ASTM D4649-03

(Guide)Standard Guide for Selection and Use of Stretch Wrap Films

Standard Guide for Selection and Use of Stretch Wrap Films

SIGNIFICANCE AND USE

This guide is for user evaluation, selection, specification, and application of stretch wrap materials. It may be used between the buyer and seller to arrive at purchase specifications. Specific methods are contained within the body of the guide for material evaluation, user performance, and quality assurance testing.

Care must be exercised in extrapolating test values obtained by use of the test methods outlined in this guide, to actual field performance.

SCOPE

1.1 This guide covers recommended guidelines and test methods for the selection, specification, and use of stretch wrap films for unitizing, reinforcing, and palletizing for indoor environments. This can include storage or transport, or both, in warehouses, closed containers such as truck trailers or rail boxcars, and associated transfer terminals. This guide does not cover the performance issues associated with outdoor exposure.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

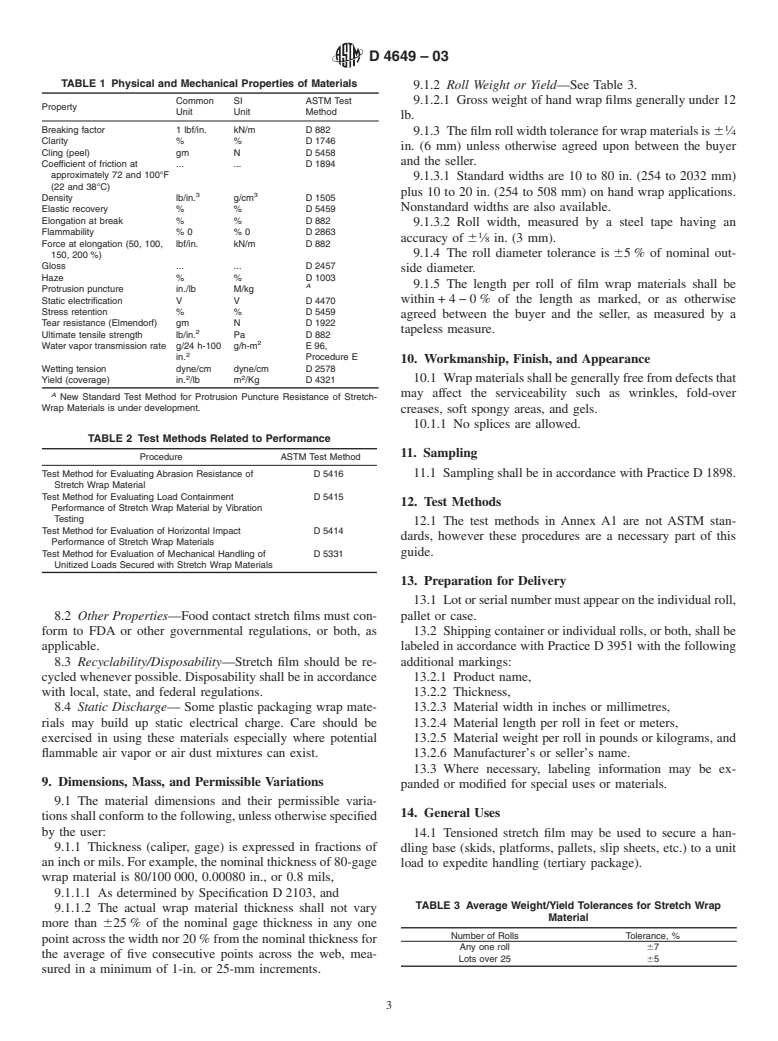

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4649 – 03

Standard Guide for

1

Selection and Use of Stretch Wrap Films

This standard is issued under the fixed designation D4649; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D1922 Test Method for Propagation Tear Resistance of

Plastic Film and Thin Sheeting by Pendulum Method

1.1 This guide covers recommended guidelines and test

D2103 Specification for Polyethylene Film and Sheeting

methodsfortheselection,specification,anduseofstretchwrap

D2457 TestMethodforSpecularGlossofPlasticFilmsand

films for unitizing, reinforcing, and palletizing for indoor

Solid Plastics

environments.Thiscanincludestorageortransport,orboth,in

D2578 Test Method for Wetting Tension of Polyethylene

warehouses, closed containers such as truck trailers or rail

and Polypropylene Films

boxcars, and associated transfer terminals.This guide does not

D2863 Test Method for Measuring the Minimum Oxygen

cover the performance issues associated with outdoor expo-

Concentration to Support Candle-Like Combustion of

sure.

Plastics (Oxygen Index)

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

D3951 Practice for Commercial Packaging

as the standard. The SI units given in parentheses are for

D4321 Test Method for Package Yield of Plastic Film

information only.

D4470 Test Method for Static Electrification

1.3 This standard does not purport to address all of the

D5331 Test Method for Mechanical Handling of Unitized

safety concerns, if any, associated with its use. It is the

Loads Secured With Stretch-Wrap Films

responsibility of the user of this standard to establish appro-

D5414 Test Method for Evaluation of Horizontal Impact

priate safety and health practices and determine the applica-

Performance of Load Unitizing Stretch Wrap Materials

bility of regulatory limitations prior to use.

D5415 Test Method for Evaluating Load Containment

2. Referenced Documents

Performance of Stretch Wrap Materials by Vibration Test-

2

ing

2.1 ASTM Standards:

D5416 Test Method for EvaluatingAbrasion Resistance of

D882 Test Methods for Tensile Properties of Thin Plastic

Stretch Wrap Materials by Vibration Testing

Sheeting

D5458 Test Method for Peel Cling of Stretch Wrap Film

D907 Terminology of Adhesives

D5459 Test Method for Machine Direction Elastic Recov-

D996 TerminologyofPackagingandDistributionEnviron-

ery and Permanent Deformation and Stress Retention of

ments

Stretch Wrap Materials

D1003 Test Method for Haze and LuminousTransmittance

E96 Test Methods for Water Vapor Transmission of Mate-

of Transparent Plastics

rials

D1505 Test Method for Density of Plastics by the Density-

E284 Terminology of Appearance

Gradient Technique

D1746 Test Method for Transparency of Plastic Sheeting

3. Terminology

D1894 Test Method for Static and Kinetic Coefficients of

3.1 Definitions—Terminology found in Terminology D996

Friction of Plastic Film and Sheeting

shall apply.

D1898 Practice for Sampling of Plastics

3.2 Definitions of Terms:

3.2.1 blocking—an undesirable adhesion between touching

layers of a material, such as occurs under moderate pressure

1

ThisguideisunderthejurisdictionofASTMCommitteeD10onPackagingand

during storage or use. (See Terminology D907.)

is the direct responsibility of Subcommittee D10.25 on Palletizing and Unitizing of

3.2.2 clarity—the characteristic of a transparent body

Loads.

whereby distinct high-contrast images or high-contrast objects

Current edition approved Oct. 1, 2003. Published December 2003. Originally

approved in 1987. Last previous edition approved in 2000 as D4649–00.

(separated by some distance from the body) are observable

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

through the body. (See Terminology E284.)

contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM

3.2.3 cling—the ability of one surface of a material to

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. adhere to itself or another surface.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4649–03

3.2.4 elastic recovery—the extent that a material returns to 5. Stretch Film Classification

its original length after being subjected to an extension.

5.1 Stretch wrap films may have the following types:

3.2.5 elongation—increaseinlength(expressedasapercent

5.1.1 Hand applied film versus machine applied film,

of original length).

5.1.2 Fabrication (blown, cast),

3.2.6 thickness (caliper, gage)— the perpendicular distance

5.1.3 Cling Mechanism (tw

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.