ASTM E754-80(2014)e1

(Test Method)Standard Test Method for Pullout Resistance of Ties and Anchors Embedded in Masonry Mortar Joints

Standard Test Method for Pullout Resistance of Ties and Anchors Embedded in Masonry Mortar Joints

SIGNIFICANCE AND USE

5.1 This test method is intended to provide a simple inexpensive means of generating conservative, comparative data on pullout strengths of various ties and anchors used with different types of masonry units and mortars. This test method is recommended for such use until economical, improved methods can be developed to simulate service conditions more inclusively.

SCOPE

1.1 This test method provides procedures for determining the ability of individual masonry ties and anchors to resist extraction from a masonry mortar joint.

1.2 Two laboratory testing procedures are provided for use with test specimens which consist of a masonry tie or anchor embedded in mortar between twin stack-bonded masonry units.

1.2.1 Procedure A—For use with small (brick-size) masonry units.

1.2.2 Procedure B—For use with large (block-size) masonry units.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: E754 − 80 (Reapproved 2014)

Standard Test Method for

Pullout Resistance of Ties and Anchors Embedded in

Masonry Mortar Joints

This standard is issued under the fixed designation E754; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Units statement was inserted in Section 1.3 editorially in October 2014.

INTRODUCTION

The attachment of masonry walls to building exteriors has been based largely on experience and

professional judgment. Codes and standards requirements relating to the attachment of masonry

veneer and nonload-bearing masonry walls generally specify the size and spacing of the fasteners to

be provided (ties or anchors) rather than the forces to be resisted. In addition, there are very limited

data available on the structural performance of most types of fasteners currently used in masonry

construction.

This test method is recommended for determining conservative ultimate pullout values of masonry

fasteners under conditions that approach those usually found in the upper courses of masonry wall

construction, which experience little or practically no vertical load restraint. Its use is recommended

until more comprehensive methods are developed which can evaluate, economically, the capacity of

masonry ties and anchors to resist pullout loads, giving due consideration to service parameters such

as expanse of surrounding wall area and in-plane dead loads.

1. Scope health practices and determine the applicability of regulatory

limitations prior to use.

1.1 This test method provides procedures for determining

the ability of individual masonry ties and anchors to resist

2. Referenced Documents

extraction from a masonry mortar joint.

2.1 ASTM Standards:

1.2 Two laboratory testing procedures are provided for use

C67 Test Methods for Sampling and Testing Brick and

with test specimens which consist of a masonry tie or anchor

Structural Clay Tile

embeddedinmortarbetweentwinstack-bondedmasonryunits.

C109/C109M Test Method for Compressive Strength of

1.2.1 Procedure A—For use with small (brick-size) masonry

Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

units.

Specimens)

1.2.2 Procedure B—For use with large (block-size) masonry

C140/C140M Test Methods for Sampling and Testing Con-

units.

crete Masonry Units and Related Units

1.3 The values stated in inch-pound units are to be regarded

C144 Specification for Aggregate for Masonry Mortar

as standard. The values given in parentheses are mathematical

C270 Specification for Mortar for Unit Masonry

conversions to SI units that are provided for information only

E4 Practices for Force Verification of Testing Machines

and are not considered standard.

E6 Terminology Relating to Methods of Mechanical Testing

1.4 This standard does not purport to address the safety E171/E171M Practice for Conditioning and Testing Flexible

Barrier Packaging

concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and E575 Practice for Reporting Data from Structural Tests of

Building Constructions, Elements, Connections, and As-

semblies

This test method is under the jurisdiction of ASTM Committee E06 on

Performance of Buildings and is the direct responsibility of Subcommittee E06.13

on Structural Performance of Connections in Building Construction. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2014. Published October 2014. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1980. Last previous edition approved in 2006 as E754 – 80 (2006). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/E0754-80R14E01. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

E754 − 80 (2014)

3. Terminology 6.2 Procedure B (Using Block-Size Masonry Units)—

Apparatus for this procedure is shown in Fig. 3 and Fig. 4. Its

3.1 Definitions—For definitions of terms used in this test

special purpose is to avoid handling an unwieldy specimen in

method, refer to Terminology E6.

apparatus such as that used in ProcedureAby applying pullout

loads to the specimen placed on a convenient work surface.

4. Summary of Test Method

The apparatus shall be of sufficient strength and stiffness to

4.1 These procedures provide for a static pullout test of a tie

minimize bending deformations that would tend to promote a

or anchor embedded in a hardened mortar joint between two

flexural bond failure of the mortar joint; and it shall have the

masonry units.

capacity to develop the pullout failure load of the fastener

without yielding.

5. Significance and Use

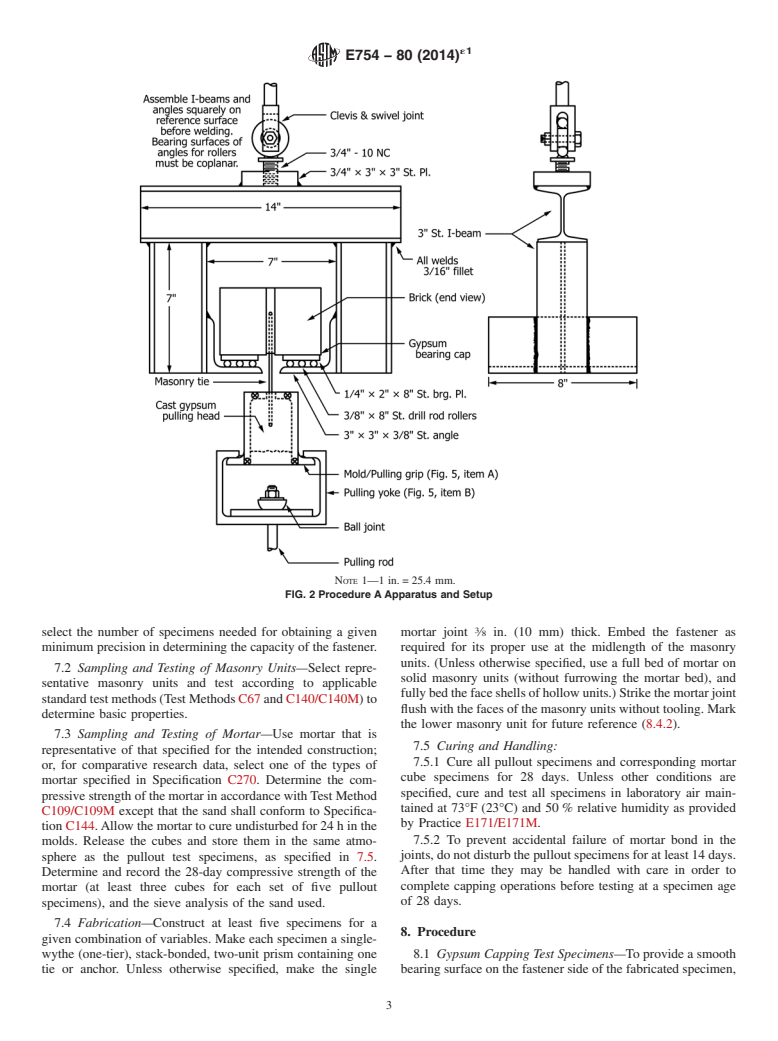

6.3 For both Procedures A and B, the apparatus is made

5.1 This test method is intended to provide a simple

from common rolled metal sections and other stock items. The

inexpensive means of generating conservative, comparative

knockdown jig used for pulling the end of the fastener

data on pullout strengths of various ties and anchors used with

protruding from the masonry also serves as a reusable mold for

different types of masonry units and mortars. This test method

casting a gypsum head on that end of the fastener.The mold/jig

is recommended for such use until economical, improved

is reassembled around the gypsum pulling head when testing.

methods can be developed to simulate service conditions more

6.4 Instrumentation—Displacement of the fastener relative

inclusively.

to the masonry shall be measured by a dial gage or by an

6. Apparatus electronic displacement transducer (for example, a linear

variable differential transformer (LVDT). The instrument used

6.1 Procedure A (Using Brick-Size Masonry Units):

shall be capable of reading 0.001 in. (0.025 mm) and be

6.1.1 The testing machine shall conform to the requirements

accurate to 1 %.

of Practices E4.

6.1.2 AuxiliarypullingapparatusisshowninFig.1andFig.

7. Test Specimen

2. These fixtures are provided with swivel joints and roller

bearings to eliminate lateral restraint and bending when apply- 7.1 Sampling of Fasteners (Masonry Ties or Anchors)—Test

ing the pullout loads. The apparatus shall be designed to have at least five specimens of a given type of fastener for each

enoughstrengthandstiffnesstopreventitsyielding(inorderto given combination of masonry constituent materials. More

minimize apparatus deformation) and to maintain uniform specimens may be needed depending on the variability of the

distribution of the axially applied test loads until failure of the masonry constituents. If necessary, determine suitable statisti-

specimen occurs. cal parameters to evaluate the composite variability and to

FIG. 1 Procedure A Apparatus and Setup

´1

E754 − 80 (2014)

NOTE 1—1 in. = 25.4 mm.

FIG. 2 Procedure A Apparatus and Setup

select the number of specimens needed for obtaining a given mortar joint ⁄8 in. (10 mm) thick. Embed the fastener as

minimum precision in determining the capacity of the fastener. required for its proper use at the midlength of the masonry

units. (Unless otherwise specified, use a full bed of mortar on

7.2 Sampling and Testing of Masonry Units—Select repre-

solid masonry units (without furrowing the mortar bed), and

sentative masonry units and test according to applicable

fullybedthefaceshellsofhollowunits.)Strikethemortarjoint

standardtestmethods(TestMethodsC67andC140/C140M)to

flush with the faces of the masonry units without tooling. Mark

determine basic properties.

the lower masonry unit for future reference (8.4.2).

7.3 Sampling and Testing of Mortar—Use mortar that is

7.5 Curing and Handling:

representative of that specified for the intended construction;

7.5.1 Cure all pullout specimens and corresponding mortar

or, for comparative research data, select one of the types of

cube specimens for 28 days. Unless other conditions are

mortar specified in Specification C270. Determine the com-

specified, cure and test all specimens in laboratory air main-

pressive strength of the mortar in accordance withTest Method

tained at 73°F (23°C) and 50 % relative humidity as provided

C109/C109M except that the sand shall conform to Specifica-

by Practice E171/E171M.

tion C144.Allow the mortar to cure undisturbed for 24 h in the

7.5.2 To prevent accidental failure of mortar bond in the

molds. Release the cubes and store them in the same atmo-

joints, do not disturb the pullout specimens for at least 14 days.

sphere as the pullout test specimens, as specified in 7.5.

After that time they may be handled with care in order to

Determine and record the 28-day compressive strength of the

complete capping operations before testing at a specimen age

mortar (at least three cubes for each set of five pullout

of 28 days.

specimens), and the sieve analysis of the sand used.

7.4 Fabrication—Construct at least five specimens for a

8. Procedure

given combination of variables. Make each specimen a single-

wythe (one-tier), stack-bonded, two-unit pri

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: E754 − 80 (Reapproved 2006) E754 − 80 (Reapproved 2014)

Standard Test Method for

Pullout Resistance of Ties and Anchors Embedded in

Masonry Mortar Joints

This standard is issued under the fixed designation E754; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Units statement was inserted in Section 1.3 editorially in October 2014.

INTRODUCTION

The attachment of masonry walls to building exteriors has been based largely on experience and

professional judgment. Codes and standards requirements relating to the attachment of masonry

veneer and nonload-bearing masonry walls generally specify the size and spacing of the fasteners to

be provided (ties or anchors) rather than the forces to be resisted. In addition, there are very limited

data available on the structural performance of most types of fasteners currently used in masonry

construction.

This test method is recommended for determining conservative ultimate pullout values of masonry

fasteners under conditions that approach those usually found in the upper courses of masonry wall

construction, which experience little or practically no vertical load restraint. Its use is recommended

until more comprehensive methods are developed which can evaluate, economically, the capacity of

masonry ties and anchors to resist pullout loads, giving due consideration to service parameters such

as expanse of surrounding wall area and in-plane dead loads.

1. Scope

1.1 This test method provides procedures for determining the ability of individual masonry ties and anchors to resist extraction

from a masonry mortar joint.

1.2 Two laboratory testing procedures are provided for use with test specimens which consist of a masonry tie or anchor

embedded in mortar between twin stack-bonded masonry units.

1.2.1 Procedure A—For use with small (brick-size) masonry units.

1.2.2 Procedure B—For use with large (block-size) masonry units.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the

user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations

prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C67 Test Methods for Sampling and Testing Brick and Structural Clay Tile

C109/C109M Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens)

C140C140/C140M Test Methods for Sampling and Testing Concrete Masonry Units and Related Units

C144 Specification for Aggregate for Masonry Mortar

This test method is under the jurisdiction of ASTM Committee E06 on Performance of Buildings and is the direct responsibility of Subcommittee E06.13 on Structural

Performance of Connections in Building Construction.

Current edition approved Oct. 1, 2006Oct. 1, 2014. Published October 2006October 2014. Originally approved in 1980. Last previous edition approved in 20002006 as

E754 – 80 (2000).(2006). DOI: 10.1520/E0754-80R06.10.1520/E0754-80R14E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

E754 − 80 (2014)

C270 Specification for Mortar for Unit Masonry

E4 Practices for Force Verification of Testing Machines

E6 Terminology Relating to Methods of Mechanical Testing

E171E171/E171M Practice for Conditioning and Testing Flexible Barrier Packaging

E575 Practice for Reporting Data from Structural Tests of Building Constructions, Elements, Connections, and Assemblies

3. Terminology

3.1 Definitions—For definitions of terms used in this test method, refer to Terminology E6.

4. Summary of Test Method

4.1 These procedures provide for a static pullout test of a tie or anchor embedded in a hardened mortar joint between two

masonry units.

5. Significance and Use

5.1 This test method is intended to provide a simple inexpensive means of generating conservative, comparative data on pullout

strengths of various ties and anchors used with different types of masonry units and mortars. This test method is recommended

for such use until economical, improved methods can be developed to simulate service conditions more inclusively.

6. Apparatus

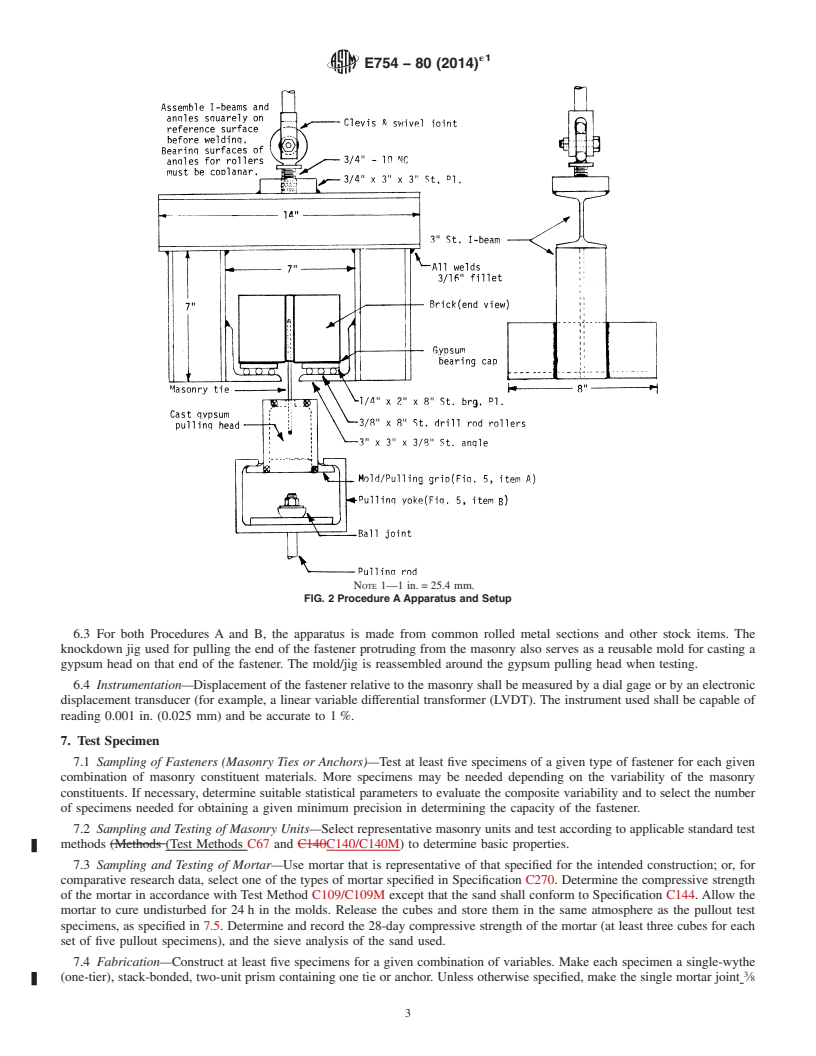

6.1 Procedure A (Using Brick-Size Masonry Units):

6.1.1 The testing machine shall conform to the requirements of Practices E4.

6.1.2 Auxiliary pulling apparatus is shown in Fig. 1 and Fig. 2. These fixtures are provided with swivel joints and roller bearings

to eliminate lateral restraint and bending when applying the pullout loads. The apparatus shall be designed to have enough strength

and stiffness to prevent its yielding (in order to minimize apparatus deformation) and to maintain uniform distribution of the axially

applied test loads until failure of the specimen occurs.

6.2 Procedure B (Using Block-Size Masonry Units)—Apparatus for this procedure is shown in Fig. 3 and Fig. 4. Its special

purpose is to avoid handling an unwieldy specimen in apparatus such as that used in Procedure A by applying pullout loads to the

specimen placed on a convenient work surface. The apparatus shall be of sufficient strength and stiffness to minimize bending

deformations that would tend to promote a flexural bond failure of the mortar joint; and it shall have the capacity to develop the

pullout failure load of the fastener without yielding.

FIG. 1 Procedure A Apparatus and Setup

´1

E754 − 80 (2014)

NOTE 1—1 in. = 25.4 mm.

FIG. 2 Procedure A Apparatus and Setup

6.3 For both Procedures A and B, the apparatus is made from common rolled metal sections and other stock items. The

knockdown jig used for pulling the end of the fastener protruding from the masonry also serves as a reusable mold for casting a

gypsum head on that end of the fastener. The mold/jig is reassembled around the gypsum pulling head when testing.

6.4 Instrumentation—Displacement of the fastener relative to the masonry shall be measured by a dial gage or by an electronic

displacement transducer (for example, a linear variable differential transformer (LVDT). The instrument used shall be capable of

reading 0.001 in. (0.025 mm) and be accurate to 1 %.

7. Test Specimen

7.1 Sampling of Fasteners (Masonry Ties or Anchors)—Test at least five specimens of a given type of fastener for each given

combination of masonry constituent materials. More specimens may be needed depending on the variability of the masonry

constituents. If necessary, determine suitable statistical parameters to evaluate the composite variability and to select the number

of specimens needed for obtaining a given minimum precision in determining the capacity of the fastener.

7.2 Sampling and Testing of Masonry Units—Select representative masonry units and test according to applicable standard test

methods (Methods (Test Methods C67 and C140C140/C140M) to determine basic properties.

7.3 Sampling and Testing of Mortar—Use mortar that is representative of that specified for the intended construction; or, for

comparative research data, select one of the types of mortar specified in Specification C270. Determine the compressive strength

of the mortar in accordance with Test Method C109/C109M except that the sand shall conform to Specification C144. Allow the

mortar to cure undisturbed for 24 h in the molds. Release the cubes and store them in the same atmosphere as the pullout test

specimens, as specified in 7.5. Determine and record the 28-day compressive strength of the mortar (at least three cubes for each

set of five pullout specimens), and the sieve analysis of the sand used.

7.4 Fabrication—Construct at least five specimens for a given combination of variables. Make each specimen a single-wythe

(one-tier), stack-bonded, two-unit prism containing one tie or anchor. Unless otherwise specified, make the single mortar joint ⁄8

´1

E754 − 80 (2014)

FIG. 3 Procedure B Apparatus and Setup

in. (10 mm) thick. Embed the fastener as required for its proper use at the midlength of the masonry units. (Unless otherwise

specified, use a full bed of mortar on solid masonry units (without furrowing the mortar bed), and fully bed the face shells of hollow

units.) Strike the mortar joint flush with the faces of the masonry units without tooling. Mark the lower masonry unit for future

reference (8.4.2).

7.5 Curing and Handling:

7.5.1 Cure all pullout specimens and corresponding mortar cube specimens for 28 days. Unless other conditions are specified,

cure and test all specimens in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.