ASTM D5937-96

(Test Method)Standard Test Method for Determination of Tensile Properties and Test Conditions for Moulding and Extrusion Plastics (Withdrawn 1998)

Standard Test Method for Determination of Tensile Properties and Test Conditions for Moulding and Extrusion Plastics (Withdrawn 1998)

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5937 – 96

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Determination of Tensile Properties of Moulding and

1

Extrusion Plastics

This standard is issued under the fixed designation D 5937; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

3

1. Scope Used for Testing Plastics

D 5938 Guide Describing the General Principles for Deter-

1.1 This test method specifies the test conditions for deter-

3

mination of Tensile Properties of Plastics

mining the tensile properties of moulding and extrusion plas-

D 5939 Practice for Preparing Multipurpose Test Specimens

tics.

3

and Bars of Thermoplastics by Injection Moulding

1.2 This test method is selectively suitable for use with the

D 5940 Practice for Preparing Small Plate Test Specimens

following range of materials:

3

of Thermoplastics by Injection Moulding

1.2.1 Rigid and semirigid thermoplastics moulding, extru-

4

2.2 ISO Standards:

sion and cast materials, including compounds filled and rein-

ISO 37:1977 Rubber, Vulcanized—Determination of Ten-

forced by, for example, short fibers, small rods, plates, or

sile Stress-Strain Properties

granules, but excluding textile fibers, in addition to unfilled

ISO 293:1986 Plastics—Compression Moulding Test Speci-

types,

mens of Thermoplastic Materials

1.2.2 Rigid and semirigid thermosetting moulding and cast

ISO 294 Plastics—Injection Moulding of Test Specimens of

materials, including filled and reinforced compounds, but

Thermoplastic Materials

excluding textile fibers as reinforcement, and

ISO 295:1991 Plastics—Compression Moulding of Test

1.2.3 Thermotropic liquid crystal polymers.

Specimens of Thermosetting Materials

1.3 This test method is not suitable for use with materials

ISO 527-1:1993 Plastics—Determination of Tensile

reinforced by textile fibers with rigid cellular materials or

Properties—Part 1: General Principles

sandwich structures containing cellular material.

ISO 527-2 Determination of Tensile Properties—Part 2:

1.4 This test method is applied using specimens that may be

Test Conditions for Moulding and Extrusion Plastics

either moulded to the chosen dimensions or machined, cut, or

ISO 1926:1979 Cellular Plastics—Determination of Tensile

punched from injection- or compression-moulded plates. The

Properties of Rigid Materials

multipurpose test specimen is preferred (see ISO 3167:1993

ISO 2818 Plastics—Preparation of Test Specimens by Ma-

(Specification D 5936)).

chining

1.5 This test method is identical to ISO 527-2. This standard

ISO 3167:1993 Plastics—Multipurpose Test Specimens

is comparable to Test Method D 638 but neither standard

should be substituted for the other. The two standards may

3. Terminology—See Guide D 5938, Section 3.

differ with respect to test specimen dimensions, test specimen

conditioning, test equipment, testing conditions, etc. The two

4. Principle—See Guide D 5938, Section 4.

methods may not give the same results.

5.

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

6. Apparatus—See Guide D 5938.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

7. Test Specimens

bility of regulatory limitations prior to use.

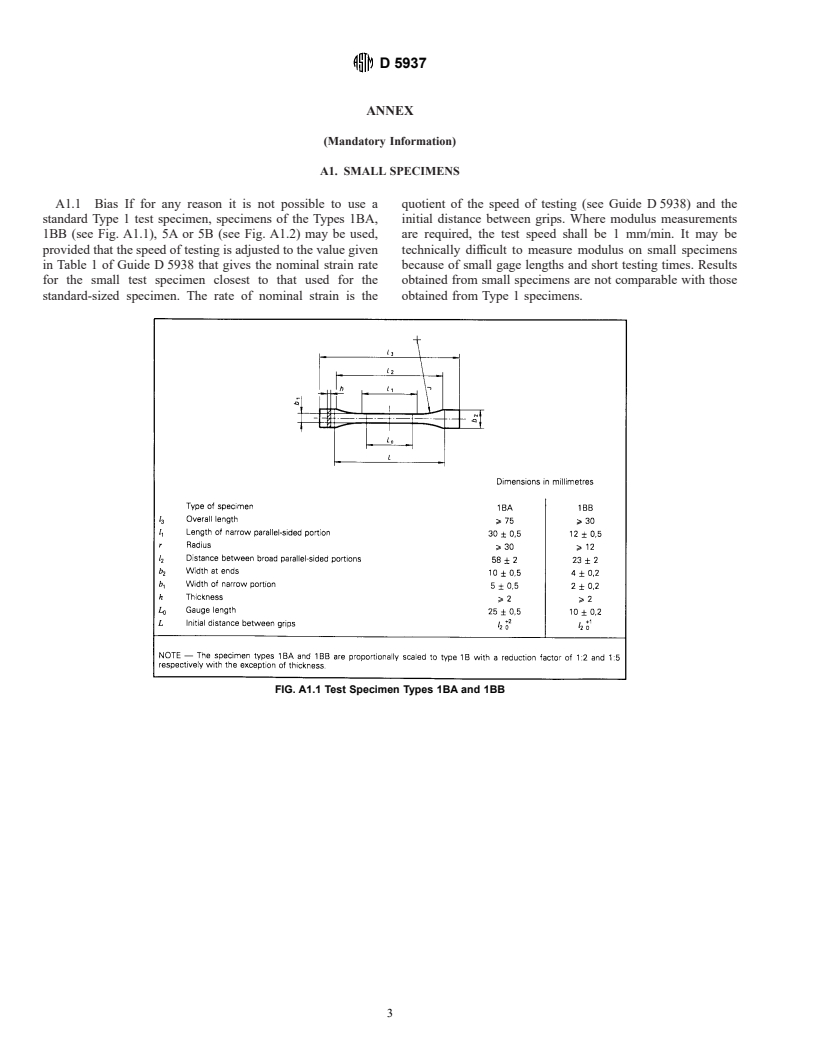

7.1 Shape and Dimensions—Wherever possible, ensure that

the test specimens are dumb bell-shaped, Types 1A and 1B as

2. Referenced Documents

shown in Fig. 1. Type 1A is preferred for directly-moulded

2.1 ASTM Standards:

multipurpose test specimens, and Type 1B is preferred for

2

D 638 Test Method for Tensile Properties of Plastics

machined specimens.

D 5936 Specification for Multipurpose Test Specimens

NOTE 1—Types 1A and 1B test specimens having 4-mm thickness are

identical to the multipurpose test specimens according to ISO 3167

1

This test method is under the jurisdiction of ASTM Committee D-20 on Plastics

and is the direct responsibility of Subcommittee D20.61 on USA Technical Advisory

Group for ISO/TC 61 on Plastics.

3

Current edition approved June 10, 1996. Published August 1996. Annual Book of ASTM Standards, Vol 08.03.

2 4

Annual Book of ASTM Standards, Vol 08.01. Available from ANSI, 11 West 42nd Street, 13th Floor, New York, NY 10036.

1

---------------------- Page: 1 ----------------------

D 5937

FIG. 1 Test Specimen Types 1A and 1B

(Specification D 5936), Types A and B, respectively.

10.2 For the measurement of the modulus of elasticity, the

speed of testing is 1 mm/min for specim

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.