ASTM A872/A872M-05

(Specification)Standard Specification for Centrifugally Cast Ferritic/Austenitic Stainless Steel Pipe for Corrosive Environments

Standard Specification for Centrifugally Cast Ferritic/Austenitic Stainless Steel Pipe for Corrosive Environments

SCOPE

1.1 This specification covers centrifugally cast ferritic/austenitic steel pipe intended for general corrosive service. These steels are susceptible to embrittlement if used for prolonged periods at elevated temperatures.

1.2 Optional supplementary requirements are provided when additional testing may be required.

1.3 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of each other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 872/A 872M – 05

Standard Specification for

Centrifugally Cast Ferritic/Austenitic Stainless Steel Pipe for

1

Corrosive Environments

This standard is issued under the fixed designationA 872/A 872M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

1. Scope* E 280 Reference Radiographs for Heavy-Walled (4 ⁄2 to

12-in. [114 to 305-mm]) Steel Castings

1.1 This specification covers centrifugally cast ferritic/

E 340 Test Method for Macroetching Metals and Alloys

austenitic steel pipe intended for general corrosive service.

E 446 Reference Radiographs for Steel Castings up to 2 in.

These steels are susceptible to embrittlement if used for

[51 mm] in Thickness

prolonged periods at elevated temperatures.

2.2 ASME Boiler and Pressure Vessel Code:

1.2 Optional supplementary requirements are provided

3

Section IX Welding Qualifications

when additional testing may be required.

2.3 ASTM Adjuncts:

1.3 The values stated in either inch-pound units or SI units

Adjunct E 186 Reference Radiographs—Transparencies in

are to be regarded separately as standard. Within the text, SI

4

Ringbinders, 3 Volumes

units are shown in brackets. The values stated in each system

Adjunct E 280 Reference Radiographs—Transparencies in

are not exact equivalents; therefore, each system must be used

5

Ringbinders, 2 Volumes

independently of each other. Combining values from the two

Adjunct E 446 Reference Radiographs—Transparencies in

systems may result in nonconformance with the specification.

6

Ringbinders, 3 Volumes

2. Referenced Documents

3. Ordering Information

2

2.1 ASTM Standards:

3.1 Orders for material to this specification shall include the

A 370 Test Methods and Definitions for MechanicalTesting

following, as required, to describe the desired material ad-

of Steel Products

equately.

A 488/A 488M Practice for Steel Castings, Welding, Quali-

3.1.1 Quantity (feet [metres] or number of lengths),

fication of Procedures and Personnel

3.1.2 Name of material (centrifugally cast ferritic/austenitic

A 781/A 781M Specification for Castings, Steel and Alloy,

steel pipe),

Common Requirements, for General Industrial Use

3.1.3 Grade (Table 1),

A 999/A 999M Specification for General Requirements for

3.1.4 Size (outside or inside diameter and minimum wall

Alloy and Stainless Steel Pipe

thickness in inches [millimetres]),

E29 Practice for Using Significant Digits in Test Data to

3.1.5 Length (specific or random, Specification A 999/

Determine Conformance with Specifications

A 999M),

E94 Guide for Radiographic Examination

3.1.6 End finish of Specification A 999/A 999M,

E 165 Test Method for Liquid Penetrant Examination

1 3.1.7 Optional Requirements (S1 through S6),

E 186 Reference Radiographs for Heavy-Walled (2 to 4 ⁄2-

3.1.8 Test report required (Section 12), and

in. [51 to 114-mm]) Steel Castings

3.1.9 Special requirements or additions to the specification.

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel,

3

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee Available from American Society of Mechanical Engineers (ASME Interna-

A01.18 on Castings. tional), Three Park Ave., New York, NY 10016-5990.

4

Current edition approved May 1, 2005. Published May 2005. Originally AvailablefromASTMInternationalHeadquarters.RequestRRE018601forVol

approved in 1977. Last previous edition approved in 2004 as A 872/A 872M – 04. I, RRE018602 for Vol II, and RRE018603 for Vol III.

2 5

For referenced ASTM standards, visit the ASTM website, www.astm.org, or AvailablefromASTMInternationalHeadquarters.RequestforRRE028001Vol

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM I and RRE028002 for Vol II.

6

Standards volume information, refer to the standard’s Document Summary page on AvailablefromASTMInternationalHeadquarters.RequestforRRE044601Vol

the ASTM website. I, RRE044602 for Vol II, and RRE044603 for Vol III.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

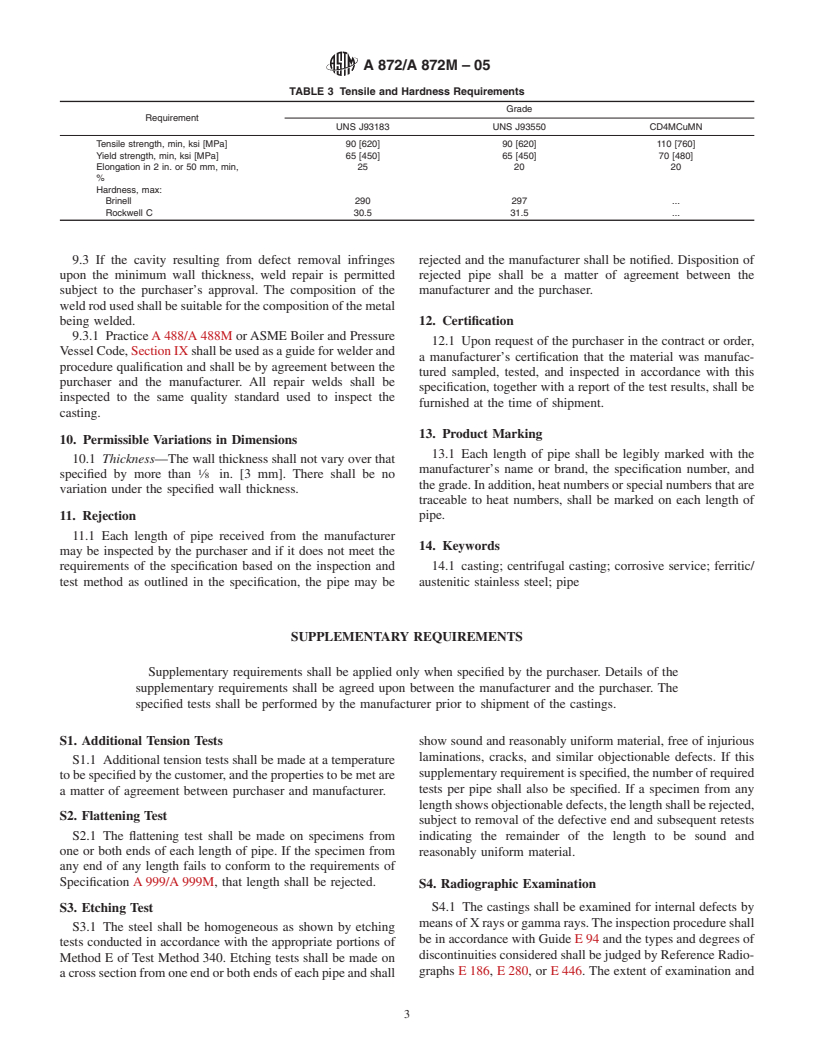

A 872/A 872M – 05

TABLE 1 Chemical Requirements

Grade

Element

UNS J93183 UNS J93550 CD4MCuMN

C 0.030 max 0.030 max 0.04

Mn 2.0 max 2.0 max 0.50–1.50

P 0.040 max 0.040 max 0.04

S 0.030 max 0.030 max 0.04

Si 2.0 max 2.0 max 1.10 max

Ni 4.00–6.00 5.00–8.00 4.5–6.0

Cr 20.0–23.0 23.0–26.0 24.5–26.5

Mo 2.00–4.00 2.00–4.00 2.5–4.0

N 0.08–0.25 0.08–0.25 0.18–0.26

Cu 1.00 max 1.00 max 1.3–3.0

Co 0.50–1.50 0.50–1.50 .

4. General Requirements 7. Te

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.