ASTM B967/B967M-09

(Specification)Standard Specification for Copper-Zinc-Tin-Bismuth Alloy Rod, Bar and Wire

Standard Specification for Copper-Zinc-Tin-Bismuth Alloy Rod, Bar and Wire

SCOPE

1.1 This specification establishes the requirements for copper-zinc-tin-bismuth alloy rod, bar and wire of alloy UNS No. C49300 intended for use in plumbing applications and drinking water systems.

1.2 Typically, rod and bar product made to this specification is furnished as straight lengths. Wire (H04) 0.08-0.3 in. [2-8 mm inclusive] is furnished in coil form.

1.3 The following safety hazard caveat pertains only to the test method(s) described in this specification.

1.3.1 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 A Japanese patent application has been submitted for UNS Alloy C49300. A patent application is being prepared for review by the U.S. Patent Office. An international patent application has been submitted to PCT (Patent Cooperation Treaty). Alternative materials will be included in this document when they become available.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B967/B967M – 09

Standard Specification for

Copper-Zinc-Tin-Bismuth Alloy Rod, Bar and Wire

This standard is issued under the fixed designation B967/B967M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Wrought Copper and Copper-Alloy Rod, Bar, Shapes and

Forgings

1.1 This specification establishes the requirements for

B250/B250M Specification for General Requirements for

copper-zinc-tin-bismuth alloy rod, bar and wire of alloy UNS

2 Wrought Copper Alloy Wire

No. C49300 intended for use in plumbing applications and

B846 Terminology for Copper and Copper Alloys

drinking water systems.

E8 Test Methods for Tension Testing of Metallic Materials

1.2 Typically, rod and bar product made to this specification

E8M Test Methods for Tension Testing of Metallic Materi-

is furnished as straight lengths. Wire (H04) 0.08-0.3 in. [2-8

als [Metric]

mm inclusive] is furnished in coil form.

E62 Test Methods for Chemical Analysis of Copper and

1.3 The following safety hazard caveat pertains only to the

Copper Alloys (Photometric Methods)

test method(s) described in this specification.

E92 Test Method for Vickers Hardness of Metallic Materi-

1.3.1 This standard does not purport to address all of the

als

safety concerns, if any, associated with its use. It is the

E478 TestMethodsforChemicalAnalysisofCopperAlloys

responsibility of the user of this standard to establish appro-

2.2 Other Standards:

priate safety and health practices and determine the applica-

ISO No. 3110 (AA) CopperAlloys – Determination ofAlu-

bility of regulatory limitations prior to use.

minum as an Alloying Element – Volumetric (Interna-

1.4 Units—The values stated in either SI units or inch-

tional Organization of Standardization)

pound units are to be regarded separately as standard. The

JIS H 1068:2005 Method for Determination of Bismuth in

values stated in each system may not be exact equivalents;

Copper and Copper Alloys (Japanese Industrial Stan-

therefore,eachsystemshallbeusedindependentlyoftheother.

dards)

Combining values from the two systems may result in non-

conformance with the standard.

3. General Requirements

1.5 A Japanese patent application has been submitted for

3.1 The following sections of Specifications B249/B249M

UNSAlloy C49300.Apatent application is being prepared for

or B250/B250M constitute a part of this specification:

review by the U.S. Patent Office. An international patent

3.1.1 Terminology,

application has been submitted to PCT (Patent Cooperation

3.1.2 Materials and Manufacture,

Treaty).Alternativematerialswillbeincludedinthisdocument

2 3.1.3 Sampling,

when they become available.

3.1.4 Number of Tests and Retests,

2. Referenced Documents 3.1.5 Specimen Preparation,

3 3.1.6 Certification,

2.1 ASTM Standards:

3.1.7 Test Reports.

B249/B249M Specification for General Requirements for

3.2 In addition, when a section with a title identical to that

referenced in X.1, above, appears in this specification, it

contains additional requirements which supplement those ap-

This test method is under the jurisdiction ofASTM Committee B05 on Copper

pearing in Specifications B249/B249M or B250/B250M.

and CopperAlloys and is the direct responsibility of Subcommittee B05.02 on Rod,

Bar, Wire, Shapes and Forgings.

4. Terminology

Current edition approved April 1, 2009. Published May 2009. DOI: 10.1520/

B0967_B0967M-09.

4.1 For definitions of terms related to copper and copper

The UNS Alloy C49300 is covered by pending patents as noted in 1.5.

alloys, refer to Terminology B846.

Interested parties are invited to submit information regarding the identification of

alternative(s)tothispendingpatenteditemtotheASTMInternationalHeadquarters.

Your comments will receive careful consideration at a meeting of the responsible

technical committee, which you may attend. Withdrawn. The last approved version of this historical standard is referenced

For referenced ASTM standards, visit the ASTM website, www.astm.org, or on www.astm.org.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from International Organization of Standards, http://www.ISO/ISO/

Standards volume information, refer to the standard’s Document Summary page on store.htm

the ASTM website. Japanese Industrial Standard, available through http://www.JIS.or.jp/

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B967/B967M – 09

5. Ordering Information 8. Temper

5.1 Include the following information when placing orders 8.1 The standard tempers for products described in this

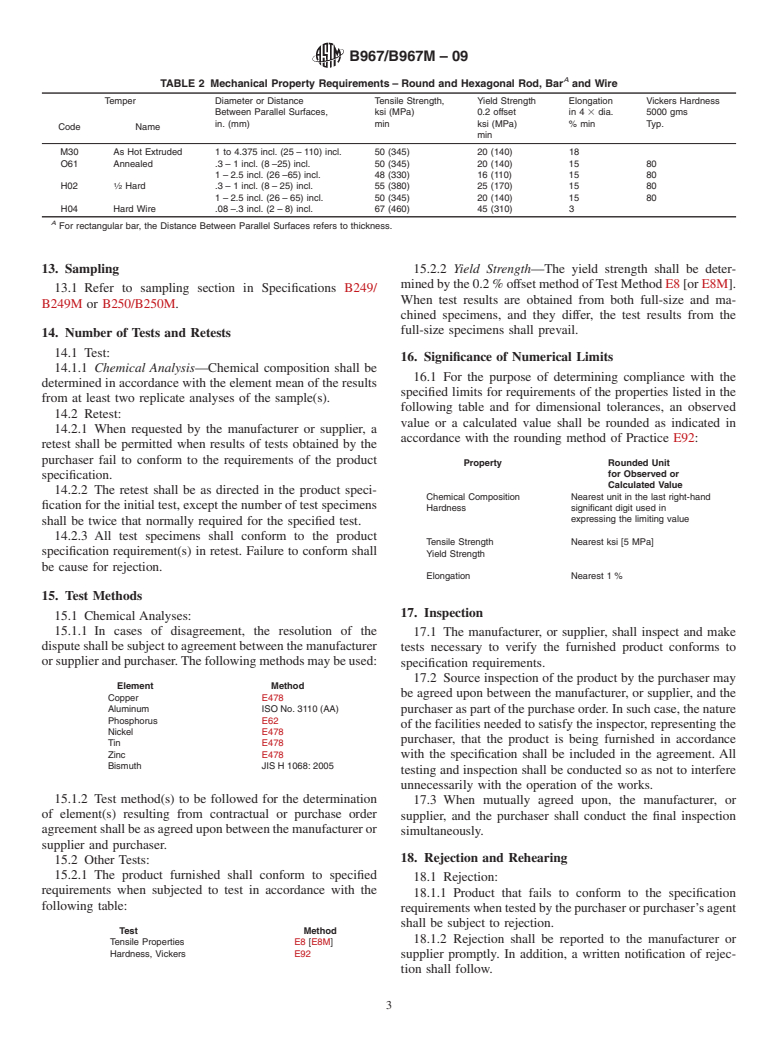

for product under this specification, as applicable: specification are given in Table 2.

5.1.1 ASTM designation and year of issue, 8.1.1 Annealed: 061 for rod and bar

5.1.2 Copper Alloy UNS No. C49300, 8.1.2 As Hot Extruded: M30 for rod and bar

5.1.3 Temper (Section 8), 8.1.3 Cold drawn half hard temper: H02 for rod and bar

5.1.4 Dimensions, diameter, or distance between parallel 8.1.4 Cold drawn hard temper: H04 for wire

surfaces,

5.1.5 How furnished: straight lengths or coils, 9. Mechanical Property Requirements

5.1.6 Quantity: total weight or total length or number of

9.1 Tensile Strength Requirements:

pieces of each size,

9.1.1 Product furnished under this specification shall con-

5.1.7 If product is purchased for agencies of the U.S.

form to the tensile requirements prescribed in Table 2, when

Government (see the Supplementary Requirements section of

tested in accordance with Test Methods E8 [or E8M].

Specifications B249/B249M or B250/B250M for additional

9.1.2 Acceptanceorrejectionshallbebaseduponthetensile

requirements, if specified).

properties prescribed in Table 2.

5.2 The following options are available and should be

specified at the time of placing of the order when required:

10. Other Requirements

5.2.1 Heat identification or traceability details,

10.1 Purchases for the U.S. Government – Product pur-

5.2.2 Certification, and

chased for agencies of the U.S. Government shall conform to

5.2.3 Mill Test Report.

the additional requirements prescribed in the Supplementary

Requirements section of Specifications B249/B249M or B250/

6. Materials and Manufacture

B250M.

6.1 Materials:

6.1.1 ThematerialofmanufactureshallbeaformofCopper

11. Dimensions, Mass, and Permissible Variation

Alloy UNS No. C49300 of such purity and soundness as to be

11.1 The dimensions and tolerances for product described

suitable for processing into the products prescribed herein.

by this specification shall be as specified in Specification

6.1.2 In the event heat identification or traceability is

B249/B249M or B250/B250M for wire as noted, with particu-

required, the purchaser shall specify the details desired.

lar reference to the following Tables and related paragraphs:

NOTE 1—Due to the discontinuous nature of the processing of castings

11.1.1 Diameter or Distance Between Parallel Surfaces

into wrought products, it is not always practical to identify a specific

11.1.1.1 Rod, Cold-Drawn, H02, H04 Table 1, B249/

casting analysis with a specific quantity of finished material.

B249M.

6.2 Manufacture: 11.1.1.2 Rod and Bar, As Extruded, O61 Table 4, B249/

6.2.1 The product shall be manufactured by such hot work- B249M.

ing, cold working, and annealing processes as to produce a 11.1.1.3 Wire Cold Drawn Hard, H04 Table 1, B250/

uniform wrought structure in the finished product. B250M.

6.2.2 Theproductshallbehotorcoldworkedtothefinished 11.1.2 ThicknessTolerance for Rectangular and Square Bar,

size, and subsequently annealed when required, to meet the Table 7, B249/B249M.

temper properties specified. 11.1.3 Width Tolerance for Rectangular Bar, Table 10,

B249/B249M.

7. Chemical Composition 11.1.4 Length: Table 13, Full Length Tolerances for Rod,

Bar, and Table 15, Schedule of Lengths with Ends for Rod and

7.1 The material shall conform to the chemical composition

Bar, B249/B249M.

requirements in Table 1 for copper alloy UNS No. C49300

11.1.5 Straightness: Table 16, Straightness Tolerances for

specified in the ordering information.

Rod, Bar, For General Use section, B249/B249M.

7.2 These composition limits do not preclude the presence

11.1.6 Edge Contour: Refer to Edge Contours section in

ofotherelements.By

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.