containing fillers, provided that, for

the latter, the following conditions are met:

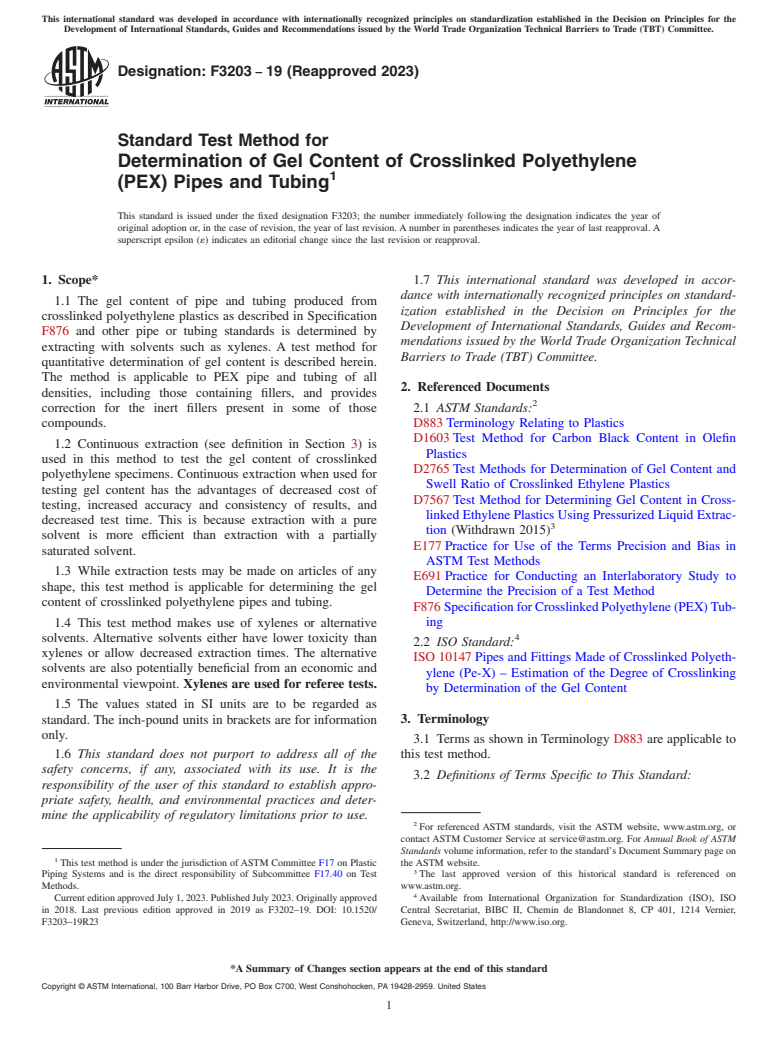

7.1 Continuous Extractor, of the following general type, as

5.2.1 The filler is not soluble in the solvent used in this

illustrated in Fig. 1. Further information regarding possible

method at the extraction temperature.

sources of components is included in the Appendix X3.

5.2.2 The amount of filler present in the compound either is 7.1.1 Boiling Flask, with a ground-glass joint. The flask

known or can be determined. may be either flat bottom or round bottom. For one or two

F3203 − 19 (2023)

modified Soxhlet extractor, jacketed Soxhlet extractor, and

Knofler-Bohm extractor. Review appendix X3.3 for supplier

information.

7.1.4 Reflux Condenser, with ground-glass joint to fit into

the extractor cup. This will typically be an Allihn or Dimroth

condenser.

7.1.5 Ring Stand and Appropriate Clamps—

7.2 Lathe, Drill Press, Plane or Planer, suitable for reduc-

ing the sample to a thickness of 0.15 mm to 0.05 mm. A bench

top lathe is preferred, although any procedure which will

produce a sample of the required fineness without generating

excessive heat is acceptable. Appendix X2 presents examples

of devices suitable for sample preparation.

7.3 Specimen Holders or Cages:

7.3.1 Specimen Holders, of the general type illustrated in

Fig. 2, machined aluminum with an internal volume of 6 cm

to 7 cm . The recommended design consists of two end caps

and a spacer ring. The end caps shall be held together either by

rare earth (samarium cobalt) magnets or a threaded connection

to the spacer ring. The end caps shall have US No. 150

stainless steel wire mesh nested inside of the openings. The

wire mesh is held between the spacer ring and the end caps to

prevent specimen particles from escaping when the specimen

holder is closed. The exposed surface area of the wire mesh in

the end caps shall be a minimum of 11 cm . Individual

specimen holders are identified by an engraved number or

letter on the end caps. Specimen holders are reusable. Con-

struction drawings for suitable specimen holders are available

in Appendix X1.

7.3.2 Specimen Cages, made from U.S. No 150 stainless

steel wire cloth. Prepare specimen cages by cutting pieces of

stainless steel wire cloth measuring 80 mm by 50 mm (3 in. by

2 in.). Fold these in half to form rectangles measuring

approximately 40 mm by 50 mm (1 ⁄2 in. by 2 in.) Fold two

sides of these rectangles closed by folding at the edges about 6

mm to 7 mm ( ⁄4 in.). In this manner, cages open at the top is

obtained. Specimen cages may be reused several times pro-

FIG. 1 Continuous Extractor

vided that they are completely free of any polymer residue and

do not have holes in them that would allow specimen particles

to escape.

determinations at a time, the minimum appropriate size is 500-

7.4 Oven, capable of heating specimen holders to 150 °C

mL. For routine testing with several determinations at one

(300 °F) with temperature indication. This oven shall be of

time, but not exceeding six, a 2000-mL flask is suitable.

such construction and design to maximize air circulation.

7.1.2 Heating Mantle or Hot Plate, to fit the flask and with

Convection toaster ovens sold for kitchen use have been found

sufficient heating capacity to boil the solvent used. If a flat

to be adequate provided they are used in a fume hood.

bottom flask is used a hotplate shall be used instead of a

Alternatively a vacuum oven may be used.

heating mantle, and shall have sufficient heating capacity to

7.5 Analytical Balance, minimum capacity of 100 g and

boil the solvent used.

capable of weighing to 6 0.0001 g.

7.1.3 Extractor Cup, with a ground-glass joint to fit the

1 1

7.6 Wood Block, 62 mm (2 ⁄2 in.) by 37 mm (1 ⁄2 in.) by 37

boiling flask, a large mouth ground-glass joint on the top and

mm (1 ⁄2 in.).

sufficient capacity to hold specimen cages as described in

7.3.2. The extractor cup shall be of a jacketed design so that the

7.7 Timer, capable of timing intervals up to 10 hours,

specimens are extracted at as near as possible to the boiling

accurate to 6 30 s per hour or better, and with an audible alarm

temperature of the solvent. The extractor cup and the boiling

at the completion of the timed interval.

flask must be of mated capacity, as the boiling flask must have

8. Reagents

sufficient solvent in to safely be used as the extractor cup fills

and drains. The extractor cup will be described with different 8.1 Extraction solvent, Xylenes are the preferred solvent

names by laboratory glassware suppliers. These names include and must be used for re

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.