ASTM C474-05

(Test Method)Standard Test Methods for Joint Treatment Materials for Gypsum Board Construction

Standard Test Methods for Joint Treatment Materials for Gypsum Board Construction

ABSTRACT

These test methods cover the physical testing of joint treatment materials such as joint compound, paper joint tape, glass-mesh joint tape, and an assembly of joint compound and paper joint tape. These materials are used in gypsum board construction. The test methods are detailed for the following: joint compound tests—for viscosity, shrinkage, check cracking, and putrefaction; joint tape tests—for tensile strength, width, and thickness; paper joint tape tests—for dimensional stability; assemblages of paper joint tape and joint compound—for bond of paper joint tape to joint compound and cracking of joint compound at tape edges; and glass-mesh joint tape test—for skewness.

SCOPE

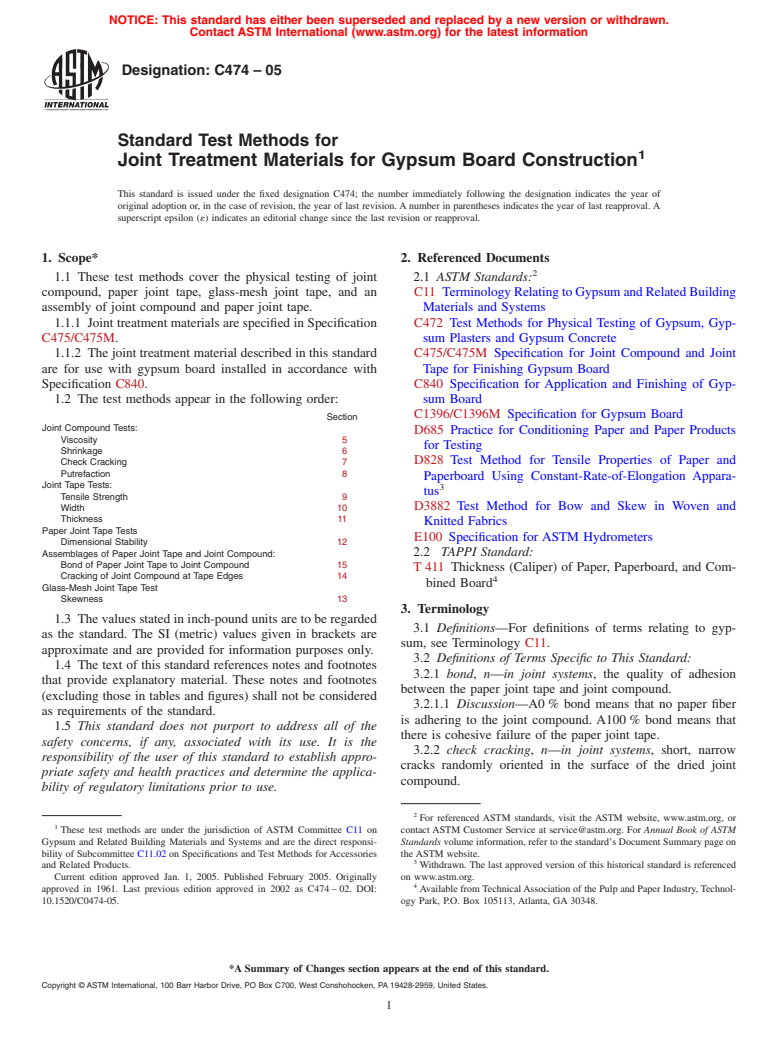

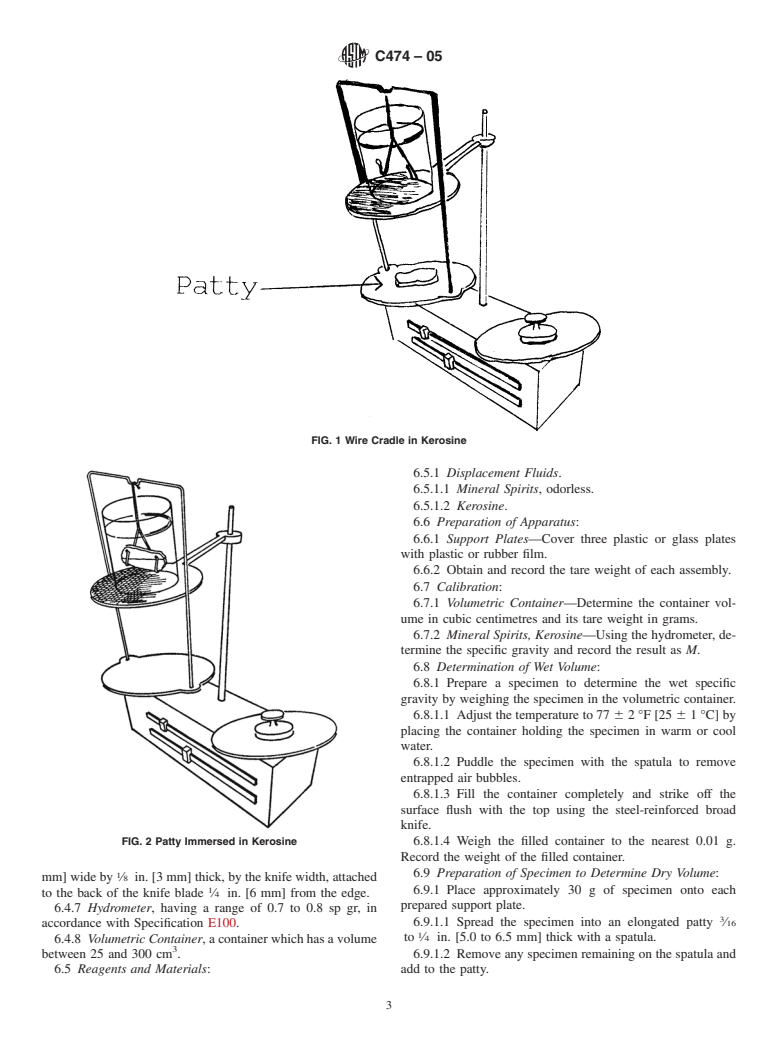

1.1 These test methods cover the physical testing of joint compound, paper joint tape, glass-mesh joint tape, and an assembly of joint compound and paper joint tape.

1.1.1 Joint treatment materials are specified in Specification C 475/C 475M.

1.1.2 The joint treatment material described in this standard are for use with gypsum board installed in accordance with Specification C 840.

1.2 The test methods appear in the following order:

1.3 The values stated in inch-pound units are to be regarded as the standard. The SI (metric) values given in brackets are approximate and are provided for information purposes only.

1.4 The text of this standard references notes and footnotes that provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C474–05

Standard Test Methods for

1

Joint Treatment Materials for Gypsum Board Construction

This standard is issued under the fixed designation C474; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

1.1 These test methods cover the physical testing of joint 2.1 ASTM Standards:

compound, paper joint tape, glass-mesh joint tape, and an C11 TerminologyRelatingtoGypsumandRelatedBuilding

assembly of joint compound and paper joint tape. Materials and Systems

1.1.1 Joint treatment materials are specified in Specification C472 Test Methods for Physical Testing of Gypsum, Gyp-

C475/C475M. sum Plasters and Gypsum Concrete

1.1.2 The joint treatment material described in this standard C475/C475M Specification for Joint Compound and Joint

are for use with gypsum board installed in accordance with Tape for Finishing Gypsum Board

Specification C840. C840 Specification for Application and Finishing of Gyp-

1.2 The test methods appear in the following order: sum Board

C1396/C1396M Specification for Gypsum Board

Section

Joint Compound Tests:

D685 Practice for Conditioning Paper and Paper Products

Viscosity 5

for Testing

Shrinkage 6

D828 Test Method for Tensile Properties of Paper and

Check Cracking 7

Putrefaction 8

Paperboard Using Constant-Rate-of-Elongation Appara-

Joint Tape Tests:

3

tus

Tensile Strength 9

Width 10 D3882 Test Method for Bow and Skew in Woven and

Thickness 11

Knitted Fabrics

Paper Joint Tape Tests

E100 Specification for ASTM Hydrometers

Dimensional Stability 12

Assemblages of Paper Joint Tape and Joint Compound: 2.2 TAPPI Standard:

Bond of Paper Joint Tape to Joint Compound 15

T411 Thickness (Caliper) of Paper, Paperboard, and Com-

Cracking of Joint Compound at Tape Edges 14

4

bined Board

Glass-Mesh Joint Tape Test

Skewness 13

3. Terminology

1.3 The values stated in inch-pound units are to be regarded

3.1 Definitions—For definitions of terms relating to gyp-

as the standard. The SI (metric) values given in brackets are

sum, see Terminology C11.

approximate and are provided for information purposes only.

3.2 Definitions of Terms Specific to This Standard:

1.4 The text of this standard references notes and footnotes

3.2.1 bond, n—in joint systems, the quality of adhesion

that provide explanatory material. These notes and footnotes

between the paper joint tape and joint compound.

(excluding those in tables and figures) shall not be considered

3.2.1.1 Discussion—A0 % bond means that no paper fiber

as requirements of the standard.

is adhering to the joint compound. A100 % bond means that

1.5 This standard does not purport to address all of the

there is cohesive failure of the paper joint tape.

safety concerns, if any, associated with its use. It is the

3.2.2 check cracking, n—in joint systems, short, narrow

responsibility of the user of this standard to establish appro-

cracks randomly oriented in the surface of the dried joint

priate safety and health practices and determine the applica-

compound.

bility of regulatory limitations prior to use.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

These test methods are under the jurisdiction of ASTM Committee C11 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Gypsum and Related Building Materials and Systems and are the direct responsi- Standards volume information, refer to the standard’s Document Summary page on

bility of Subcommittee C11.02 on Specifications and Test Methods forAccessories the ASTM website.

3

and Related Products. Withdrawn. The last approved version of this historical standard is referenced

Current edition approved Jan. 1, 2005. Published February 2005. Originally on www.astm.org.

4

approved in 1961. Last previous edition approved in 2002 as C474 – 02. DOI: Available from TechnicalAssociation of the Pulp and Paper Industry, Technol-

10.1520/C0474-05. ogy Park, P.O. Box 105113, Atlanta, GA 30348.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C474–05

3.2.3 joint compound, powder, n—Adrying-type or setting-

in. [mm]

Shaft diameter 0.187 6 0.015 [4.75 6 0.38]

type cementitious material to be mixed with water.

Pin diameter 0.094 6 0.015 [2.39 6 0.38]

3.2.4 joint compound, ready-mix, n—Adrying-type cemen-

Immersion depth (from bottom of spindle) 1.625 6 0.015 [41.3 6 0.38]

titious material that is factory mixed in ready-to-use form. Length of pin projecting f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.