ASTM D4649-00

(Guide)Standard Guide for Selection and Use of Stretch Wrap Films

Standard Guide for Selection and Use of Stretch Wrap Films

SCOPE

1.1 This guide covers recommended guidelines and test methods for the selection, specification, and use of stretch wrap films for unitizing, reinforcing, and palletizing for indoor environments. This can include storage or transport, or both, in warehouses, closed containers such as truck trailers or rail boxcars, and associated transfer terminals. This guide does not cover the performance issues associated with outdoor exposure.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4649 – 00

Standard Guide for

Selection and Use of Stretch Wrap Films

This standard is issued under the fixed designation D 4649; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 2457 Test Method for Specular Gloss of Plastic Films and

Solid Plastics

1.1 This guide covers recommended guidelines and test

D 2578 Test Method for Wetting Tension of Polyethylene

methods for the selection, specification, and use of stretch wrap

and Polypropylene Films

films for unitizing, reinforcing, and palletizing for indoor

D 2863 Test Method for Measuring the Minimum Oxygen

environments. This can include storage or transport, or both, in

Concentration to Support Candle-Like Combustion of

warehouses, closed containers such as truck trailers or rail

Plastics (Oxygen Index)

boxcars, and associated transfer terminals. This guide does not

D 3951 Practice for Commercial Packaging

cover the performance issues associated with outdoor expo-

D 4321 Test Method for Package Yield of Plastic Film

sure.

D 4470 Test Method for Static Electrification

1.2 The values stated in inch-pound units are to be regarded

D 5331 Test Method for Mechanical Handling of Unitized

as the standard. The SI units given in parentheses are for

Loads Secured With Stretch-Wrap Films

information only.

D 5414 Test Method for Evaluation of Horizontal Impact

1.3 This standard does not purport to address all of the

Performance of Load Unitizing Stretch Wrap Materials

safety concerns, if any, associated with its use. It is the

D 5415 Test Method for Evaluating Load Containment

responsibility of the user of this standard to establish appro-

Performance of Stretch Wrap Materials by Vibration Test-

priate safety and health practices and determine the applica-

ing

bility of regulatory limitations prior to use.

D 5416 Test Method for Evaluating Abrasion Resistance of

2. Referenced Documents Stretch Wrap Materials by Vibration Testing

D 5458 Test Method for Peel Cling of Stretch Wrap Film

2.1 ASTM Standards:

D 5459 Test Method for Machine Direction Elastic Recov-

D 882 Test Methods for Tensile Properties of Thin Plastic

ery and Permanent Deformation and Stress Retention of

Sheeting

Stretch Wrap Materials

D 907 Terminology of Adhesives

E 96 Test Methods for Water Vapor Transmission of Mate-

D 996 Terminology of Packaging and Distribution Environ-

rials

ments

E 284 Terminology of Appearance

D 1003 Test Method for Haze and Luminous Transmittance

of Transparent Plastics

3. Terminology

D 1505 Test Method for Density of Plastics by the Density-

2 3.1 Definitions—Terminology found in Terminology D 996

Gradient Technique

shall apply.

D 1746 Test Method for Transparency of Plastic Sheeting

3.2 Definitions of Terms:

D 1894 Test Method for Static and Kinetic Coefficients of

3.2.1 blocking—an undesirable adhesion between touching

Friction of Plastic Film and Sheeting

2 layers of a material, such as occurs under moderate pressure

D 1898 Practice for Sampling of Plastics

during storage or use. (See Terminology D 907.)

D 1922 Test Method for Propagation Tear Resistance of

2 3.2.2 clarity—the characteristic of a transparent body

Plastic Film and Thin Sheeting by Pendulum Method

whereby distinct high-contrast images or high-contrast objects

D 2103 Specification for Polyethylene Film and Sheeting

(separated by some distance from the body) are observable

through the body. (See Terminology E 284.)

This guide is under the jurisdiction of ASTM Committee D10 on Packaging and

is the direct responsibility of Subcommittee D10.25 on Palletizing and Unitizing of

Loads. Annual Book of ASTM Standards, Vol 08.02.

Current edition approved Nov. 10, 2000. Published January 2001. Originally Annual Book of ASTM Standards, Vol 15.09.

published as D 4649 – 87. Last previous edition D 4649 – 95. Annual Book of ASTM Standards, Vol 10.02.

2 7

Annual Book of ASTM Standards, Vol 08.01. Annual Book of ASTM Standards, Vol 04.06.

3 8

Annual Book of ASTM Standards, Vol 15.06. Annual Book of ASTM Standards, Vol 06.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D4649–00

3.2.3 cling—the ability of one surface of a material to 5. Stretch Film Classification

adhere to itself or another surface.

5.1 Stretch wrap films may have the following types:

3.2.4 elastic recovery—the extent that a material returns to

5.1.1 Hand applied film versus machine applied film,

its original length after being subjected to an extension.

5.1.2 Fabrication (blown, cast),

3.2.5 elongation—increase in length (expressed as a percent

5.1.3 Cling Mechanism (two side, one side, no cling,

of original length).

migratory, non-migratory, one side slip, differentiated), and

3.2.6 thickness (caliper, gage)— the perpendicular distance

5.1.4 Layer (monolayer, co-extruded).

between opposite surface of a material.

5.2 Grade:

3.3 Definitions of Terms Specific to This Standard:

5.2.1 Colors, (clear, tints, opaque).

3.3.1 conventional braking—a mode of stretch wrap ma-

5.3 Class:

chinery operation in which wrap material elongation is

5.3.1 Food Contact, and

achieved by relative load motion and supply roll tension.

5.3.2 Non-food Contact.

3.3.2 core extension—the length to which the core extends

beyond the edge of the wrap material.

6. Raw Materials and Fabrication

3.3.3 cut growth resistance—the ability of a wrap material

6.1 Typical materials covered by this guide are as follows:

to resist nick or cut propagation.

6.1.1 Low-density polyethylene (LDPE),

3.3.4 film force to load—the amount of force applied by the

6.1.2 Medium-density polyethylene (MDPE),

film to a load in providing load containment.

6.1.3 Linear low-density polyethylene (LLDPE),

3.3.5 film tail—that portion of wrap material that is applied

6.1.4 Metallocene/m linear low density polyethylene (mLL-

to the load after relative load motion ceases.

DPE):

3.3.6 food wrap material—a material designed for use in

6.1.5 Ethylene vinyl acetate copolymer (EVA),

direct food contact.

6.1.6 Poly(vinyl chloride) (PVC),

3.3.7 load containment—the utilization and protection, or

6.1.7 Polypropylene (PP),

both, of product(s) for distribution and storage or both.

6.1.8 Other polymeric materials or blends that meet the

3.3.8 marking wheel—a device that makes repetitive marks

requirements of this guide. High density polyethylene (HDPE),

indicating a known distance.

6.1.9 Ethylene methyl acrylate copolymer (EMA),

3.3.9 measured stretch—see elongation.

6.1.10 Very low density polyethylene (VLDPE),

3.3.10 mechanical prestretch—a mode of stretch wrap ma-

chinery operation in which wrap material elongation is 6.1.11 Ethylene metallocene plastomers, and

6.1.12 Additives, modifiers and pigments.

achieved through the use of a prestretch device and relative

load motion.

3.3.11 nonfood wrap material—a material not for direct 7. Ordering Information

food contact.

7.1 The inquiry and order for materials shall indicate the

3.3.12 overlap—the width of wrap material that covers a

following where applicable:

previous layer of wrap material.

7.1.1 Grade and class required,

3.3.13 powered prestretch—a mode of stretch wrap machin-

7.1.2 Thickness,

ery operation in which wrap material elongation is achieved

7.1.3 Material length per roll,

through use of a power assist prestretch device and relative

7.1.4 Outside roll diameter,

load motion.

7.1.5 Material width,

3.3.14 protrusion puncture resistance—the ability of a wrap

7.1.6 Core dimension (inside diameter and extension), and

material to withstand the force exerted by a protrusion.

7.1.7 ASTM designation, including revision date.

3.3.15 stretch wrap material—a material used for over-

7.2 Where necessary, ordering information may be ex-

wrapping that elongates when applied under tension and,

panded or modified for special uses or materials, such as

through elastic recovery conforms to the item(s) packaged.

method of stretch and stretch percentage expected.

3.3.16 wrap cycle—the series of operations used to wrap a

load.

8. Stretch Film and Additives’ Characteristics

3.3.17 yield (coverage)—area per unit weight.

8.1 Physical and Mechanical Properties:

3.3.18 zipper (tear)—a self-propagating tear.

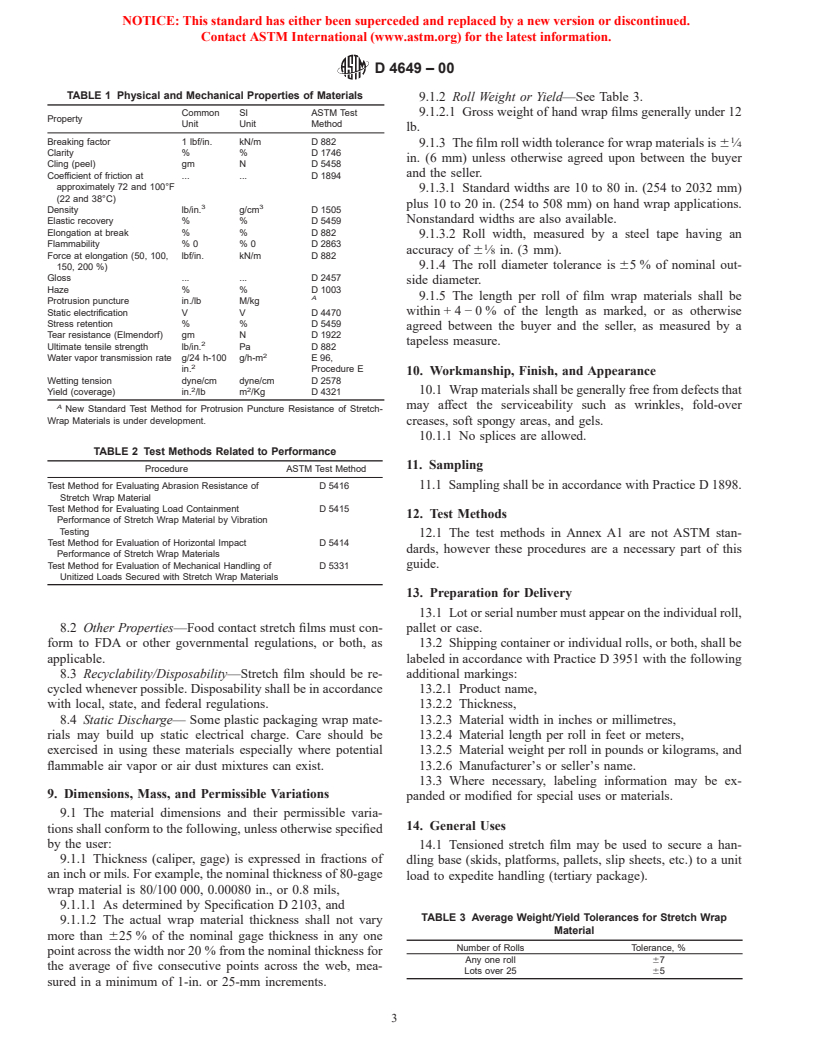

8.1.1 The properties and test methods in Table 1 shall be

4. Significance and Use

used when describing the physical and mechanical character-

istics of wrap materials as manufactured.

4.1 This guide is for user evaluation, selection, specifica-

tion, and application of stretch wrap materials. It may be used 8.1.2 The practices listed in Table 2 can be an aid when

describing performance characteristics of wrap materials, as

between the buyer and seller to arrive at purchase specifica-

tions. Specific methods are contained within the body of the used for unitizing, reinforcing, and palletizing.

8.1.3 Some of the test methods described in Table 1 may be

guide for material evaluation, user performance, and quality

assurance testing. applied to multiple wraps or stretched specimens, or both, to

aid in assessing their performance characteristics.

4.2 Care must be exercised in extrapolating test values

obtained by use of the test methods outlined in this guide, to 8.1.4 Other tests that may be of value for evaluating actual

actual field performance. performance are given in Annex A1.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D4649–00

TABLE 1 Physical and Mechanical Properties of Materials

9.1.2 Roll Weight or Yield—See Table 3.

Common SI ASTM Test 9.1.2.1 Gross weight of hand wrap films generally under 12

Property

Unit Unit Method

lb.

Breaking factor 1 lbf/in. kN/m D 882

9.1.3 The film roll width tolerance for wrap materials is 6 ⁄4

Clarity % % D 1746

in. (6 mm) unless otherwise agreed upon between the buyer

Cling (peel) gm N D 5458

and the seller.

Coefficient of friction at . . D 1894

approximately 72 and 100°F

9.1.3.1 Standard widths are 10 to 80 in. (254 to 2032 mm)

(22 and 38°C)

plus 10 to 20 in. (254 to 508 mm) on hand wrap applications.

3 3

Density lb/in. g/cm D 1505

Nonstandard widths are also available.

Elastic recovery % % D 5459

Elongation at break % % D 882

9.1.3.2 Roll width, measured by a steel tape having an

Flammability % 0 % 0 D 2863

accuracy of 6 ⁄8 in. (3 mm).

Force at elongation (50, 100, lbf/in. kN/m D 882

9.1.4 The roll diameter tolerance is 65 % of nominal out-

150, 200 %)

Gloss . . D 2457

side diameter.

Haze % % D 1003

9.1.5 The length per roll of film wrap materials shall be

A

Protrusion puncture in./lb M/kg

Static electrification V V D 4470 within+4−0% of the length as marked, or as otherwise

Stress retention % % D 5459

agreed between the buyer and the seller, as measured by a

Tear resistance (Elmendorf) gm N D 1922

2 tapeless measure.

Ultimate tensile strength lb/in. Pa D 882

Water vapor transmission rate g/24 h-100 g/h-m E 96,

in. Procedure E

10. Workmanship, Finish, and Appearance

Wetting tension dyne/cm dyne/cm D 2578

2 2

10.1 Wrap materials shall be generally free from defects that

Yield (coverage) in. /lb m /Kg D 4321

A

may affect the serviceability such as wrinkles, fold-over

New Standard Test Method for Protrusion Puncture Resistance of Stretch-

Wrap Materials is under development.

creases, soft spongy areas, and gels.

10.1.1 No splices are allowed.

TABLE 2 Test Methods Related to Performance

11. Sampling

Procedure ASTM Test Method

Test Method for Evaluating Abrasion Resistance of D 5416 11.1 Sampling shall be in accordance with Practice D 1898.

Stretch Wrap Material

Test Method for Evaluating Load Containment D 5415

12. Test Methods

Performance of Stretch Wrap Material by Vibration

Testing

12.1 The test methods in Annex A1 are not ASTM stan-

Test Method for Evaluation of Horizontal Impact D 5414

dards, however these procedures are a necessary part of this

Performance of Stretch Wrap Materials

guide.

Test Method for Evaluation of Mechanical Handling of D 5331

Unitized Loads Secured with Stretch Wrap Materials

13. Preparation for Delivery

13.1 Lot or serial number must appear on the individual roll,

8.2 Other Properties—Food contact stretch films must con- pallet or case.

form to FDA or other governmental regulations, or both, as 13.2 Shipping container or individual rolls, or both, shall be

applicable. labeled in accordance with Practice D 3951 with the following

8.3 Recyclability/Disposability—Stretch film should be re- additional markings:

cycled whenever possible. Disposability shall be in accordance 13.2.1 Product name,

with local, state, and federal regulations. 13.2.2 Thickness,

8.4 Static Discharge— Some plastic packaging wrap mate- 13.2.3 Material width in inches or millimetres,

rials may build up static electrical charge. Care should be 13.2.4 Material length per roll in feet or meters,

exercised in using these materials especially where potential 13.2.5 Material weight per roll in pounds or kilograms, and

flammable air vapor or air dust mixtures can exist. 13.2.6 Manufacturer’s or seller’s name.

13.3 Where necessary, labeling information may be ex-

9. Dimensions, Mass, and Permissible Variations

panded or modified for special uses or materials.

9.1 The material dimensions and their permissible varia-

14. General Uses

tions shall conform to the following, unless otherwise specified

by the user:

14.1 Tensioned stretch film may be used to secure a han-

9.1.1 Thickness (caliper, gage) is expressed in fractions of

dling base (skids, platforms, pallets, slip sheets, etc.) to a unit

an inch or mils. For example, the nominal thickness of 80-gage

load to expedite handling (tertiary package).

wrap material is 80/100 000, 0.00080 in., or 0.8 mils,

9.1.1.1 As determined by Specification D 2103, and

TABLE 3 Average Weight/Yield Tolerances for Stretch Wrap

9.1.1.2 The actual wrap material thickness shall not vary

Material

more than 625 % of the nominal gage thickness in any one

Number of Rolls Tolerance, %

point across the width nor 20 % from the nominal thickness for

Any one roll 67

the average of five consecutive points across the web, mea-

Lots over 25 65

sured in a minimum of 1-in. or 25-mm increments.

NOTICE: This standard has either been superceded and replaced by a new vers

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.