ASTM D1937-23

(Test Method)Standard Test Method for Carbon Black, Pelleted-Mass Strength

Standard Test Method for Carbon Black, Pelleted-Mass Strength

SIGNIFICANCE AND USE

4.1 Mass strength gives an indication of the flowability in bulk handling. It is affected by pellet properties such as hardness, size, shape, and especially fines content. Due to the influence of other variables, the user and the producer must determine an acceptable mass strength level.

SCOPE

1.1 This test method covers the determination of the mass strength of pelleted carbon black. It is designed to determine the force required to pack a cylindrical column of pelleted carbon black. The results of this test are believed to relate to the ability of the carbon black to flow in bulk handling systems.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Frequently Asked Questions

ASTM D1937-23 is a standard published by ASTM International. Its full title is "Standard Test Method for Carbon Black, Pelleted-Mass Strength". This standard covers: SIGNIFICANCE AND USE 4.1 Mass strength gives an indication of the flowability in bulk handling. It is affected by pellet properties such as hardness, size, shape, and especially fines content. Due to the influence of other variables, the user and the producer must determine an acceptable mass strength level. SCOPE 1.1 This test method covers the determination of the mass strength of pelleted carbon black. It is designed to determine the force required to pack a cylindrical column of pelleted carbon black. The results of this test are believed to relate to the ability of the carbon black to flow in bulk handling systems. 1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only. 1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

SIGNIFICANCE AND USE 4.1 Mass strength gives an indication of the flowability in bulk handling. It is affected by pellet properties such as hardness, size, shape, and especially fines content. Due to the influence of other variables, the user and the producer must determine an acceptable mass strength level. SCOPE 1.1 This test method covers the determination of the mass strength of pelleted carbon black. It is designed to determine the force required to pack a cylindrical column of pelleted carbon black. The results of this test are believed to relate to the ability of the carbon black to flow in bulk handling systems. 1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only. 1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

ASTM D1937-23 is classified under the following ICS (International Classification for Standards) categories: 83.040.20 - Rubber compounding ingredients. The ICS classification helps identify the subject area and facilitates finding related standards.

ASTM D1937-23 has the following relationships with other standards: It is inter standard links to ASTM D1900-06(2015), ASTM D1799-03a(2014), ASTM D1900-06(2011), ASTM D1799-03a(2008), ASTM D1900-06, ASTM D1799-03a, ASTM D1799-03, ASTM D1799-02, ASTM D1799-93(1997), ASTM D1900-94(2002). Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ASTM D1937-23 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ASTM standards.

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D1937 − 23

Standard Test Method for

Carbon Black, Pelleted—Mass Strength

This standard is issued under the fixed designation D1937; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope the cylinder is opened, whereupon all of the carbon black either

falls out the bottom or forms a ring or bridge in the cylinder.

1.1 This test method covers the determination of the mass

The process is repeated with a new sample until the minimum

strength of pelleted carbon black. It is designed to determine

force required for the carbon black to form a ring or bridge is

the force required to pack a cylindrical column of pelleted

found. The resultant force is called mass strength and is

carbon black. The results of this test are believed to relate to the

reported in Newtons.

ability of the carbon black to flow in bulk handling systems.

1.2 The values stated in SI units are to be regarded as the

4. Significance and Use

standard. The values given in parentheses are for information

4.1 Mass strength gives an indication of the flowability in

only.

bulk handling. It is affected by pellet properties such as

1.3 This standard does not purport to address all of the

hardness, size, shape, and especially fines content. Due to the

safety concerns, if any, associated with its use. It is the

influence of other variables, the user and the producer must

responsibility of the user of this standard to establish appro-

determine an acceptable mass strength level.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

5. Apparatus

1.4 This international standard was developed in accor- 3

5.1 Mass Strength Tester, with a compression chamber

dance with internationally recognized principles on standard-

comprising:

ization established in the Decision on Principles for the

5.1.1 Hollow Compression Cylinder, of 95.25 mm (3.75 in.)

Development of International Standards, Guides and Recom-

depth and 52.4 mm (2.06 in.) diameter, made of stainless steel.

mendations issued by the World Trade Organization Technical

5.1.2 Plunger, of 50.8 mm (2 in.) diameter and a central

Barriers to Trade (TBT) Committee.

bore of 12.7 mm (0.5 in.) diameter and 19 mm (0.75 in.) depth,

made of stainless steel.

2. Referenced Documents

5.1.3 Force Application Mechanism, allowing the applica-

2.1 ASTM Standards:

tion of a controllable force onto the plunger.

D1799 Practice for Carbon Black—Sampling Packaged

5.2 Powder Funnel, to completely fill the cylinder.

Shipments

D1900 Practice for Carbon Black—Sampling Bulk Ship-

5.3 Spatula, with a straight edge of at least 55 mm (2.2 in.).

ments

5.4 Brush, approximately 40 mm (1.5 in.), stiff bristle.

D4483 Practice for Evaluating Precision for Test Method

Standards in the Rubber and Carbon Black Manufacturing

6. Sampling

Industries

6.1 Samples shall be taken in accordance with Practices

3. Summary of Test Method D1799 or D1900.

3.1 A sample of carbon black is placed in a vertical cylinder

7. Calibration

and pressed with a plunger for 10 s after which the bottom of

7.1 The manufacturer will typically calibrate the instru-

ment’s measurement system before delivery. Load cells are

This test method is under the jurisdiction of ASTM Committee D24 on Carbon

typically calibrated or verified using a reference load cell or

Black and is the direct responsibility of Subcommittee D24.51 on Carbon Black

calibrated masses, or both. Traceability is recommended for all

Pellet Properties.

Current edition approved May 1, 2023. Published May 2023. Originally

calibration devices. Follow the manufacturer’s recommenda-

approved in 1962. Last previous edition approved in 2021 as D1937 – 21. DOI:

tions for calibration frequency and procedure.

10.1520/D1937-23.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on For information about known sources of supply of mass strength tester

the ASTM website. instruments, please contact ASTM International at service@astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1937 − 23

NOTE 3—Data obtained in lbf can be converted to N as follows: 1 lbf

8. Procedure

= 4.448 N.

8.1 Compress the sample using a mass strength tester per

the manufacturer instructions. A general procedure for com-

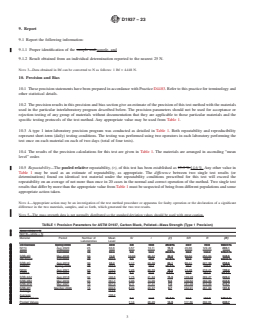

10. Precision and Bias

pressing carbon black involves the following steps:

10.1 These precision statements have been prepared in

8.1.1 Clean the cylinder with a brush to remove any

accordance with Practice D4483. Refer to this practice for

adhering carbon black. With the sliding door (cylinder trap

terminology and other statistical details.

door) closed and the funnel in position, pour carbon black

10.2 The precision results in this precision and bias section

pellets into the cylinder until an excess of pellets forms a cone

give an estimate of the precision of this test method with the

above the rim. Level the surface with a single sweep of a

materials used in the particular interlaboratory program de-

straightedge or spatula held perpendicular to, and in firm

scribed below. The precision parameters should not be used for

contact with the top of the cylinder. The top surface of the

acceptance or rejection testing of any group of materials

carbon black column shall be level to prevent unequal pressure

without documentation that they are applicable to those par-

on the column.

ticular materials and the specific testing protocols of the test

8.1.2 Select the force to be applied. The setting for the

method. Any appropriate value may be used from Table 1.

initial press is discretionary and is based usually on lab

experience.

10.3 A type 1 inter-laborator

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1937 − 21 D1937 − 23

Standard Test Method for

Carbon Black, Pelleted—Mass Strength

This standard is issued under the fixed designation D1937; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the mass strength of pelleted carbon black. It is designed to determine the force

required to pack a cylindrical column of pelleted carbon black. The results of this test are believed to relate to the ability of the

carbon black to flow in bulk handling systems.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D1799 Practice for Carbon Black—Sampling Packaged Shipments

D1900 Practice for Carbon Black—Sampling Bulk Shipments

D4483 Practice for Evaluating Precision for Test Method Standards in the Rubber and Carbon Black Manufacturing Industries

3. Summary of Test Method

3.1 A sample of carbon black is placed in a vertical cylinder and pressed with a plunger for 10 s after which the bottom of the

cylinder is opened, whereupon all of the carbon black either falls out the bottom or forms a ring or bridge in the cylinder. The

process is repeated with a new sample until the minimum force required for the carbon black to form a ring or bridge is found.

The resultant force is called mass strength and is reported in Newtons.

4. Significance and Use

4.1 Mass strength gives an indication of the flowability in bulk handling. It is affected by pellet properties such as hardness, size,

shape, and especially fines content. Due to the influence of other variables, the user and the producer must determine an acceptable

mass strength level.

This test method is under the jurisdiction of ASTM Committee D24 on Carbon Black and is the direct responsibility of Subcommittee D24.51 on Carbon Black Pellet

Properties.

Current edition approved Nov. 1, 2021May 1, 2023. Published December 2021May 2023. Originally approved in 1962. Last previous edition approved in 20182021 as

D1937 – 18.D1937 – 21. DOI: 10.1520/D1937-21.10.1520/D1937-23.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1937 − 23

5. Apparatus

5.1 Mass Strength Tester, with a compression chamber comprising:

5.1.1 Hollow Compression Cylinder, of 95.25 mm (3.75 in.) depth and 52.4 mm (2.06 in.) diameter, made of stainless steel.

5.1.2 Plunger, of 50.8 mm (2 in.) diameter and a central bore of 12.7 mm (0.5 in.) diameter and 19 mm (0.75 in.) depth, made

of stainless steel.

5.1.3 Force Application Mechanism, allowing the application of a controllable force onto the plunger.

5.2 Powder Funnel, to completely fill the cylinder.

5.3 Spatula, with a straight edge of at least 55 mm (2.2 in.).

5.4 Brush, approximately 40 mm (1.5 in.), stiff bristle.

6. Sampling

6.1 Samples shall be taken in accordance with Practices D1799 or D1900.

7. Calibration

7.1 The manufacturer will typically calibrate the instrument’s measurement system before delivery. Load cells are typically

calibrated or verified using a reference load cell or calibrated masses, or both. Traceability is recommended for all calibration

devices. Follow the manufacturer’s recommendations for calibration frequency and procedure.

8. Procedure

8.1 Compress the sample using a mass strength tester per the manufacturer instructions. A general procedure for compressing

carbon black involves the following steps:

8.1.1 Clean the cylinder with a brush to remove any adhering carbon black. With the sliding door (cylinder trap door) closed and

the funnel in position, pour carbon black pellets into the cylinder until an excess of pellets forms a cone above the rim. Level the

surface with a single sweep of a straightedge or spatula held perpendicular to, and in firm contact with the top of the cylinder. The

top surface of the carbon black column shall be level to prevent unequal pressure on the column.

8.1.2 Select the force to be applied. The setting for the initial press is discretionary and is based usually on lab experience.

NOTE 1—Soft pellets with irregular shape and high fines tend to have low mass strength. For these materials an initial setting of 100 N is suggested. More

spherical pellets with higher pellet hardness and low fines tend to have high mass strength. For these materials an initial setting of 250 N is suggested.

8.1.3 Activate the plunger, to start the compression. The timer shall be set to allow a total plunger application time of 10 s on the

sample.

8.1.4 After the plunger returns to the rest position above the sample, open the sliding door carefully and observe the inside of the

cylinder. If no black remains in the cylinder, the end point has not been reached. The test is then repeated on untested portions of

the sample using successively higher pressures following the test sequence in 8.1.1 – 8.1.4.

NOTE 2—The increments of increased force are discretionary. Steps of 50 or 100 N are appropriate.

8.2 Once a bridge of pressed carbon black is formed, the end point has been reached or exceeded. An additional test should be

performed at lower pressure(s) in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...