ASTM E1127-03

(Guide)Standard Guide for Depth Profiling in Auger Electron Spectroscopy

Standard Guide for Depth Profiling in Auger Electron Spectroscopy

SIGNIFICANCE AND USE

Auger electron spectroscopy yields information concerning the chemical and physical state of a solid surface in the near surface region. Nondestructive depth profiling is limited to this near surface region. Techniques for measuring the crater depths and film thicknesses are given in (35).

Ion sputtering is primarily used for depths of less than the order of 1 μm.

Angle lapping or mechanical cratering is primarily used for depths greater than the order of 1 μm.

The choice of depth profiling methods for investigating an interface depends on surface roughness, interface roughness, and film thickness (1).3

SCOPE

1.1 This guide covers procedures used for depth profiling in Auger electron spectroscopy.

1.2 Guidelines are given for depth profiling by the following:SectionIon Sputtering6Angle Lapping and Cross-Sectioning7Mechanical Cratering8Nondestructive Depth Profiling9

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1127 – 03

Standard Guide for

1

Depth Profiling in Auger Electron Spectroscopy

This standard is issued under the fixed designation E 1127; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

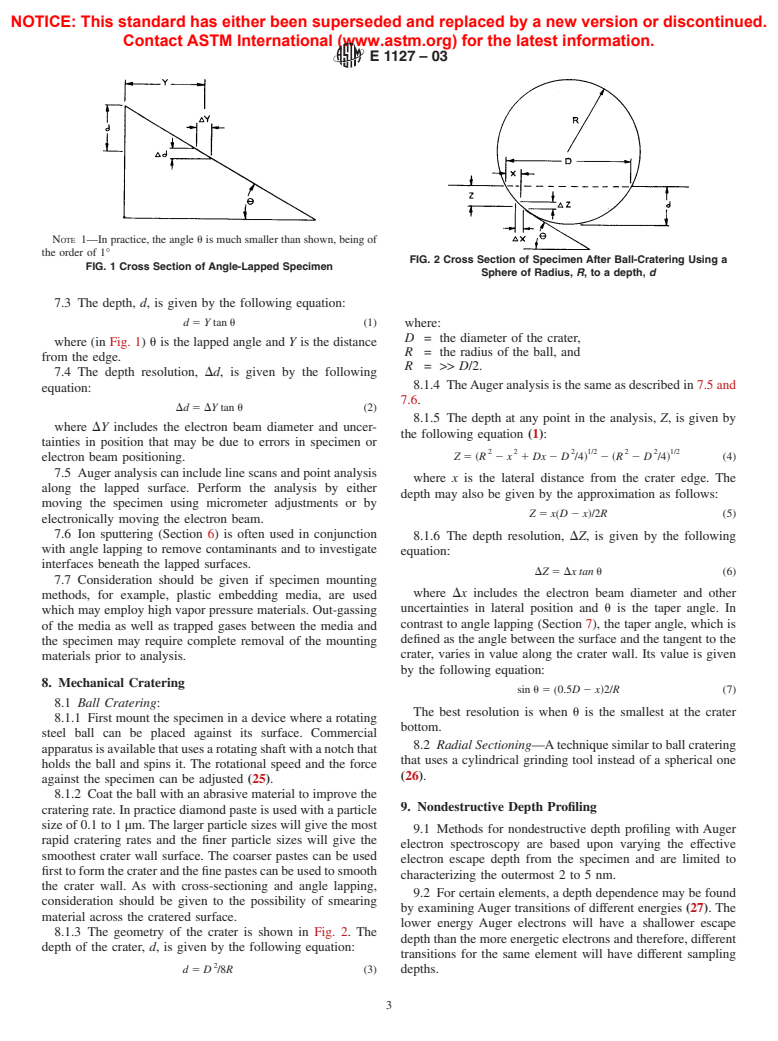

1. Scope 4.3 In mechanical cratering, a spherical or cylindrical crater

is created in the surface using a rotating ball or wheel. The

1.1 This guide covers procedures used for depth profiling in

sloping sides of the crater are used to improve the depth

Auger electron spectroscopy.

resolution as in angle lapping.

1.2 Guidelines are given for depth profiling by the follow-

4.4 In nondestructive techniques, different methods of vary-

ing:

ing the electron information depth are involved.

Section

Ion Sputtering 6

5. Significance and Use

Angle Lapping and Cross-Sectioning 7

Mechanical Cratering 8

5.1 Auger electron spectroscopy yields information con-

Nondestructive Depth Profiling 9

cerning the chemical and physical state of a solid surface in the

1.3 This standard does not purport to address all of the

near surface region. Nondestructive depth profiling is limited

safety problems, if any, associated with its use. It is the

to this near surface region.Techniques for measuring the crater

responsibility of the user of this standard to establish appro-

depths and film thicknesses are given in (35).

priate safety and health practices and determine the applica-

5.2 Ion sputtering is primarily used for depths of less than

bility of regulatory limitations prior to use.

the order of 1 µm.

5.3 Angle lapping or mechanical cratering is primarily used

2. Referenced Documents

for depths greater than the order of 1 µm.

2.1 ASTM Standards:

5.4 The choice of depth profiling methods for investigating

2

E 673 Terminology Relating to Surface Analysis

an interface depends on surface roughness, interface rough-

E 684 Practice for Approximate Determination of Current 3

ness, and film thickness (1).

Density of Large-Diameter Ion Beams for Sputter Depth

2

Profiling of Solid Surfaces 6. Ion Sputtering

E 827 Practice for Elemental Identification by Auger Elec-

6.1 First introduce the specimen into a vacuum chamber

2

tron Spectroscopy

equipped with an Auger analyzer and an ion sputtering gun.

E 1634 Guide for Performing Sputter Crater Depth Mea-

Align the ion beam using a sputtering target or a Faraday cup,

2

surements

paying careful attention to the relative spot size of the electron

beam, ion beam, and Faraday cup and their respective orien-

3. Terminology

tations to ensure accurate convergence of the two beams at the

3.1 Definitions:

specimen surface.

3.1.1 For definitions of terms used in this guide, refer to

6.1.1 Place the specimen in front of theAuger analyzer and

Terminology E 673.

direct the ion gun towards the analysis area. If the ion beam is

not normal to the specimen surface then possible shadowing of

4. Summary of Guide

the analysis area from the ion beam must be considered.

4.1 In ion sputtering, the surface layers are removed by ion

6.2 Choose the elements to be investigated from previous

bombardment in conjunction with Auger analysis.

experience or from an initial Auger electron spectrum or an

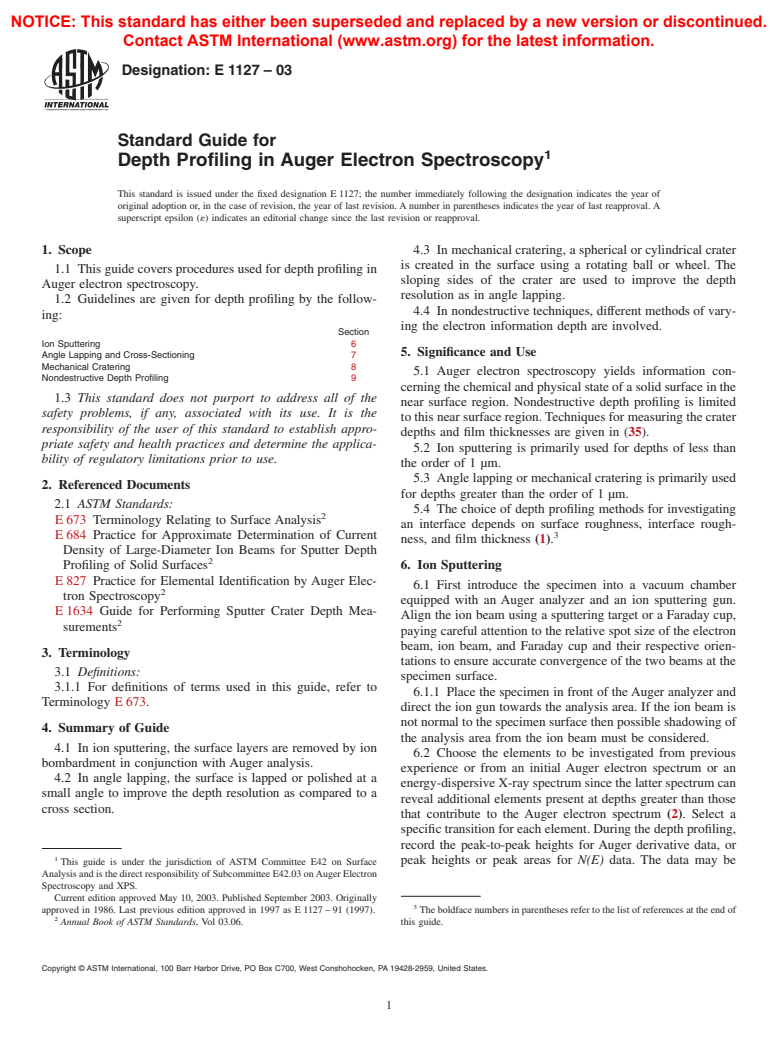

4.2 In angle lapping, the surface is lapped or polished at a

energy-dispersive X-ray spectrum since the latter spectrum can

small angle to improve the depth resolution as compared to a

reveal additional elements present at depths greater than those

cross section.

that contribute to the Auger electron spectrum (2). Select a

specific transition for each element. During the depth profiling,

record the peak-to-peak heights for Auger derivative data, or

1

peak heights or peak areas for N(E) data. The data may be

This guide is under the jurisdiction of ASTM Committee E42 on Surface

Analysis and is the direct responsibility of Subcommittee E42.03 onAuger Electron

Spectroscopy and XPS.

Current edition approved May 10, 2003. Published September 2003. Originally

3

approved in 1986. Last previous edition approved in 1997 as E 1127 – 91 (1997). The boldface numbers in parentheses refer to the list of references at the end of

2

Annual Book of ASTM Standards, Vol 03.06. this guide.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E1127–03

gatheredduringcontinuoussputteringorbetweentimedsputter modelling of these and other ion-induced phenomena has been

segments.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.