ASTM D2860/D2860M-17

(Test Method)Standard Test Method for Adhesion of Pressure-Sensitive Tape to Fiberboard at 90° Angle and Constant Stress

Standard Test Method for Adhesion of Pressure-Sensitive Tape to Fiberboard at 90° Angle and Constant Stress

SIGNIFICANCE AND USE

5.1 This test method is designed to show the adhesion of a pressure-sensitive tape to fiberboard when the tape is under a constant stress. Test data from this test method for some types of packaging tape relates to tape performance on fiberboard box closure.

5.2 Procedure A should be used when comparing tapes to an established requirement. The requirement may be established using either the standard linerboard or another linerboard representing a specific fiberboard.

5.3 Procedure B should be used to rank tapes as to their ability to adhere to fiberboard.

SCOPE

1.1 This test method covers the determination of the property of adhesion of pressure-sensitive tape to a fiber-board surface. The user of this test method has the option of choosing the paper surface for the test. The test surface may be the standard linerboard, another linerboard (or paper) of individual interest, or a specific fiberboard.

1.2 The values stated in either SI or inch-pound units are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore, each system must be used independently, without combining values in any way.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2860/D2860M − 17

Standard Test Method for

Adhesion of Pressure-Sensitive Tape to Fiberboard at 90°

1

Angle and Constant Stress

This standard is issued under the fixed designation D2860/D2860M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope D2904 Practice for Interlaboratory Testing of a Textile Test

Method that Produces Normally Distributed Data (With-

1.1 This test method covers the determination of the prop-

3

drawn 2008)

erty of adhesion of pressure-sensitive tape to a fiber-board

D2906 Practice for Statements on Precision and Bias for

surface.The user of this test method has the option of choosing

3

Textiles (Withdrawn 2008)

the paper surface for the test. The test surface may be the

D4332 Practice for Conditioning Containers, Packages, or

standard linerboard, another linerboard (or paper) of individual

Packaging Components for Testing

interest, or a specific fiberboard.

3. Terminology

1.2 The values stated in either SI or inch-pound units are to

be regarded separately as standard. The values stated in each

3.1 Definitions—Terminology found in Terminology D996

system are not exact equivalents; therefore, each system must

shall apply.

be used independently, without combining values in any way.

4. Summary of Test Method

1.3 This standard does not purport to address all of the

4.1 ProcedureA—Thepressure-sensitivetapeismountedon

safety concerns, if any, associated with its use. It is the

a rigid panel. The adhesive side is exposed. A strip of

responsibility of the user of this standard to establish appro-

linerboard, which represents the fiberboard, is placed against

priate safety and health practices and determine the applica-

the tape adhesive with controlled pressure. The area of contact

bility of regulatory limitations prior to use.

is specified. The panel is mounted in a horizontal position. A

1.4 This international standard was developed in accor-

specified mass is fastened to one end of the linerboard. The

dance with internationally recognized principles on standard-

mass acts to peel the linerboard away from the adhesive at an

ization established in the Decision on Principles for the

angle of 90°. The time required to peel the linerboard from the

Development of International Standards, Guides and Recom-

tape is measured.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

4.2 Procedure B—In this procedure, the fiberboard or the

linerboard representing it is adhered to a rigid panel and the

2. Referenced Documents

tape peeled from it. In all other respects, the procedure is the

2

same as Procedure A.

2.1 ASTM Standards:

D996 Terminology of Packaging and Distribution Environ-

5. Significance and Use

ments

5.1 This test method is designed to show the adhesion of a

pressure-sensitive tape to fiberboard when the tape is under a

1

constant stress. Test data from this test method for some types

This test method is under the jurisdiction of ASTM Committee D10 on

Packaging and is the direct responsibility of Subcommittee D10.14 on Tape and

of packaging tape relates to tape performance on fiberboard

Labels.

box closure.

CurrenteditionapprovedMay1,2017.PublishedJuly2017.Originallyapproved

in 1970. Last previous edition approved in 2010 as D2860/D2860M – 04 (2010).

5.2 ProcedureAshould be used when comparing tapes to an

DOI: 10.1520/D2860_D2860M-17.

established requirement. The requirement may be established

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website.

www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2860/D2860M − 17

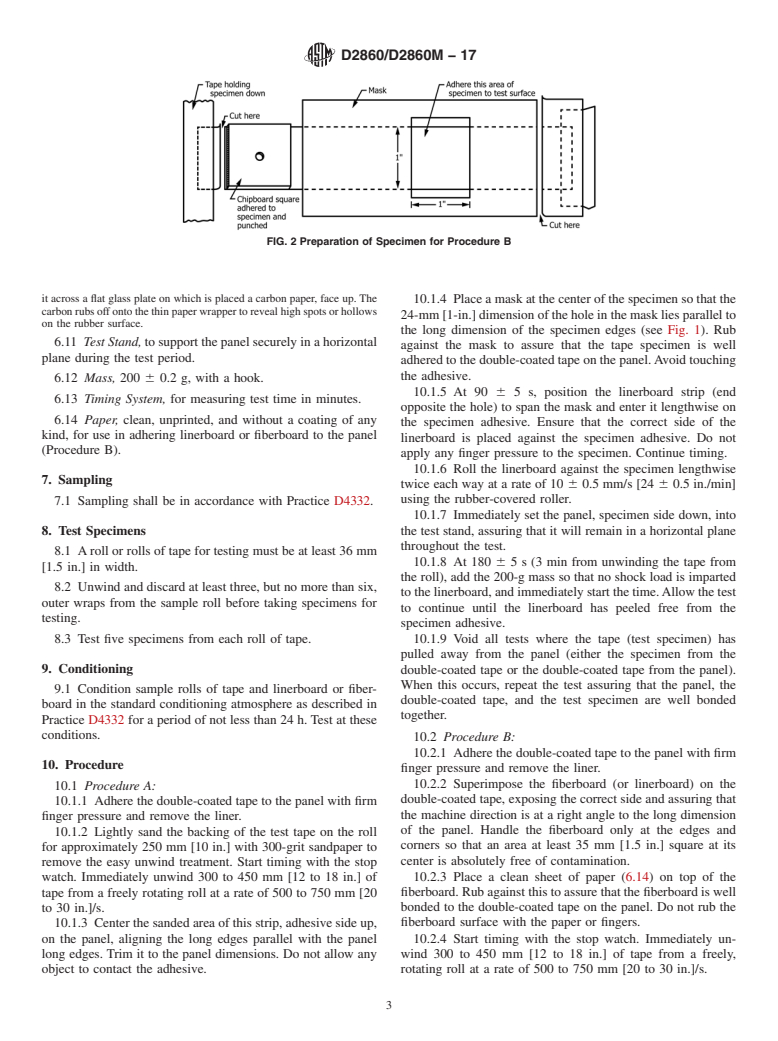

NOTE 1—Fix panel securely in a horizontal plane.

FIG. 1 Test Assembly for Procedure A

4

using either the standard linerboard or another linerboard 6.9 Fiberboard or Linerboard Surface, against which the

representing a specific fiberboard. test is made.

6.9.1 For Procedure A, cut a rectangle exactly 24 6 0.25

5.3 Procedure B should be used to rank tapes as to their

mm [1.0 6 0.01 in.] wide by at least 125 mm [5 in.] in length,

ability to adhere to fiberboard.

from the linerboard representing the fiberboard on which the

tape will be used. The long

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2860/D2860M − 04 (Reapproved 2010) D2860/D2860M − 17

Standard Test Method for

Adhesion of Pressure-Sensitive Tape to Fiberboard at 90°

1

Angle and Constant Stress

This standard is issued under the fixed designation D2860/D2860M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This test method covers the determination of the property of adhesion of pressure-sensitive tape to a fiber-board surface. The

user of this test method has the option of choosing the paper surface for the test. The test surface may be the standard linerboard,

another linerboard (or paper) of individual interest, or a specific fiberboard.

1.2 The values stated in either SI or inch-pound units are to be regarded separately as standard. The values stated in each system

are not exact equivalents; therefore, each system must be used independently, without combining values in any way.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D996 Terminology of Packaging and Distribution Environments

3

D2904 Practice for Interlaboratory Testing of a Textile Test Method that Produces Normally Distributed Data (Withdrawn 2008)

3

D2906 Practice for Statements on Precision and Bias for Textiles (Withdrawn 2008)

D4332 Practice for Conditioning Containers, Packages, or Packaging Components for Testing

3. Terminology

3.1 Definitions—Terminology found in Terminology D996 shall apply.

4. Summary of Test Method

4.1 Procedure A—The pressure-sensitive tape is mounted on a rigid panel. The adhesive side is exposed. A strip of linerboard,

which represents the fiberboard, is placed against the tape adhesive with controlled pressure. The area of contact is specified. The

panel is mounted in a horizontal position. A specified mass is fastened to one end of the linerboard. The mass acts to peel the

linerboard away from the adhesive at an angle of 90°. The time required to peel the linerboard from the tape is measured.

4.2 Procedure B—In this procedure, the fiberboard or the linerboard representing it is adhered to a rigid panel and the tape

peeled from it. In all other respects, the procedure is the same as Procedure A.

5. Significance and Use

5.1 This test method is designed to show the adhesion of a pressure-sensitive tape to fiberboard when the tape is under a constant

stress. Test data from this test method for some types of packaging tape relates to tape performance on fiberboard box closure.

1

This test method is under the jurisdiction of ASTM Committee D10 on Packaging and is the direct responsibility of Subcommittee D10.14 on Tape and Labels.

Current edition approved April 1, 2010May 1, 2017. Published May 2010July 2017. Originally approved in 1970. Last previous edition approved in 20042010 as

D2860/D2860M – 04.D2860/D2860M – 04 (2010). DOI: 10.1520/D2860_D2860M-04R10.10.1520/D2860_D2860M-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2860/D2860M − 17

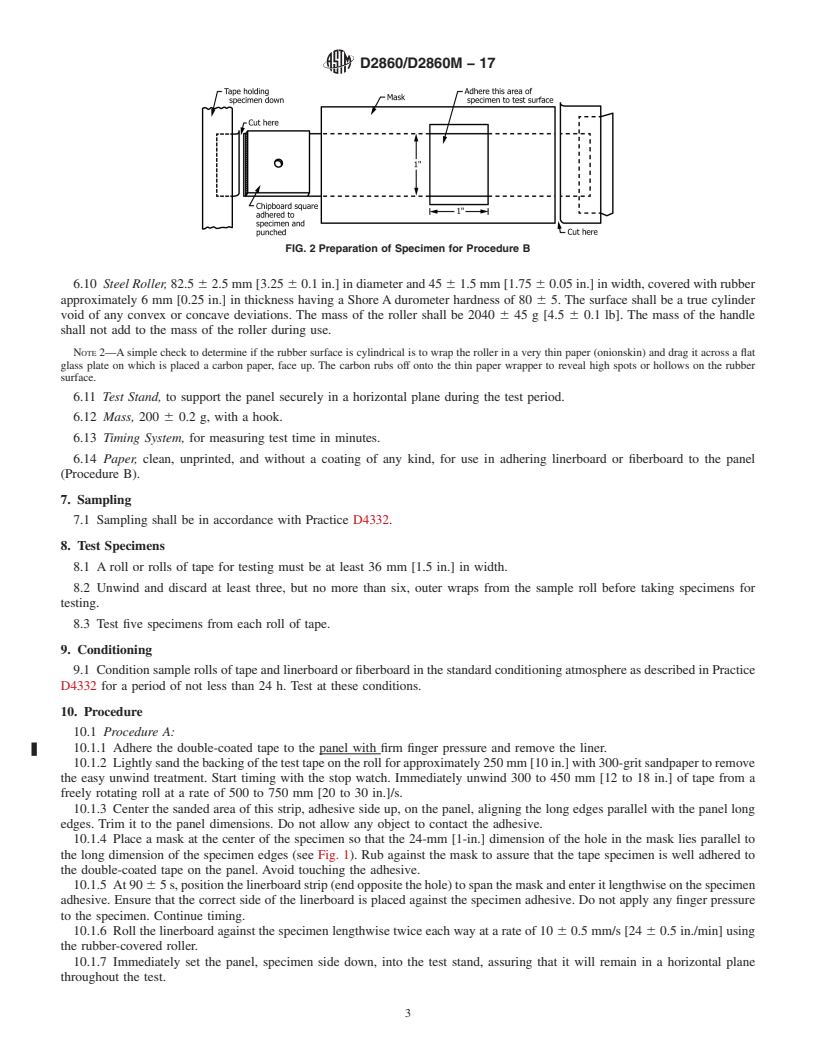

NOTE 1—Fix panel securely in a horizontal plane.

FIG. 1 Test Assembly for Procedure A

5.2 Procedure A should be used when comparing tapes to an established requirement. The requirement may be established using

either the standard linerboard or another linerboard representing a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.