ASTM C669-00

(Specification)Standard Specification for Glazing Compounds for Back Bedding and Face Glazing of Metal Sash (Withdrawn 2002)

Standard Specification for Glazing Compounds for Back Bedding and Face Glazing of Metal Sash (Withdrawn 2002)

SCOPE

1.1 This specification covers glazing compounds for application on any metal sash for back bedding and face glazing for exterior or interior exposure. This specification does not apply to materials for use in channel or stop glazing.

1.2 The following safety hazards caveat pertains only to the test method described in this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 669 – 00

Standard Specification for

Glazing Compounds for Back Bedding and Face Glazing of

1

Metal Sash

This standard is issued under the fixed designation C 669; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 4. Manufacture

1.1 This specification covers glazing compounds for appli- 4.1 The manufacturing process shall ensure a homogeneous

cation on any metal sash for back bedding and face glazing for mix, free of defects that will affect serviceability, and of a

exterior or interior exposure. This specification does not apply consistency suitable for application by hand or hand tool,

to materials for use in channel or stop glazing. without special preparation.

1.2 The following safety hazards caveat pertains only to the

5. Requirements

test method described in this specification. This standard does

not purport to address all of the safety concerns, if any, 5.1 Composition—The glazing compound shall consist of

uniform mixtures of pigments, homogeneously mixed in suit-

associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices able oils or resinous vehicles, or both. The pigment shall be

free of refractory particles larger than 50-mesh fine, other than

and determine the applicability of regulatory limitations prior

to use. asbestos fibers; shall be free of lumps; and shall have the

structural and physical characteristics necessary to provide the

1.3 The committee with jurisdiction over this standard is not

aware of any comparable standard published by other organi- specified physical properties (see 7.5).

5.2 Working Properties—The glazing compound after thor-

zations.

ough working in the hands shall have a smooth and uniform

2. Referenced Documents

quality; shall work readily and smoothly under a knife, without

2.1 ASTM Standards: crumbling or cracking; and after being molded into place, shall

2

C 717 Terminology of Building Seals and Sealants hold its shape until set.

C 797 Practices and Terminology for Use of Oil- and 5.3 Color—Unless otherwise specified, the color shall be in

2

Resin-Based Putty and Glazing Compounds the range of the commercial natural and gray shades of glazing

D 2249 Test Method for Predicting the Effect of Weathering compounds. Tinting or coloring pigments, if used, shall be of

2

on Face Glazing and Bedding Compounds on Metal Sash such quality and color to match a sample mutually agreed upon

D 2376 Test Method for Slump of Face Glazing and Bed- by purchaser and seller.

2

ding Compounds on Metal Sash 5.4 Degree of Set of Cured Compound— The compound

D 2451 Test Method for Degree of Set for Glazing Com- shall show a minimum penetration of 20 and a maximum

2

pounds on Metal Sash penetration of 120 tenths of a millimetre.

3

2.2 Federal Specifications: 5.5 Accelerated Weathering Tests:

RR-S-366E, Sieve, Test 5.5.1 Surface Cracking and Peeling—The compound shall

show no surface cracking or peeling greater than illustrated by

3. Terminology

No. 5 of Fig. 1.

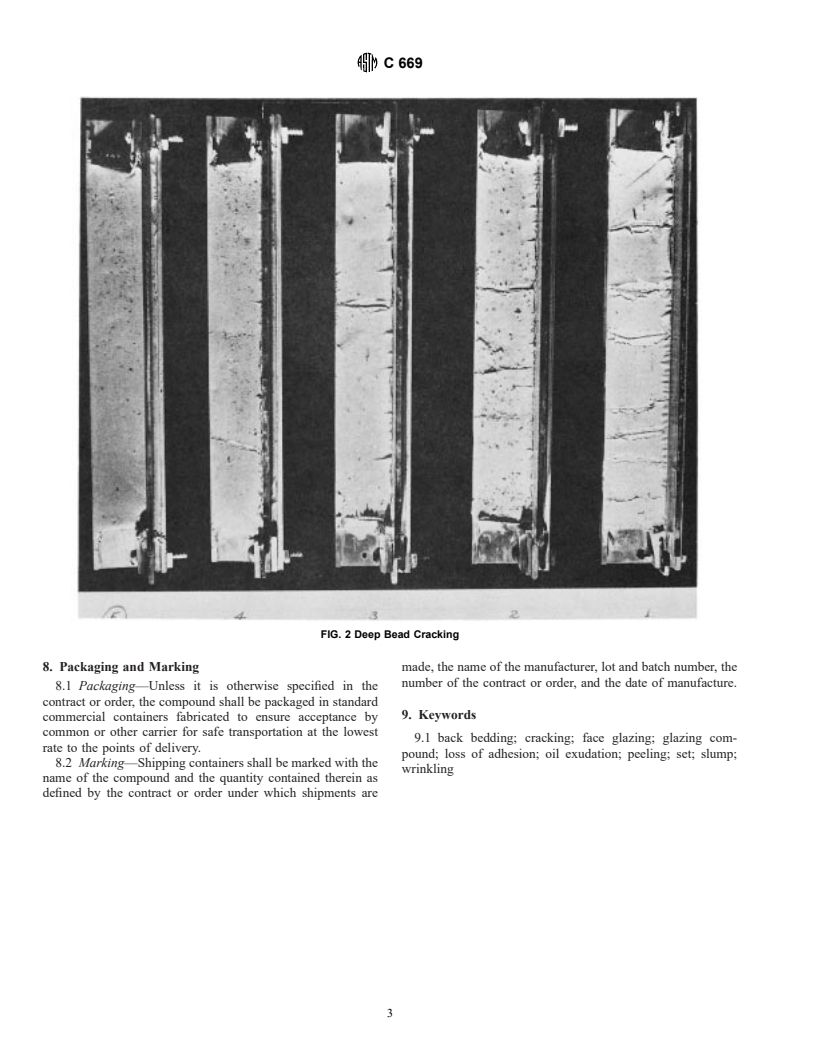

3.1 Definitions—Refer to Terminology C 717 for definitions 5.5.2 Deep-Bead Cracking—The compound shall show no

of the following terms: adhesive failure (loss of adhesion),

deep-bead cracking greater than illustrated by No. 5 of Fig. 2.

bedding, compound, cured, face glazing. 5.5.3 Loss of Adhesion—The compound shall show no loss

of adhesion greater than illustrated by Nos. 4 and 5 of Fig. 3.

1 NOTE 1—Some slight degree of loss of adhesion is permissible in the

This specification is under the jurisdiction of ASTM Committee C-24 on

test specimen due to the difficulty in the preparation of the specimen. This

Building Seals and Sealants, and is the direct responsibility of Subcommittee

condition would not be encountered when glazing compound is applied

C24.12 on Oil and Resin Base Glazing and Caulking Sealants.

Current edition approved June 10, 2000. Published July 2000. Originally under field conditions, such as a full sash, rather than a single Muntin Bar.

published as C 669 – 70. Last previous edition C 669 – 95.

2 5.5.4 Wrinkling—The compound shall show no wrinkling

Annual Book of ASTM Standards, Vol 04.07.

3

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700 greater than illustrated by Nos. 4 and 5 of Fig. 4.

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C 669

FIG. 1 Surface Crack

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.