ASTM F2237-03(2015)

(Test Method)Standard Test Method for Performance of Upright Overfired Broilers

Standard Test Method for Performance of Upright Overfired Broilers

SIGNIFICANCE AND USE

5.1 The energy input rate test is used to confirm that the overfired broiler is operating properly prior to further testing.

5.2 Temperature uniformity of the broiler cavity may be used by food service operators to select an overfired broiler with the desired temperature gradients.

5.3 Preheat energy and time can be useful to food service operators to manage energy demands and to know how quickly the overfired broiler can be ready for operation.

5.4 Idle energy rate and pilot energy rate can be used to estimate energy consumption during non-cooking periods.

5.5 Cooking energy efficiency is a precise indicator of overfired broiler energy performance while cooking a typical food product under various loading conditions. If energy performance information is desired using a food product other than the specified test food, the test method could be adapted and applied. Energy performance information allows an end user to better understand the operating characteristics of an overfired broiler.

5.6 Production capacity can help an end user to better understand the production capabilities of an overfired broiler as it is used to cook a typical food product, helping with specification of the proper size and quantity of equipment. If production information is desired using a food product other than the specified test food, the test method could be adapted and applied.

SCOPE

1.1 This test method evaluates the energy consumption and cooking performance of overfired broilers. The food service operator can use this evaluation to select an overfired broiler and understand its performance and energy consumption.

1.2 This test method is applicable to gas and electric upright overfired broilers having input rates greater than 60,000 Btu/h (gas overfired broilers) or 10kW (electric overfired broilers).

1.3 The overfired broiler can be evaluated with respect to the following (where applicable):

1.3.1 Energy input rate (see 10.2),

1.3.2 Temperature uniformity of the broiler cavity (see 10.3),

1.3.3 Preheat energy consumption and time (see 10.4),

1.3.4 Pilot energy rate (if applicable) (see 10.5),

1.3.5 Idle energy rate (see 10.6), and

1.3.6 Cooking energy efficiency and production capacity (see 10.7).

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This test method may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2237 −03 (Reapproved 2015) An American National Standard

Standard Test Method for

Performance of Upright Overfired Broilers

This standard is issued under the fixed designation F2237; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D3588Practice for Calculating Heat Value, Compressibility

Factor, and Relative Density of Gaseous Fuels

1.1 This test method evaluates the energy consumption and

2.2 AOAC Document:

cooking performance of overfired broilers. The food service

AOAC Official Action 950.46Air Drying to Determine

operator can use this evaluation to select an overfired broiler

Moisture Content of Meat and Meat Products

and understand its performance and energy consumption.

2.3 ASHRAE Standard:

1.2 Thistestmethodisapplicabletogasandelectricupright

ASHRAE Handbook of Fundamentals“Thermal and Re-

overfired broilers having input rates greater than 60,000 Btu/h

latedPropertiesofFoodandFoodMaterials,”Chapter30,

(gas overfired broilers) or 10kW (electric overfired broilers).

Table 1, 1989

1.3 The overfired broiler can be evaluated with respect to

2.4 ANSI Standard:

the following (where applicable): 5

ANSI Z83.11Gas Food Service Equipment

1.3.1 Energy input rate (see 10.2),

1.3.2 Temperature uniformity of the broiler cavity (see

3. Terminology

10.3),

3.1 Definitions:

1.3.3 Preheat energy consumption and time (see 10.4),

3.1.1 broiler cavity, n—that portion of the overfired broiler

1.3.4 Pilot energy rate (if applicable) (see 10.5),

in which food products are heated or cooked.

1.3.5 Idle energy rate (see 10.6), and

3.1.2 cooking energy effıciency, n—quantity of energy im-

1.3.6 Cooking energy efficiency and production capacity

parted to the specified food product, expressed as a percentage

(see 10.7).

ofenergyconsumedbytheoverfiredbroilerduringthecooking

1.4 The values stated in inch-pound units are to be regarded

event.

as standard. The values given in parentheses are mathematical

3.1.3 cooking energy rate, n—average rate of energy con-

conversions to SI units that are provided for information only

sumption (Btu/h or kW) during the cooking energy efficiency

and are not considered standard.

tests.

1.5 This test method may involve hazardous materials,

3.1.4 grate, broiler grate, n—the platform on which food is

operations, and equipment. This standard does not purport to

placed while cooking in an overfired broiler.

address all of the safety concerns, if any, associated with its

3.1.5 idle energy rate, n—the overfired broiler’s rate of

use. It is the responsibility of the user of this standard to

establish appropriate safety and health practices and deter- energy consumption (kW or Btu/h), when empty, required to

maintainthebroiler’soperatingtemperaturewhilenotcooking.

mine the applicability of regulatory limitations prior to use.

3.1.6 overfiredbroiler,n—anappliancewithahightempera-

2. Referenced Documents

ture radiant heat source above a heavy duty, sliding grate for

cooking food, characterized by an open front cooking cavity

2.1 ASTM Standards:

and having an input rate greater than 60000 Btu/h or 10kW.

A36/A36MSpecification for Carbon Structural Steel

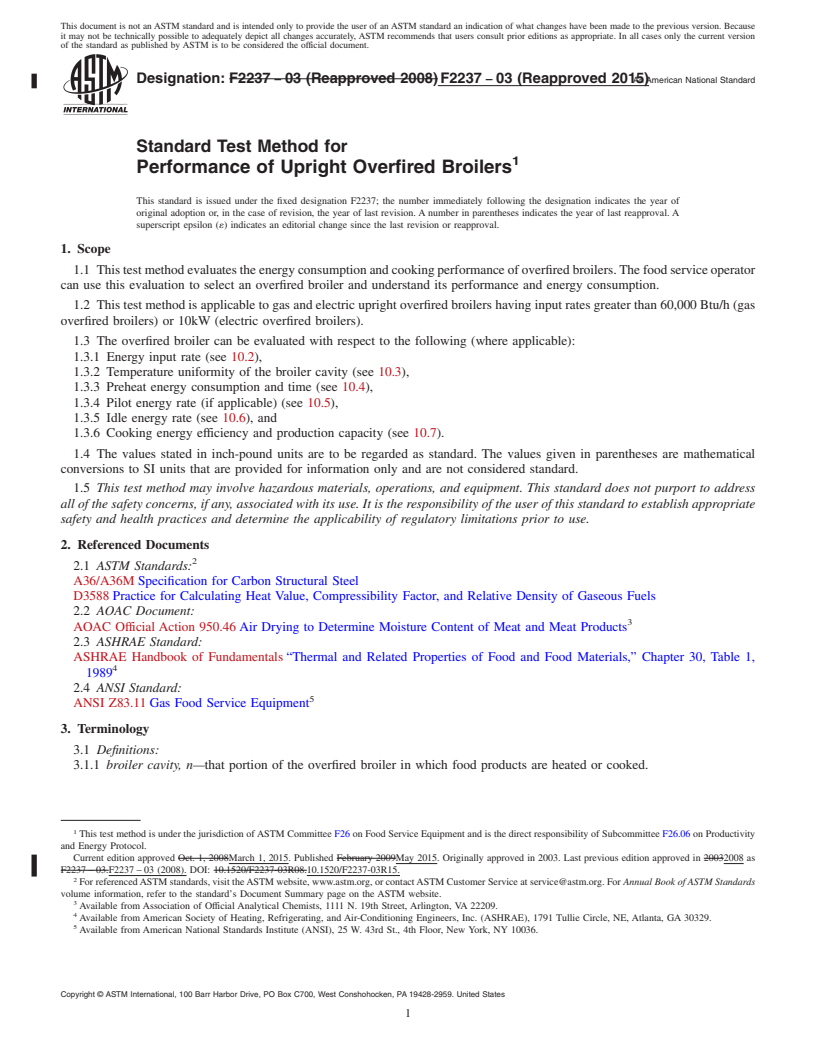

NOTE 1—The upright overfired broiler is distinguished from the

salamanderandthecheesemelterbyitsheavyduty,stand-aloneconstruc-

tion and high energy input rate (see Fig. 1).

This test method is under the jurisdiction of ASTM Committee F26 on Food

Service Equipment and is the direct responsibility of Subcommittee F26.06 on

Productivity and Energy Protocol.

Current edition approved March 1, 2015. Published May 2015. Originally Available from Association of Official Analytical Chemists, 1111 N. 19th

approved in 2003. Last previous edition approved in 2008 as F2237–03 (2008). Street, Arlington, VA 22209.

DOI: 10.1520/F2237-03R15. Available from American Society of Heating, Refrigerating, and Air-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Conditioning Engineers, Inc. (ASHRAE), 1791 Tullie Circle, NE, Atlanta, GA

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 30329.

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2237−03 (2015)

FIG. 1Upright Overfired Broiler Construction

3.1.7 pilot energy rate, n—rate of energy consumption 4.6 Withthecontrolssetsuchthatthebroilingareadoesnot

(Btu/h) by an overfired broiler’s continuous pilot (if appli- exceed 800°F (315°C), the overfired broiler is used to cook

cable). 5-oz boneless, skinless, chicken breasts to an internal tempera-

tureof170°F.Cookingenergyefficiencyisdeterminedforlight

3.1.8 preheat energy, n—amount of energy consumed (Btu

and heavy loading conditions.

or kWh), by the overfired broiler while preheating its cavity

from ambient temperature to the calibrated control set point.

4.7 Production capacity is determined for the heavy loading

scenario.

3.1.9 preheat time, n—time(min.)requiredfortheoverfired

broiler cavity to preheat from ambient temperature to the

5. Significance and Use

calibrated control set point.

3.1.10 production capacity, n—maximum rate (lb/h) at

5.1 The energy input rate test is used to confirm that the

which an overfired broiler can bring the specified food product overfired broiler is operating properly prior to further testing.

to a specified “cooked” condition.

5.2 Temperature uniformity of the broiler cavity may be

3.1.11 uncertainty, n—measure of systematic and precision

used by food service operators to select an overfired broiler

errors in specified instrumentation or measure of repeatability

with the desired temperature gradients.

of a reported test result.

5.3 Preheat energy and time can be useful to food service

operatorstomanageenergydemandsandtoknowhowquickly

4. Summary of Test Method

the overfired broiler can be ready for operation.

4.1 The overfired broiler is connected to the appropriate

5.4 Idle energy rate and pilot energy rate can be used to

metered energy source,andtheenergyinputrateis determined

estimate energy consumption during non-cooking periods.

to confirm that the appliance is operating within 5% of the

nameplate energy input rate. 5.5 Cooking energy efficiency is a precise indicator of

overfired broiler energy performance while cooking a typical

4.2 The broiler grate is covered with 5-in. (127-mm) diam-

food product under various loading conditions. If energy

eter steel disks and the overfired broiler’s controls are set such

performance information is desired using a food product other

that the broiling area does not exceed a maximum temperature

than the specified test food, the test method could be adapted

of 800°F (315°C). The temperature uniformity of the broiling

and applied. Energy performance information allows an end

area is determined by monitoring thermocoupled steel disks

user to better understand the operating characteristics of an

placed on the broiler grate.

overfired broiler.

4.3 Withthecontrolssetsuchthatthebroilingareadoesnot

5.6 Production capacity can help an end user to better

exceed800°F(315°C),theamountofenergyandtimerequired

understandtheproductioncapabilitiesofanoverfiredbroileras

to preheat the broiling area to 700°F (260°C) is determined.

it is used to cook a typical food product, helping with

4.4 Thepilotenergyrateisdetermined,whenapplicable,for

specification of the proper size and quantity of equipment. If

gas overfired broilers.

production information is desired using a food product other

4.5 Idle energy rate is determined while maintaining the than the specified test food, the test method could be adapted

broiler cavity at its operating temperature while not cooking. and applied.

F2237−03 (2015)

6. Apparatus at least 10 Wh and a maximum uncertainty no greater than

1.5% of the measured value for any demand greater than 100

6.1 Analytical Balance Scale, for measuring weights up to

W. For any demand less than 100 W, the meter shall have a

20 lb, with a resolution of 0.01 lb, and an uncertainty of 0.01

resolution of at least 10 Wh and a maximum uncertainty no

lb.

greater than 10%.

6.2 Barometer, for measuring absolute atmospheric

7. Reagents and Materials

pressure, to be used for adjustment of measured natural gas

volume to standard conditions. Shall have a resolution of 0.2 7.1 Aluminum Sheet Pans,measuring18by26by1in.(457

in. Hg and an uncertainty of 0.2 in. Hg.

by 660 by 25 mm), for use in packaging chicken breasts.

6.3 Canopy Exhaust Hood,4ftindepth,wall-mountedwith 7.2 Chicken Breasts,shallbenominal5-ozfrozen,boneless,

the lower edge of the hood 6 ft, 6 in. from the floor and with skinless, butterfly cut, chicken breasts (whole meat, not fabri-

the capacity to operate at a nominal exhaust ventilation rate of cated). When thawed and drained, each chicken breast shall

300 cfm per linear foot of active hood length. This hood shall weigh 4.8 6 0.2 oz.

extend a minimum of 6 in. past both sides and the front of the

7.3 Drip Rack, sized to fit 18 by 26 by 1 in. (457 by 660 by

cooking appliance and shall not incorporate side curtains or

25 mm) aluminum sheet pans, for packaging chicken breasts.

partitions.

7.4 FishHooks,size1,foruseinattachingthermocouplesto

6.4 Convection Drying Oven,withtemperaturecontrolledat

chicken breasts.

215 to 220°F (101 to 104°C), used to determine moisture

7.5 Plastic Wrap, commercial grade, 18 in. (457 mm) wide,

content of both the raw and cooked food product.

for use in packaging chicken breasts.

6.5 Data Acquisition System, for measuring energy and

7.6 Tongs, commercial grade, metal construction, for han-

temperatures, capable of multiple-temperature displays updat-

dling chicken breasts.

ing at least every 5 s.

8. Sampling and Test Units

6.6 Gas Meter, for measuring the gas consumption of an

overfired broiler, shall be a positive displacement type with a 8.1 Overfired Broiler—Select a representative production

resolution of at least 0.01 ft and a maximum uncertainty no model for performance testing.

greaterthan1%ofthemeasuredvalueforanydemandgreater

9. Preparation of Apparatus

than 2.2 ft /h. If the meter is used for measuring the gas

9.1 Install the appliance according to the manufacturer’s

consumed by the pilot lights, it shall have a resolution of at

instructions under a canopy exhaust hood. Position the over-

least 0.01 ft and a maximum uncertainty no greater than 2%

fired broiler so that a minimum of 6 in. is maintained between

of the measured value.

the edge of the hood and the vertical plane of the front and

6.7 Pressure Gage, for monitoring natural gas pressure.

sides of the appliance. In addition, both sides of the overfired

Shall have a range of zero to 10 in. water, a resolution of 0.5

broiler shall be a minimum of 3 ft from any side wall, side

in. water, and a maximum uncertainty of 1% of the measured

partition, or other operating appliance. The exhaust ventilation

value.

rate shall be 300 cfm per linear foot of active hood length.The

6.8 Steel Disks, composed of structural-grade carbon steel

associated heating or cooling system shall be capable of

in accordance with Specification A36/A36M, free of rust or maintaining an ambient temperature of 75 6 5°F within the

corrosion, 5-in. (127 mm) diameter, and ⁄4-in. (6.3-mm) thick.

testing environment when the exhaust ventilation system is

The disks shall be flat to within 0.010 in. (0.25 mm) over the operating.

diameter. NOTE 2—The ambient temperature requirements are designed to simu-

laterealworldkitchentemperaturesandaremeanttoprovideareasonable

6.9 Stop Watch, with a 1-s resolution.

guideline for the temperature requirements during testing. If a facility is

not able to maintain the required temperatures, then it is reasonable to

6.10 Strain Gage Welder,capableofweldingthermocouples

expectthattheapplicationoftheproceduremaydeviatefromthespecified

to steel.

requirements(ifitcannotbeavoided)aslongasthosedeviationsarenoted

on the Results Reporting Sheets.

6.11 Temperature Sensor, for measuring natural gas tem-

9.2 Connect the overfired broiler to a calibrated energy test

perature in the range of 50 to 100°F (10 to 38°C) with an

meter. For gas installations, install a pressure regulator down-

uncertainty of 61°F (0.56°C).

stream from the meter to maintain a constant pressure of gas

6.12 Thermocouple(s),fiberglassinsulated,24gage,TypeK

for all tests. Install instrumentation to record both the pressure

thermocouple wire, peened flat at the exposed ends and spot

andtemperatureofthegassuppliedtotheoverfiredbroilerand

weldedtothecenterofthesteeldisksurfaceswithastraingage

the barometric pressure during each test so that the measured

welder.

gas flow can be corrected to standard conditions. For electric

6.13 Thermocouple(s),fiberglassinsulated,24gage,TypeK

installations,avoltageregulatormayberequiredduringtestsif

thermocouplewire,weldedandcalibrated,foruseindetermin-

the voltage supply is not within 62.5% of the manufacturer’s

ing the temperature of the chicken breasts.

nameplate voltage.

6.14 Watt-Hour Meter, for measuring the electrical energy 9.3 For an electric overfired broiler, confirm (while the

consumption of an overfired broiler, shall have a resolution of overfired broiler elements are energized) that the supply

F2237−03 (2015)

voltage is within 62.5% of the operating voltage specified by 10.2.3 Calculate and record the overfired broiler’s energy

the manufacturer. Record the test voltage for each test. input rate and compare the result to the rated nameplate input.

NOTE 3—It is the intent of the test procedure herein to evaluate the

Confirm that the measured input rate (Btu/h (kJ/h)) for a gas

performance of an overfired broiler at its rated gas pressure or electric

overfired broiler and kW for an electric overfired broiler) is

voltage.Ifanelectricunitisrateddualvoltage(thatis,designedtooperate

within 5% of the rated nameplate input. If the difference is

ateither208or240Vwithnochangeincomponents),thevoltageselected

greater than 5%, terminate testing and contact the manufac-

by the manufacturer or tester, or both, shall be reported. If an overfired

turer. The manufacturer may make appropriate changes or

broiler is designed to operate at two voltages without a change in the

resistance of the heating elements, the performance of the unit (for

adjustmentstotheoverfiredbroiler,orsupplya

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2237 − 03 (Reapproved 2008) F2237 − 03 (Reapproved 2015)An American National Standard

Standard Test Method for

Performance of Upright Overfired Broilers

This standard is issued under the fixed designation F2237; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method evaluates the energy consumption and cooking performance of overfired broilers. The food service operator

can use this evaluation to select an overfired broiler and understand its performance and energy consumption.

1.2 This test method is applicable to gas and electric upright overfired broilers having input rates greater than 60,000 Btu/h (gas

overfired broilers) or 10kW (electric overfired broilers).

1.3 The overfired broiler can be evaluated with respect to the following (where applicable):

1.3.1 Energy input rate (see 10.2),

1.3.2 Temperature uniformity of the broiler cavity (see 10.3),

1.3.3 Preheat energy consumption and time (see 10.4),

1.3.4 Pilot energy rate (if applicable) (see 10.5),

1.3.5 Idle energy rate (see 10.6), and

1.3.6 Cooking energy efficiency and production capacity (see 10.7).

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.5 This test method may involve hazardous materials, operations, and equipment. This standard does not purport to address

all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate

safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

A36/A36M Specification for Carbon Structural Steel

D3588 Practice for Calculating Heat Value, Compressibility Factor, and Relative Density of Gaseous Fuels

2.2 AOAC Document:

AOAC Official Action 950.46 Air Drying to Determine Moisture Content of Meat and Meat Products

2.3 ASHRAE Standard:

ASHRAE Handbook of Fundamentals “Thermal and Related Properties of Food and Food Materials,” Chapter 30, Table 1,

2.4 ANSI Standard:

ANSI Z83.11 Gas Food Service Equipment

3. Terminology

3.1 Definitions:

3.1.1 broiler cavity, n—that portion of the overfired broiler in which food products are heated or cooked.

This test method is under the jurisdiction of ASTM Committee F26 on Food Service Equipment and is the direct responsibility of Subcommittee F26.06 on Productivity

and Energy Protocol.

Current edition approved Oct. 1, 2008March 1, 2015. Published February 2009May 2015. Originally approved in 2003. Last previous edition approved in 20032008 as

F2237 – 03.F2237 – 03 (2008). DOI: 10.1520/F2237-03R08.10.1520/F2237-03R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from Association of Official Analytical Chemists, 1111 N. 19th Street, Arlington, VA 22209.

Available from American Society of Heating, Refrigerating, and Air-Conditioning Engineers, Inc. (ASHRAE), 1791 Tullie Circle, NE, Atlanta, GA 30329.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2237 − 03 (2015)

3.1.2 cooking energy effıciency, n—quantity of energy imparted to the specified food product, expressed as a percentage of

energy consumed by the overfired broiler during the cooking event.

3.1.3 cooking energy rate, n—average rate of energy consumption (Btu/h or kW) during the cooking energy efficiency tests.

3.1.4 grate, broiler grate, n—the platform on which food is placed while cooking in an overfired broiler.

3.1.5 idle energy rate, n—the overfired broiler’s rate of energy consumption (kW or Btu/h), when empty, required to maintain

the broiler’s operating temperature while not cooking.

3.1.6 overfired broiler, n—an appliance with a high temperature radiant heat source above a heavy duty, sliding grate for cooking

food, characterized by an open front cooking cavity and having an input rate greater than 60 000 Btu/h or 10kW.

NOTE 1—The upright overfired broiler is distinguished from the salamander and the cheese melter by its heavy duty, stand-alone construction and high

energy input rate (see Fig. 1).

3.1.7 pilot energy rate, n—rate of energy consumption (Btu/h) by an overfired broiler’s continuous pilot (if applicable).

3.1.8 preheat energy, n—amount of energy consumed (Btu or kWh), by the overfired broiler while preheating its cavity from

ambient temperature to the calibrated control set point.

3.1.9 preheat time, n—time (min.) required for the overfired broiler cavity to preheat from ambient temperature to the calibrated

control set point.

3.1.10 production capacity, n—maximum rate (lb/h) at which an overfired broiler can bring the specified food product to a

specified “cooked” condition.

3.1.11 uncertainty, n—measure of systematic and precision errors in specified instrumentation or measure of repeatability of a

reported test result.

4. Summary of Test Method

4.1 The overfired broiler is connected to the appropriate metered energy source, and the energy input rate is determined to

confirm that the appliance is operating within 5 % of the nameplate energy input rate.

4.2 The broiler grate is covered with 5-in. (127-mm) diameter steel disks and the overfired broiler’s controls are set such that

the broiling area does not exceed a maximum temperature of 800°F (315°C). The temperature uniformity of the broiling area is

determined by monitoring thermocoupled steel disks placed on the broiler grate.

4.3 With the controls set such that the broiling area does not exceed 800°F (315°C), the amount of energy and time required

to preheat the broiling area to 700°F (260°C) is determined.

4.4 The pilot energy rate is determined, when applicable, for gas overfired broilers.

4.5 Idle energy rate is determined while maintaining the broiler cavity at its operating temperature while not cooking.

4.6 With the controls set such that the broiling area does not exceed 800°F (315°C), the overfired broiler is used to cook 5-oz

boneless, skinless, chicken breasts to an internal temperature of 170°F. Cooking energy efficiency is determined for light and heavy

loading conditions.

4.7 Production capacity is determined for the heavy loading scenario.

FIG. 1 Upright Overfired Broiler Construction

F2237 − 03 (2015)

5. Significance and Use

5.1 The energy input rate test is used to confirm that the overfired broiler is operating properly prior to further testing.

5.2 Temperature uniformity of the broiler cavity may be used by food service operators to select an overfired broiler with the

desired temperature gradients.

5.3 Preheat energy and time can be useful to food service operators to manage energy demands and to know how quickly the

overfired broiler can be ready for operation.

5.4 Idle energy rate and pilot energy rate can be used to estimate energy consumption during non-cooking periods.

5.5 Cooking energy efficiency is a precise indicator of overfired broiler energy performance while cooking a typical food

product under various loading conditions. If energy performance information is desired using a food product other than the

specified test food, the test method could be adapted and applied. Energy performance information allows an end user to better

understand the operating characteristics of an overfired broiler.

5.6 Production capacity can help an end user to better understand the production capabilities of an overfired broiler as it is used

to cook a typical food product, helping with specification of the proper size and quantity of equipment. If production information

is desired using a food product other than the specified test food, the test method could be adapted and applied.

6. Apparatus

6.1 Analytical Balance Scale, for measuring weights up to 20 lb, with a resolution of 0.01 lb, and an uncertainty of 0.01 lb.

6.2 Barometer, for measuring absolute atmospheric pressure, to be used for adjustment of measured natural gas volume to

standard conditions. Shall have a resolution of 0.2 in. Hg and an uncertainty of 0.2 in. Hg.

6.3 Canopy Exhaust Hood, 4 ft in depth, wall-mounted with the lower edge of the hood 6 ft, 6 in. from the floor and with the

capacity to operate at a nominal exhaust ventilation rate of 300 cfm per linear foot of active hood length. This hood shall extend

a minimum of 6 in. past both sides and the front of the cooking appliance and shall not incorporate side curtains or partitions.

6.4 Convection Drying Oven, with temperature controlled at 215 to 220°F (101 to 104°C), used to determine moisture content

of both the raw and cooked food product.

6.5 Data Acquisition System, for measuring energy and temperatures, capable of multiple-temperature displays updating at least

every 5 s.

6.6 Gas Meter, for measuring the gas consumption of an overfired broiler, shall be a positive displacement type with a resolution

3 3

of at least 0.01 ft and a maximum uncertainty no greater than 1 % of the measured value for any demand greater than 2.2 ft /h.

If the meter is used for measuring the gas consumed by the pilot lights, it shall have a resolution of at least 0.01 ft and a maximum

uncertainty no greater than 2 % of the measured value.

6.7 Pressure Gage, for monitoring natural gas pressure. Shall have a range of zero to 10 in. water, a resolution of 0.5 in. water,

and a maximum uncertainty of 1 % of the measured value.

6.8 Steel Disks, composed of structural-grade carbon steel in accordance with Specification A36/A36M, free of rust or

corrosion, 5-in. (127 mm) diameter, and ⁄4-in. (6.3-mm) thick. The disks shall be flat to within 0.010 in. (0.25 mm) over the

diameter.

6.9 Stop Watch, with a 1-s resolution.

6.10 Strain Gage Welder, capable of welding thermocouples to steel.

6.11 Temperature Sensor, for measuring natural gas temperature in the range of 50 to 100°F (10 to 38°C) with an uncertainty

of 61°F (0.56°C).

6.12 Thermocouple(s), fiberglass insulated, 24 gage, Type K thermocouple wire, peened flat at the exposed ends and spot

welded to the center of the steel disk surfaces with a strain gage welder.

6.13 Thermocouple(s), fiberglass insulated, 24 gage, Type K thermocouple wire, welded and calibrated, for use in determining

the temperature of the chicken breasts.

6.14 Watt-Hour Meter, for measuring the electrical energy consumption of an overfired broiler, shall have a resolution of at least

10 Wh and a maximum uncertainty no greater than 1.5 % of the measured value for any demand greater than 100 W. For any

demand less than 100 W, the meter shall have a resolution of at least 10 Wh and a maximum uncertainty no greater than 10 %.

7. Reagents and Materials

7.1 Aluminum Sheet Pans, measuring 18 by 26 by 1 in. (457 by 660 by 25 mm), for use in packaging chicken breasts.

7.2 Chicken Breasts, shall be nominal 5-oz frozen, boneless, skinless, butterfly cut, chicken breasts (whole meat, not fabricated).

When thawed and drained, each chicken breast shall weigh 4.8 6 0.2 oz.

F2237 − 03 (2015)

7.3 Drip Rack, sized to fit 18 by 26 by 1 in. (457 by 660 by 25 mm) aluminum sheet pans, for packaging chicken breasts.

7.4 Fish Hooks, size 1, for use in attaching thermocouples to chicken breasts.

7.5 Plastic Wrap, commercial grade, 18 in. (457 mm) wide, for use in packaging chicken breasts.

7.6 Tongs, commercial grade, metal construction, for handling chicken breasts.

8. Sampling and Test Units

8.1 Overfired Broiler—Select a representative production model for performance testing.

9. Preparation of Apparatus

9.1 Install the appliance according to the manufacturer’s instructions under a canopy exhaust hood. Position the overfired broiler

so that a minimum of 6 in. is maintained between the edge of the hood and the vertical plane of the front and sides of the appliance.

In addition, both sides of the overfired broiler shall be a minimum of 3 ft from any side wall, side partition, or other operating

appliance. The exhaust ventilation rate shall be 300 cfm per linear foot of active hood length. The associated heating or cooling

system shall be capable of maintaining an ambient temperature of 75 6 5°F within the testing environment when the exhaust

ventilation system is operating.

NOTE 2—The ambient temperature requirements are designed to simulate real world kitchen temperatures and are meant to provide a reasonable

guideline for the temperature requirements during testing. If a facility is not able to maintain the required temperatures, then it is reasonable to expect

that the application of the procedure may deviate from the specified requirements (if it cannot be avoided) as long as those deviations are noted on the

Results Reporting Sheets.

9.2 Connect the overfired broiler to a calibrated energy test meter. For gas installations, install a pressure regulator downstream

from the meter to maintain a constant pressure of gas for all tests. Install instrumentation to record both the pressure and

temperature of the gas supplied to the overfired broiler and the barometric pressure during each test so that the measured gas flow

can be corrected to standard conditions. For electric installations, a voltage regulator may be required during tests if the voltage

supply is not within 62.5 % of the manufacturer’s nameplate voltage.

9.3 For an electric overfired broiler, confirm (while the overfired broiler elements are energized) that the supply voltage is within

62.5 % of the operating voltage specified by the manufacturer. Record the test voltage for each test.

NOTE 3—It is the intent of the test procedure herein to evaluate the performance of an overfired broiler at its rated gas pressure or electric voltage.

If an electric unit is rated dual voltage (that is, designed to operate at either 208 or 240 V with no change in components), the voltage selected by the

manufacturer or tester, o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.