ASTM D5486/D5486M-06(2020)

(Specification)Standard Specification for Pressure-Sensitive Tape for Packaging, Box Closure, and Sealing

Standard Specification for Pressure-Sensitive Tape for Packaging, Box Closure, and Sealing

ABSTRACT

This specification covers pressure-sensitive tapes of film, paper, and cloth types, with applications in packaging, box closure, and sealing. Covered in this specification are five types of tape: waterproof, weather-resistant, polyester-backed tape (Type I), water-resistant polyester-backed tape (Type II), water-resistant polypropylene-backed tape (Type III), water-resistant woven-cloth-backed tape (Type IV), and weather-resistant paper-backed tape. The tape shall be manufactured with film, paper, or cloth backing, coated with a smooth and uniformly distributed layer of pressure-sensitive water-insoluble adhesive. The tape shall be in wound into rolls on cores of paper fiber or plastic and shall be free from defects, with the edges clean, straight, and unbroken. Tests for adhesion, break strength, tear resistance, thickness, water-penetration rate, water solubility, water-vapor transmission rate, and weathering shall be performed and shall conform to the requirements specified.

SCOPE

1.1 This specification covers film, paper, and cloth pressure-sensitive tapes used for box closure and sealing.

1.2 The values stated in either inch-pound or SI units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system must be used independently, without combining values in any way.

1.3 The following safety hazards caveat pertains only to the test methods portion, Section 14, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5486/D5486M −06 (Reapproved 2020)

Standard Specification for

Pressure-Sensitive Tape for Packaging, Box Closure, and

1,2

Sealing

This standard is issued under the fixed designation D5486/D5486M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope Sensitive Tape to Fiberboard at 90° Angle and Constant

Stress

1.1 Thisspecificationcoversfilm,paper,andclothpressure-

D3330/D3330MTestMethodforPeelAdhesionofPressure-

sensitive tapes used for box closure and sealing.

Sensitive Tape

1.2 The values stated in either inch-pound or SI units are to

D3611Practice forAcceleratedAging of Pressure-Sensitive

be regarded separately as standard. The values stated in each

Tapes

system may not be exact equivalents; therefore, each system

D3652/D3652MTest Method for Thickness of Pressure-

must be used independently, without combining values in any

Sensitive Tapes

way.

D3654/D3654M Test Methods for Shear Adhesion of

1.3 The following safety hazards caveat pertains only to the Pressure-Sensitive Tapes

test methods portion, Section 14, of this specification. This

D3715/D3715MPractice for QualityAssurance of Pressure-

standard does not purport to address all of the safety concerns, Sensitive Tapes

if any, associated with its use. It is the responsibility of the user

D3759/D3759MTest Method for Breaking Strength and

of this standard to establish appropriate safety, health, and Elongation of Pressure-Sensitive Tape

environmental practices and determine the applicability of

D3811/D3811MTestMethodforUnwindForceofPressure-

regulatory limitations prior to use. Sensitive Tapes

1.4 This international standard was developed in accor-

D3815/D3815MPractice for Accelerated Weathering of

dance with internationally recognized principles on standard- Pressure-Sensitive Tapes by Open-Flame Carbon-Arc Ex-

ization established in the Decision on Principles for the

posure Apparatus

Development of International Standards, Guides and Recom- D3816/D3816MTest Method for Water Penetration Rate of

mendations issued by the World Trade Organization Technical Pressure-Sensitive Tapes

Barriers to Trade (TBT) Committee.

D3833/D3833MTest Method for Water Vapor Transmission

of Pressure-Sensitive Tapes

2. Referenced Documents

D3951Practice for Commercial Packaging

D4727/D4727MSpecification for Corrugated and Solid Fi-

2.1 ASTM Standards:

berboard Sheet Stock (Container Grade) and Cut Shapes

D996Terminology of Packaging and Distribution Environ-

D5570Test Method for Water Resistance of Tape and

ments

Adhesives Used as Box Closure

D1974Practice for Methods of Closing, Sealing, and Rein-

forcing Fiberboard Boxes 2.2 TAPPI Standard:

D2860/D2860MTest Method for Adhesion of Pressure- T 414Internal Tear Resistance of Paper (Elmendorf-Type

Method)

2.3 Federal Specifications:

This specification is under the jurisdiction of ASTM Committee D10 on 5

PPP-T-60Tape: Packaging, Waterproof

Packaging and is the direct responsibility of Subcommittee D10.14 on Tape and

PPP-T-76Tape, Packaging, Paper (for Carton Sealing)

Labels.

Current edition approved Oct. 1, 2020. Published October 2020. Originally PPP-T-680 Tape, Pressure-Sensitive Adhesion: Packaging

approved in 1993. Last previous edition approved in 2012 as D5486/D5486M –

and Packing of

06(2012). DOI: 10.1520/D5486_D5486M-06R20.

This specification is intended to replace Federal Specifications PPP-T-60 and

PPP-T-76.

3 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from TechnicalAssociation of the Pulp and Paper Industry (TAPPI),

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 15 Technology Parkway South, Norcross, GA 30092, http://www.tappi.org.

Standards volume information, refer to the standard’s Document Summary page on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5486/D5486M − 06 (2020)

FED-STD-595Colors 4.5 Type V is a paper-backed weather-resistant, water-

resistant pressure-sensitive tape for box closure and sealing

2.4 ISO Standard:

applications where weather resistance and water resistance are

ISO 9000:2000Quality Management Systems–Fundamen-

required. It may be used on weather-resistant or domestic

tals and Vocabulary

fiberboard (Classes WR, WWVR, and D of Specification

ISO 9001:2000 Quality Management Systems–Require-

D4727/D4727M). The tape is suited for center seam and

ments

H-type closures or sealing of regular slotted boxes (Closure

ISO 9004:2000Quality Management Systems–Guidelines

Methods 2B3, 2B4, and 2B7 of Practice D1974) and other

for Performance Improvements

applications where it may be overlapped onto itself.

NOTE 1—The following is a comparison of types and classes of this

specification compared with PPP-T-60 and PPP-T-76:

5. Classification

D5486/D5486M PPP-T-60 PPP-T-76

Type I Type III N/A 5.1 Types and Classes:

Class 1 Class 1

5.1.1 Type I—Waterproof, weather-resistant, polyester-

Class 2 Class 2

backed:

Type II N/A N/A

Type III N/A N/A 5.1.1.1 Class 1—Colored.

Type IV Type IV N/A

5.1.1.2 Class 2—Transparent.

Type V N/A Same

5.1.2 Type II—Water-resistant polyester backed.

5.1.2.1 Class 1—Tan.

3. Terminology

5.1.2.2 Class 2—Transparent.

3.1 Definitions:

5.1.3 Type III—Water-resistant polypropylene.

3.1.1 General definitions for packaging and distribution

5.1.4 Type IV—Water-resistant woven cloth backed.

environments are found in Terminology D996.

5.1.5 Type V—Weather-resistant paper backed.

4. Significance and Use

6. Ordering Information

4.1 TypeIisapolyesterfilm-backedpressure-sensitivetape

6.1 The inquiry or order shall include the following:

intended for box closure and sealing applications where

6.1.1 ASTM Designation and date of issue;

strengthandresistancetosunlight,rain,andotherdeteriorating

6.1.2 Type and Class required (see 5.1);

elements are required. It is usually used on weather-resistant

6.1.3 Roll width and length (see 9.1);

fiberboard (Class WR or WWVR of Specification D4727/

6.1.4 Color where applicable (see 10.1);

D4727M).ThetapeisintendedforH-typeclosureorsealingof

6.1.5 When backing certification is required (see 17.1);

regularslottedboxes(ClosureMethod2B3and2B4ofPractice

6.1.6 When testing and inspection certification is required

D1974), and other applications where the tape will be over-

(see 17.2);

lapped onto itself. Type I, Class 2 transparent tape can also be

6.1.7 Levelofpackagingandpackingifotherthancommer-

used for label attachment and covering applications where

cial (see Section 18);

weather resistance is needed.

6.1.8 For packaging and packing for shipments to the U.S.

4.2 Type II is a polyester film-backed pressure-sensitive

Government (see 18.2); and

tape intended for box closure applications where strength and

6.1.9 When core marking is required (see 18.3).

water-resistance are required. It is usually used on domestic

grade fiberboard (Class D of Specification D4727/D4727M).

7. Materials and Manufacture

The tape is most suited for center seam closure of regular or

7.1 The materials used in the construction of the tape shall

regular slatted boxes (Closure Method 2B4 of Practice D1974)

be such as to assure performance of the tape over the

and other applications where the tape will not be overlapped

temperature range from −65 to 160°F [−55 to 71°C] and shall

onto itself. Type II, Class 2 tape is also used for label

conform to the requirements of this specification.

attachmentandcoveringapplicationswherewaterresistanceis

7.2 Backing:

desired.

7.2.1 Type I backing shall be polyester film.

4.3 Type III is a polypropylene film-backed pressure-

7.2.2 Type II backing shall be a polyester film.

sensitive tape intended for box closure applications where a

7.2.3 Type III backing shall be a polypropylene film.

general purpose water-resistant tape is desired. It is used on

7.2.4 Type IV backing shall be a woven cloth.

domestic grade fiberboard (Class D of Specification D4727/

7.2.5 Type V backing shall be a treated paper.

D4727M).Thetapeissuitedforcenterseamclosureofregular

7.3 Adhesive—The adhesive shall be pressure-sensitive

slotted boxes (Closure Method 2B4 of Practice D1974).

water-insoluble and shall require no moisture heat or other

4.4 TypeIVisawovencloth-backedpressure-sensitivetape

preparation prior to or after application to clean, dry surfaces.

for less critical packaging applications where a cloth-backed

The adhesive shall be coated in a smooth and evenly distrib-

tape is desired.

uted layer on one side of the backing.

7.4 Rolls—Thetapeshallbeevenlywoundinrolls,adhesive

side in, on cores made of paper-fiber or plastic. The core shall

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. have sufficient rigidity to prevent distortion of the roll under

D5486/D5486M − 06 (2020)

normal conditions of transportation and use. The inside diam- 9.3.1 Splices shall be such that they will not separate when

eter of the core shall be 7.6,−0,+1.6 mm [3,−0,+ ⁄16 in.]. the roll is unwound by hand or machine (see Table 1).

When the roll is unwound, the backing shall not tear, the

10. Color

adhesive shall not transfer nor split from the face of the tape

backing to the adjacent layer before or after aging (see Table

10.1 Type I, Class 1 tape shall correspond reasonably in

1).

shadetothecolorsfollowingglosscardsofFED-STD-595:red

11136, olive drab 14087, dark green 14110, black 17038, and

8. Physical Properties

tan (no color card available for tan).

8.1 The tape shall comply with the physical property re-

10.2 Type II, Class 1 tape shall be tan in color.

quirements listed in Table 2 and the water-solubility require-

10.3 Type III color shall be as ordered in commercially

ment of Test Method D5570.

available colors and transparent.

9. Dimensions, Mass, and Permissible Variations

10.4 Type IV tape shall correspond reasonably in shade to

the following lusterless color cards of FED-STD-595: red

9.1 The width of the roll shall be 48 or 72 mm [2 or 3 in.]

31116, olive drab X34087, dark green 34108, black 37038,

or other commercially available widths, as specified (see

white 37875 and tan 30450.

6.1.3).

9.1.1 A width tolerance of 1.5 mm [6 ⁄16 in.] shall be

10.5 Type V color shall be as manufactured.

allowed on all widths.

10.6 Types I and II, Class 2 tapes shall be sufficiently clear

NOTE 2—Uses of pressure-sensitive tapes in closure and sealing

and transparent to allow easy reading of 10-point type when

applications call for commonly available commercial widths. The widths

tape is applied directly over printed matter.

common in the inch-pound system are not identical to the available SI

replacement widths. The most frequent width conversions are:

11. Workmanship, Finish, and Appearance

Inch-Pound, in. SI, mm

11.1 The tape shall be uniformly constructed and free from

1.5 36

defects that impair the usefulness of the tape for the purpose

intended (see Section 5). The tape adhesive coating shall be

496 uniform,coveringentirelyonesideofthetape.Theedgesshall

be clean, straight, and unbroken. The rolls shall be evenly

NOTE 3—The effect of this width difference on packaging performance

wound. The finished product shall conform to the levels of

is not considered significant.

quality established herein.

9.2 Length:

9.2.1 Types I, II, III, and IV—The length of the roll shall be

12. Sampling

50 or 55 m [55 or 60 yd], or other commercially available

12.1 End Item Examination—The lot size for visual inspec-

lengths, as specified (see 6.1.3).

tion shall be in accordance with Practice D3715/D3715M.

9.2.2 Type V—The length of the roll shall be 100 m [120

Sample size shall be one roll.

yd], or other commercially available length, as specified (see

6.1.3).

12.2 End-Item Testing—The lot size for end-item testing

shall be in accordance with Practice D3715/D3715M. The

9.3 Splices—Therollshallconsistofasinglelengthoftape,

acceptable quality level (AQL) shall be 4.0%.

except any single roll of Types I, II, III, and IV may contain a

maximumofonesplice.AnysinglerollofTypeVmaycontain

13. Specimen Preparation and Number of Tests

a maximum of four splices.

13.1 Specimen preparation shall be as specified in the

appropriate test method.

13.2 Number of tests per unit of product shall be as

Supporting data have been filed atASTM International Headquarters and may

beobtainedbyrequestingResearchReportRR:D10-1004.ContactASTMCustomer specified in the appropriate test method.

Service at service@astm.org.

13.3 First article of manufacture specimens shall consist of

at least five rolls of tape.

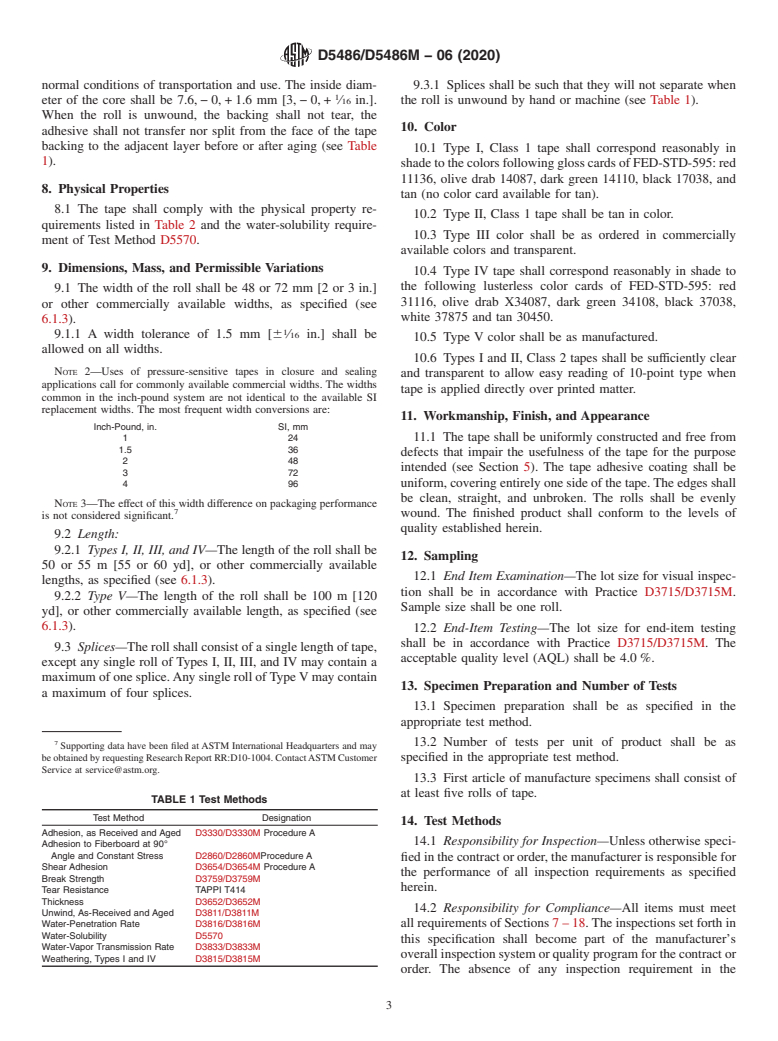

TABLE 1 Test Methods

Test Method Designation

14. Test Methods

Adhesion, as Received and Aged D3330/D3330M Procedure A

14.1 Responsibility for Inspection—Unless otherwise speci-

Adhesion to Fiberboard at 90°

Angle and Constant Stress D2860/D2860MProcedure A

fiedinthecontractororder,themanufacturerisresponsiblefor

Shear Adhesion D3654/D3654M Procedure A

the performance of all inspection requirements as specified

Break Strength D3759/D3759M

herein.

Tear Resistance TAPPI T414

Thickness D3652/D3652M

14.2 Responsibility for Compliance—All items must meet

Unwind, As-Received and Aged D3811/D3811M

Water-Penetration Rate D3816/D3816M allrequirementsofSections7–18.Theinspectionssetforthin

Water-Solubility D5570

this specification shall become part of the manufacturer’s

Water-Vapor Transmission Rate D3833/D3833M

overallinspectionsystemorqualityprogramforthecontractor

Weathering, Types I and IV D3815/D3815M

order. The absence of any inspection requirement in the

D5486/D5486M − 06 (2020)

TABLE 2 Physical Property Requirements

NOTE 1—N/A=not applicable.

Type I Type II

Property Type III Type IV Type V Reference Test

Class 1 Class 2 Class 1 Class 2

Adhesion, min

As received (N/100 mm) 55 55 55 55 49 44 38 Table 1

(oz/in.) 50 50 50 50 45 40 35

Aged (N/100 mm) 49 49 49 49 49 33 38 Table 1 and

(oz/in.) 45 45 45 45 45 30 35 14.4.2

A A A

Weathered (N/100 mm) 49 27 N/A N/A N/A 27 N/A 14.4.4

A A A

(oz/in.) 45 25 N/A N/A N/A 25 N/A

To own backing

As received (N/100 mm) 16 N/A N/A N/A N/A 16 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.