ASTM B524/B524M-99(2011)

(Specification)Standard Specification for Concentric-Lay-Stranded Aluminum Conductors, Aluminum-Alloy Reinforced (ACAR, 1350/6201)

Standard Specification for Concentric-Lay-Stranded Aluminum Conductors, Aluminum-Alloy Reinforced (ACAR, 1350/6201)

ABSTRACT

This specification covers concentric-lay-stranded conductors made from round aluminum 1350-H19 (extra hard) wires and round aluminum-alloy 6201-T81 (hard, solution heat treated, cold worked, and then artificially aged) core wires for use as overhead electrical conductors. Conductors shall conform to construction requirements in terms of mass, mass per unit length, recommended reel sizes, and shipping lengths. Wires shall also be tested to evaluate their conformance to physical, mechanical, and electrical properties such as density, cross sectional area, breaking strength, and mass electrical resistance.

SCOPE

1.1 This specification covers concentric-lay-stranded conductors made from round aluminum 1350-H19 (extra hard) wires and round aluminum-alloy 6201-T81 (hard: solution heat treated, cold worked, and then artificially aged) core wires for use as overhead electrical conductors (Explanatory Note 1).

Note 1—The aluminum, alloy, and temper designations conform to ANSI H35.1/ANSI H35.1[M]. Aluminum 1350 and Alloy 6201 correspond to unified numbering system A91350 and A96201, respectively, in accordance with Practice E527.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.2.1 For density, resistivity and temperature, the values stated in SI units are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B524/B524M −99(Reapproved 2011)

Standard Specification for

Concentric-Lay-Stranded Aluminum Conductors, Aluminum-

Alloy Reinforced (ACAR, 1350/6201)

This standard is issued under the fixed designation B524/B524M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope B354 Terminology Relating to Uninsulated Metallic Electri-

cal Conductors

1.1 This specification covers concentric-lay-stranded con-

B398/B398M Specification for Aluminum-Alloy 6201-T81

ductors made from round aluminum 1350-H19 (extra hard)

Wire for Electrical Purposes

wiresandroundaluminum-alloy6201-T81(hard:solutionheat

B682 SpecificationforMetricSizesofElectricalConductors

treated, cold worked, and then artificially aged) core wires for

E29 Practice for Using Significant Digits in Test Data to

use as overhead electrical conductors (Explanatory Note 1).

Determine Conformance with Specifications

NOTE 1—The aluminum, alloy, and temper designations conform to

E527 Practice for Numbering Metals and Alloys in the

ANSI H35.1/ANSI H35.1[M]. Aluminum 1350 and Alloy 6201 corre-

Unified Numbering System (UNS)

spond to unified numbering system A91350 and A96201, respectively, in

2.3 ANSI Standard:

accordance with Practice E527.

ANSI H35.1 American National Standard for Alloy and

1.2 The values stated in inch-pound units are to be regarded

Temper Designation Systems for Aluminum

as standard. The values given in parentheses are mathematical

ANSI H35.1[M] American National Standard for Alloy and

conversions to SI units that are provided for information only

Temper Designation Systems for Aluminum

and are not considered standard.

2.4 NIST Document:

1.2.1 For density, resistivity and temperature, the values

NBS Handbook 100 Copper Wire Tables

stated in SI units are to be regarded as standard.

1.3 This standard does not purport to address all of the

3. Ordering Information

safety concerns, if any, associated with its use. It is the

3.1 Orders for material under this specification shall include

responsibility of the user of this standard to establish appro-

the following information:

priate safety and health practices and determine the applica-

3.1.1 Quantity of each size and stranding;

bility of regulatory limitations prior to use.

3.1.2 Conductor size (see 7.1);

3.1.3 Total number of wires, aluminum 1350 and aluminum

2. Referenced Documents

alloy 6201 (Table 1 or Table 2);

2.1 The following documents of the issue in effect on date

3.1.4 Direction of lay of outer layer of wires if other than

of material purchase form a part of this specification to the

right-hand (see 6.2);

extent referenced herein:

3.1.5 Special tension test, if required (see 8.2);

3.1.6 Place of inspection (see 14.1);

2.2 ASTM Standards:

3.1.7 Package size and type (see 16.1);

B230/B230M Specification for Aluminum 1350–H19 Wire

3.1.8 Heavy wood lagging, if required (Section 16); and

for Electrical Purposes

3.1.9 Special package marking, if required (Section 15).

B263 Test Method for Determination of Cross-Sectional

Area of Stranded Conductors

4. Requirement for Wires

4.1 Beforestranding,the1350-H19wireusedshallmeetthe

requirements of Specification B230/B230M.

This specification is under the jurisdiction of ASTM Committee B01 on

Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on

4.2 Before stranding, the 6201-T81 wire used shall meet the

Conductors of Light Metals.

requirements of Specification B398/B398M.

Current edition approved Oct. 1, 2011. Published February 2012. Originally

approved in 1970. Last previous edition approved in 2005 as B524 – 99 (2005).

DOI: 10.1520/B0524_B0524M-99R11.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

Standards volume information, refer to the standard’s Document Summary page on Available from National Institute of Standards and Technology (NIST), 100

the ASTM website. Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B524/B524M − 99 (2011)

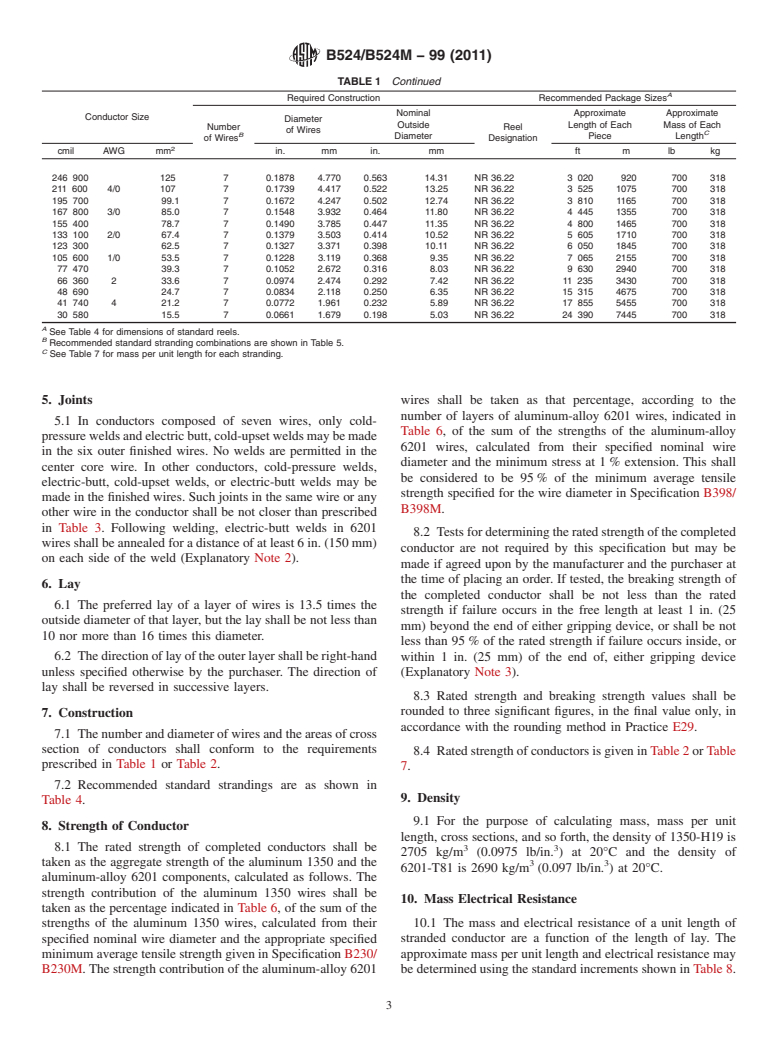

TABLE 1 Construction Requirements of Concentric-Lay-Stranded Aluminum Conductors, Aluminum Alloy Reinforced

A

Required Construction Recommended Package Sizes

Nominal Approximate Approximate

Conductor Size

Diameter

Outside Length of Each Mass of Each

Number Reel

of Wires

C

B

Diameter Piece Length

of Wires Designation

cmil AWG mm in. mm in. mm ft m lb kg

3 000 000 1520 91 0.1816 4.613 1.998 50.74 RMT 90.45 3 200 975 9 100 4130

2 750 000 1393 91 0.1738 4.415 1.912 48.56 RMT 90.45 3 490 1065 9 100 4130

2 500 000 1267 91 0.1657 4.209 1.823 46.30 RMT 90.45 3 840 1170 9 100 4130

2 493 000 1263 91 0.1655 4.204 1.8207 46.25 RMT 96.60 6 500 1981 15 400 6970

2 338 000 1185 61 0.1958 4.973 1.7620 44.75 RMT 96.60 7 500 2286 16 700 7540

2 250 000 1140 91 0.1572 3.993 1.729 43.92 RMT 90.45 4 270 1300 9 100 4130

2 000 000 1013 91 0.1482 3.764 1.630 41.40 RMT 90.45 4 850 1480 9 100 4130

2 000 000 1013 61 0.1811 4.600 1.630 41.40 RMT 90.45 5 200 1585 9 760 4425

1 933 000 979 61 0.1780 4.522 1.6021 40.69 RMT 96.60 9 200 2804 16 700 7570

1 900 000 963 61 0.1765 4.483 1.588 40.35 RMT 90.45 5 470 1665 9 760 4425

1 800 000 912 61 0.1718 4.364 1.546 39.28 RMT 90.45 5 780 1760 9 760 4425

1 798 000 911 61 0.1717 4.361 1.5452 39.25 RMT 96.60 9 200 2804 15 600 7040

1 750 000 887 61 0.1694 4.303 1.525 38.73 RMT 90.45 5 940 1810 9 760 4425

1 703 000 863 61 0.1671 4.244 1.8380 46.68 RMT 96.60 9 000 2743 14 400 6530

1 700 000 861 61 0.1669 4.239 1.502 38.15 RMT 90.45 6 120 1865 9 760 4425

1 600 000 811 61 0.1620 4.115 1.458 37.04 RMT 90.45 6 500 1980 9 760 4425

1 534 400 777 61 0.1586 4.028 1.4274 36.26 RMT 96.60 10 000 3048 14 400 6530

1 500 000 760 61 0.1568 3.983 1.411 35.85 RMT 90.45 6 930 2110 9 760 4425

1 400 000 709 61 0.1515 3.848 1.364 34.63 RMT 90.45 7 430 2265 9 760 4425

1 361 500 690 61 0.1494 3.795 1.3446 34.15 RMT 96.60 11 250 3429 14 400 6530

1 300 000 659 61 0.1460 3.708 1.314 33.37 RMT 90.45 8 000 2440 9 760 4425

1 300 000 659 37 0.1874 4.760 1.312 33.32 RMT 84.45 6 065 1850 7 400 3355

1 277 000 647 61 0.1447 3.675 1.3022 33.08 RMT 96.60 12 000 3658 14 400 6520

1 250 000 633 61 0.1431 3.635 1.288 32.72 RMT 90.45 8 320 2535 9 760 4425

1 250 000 633 37 0.1838 4.669 1.287 32.70 RMT 84.45 6 310 1920 7 400 3355

1 200 000 608 61 0.1403 3.564 1.263 32.08 RMT 90.45 8 660 2640 9 760 4425

1 200 000 608 37 0.1801 4.575 1.261 32.02 RMT 84.45 6 565 2000 7 400 3355

1 198 000 607 37 0.1799 4.570 1.2596 31.99 RMT 96.60 12 850 3917 14 500 6550

1 172 000 594 37 0.1780 4.521 1.2458 31.64 RMT 96.60 14 400 4389 15 900 7180

1 109 000 562 37 0.1731 4.397 1.2119 30.78 RMT 96.60 13 850 4221 14 500 6540

1 100 000 557 61 0.1343 3.411 1.209 30.70 RMT 90.45 9 450 2880 9 760 4425

1 100 000 557 37 0.1724 4.379 1.207 30.65 RMT 84.45 7 160 2180 7 400 3355

1 080 600 548 37 0.1709 4.341 1.1963 30.39 RMT 96.60 15 600 4755 15 800 7170

1 024 500 519 37 0.1664 4.227 1.1648 29.59 RMT 96.60 15 000 4572 14 500 6540

1 000 000 507 61 0.1280 3.251 1.152 29.26 RMT 90.45 10 400 3170 9 760 4425

1 000 000 507 37 0.1644 4.176 1.151 29.23 RMT 84.45 7 880 2400 7 400 3355

950 000 481 37 0.1602 4.069 1.121 28.48 RMT 84.45 8 300 2530 7 400 3355

927 200 470 37 0.1583 4.021 1.1081 28.15 RMT 90.45 10 400 3170 9 050 4110

900 000 456 37 0.1560 3.962 1.092 27.73 RMT 84.45 8 760 2670 7 400 3355

853 700 433 37 0.1519 3.858 1.0633 27.01 RMT 96.60 18 000 5486 14 500 6540

850 000 431 37 0.1516 3.851 1.061 26.96 RMT 84.45 9 270 2825 7 400 3355

800 000 405 37 0.1470 3.734 1.029 26.14 RMT 84.45 9 850 3000 7 400 3355

750 000 380 37 0.1424 3.617 0.997 25.32 RMT 84.45 10 510 3200 7 400 3355

739 800 375 37 0.1414 3.592 0.9898 25.14 RMT 90.45 13 010 3965 9 020 4090

700 000 355 37 0.1375 3.493 0.962 24.45 RMT 84.45 11 260 3430 7 400 3355

653 100 331 19 0.1854 4.709 0.9270 23.55 RMT 84.45 9 910 3021 6 070 2760

650 000 329 37 0.1325 3.366 0.928 23.56 RMT 84.45 12 130 3695 7 400 3355

649 500 329 37 0.1325 3.365 0.9274 23.56 NR 66.28 6 890 2100 4 200 1910

600 000 304 37 0.1273 3.233 0.891 22.63 RMT 84.45 13 140 4005 7 400 3355

600 000 304 19 0.1777 4.513 0.888 22.56 RM 66.32 6 750 2060 3 800 1725

NR 66.28

587 200 298 19 0.1758 4.465 0.8790 22.33 NR 66.28 8 030 2448 4 430 2010

550 000 279 37 0.1219 3.096 0.853 21.67 RMT 84.45 14 330 4365 7 400 3355

550 000 279 19 0.1701 4.321 0.850 21.60 RM 66.32 7 360 2245 3 800 1725

NR 66.28

503 600 255 19 0.1628 4.135 0.8140 20.68 NR 66.28 8 030 2448 3 800 1730

500 000 253 37 0.1162 2.951 0.813 20.66 RMT 84.45 15 765 4805 7 400 3355

500 000 253 19 0.1622 4.120 0.811 20.60 RM 66.32 8 100 2470 3 800 1725

NR 66.28

450 000 228 19 0.1539 3.909 0.770 19.54 RM 66.32 9 000 2745 3 800 1725

NR 66.28

400 000 203 19 0.1451 3.685 0.726 18.42 RM 66.32 10 120 3085 3 800 1725

NR 66.28

350 000 177 19 0.1357 3.447 0.678 17.24 RM 66.32 11 560 3530 3 800 1725

NR 66.28

300 000 152 19 0.1257 3.193 0.628 15.96 RM 66.32 13 490 4115 3 800 1725

NR 66.28

250 000 127 19 0.1147 2.913 0.574 14.56 RM 66.32 16 190 4940 3 800 1725

NR 66.28

B524/B524M − 99 (2011)

TABLE 1 Continued

A

Required Construction Recommended Package Sizes

Nominal Approximate Approximate

Conductor Size

Diameter

Outside Length of Each Mass of Each

Number Reel

of Wires

C

B

Diameter Piece Length

of Wires Designation

cmil AWG mm in. mm in. mm ft m lb kg

246 900 125 7 0.1878 4.770 0.563 14.31 NR 36.22 3 020 920 700 318

211 600 4/0 107 7 0.1739 4.417 0.522 13.25 NR 36.22 3 525 1075 700 318

195 700 99.1 7 0.1672 4.247 0.502 12.74 NR 36.22 3 810 1165 700 318

167 800 3/0 85.0 7 0.1548 3.932 0.464 11.80 NR 36.22 4 445 1355 700 318

155 400 78.7 7 0.1490 3.785 0.447 11.35 NR 36.22 4 800 1465 700 318

133 100 2/0 67.4 7 0.1379 3.503 0.414 10.52 NR 36.22 5 605 1710 700 318

123 300 62.5 7 0.1327 3.371 0.398 10.11 NR 36.22 6 050 1845 700 318

105 600 1/0 53.5 7 0.1228 3.119 0.368 9.35 NR 36.22 7 065 2155 700 318

77 470 39.3 7 0.1052 2.672 0.316 8.03 NR 36.22 9 630 2940 700 318

66 360 2 33.6 7 0.0974 2.474 0.292 7.42 NR 36.22 11 235 3430 700 318

48 690 24.7 7 0.0834 2.118 0.250 6.35 NR 36.22 15 315 4675 700 318

41 740 4 21.2 7 0.0772 1.961 0.232 5.89 NR 36.22 17 855 5455 700 318

30 580 15.5 7 0.0661 1.679 0.198 5.03 NR 36.22 24 390 7445 700 318

A

See Table 4 for dimensions of standard reels.

B

Recommended standard stranding combinations are shown in Table 5.

C

See Table 7 for mass per unit length for each stranding.

5. Joints wires shall be taken as that percentage, according to the

number of layers of aluminum-alloy 6201 wires, indicated in

5.1 In conductors composed of seven wires, only cold-

Table 6, of the sum of the strengths of the aluminum-alloy

pressureweldsandelectricbutt,cold-upsetweldsmaybemade

6201 wires, calculated from their specified nominal wire

in the six outer finished wires. No welds are permitted in the

diameter and the minimum stress at 1 % extension. This shall

center core wire. In other conductors, cold-pressure welds,

be considered to be 95 % of the minimum average tensile

electric-butt, cold-upset welds, or electric-butt welds may be

strength specified for the wire diameter in Specification B398/

made in the finished wires. Such joints in the same wire or any

B398M.

other wire in the conductor shall be not closer than prescribed

in Table 3. Following welding, electric-butt welds in 6201

8.2 Testsfordeterminingtheratedstrengthofthecompleted

wires shall be annealed for a distance of at least 6 in. (150 mm)

conductor are not required by this specification but may be

on each side of the weld (Explanatory Note 2).

made if agreed upon by the manufacturer and the purchaser at

the time of placing an order. If tested, the breaking strength of

6. Lay

the completed conductor shall be not less than the rated

6.1 The preferred lay of a layer of wires is 13.5 times the

strength if failure occurs in the free length at least 1 in. (25

outside diameter of that layer, but the lay shall be not less than

mm) beyond the end of either gripping device, or shall be not

10 nor more than 16 times this diameter.

less than 95 % of the rated strength if failure occurs inside, or

6.2 Thedirectionoflayoftheouterlayershallberight-hand

within 1 in. (25 mm) of the end of, either gripping device

unless specified otherwise by the purchaser. The direction of (Explanatory Note 3).

lay shall be reversed in successive layers.

8.3 Rated strength and breaking strength values shall be

rounded to three significant figures, in the final value only, in

7. Construction

accordance with the rounding method in Practice E29.

7.1 Thenumberanddiameterofwiresandtheareasofcross

section of conductors shall conform to the requirements

8.4 RatedstrengthofconductorsisgiveninTable2orTable

prescribed in Table 1 or Table 2.

7.

7.2 Recommended standard strandings are as shown in

9. Density

Table 4.

9.1 For the purpose of calculating mass, mass per unit

8. Strength of Conductor

length, cross sections, and so forth, the density of 1350-H19 is

8.1 The rated strength of completed conductors shall be 3 3

2705 kg/m (0.0975 lb/in. ) at 20°C and the density of

taken as the aggregate strength of the aluminum 1350 and the 3 3

6201-T81 is 2690 kg/m (0.097 lb/in. ) at 20°C.

aluminum-alloy 6201 components, calculated as follows. The

strength contribution of the aluminum 1350 wires shall be

10. Mass Electrical Resistance

taken as the percentage indicated in Table 6, of the sum of the

10.1 The mass and electrical resistance of a unit length of

strengths of the aluminum 1350 wires, calculated from their

specified nominal wire diameter and the appropriate specified stranded conductor are a function of the length of lay. The

minimum average tensile strength given in Specification B230/ approximate mass per unit length and electrical resistance may

B230M. The strength contribution of the aluminum-alloy 6201 be determined using the standard increments shown in Table 8.

B524/B524M − 99 (2011)

TABLE 2 Construction Requirements, Mass, Mass Per Unit Length, Recommended Reel Sizes, and Shipping Lengths of Conductors

NOTE 1—The sizes in boldface type indicate those preferred sizes from Specification B682.

A B

Mass per Unit Length Recommended Package Sizes

Conductor Diameter of Conductor

Size, Wires, Diameter, Related Strength

1350, kg/km 620

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.