ASTM D2221-01(2010)

(Test Method)Standard Test Method for Creep Properties of Package Cushioning Materials

Standard Test Method for Creep Properties of Package Cushioning Materials

SIGNIFICANCE AND USE

This test method determines the extent and nature of cushion thickness change under static load. Creep data obtained by this test method are applicable to the cushion under the conditions of the particular test and are not necessarily the same as obtained in a complete pack in actual packaging environments. Data may be affected by magnitude of static load, specimen area, shape, and thickness, by varying ambient conditions of temperature, humidity, by friction in the movable platen guide system, and by actual cushion thickness. Vibration in the vicinity of the test fixtures may also influence data results.

SCOPE

1.1 This test method covers the determination of creep properties of package cushioning materials. It is applicable to materials available in bulk, sheet, or molded form used for the cushioning of articles during storage, handling, and shipment.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2221 − 01(Reapproved 2010)

Standard Test Method for

Creep Properties of Package Cushioning Materials

This standard is issued under the fixed designation D2221; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 3.1.2 permanent set—the permanent change in thickness of

anunloadedcushionasaresultofanappliedcompressiveload

1.1 This test method covers the determination of creep

for any given time interval and any given unloaded recovery

properties of package cushioning materials. It is applicable to

time period.

materials available in bulk, sheet, or molded form used for the

cushioning of articles during storage, handling, and shipment.

4. Summary of Test Method

1.2 The values stated in inch-pound units are to be regarded

4.1 The test apparatus consists of a suitable testing device

as standard. The values given in parentheses are mathematical

having a base plate and a guided movable platen which can be

conversions to SI units that are provided for information only

loaded with weights.The loaded movable platen is placed on a

and are not considered standard.

cushion to simulate static compressive loading of cushioning

1.3 This standard does not purport to address all of the material in actual packaging. By measuring the change in

thickness of the loaded cushion with time, creep properties of

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- the cushioning material can be obtained.

priate safety and health practices and determine the applica-

5. Significance and Use

bility of regulatory limitations prior to use.

5.1 This test method determines the extent and nature of

cushion thickness change under static load. Creep data ob-

2. Referenced Documents

tained by this test method are applicable to the cushion under

2.1 ASTM Standards:

the conditions of the particular test and are not necessarily the

D4332Practice for Conditioning Containers, Packages, or

same as obtained in a complete pack in actual packaging

Packaging Components for Testing

environments. Data may be affected by magnitude of static

E105Practice for Probability Sampling of Materials

load, specimen area, shape, and thickness, by varying ambient

E122PracticeforCalculatingSampleSizetoEstimate,With

conditionsoftemperature,humidity,byfrictioninthemovable

Specified Precision, the Average for a Characteristic of a

platenguidesystem,andbyactualcushionthickness.Vibration

Lot or Process

in the vicinity of the test fixtures may also influence data

results.

3. Terminology

6. Apparatus

3.1 Definitions of Terms Specific to This Standard:

3.1.1 creep—the deformation of a material occurring with

6.1 Movable, Guided Platen, capable of being weighted to

time and due to an externally applied constant stress. For achieve the desired loading along with a base to support the

cushioning materials specifically, it may be defined as the

sample throughout the duration of the test. Two such assem-

change in thickness of a cushion under static compressive load blies are shown in Fig. 1 and Fig. 2.

over a period of time.

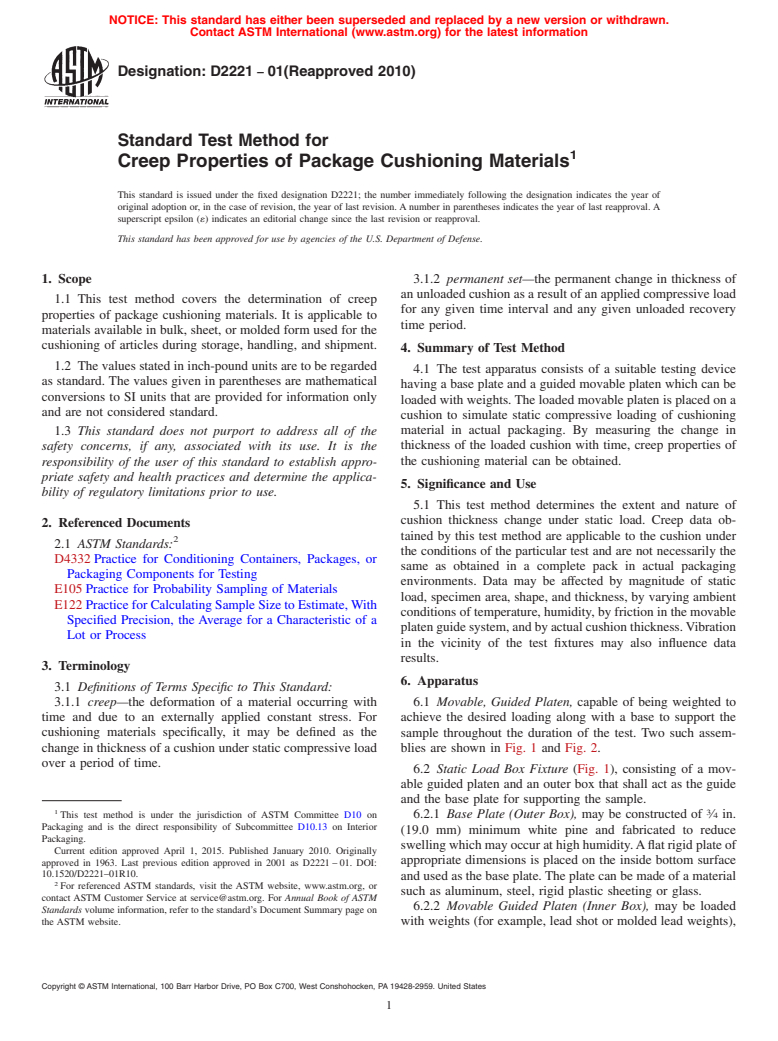

6.2 Static Load Box Fixture (Fig. 1), consisting of a mov-

able guided platen and an outer box that shall act as the guide

and the base plate for supporting the sample.

1 3

This test method is under the jurisdiction of ASTM Committee D10 on

6.2.1 Base Plate (Outer Box), may be constructed of ⁄4 in.

Packaging and is the direct responsibility of Subcommittee D10.13 on Interior

(19.0 mm) minimum white pine and fabricated to reduce

Packaging.

swellingwhichmayoccurathighhumidity.Aflatrigidplateof

Current edition approved April 1, 2015. Published January 2010. Originally

appropriate dimensions is placed on the inside bottom surface

approved in 1963. Last previous edition approved in 2001 as D2221–01. DOI:

10.1520/D2221–01R10.

and used as the base plate.The plate can be made of a material

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

such as aluminum, steel, rigid plastic sheeting or glass.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.2.2 Movable Guided Platen (Inner Box), may be loaded

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. with weights (for example, lead shot or molded lead weights),

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2221 − 01 (2010)

NOTE 1—All dimensions are for reference only and are dependent on

the materials tested.

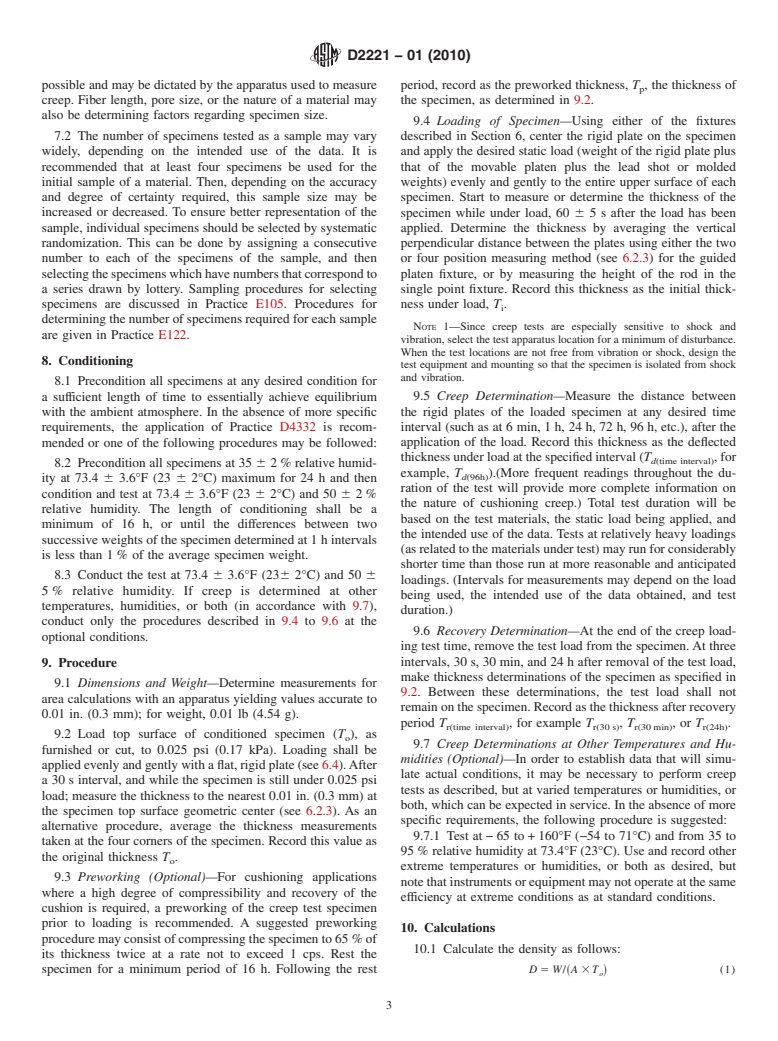

FIG. 2 Typical Single Point Creep Apparatus

without binding. The rod shall be attached to the platen so as

NOTE 1—All dimensions are for reference only and are dependent on

tolimitlateralmotion.(Theweightofbothplatenandrodshall

the materials tested.

be constructed to achieve the minimum static loading for

Inside Dimensions of Outer Box

165 (+2,−0) × 165 (+2,−0) × 254 (±3) mm

original thickness measurement in 9.2.)Weights may be added

mm 2 162 165 203 254

to the platen top surface to achieve the desired static loading.

in. 0.08 6.37 6.50 8 10

6.3.2 Measurements shall be taken from the top of the rod

FIG. 1 Typical Static Load Box Creep Apparatus

with a dial micrometer or other similar device capable of

measurement to 0.01 in. (0.3 mm).

6.4 Flat Rigid Plate, for measuring specimen thickness (see

and fabricated in the same manner as described in 6.2.1.Aflat

9.2)shouldbeconstructedtoyielda0.025psi(0.17kPa)static

rigid plate similar to that described in 6.2.1 is placed between

load. Plates referenced in 6.2.1 and 6.2.2 used with the static

the top of the test specimen and the movable platen and serves

load box may be utilized if constructed to the proper weight

as a reference for measuring the height of the specimen.

required to achieve the desired static load.

6.2.3 Two means of measurement, two position and four

position,maybeutilized.Amicrometerorsteelrulecapableof 7. Test Specimens

measurement to 0.01 in. (0.3 mm) shall be utilized.

7.1 Test specimens shall be right square prisms or right

6.2.3.1 Two Position—A vertical line, scribed at the center

cylinders with the lateral dimensions at least the same as the

of both (movable and base) flat, rigid plate edges (Fig. 1)

original thickness, and with minimum dimensions of not less

serves as location references for specimen thickness measure-

than 2 by 2 by 1 in. (51 by 51 by 25 mm) thick. The preferred

ments (distance between the plates) at various time intervals.

size is 6 by 6 by 4 in. (152 by 152 by 102 mm) thick. If the

Measurementsaretakenattheverticalscribedlinesatboththe

cushioning material, as supplied, is less than 1 in. (25.4 mm)

front and back of the box.

thick, the required thickness may be obtained by using two or

6.2.3.2 Four Position—Measurements are taken at the four

more layers of the material. For thin gage materials requiring

box corners for specimen thickness measurements (see

the stacking of several layers to achieve the desired specimen

6.2.3.1).

thickness, interleaving between layers with light weight,

6.3 The single point fixture shall consist of a support noncompressible,flat,rigidplatescanhelpstabilizethestacked

structureguidingarodperpendicularlyattachedtoaplaten(see specimen.However,thecumulativethicknessesandweightsof

Fig. 2). these plates must be accounted for in all thickness measure-

6.3.1 The support structure shall be constructed in such a ments before calculating any values described in Section 10.

manner as to keep the rod and platen perpendicular to the base Specimens with larger areas are recommended whenever

D2221 − 01 (2010)

possible and may be dictated by the apparatus used to measure period, record as the preworked thickness, T , the thickness of

p

creep. Fiber length, pore size, or the nature of a material may the specimen, as determined in 9.2.

also be determining factors regarding specimen size.

9.4 Loading of Specimen—Using either of the fixtures

7.2 The number of specimens tested as a sample may vary described in Section 6, center the rigid plate on the specimen

widely, depending on the intended use of the data. It is and apply the desired static load (weight of the rigid plate plus

recommended that at least four specimens be used for the that of the movable platen plus the lead shot or molded

initial sample of a material. Then, depending on the accuracy weights) evenly and gently to the entire upper surface of each

and degree of certainty required, this sample size may be specimen. Start to measure or determine the thickness of the

increased or decreased. To ensure better representation of the specimen while under load, 60 6 5 s after the load has been

sample, individual specimens should be selected by systematic applied. Determine the thickness by averaging the vertical

randomization. This can be done by assigning a consecutive perpendicular distance between the plates using either the two

number to each of the specimens of the sample, and then or four position measuring method (see 6.2.3) for the guided

selectingthespecimenswhichhavenumbersthatcorrespondto platen fixture, or by measuring the height of the rod in the

a series drawn by lottery. Sampling procedures for selecting single point fixture. Record this thickness as the initial thick-

specimens are discussed in Practice E105. Procedures for ness under load, T.

i

determiningthenumberofspecimensrequiredforeachsample

NOTE 1—Since creep tests

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.