ASTM E822-92(2009)

(Practice)Standard Practice for Determining Resistance of Solar Collector Covers to Hail by Impact With Propelled Ice Balls

Standard Practice for Determining Resistance of Solar Collector Covers to Hail by Impact With Propelled Ice Balls

SIGNIFICANCE AND USE

In many geographic areas there is concern about the effect of falling hail upon solar collector covers. This practice may be used to determine the ability of flat-plate solar collector covers to withstand the impact forces of hailstones. In this practice, the ability of a solar collector cover plate to withstand hail impact is related to its tested ability to withstand impact from ice balls. The effects of the impact on the material are highly variable and dependent upon the material.

This practice describes a standard procedure for mounting the test specimen, conducting the impact test, and reporting the effects.

The procedures for mounting cover plate materials and collectors are provided to ensure that they are tested in a configuration that relates to their use in a solar collector.

The corner locations of the four impacts are chosen to represent vulnerable sites on the cover plate. Impacts near corner supports are more critical than impacts elsewhere. Only a single impact is specified at each of the impact locations. For test control purposes, multiple impacts in a single location are not permitted because a subcritical impact may still cause damage that would alter the response to subsequent impacts.

Resultant velocity is used to simulate the velocity that may be reached by hail accompanied by wind. The resultant velocity used in this practice is determined by vector addition of a 20 m/s (45 mph) horizontal velocity to the vertical terminal velocity.

Ice balls are used in this practice to simulate hailstones because natural hailstones are not readily available to use, and ice balls closely approximate hailstones. However, no direct relationship has been established between the effect of impact of ice balls and hailstones. Hailstones are highly variable in properties such as shape, density, and frangibility. These properties affect factors such as the kinetic energy delivered to the cover plate, the period during which energy is delivered, and the are...

SCOPE

1.1 This practice covers a procedure for determining the ability of cover plates for flat-plate solar collectors to withstand impact forces of falling hail. Propelled ice balls are used to simulate falling hailstones. This practice is not intended to apply to photovoltaic cells or arrays.

1.2 This practice defines two types of test specimens, describes methods for mounting specimens, specifies impact locations on each test specimen, provides an equation for determining the velocity of any size ice ball, provides a method for impacting the test specimens with ice balls, and specifies parameters that must be recorded and reported.

1.3 This practice does not establish pass or fail levels. The determination of acceptable or unacceptable levels of ice-ball impact resistance is beyond the scope of this practice.

1.4 The size of ice ball to be used in conducting this test is not specified in this practice. This practice can be used with various sizes of ice balls.

1.5 The categories of solar collector cover plate materials to which this practice may be applied cover the range of:

1.5.1 Brittle sheet, such as glass,

1.5.2 Semirigid sheet, such as plastic, and

1.5.3 Flexible membrane, such as plastic film.

1.6 Solar collector cover materials should be tested as:

1.6.1 Part of an assembled collector (Type 1 specimen), or

1.6.2 Mounted on a separate test frame cover plate holder (Type 2 specimen).

1.7 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E822 − 92(Reapproved 2009)

Standard Practice for

Determining Resistance of Solar Collector Covers to Hail by

Impact With Propelled Ice Balls

This standard is issued under the fixed designation E822; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

1.1 This practice covers a procedure for determining the

bility of regulatory limitations prior to use.

abilityofcoverplatesforflat-platesolarcollectorstowithstand

impact forces of falling hail. Propelled ice balls are used to

2. Significance and Use

simulate falling hailstones. This practice is not intended to

2.1 In many geographic areas there is concern about the

apply to photovoltaic cells or arrays.

effect of falling hail upon solar collector covers. This practice

1.2 This practice defines two types of test specimens,

maybeusedtodeterminetheabilityofflat-platesolarcollector

describes methods for mounting specimens, specifies impact

covers to withstand the impact forces of hailstones. In this

locations on each test specimen, provides an equation for

practice,theabilityofasolarcollectorcoverplatetowithstand

determiningthevelocityofanysizeiceball,providesamethod

hail impact is related to its tested ability to withstand impact

for impacting the test specimens with ice balls, and specifies

from ice balls. The effects of the impact on the material are

parameters that must be recorded and reported.

highly variable and dependent upon the material.

1.3 This practice does not establish pass or fail levels. The

2.2 This practice describes a standard procedure for mount-

determination of acceptable or unacceptable levels of ice-ball

ingthetestspecimen,conductingtheimpacttest,andreporting

impact resistance is beyond the scope of this practice.

the effects.

1.4 The size of ice ball to be used in conducting this test is 2.2.1 The procedures for mounting cover plate materials

not specified in this practice. This practice can be used with and collectors are provided to ensure that they are tested in a

various sizes of ice balls. configuration that relates to their use in a solar collector.

2.2.2 The corner locations of the four impacts are chosen to

1.5 Thecategoriesofsolarcollectorcoverplatematerialsto

represent vulnerable sites on the cover plate. Impacts near

which this practice may be applied cover the range of:

corner supports are more critical than impacts elsewhere. Only

1.5.1 Brittle sheet, such as glass,

asingleimpactisspecifiedateachoftheimpactlocations.For

1.5.2 Semirigid sheet, such as plastic, and

test control purposes, multiple impacts in a single location are

1.5.3 Flexible membrane, such as plastic film.

not permitted because a subcritical impact may still cause

1.6 Solar collector cover materials should be tested as:

damage that would alter the response to subsequent impacts.

1.6.1 Part of an assembled collector (Type 1 specimen), or

2.2.3 Resultant velocity is used to simulate the velocity that

1.6.2 Mounted on a separate test frame cover plate holder

may be reached by hail accompanied by wind. The resultant

(Type 2 specimen).

velocity used in this practice is determined by vector addition

1.7 The values stated in SI units are to be regarded as the ofa20m/s(45mph)horizontalvelocitytotheverticalterminal

standard. The values given in parentheses are for information velocity.

2.2.4 Iceballsareusedinthispracticetosimulatehailstones

only.

because natural hailstones are not readily available to use, and

1.8 This standard does not purport to address all of the

ice balls closely approximate hailstones. However, no direct

safety concerns, if any, associated with its use. It is the

relationship has been established between the effect of impact

of ice balls and hailstones. Hailstones are highly variable in

properties such as shape, density, and frangibility. These

This practice is under the jurisdiction of ASTM Committee E44 on Solar,

properties affect factors such as the kinetic energy delivered to

GeothermalandOtherAlternativeEnergySourcesandisthedirectresponsibilityof

Subcommittee E44.05 on Solar Heating and Cooling Systems and Materials.

Current edition approved April 1, 2009. Published June 2009. Originally

approved in 1981. Last previous edition approved in 2003 as E822–92(2003). DOI: Gokhale, N. R., Hailstorms and Hailstone Growth, State University of New

10.1520/E0822-92R09. York Press, Albany, NY, 1975.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E822 − 92 (2009)

the cover plate, the period during which energy is delivered,

and the area over which the energy is distributed. Ice balls,

withadensity,frangibility,andterminalvelocityneartherange

ofhailstones,arethenearesthailstoneapproximationknownat

this time. Perhaps the major difference between ice balls and

hailstones is that hailstones are much more variable than ice

balls. However, ice balls can be uniformly and repeatedly

manufactured to ensure a projectile with known properties.

2.2.5 A wide range of observable effects may be produced

by impacting the various types of cover plate materials. The

effects may vary from no effect to total destruction. Some

changes in the cover material may be visible when there is no

apparent functional impairment of the cover plate material.All

effectsofeachimpactmustbedescribedinthereportsothatan

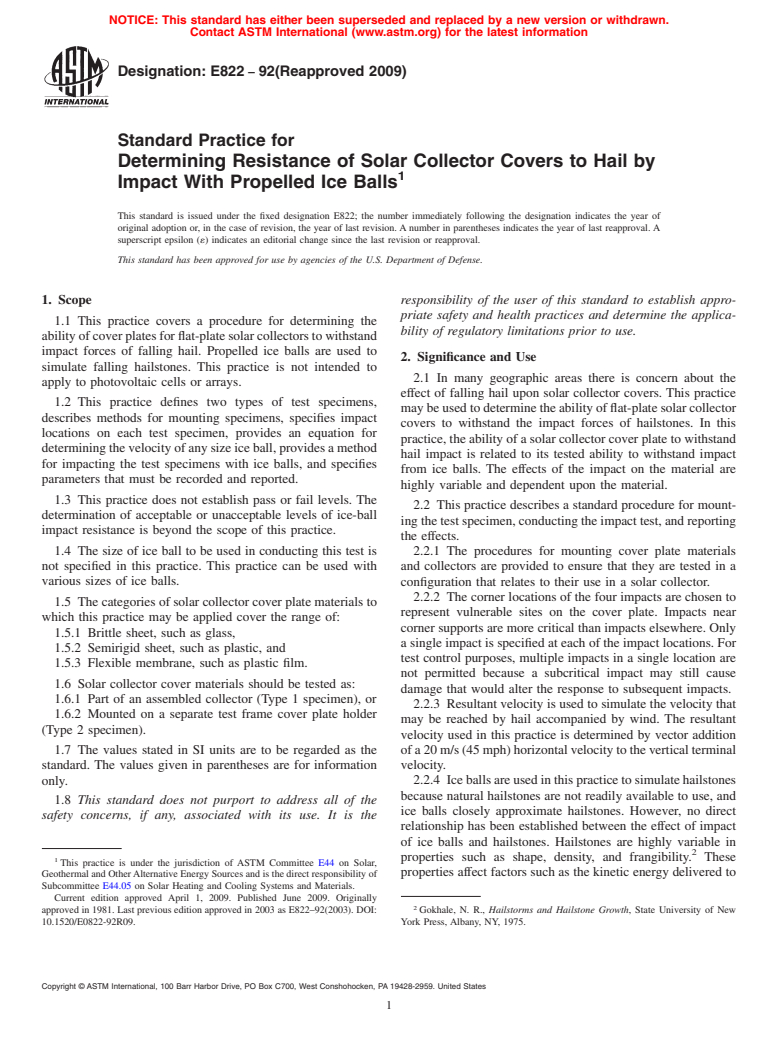

FIG. 1 Frame Dimensions and Location of Test Impact Points

estimate of their significance can be made.

2.3 Data generated using this practice may be used: (1)to

evaluate impact resistance of a single material or collector, (2)

3.2 Velocity Meter, for measuring the ice ball velocity with

to compare the impact resistance of several materials or

an accuracy of 62.0%.

collectors,(3)toprovideacommonbasisforselectionofcover

3.3 Test Base—A structurally rigid support for mounting a

materials or collectors for use in various geographic areas, or

complete solar collector panel (Type 1 specimen), or for

(4) to evaluate changes in impact resistance due to environ-

mounting a solar collector cover plate material (Type 2

mental factors such as weather.

specimen) set in the cover holder.

2.4 Thispracticedoesnotstatethesize(s)oficeball(s)tobe

3.4 CoverHolder—Arigidedgingframe(seeFig.1andFig.

usedinmakingtheimpact.Eitherthepersonrequestingthetest

2) designed to hold an approximately 860 by 1930-mm (34 by

or the person performing the test must determine ice ball size

76-in.) cover plate.

to be used in the testing. Choice of ice ball size may relate to

NOTE 2—Hardwood, such as oak, birch, maple, or hickory, is manda-

the intent of the testing.

tory if wood is used for the cover holder.

2.4.1 If the testing is being performed to evaluate impact

NOTE 3—Corner straps, as shown in Fig. 3 and Fig. 4, have been found

resistance of a single material or collector, or several materials

useful to ensure the cover holder is rigid.

orcollectors,itmaybedesirabletorepeatthetestusingseveral

3.5 Molds, for casting spherical crack-free ice balls of

sizesoficeballs.Inthis manner the different effectsofvarious

appropriate diameter.

sizes of ice balls may be determined.

2.4.2 The size and frequency of hail varies significantly

NOTE 4—Molds made from room-temperature vulcanizing rubber and

expanded polystyrene have been found suitable.

among various geographic areas. If testing is being performed

toevaluatematerialsorcollectorsintendedforuseinaspecific

3.6 Freezer—Adevice controlled at−12 6 5°C (106 9°F)

geographicarea,theiceballsizeshouldcorrespondtothelevel

for making and storing ice balls.

of hail impact resistance required for that area. Information on

hail size and frequency may be available from local historical 4. Test Specimen

weather records or may be determined from the publications

4.1 Type 1—The test specimen shall consist of a complete

listed in Appendix X1.

glazing assembly or a complete solar collector panel with

2.5 The hail impact resistance of materials may change as

necessary mounting brackets or fixtures.

the materials are exposed to various environmental factors.

4.2 Type 2—The test specimen shall consist of a section of

This practice may be used to generate data to evaluate

solar collector cover plate material mounted in the cover

degradation by comparison of hail impact resistance data

holder.

measured before and after exposure to such aging.

3. Apparatus

3.1 Launcher—A mechanism capable of propelling a se-

lected ice ball at the corresponding resultant velocity. The

aimingaccuracyofthelaunchermustbesufficienttopropelthe

ice ball to strike the cover plate within 25 mm (61 in.) ofthe

specified impact points. See Fig. 1.

NOTE 1—A launcher that has proven suitable uses a compressed air

supply, an accumulator tank, a large-diameter quick-opening valve and

interchangeable barrels to accommodate the sizes of ice balls to be used.

Barrels should be made from materials with low thermal conductivity to

reducemeltingoftheiceball.Barrelsshouldbesizedsuchthattheiceball

remains intact during loading and launching. FIG. 2 Cover Holder, Empty (Section A-A of Fig. 1)

E822 − 92 (2009)

fixtures,orboth.Donotobstructthespecifiedimpactpointsby

the mounting fixtures.

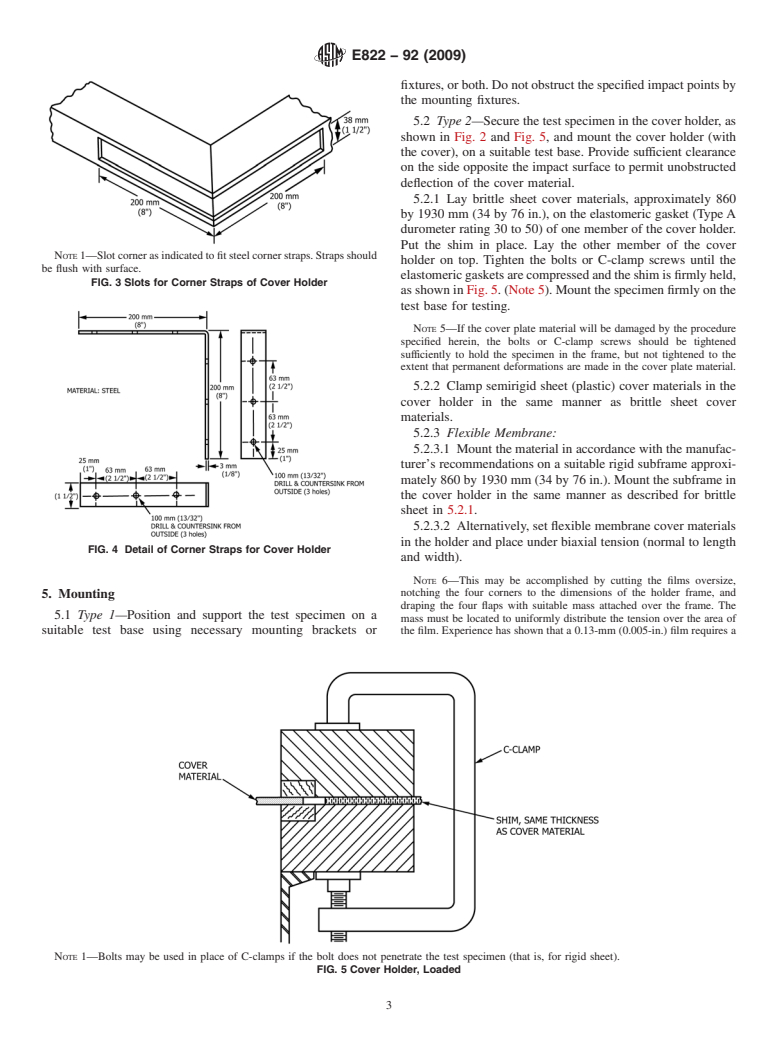

5.2 Type 2—Securethetestspecimeninthecoverholder,as

shown in Fig. 2 and Fig. 5, and mount the cover holder (with

the cover), on a suitable test base. Provide sufficient clearance

on the side opposite the impact surface to permit unobstructed

deflection of the cover material.

5.2.1 Lay brittle sheet cover materials, approximately 860

by 1930 mm (34 by 76 in.), on the elastomeric gasket (TypeA

durometer rating 30 to 50) of one member of the cover holder.

Put the shim in place. Lay the other member of the cover

NOTE1—Slotcornerasindicatedtofitsteelcornerstraps.Strapsshould

holder on top. Tighten the bolts or C-clamp screws until the

be flush with surface.

elastomericgasketsarecompressedandtheshimisfirmlyheld,

FIG. 3 Slots for Corner Straps of Cover Holder

asshowninFig.5.(Note5).Mountthespecimenfirmlyonthe

test base for testing.

NOTE 5—If the cover plate material will be damaged by the procedure

specified herein, the bolts or C-clamp screws should be tightened

sufficiently to hold the specimen in the frame, but not tightened to the

extent that permanent deformations are made in the cover plate material.

5.2.2 Clamp semirigid sheet (plastic) cover materials in the

cover holder in the same manner as brittle sheet cover

materials.

5.2.3 Flexible Membrane:

5.2.3.1 Mountthematerialinaccordancewiththemanufac-

turer’s recommendations on a suitable rigid subfram

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.