ASTM F504-00

(Test Method)Standard Test Method for Measuring the Quasi-Static Release Moments of Alpine Ski Bindings

Standard Test Method for Measuring the Quasi-Static Release Moments of Alpine Ski Bindings

SCOPE

1.1 This test method covers a procedure for the measurement of release moments of ski bindings under conditions where inertia loadings of the ski binding system are not significant.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 504 – 00

Standard Test Method for

Measuring the Quasi-Static Release Moments of Alpine Ski

Bindings

This standard is issued under the fixed designation F 504; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a procedure for the measure-

ment of release moments of ski bindings under conditions

where inertia loadings of the ski binding system are not

significant.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

F 498 Test Method for Center Spring Constant and Spring

Constant Balance of Alpine Skis

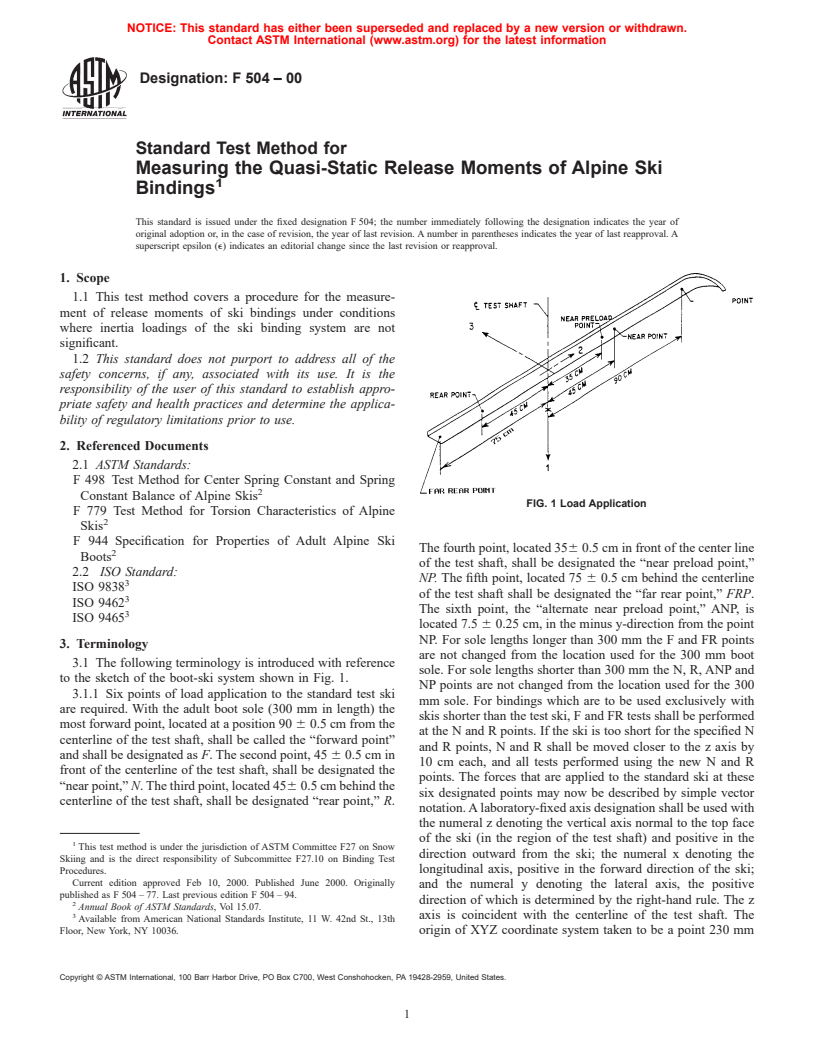

FIG. 1 Load Application

F 779 Test Method for Torsion Characteristics of Alpine

Skis

F 944 Specification for Properties of Adult Alpine Ski

The fourth point, located 356 0.5 cm in front of the center line

Boots

of the test shaft, shall be designated the “near preload point,”

2.2 ISO Standard:

NP. The fifth point, located 75 6 0.5 cm behind the centerline

ISO 9838

of the test shaft shall be designated the “far rear point,” FRP.

ISO 9462

The sixth point, the “alternate near preload point,” ANP, is

ISO 9465

located 7.5 6 0.25 cm, in the minus y-direction from the point

NP. For sole lengths longer than 300 mm the F and FR points

3. Terminology

are not changed from the location used for the 300 mm boot

3.1 The following terminology is introduced with reference

sole. For sole lengths shorter than 300 mm the N, R, ANP and

to the sketch of the boot-ski system shown in Fig. 1.

NP points are not changed from the location used for the 300

3.1.1 Six points of load application to the standard test ski

mm sole. For bindings which are to be used exclusively with

are required. With the adult boot sole (300 mm in length) the

skis shorter than the test ski, F and FR tests shall be performed

most forward point, located at a position 90 6 0.5 cm from the

at the N and R points. If the ski is too short for the specified N

centerline of the test shaft, shall be called the “forward point”

and R points, N and R shall be moved closer to the z axis by

and shall be designated as F. The second point, 45 6 0.5 cm in

10 cm each, and all tests performed using the new N and R

front of the centerline of the test shaft, shall be designated the

points. The forces that are applied to the standard ski at these

“near point,” N. The third point, located 456 0.5 cm behind the

six designated points may now be described by simple vector

centerline of the test shaft, shall be designated “rear point,” R.

notation. A laboratory-fixed axis designation shall be used with

the numeral z denoting the vertical axis normal to the top face

of the ski (in the region of the test shaft) and positive in the

This test method is under the jurisdiction of ASTM Committee F27 on Snow

direction outward from the ski; the numeral x denoting the

Skiing and is the direct responsibility of Subcommittee F27.10 on Binding Test

longitudinal axis, positive in the forward direction of the ski;

Procedures.

Current edition approved Feb 10, 2000. Published June 2000. Originally

and the numeral y denoting the lateral axis, the positive

published as F 504 – 77. Last previous edition F 504 – 94.

direction of which is determined by the right-hand rule. The z

Annual Book of ASTM Standards, Vol 15.07.

axis is coincident with the centerline of the test shaft. The

Available from American National Standards Institute, 11 W. 42nd St., 13th

Floor, New York, NY 10036. origin of XYZ coordinate system taken to be a point 230 mm

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F504–00

along the axis of the test shaft from the bearing surface of the markers on the boot or ski the center of the boot sole shall be

tests sole for 300 mm test soles. The location is changed located 15 6 0.5 cm behind the center of the ski’s projected

proportionally for soles other than 300 mm. The direction of length unless the relevant ASTM standard applies.

any force applied to the ski is defined by its unit vector. The 6.2 Boot—Four boot soles are defined in Table 2 of ISO

magnitude of a preload force applied to the ski is defined by the 9462. The standard boot sole shall be 300 6 0.5 cm in length

M or M moment created by the force. and shall be adjustable, 64 cm. It shall be constructed of

z y

materials and have a tread pattern as established in specifica-

4. Summary of Test Method

tions. Details concerning boot characteristics shall conform to

the relevant ASTM standard. However, it shall be permissible

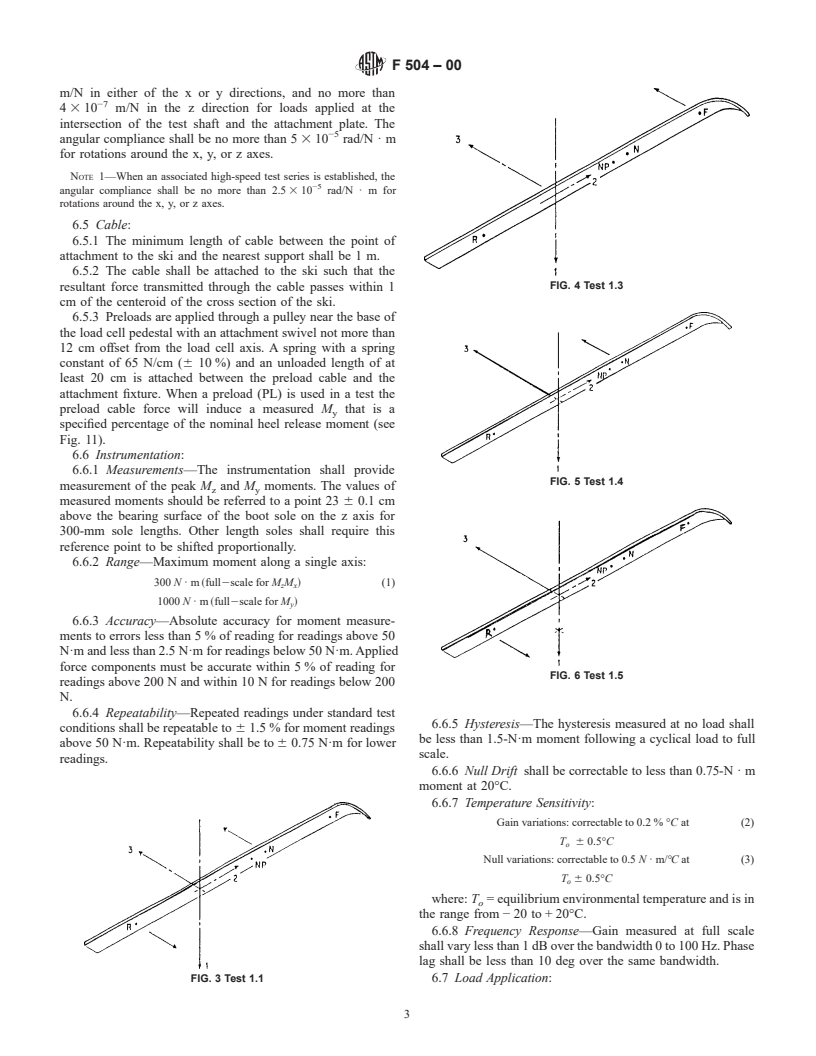

4.1 The ski binding is mounted on a standard ski and a

standard boot is inserted into the binding. A relatively stiff test to modify the boot if the binding manufacturer specifies that

shaft instrumented for moments is affixed to the inside of the modification is necessary for proper function of the binding.

boot and attached rigidly to the test frame. The test equipment 6.3 Stiffener—When called for, a channel of dimensions 80

is shown in Fig. 2. mm wide by 40 mm high by 4 mm thick shall be used to stiffen

4.2 Loads sufficient to produce binding release are applied the ski between the near and rear points. The channel shall be

to the binding by forcing the ski to displace relative to the made of 6061 T6 aluminum, or equivalent. The bar shall be

frame until the release occurs. The components of the moments attached to the ski by bolts or screws at near and rear points and

transmitted through the binding to the test shaft are recorded. at a point half way between near and rear.

These records are interpreted to provide the static release 6.4 Test Frame:

moments of the binding.

6.4.1 The test frame consists of all mechanical components

that connect the boot to a stationary reference, including the

5. Significance and Use

boot sole attachment, the test shaft, and the supporting struc-

5.1 This test method involves simulation in the laboratory of ture for the test shaft. The test frame shall include a boot sole

attachment constructed in accordance with ISO 9838 for the

potential injury-producing loads that can occur in skiing,

without implying the frequency or the magnitude of the danger. standard sole.

This test method does not include the simulation of all or part 6.4.2 The angle between the bottom of the boot sole and the

of a skier, and care must be taken not to confuse the values of test shaft shall be 90 6 1 deg in the z−x and z−y planes; the

moments measured by the test shaft with the values of these

positions of centerline of the test shaft relative to the boot shall

quantities that would occur in the tibia of a skie

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.