ASTM B607-91(1998)

(Specification)Standard Specification for Autocatalytic Nickel Boron Coatings for Engineering Use

Standard Specification for Autocatalytic Nickel Boron Coatings for Engineering Use

SCOPE

1.1 Nickel boron coatings are produced by autocatalytic (electroless) deposition from aqueous solutions. These solutions contain either an alkylamineborane or sodium borohydride as a reducing agent, a source of nickel ions, a buffer, complexant, and control chemicals.

1.2 This standard describes the requirements for coatings of autocatalytic nickel boron deposited from aqueous solutions onto substrates for engineering use. The specification classifies these coatings into two types:

1.2.1 Type 1 coatings have a boron content of 0.1 to less than 3.5 mass percent with the balance nickel.

1.2.2 Type 2 coatings have a boron content of 3.5 to 6 mass percent and a minimum of 90 mass percent nickel.

1.3 The coatings are hard and uniform in thickness, even on irregular shaped parts, and used in a wide range of applications.

1.4 Process solutions formulated with an alkylamineborane usually produce coatings that contain 0.1 to 3.5% boron. Thin coatings of this type provide bondability and solderability on electronic components such as lead frames, electrical contacts, and headers. To maintain solderability, these coatings are generally not heat treated.

1.5 Process solutions formulated with sodium borohydride are strongly alkaline and are frequently used to plate steel and titanium parts to impart surface hardness and wear resistance properties. Deposits produced from these processes can contain 3 to 5% boron and thallium or other metals which are used to stabilize the plating solution and modify the coating properties.

1.6 The physical and mechanical properties of these deposits such as density, hardness, stress, and melting point will vary with the boron content. The variation of boron content also affects the quantity and structure of nickel boride precipitated during heat treatment. In the as-plated condition the deposit consists of a predominantly amorphous mixture of nickel and boron with a hardness of about 700 HKN. When the deposit is heated above 300°C the nickel crystallizes, forming nickel clusters of Ni (111) and boron precipitates as nickel boride, Ni B (211) and (311), increasing the hardness to greater than 1000 HK 100 for Type 2 coatings.

1.7 The nickel boron coatings are microporous and offer limited corrosion protection. Their columnar structure, however, is beneficial in reducing wear because it provides a means of trapping lubricants within the surface of the coated part.

1.8 This document describes only autocatalytic nickel boron coatings that have been produced without use of external electric sources.

1.9 The following hazards caveat pertains only to the Test Methods section of this specification: This standard does not purport to address the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Note 1-The following AMS standards are not requirements. They are referenced for information only: AMS2399 and AMS2433.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 607 – 91 (Reapproved 1998)

Standard Specification for

Autocatalytic Nickel Boron Coatings for Engineering Use

This standard is issued under the fixed designation B 607; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 1.7 The nickel boron coatings are microporous and offer

limited corrosion protection. Their columnar structure, how-

1.1 Nickel boron coatings are produced by autocatalytic

ever, is beneficial in reducing wear because it provides a means

(electroless) deposition from aqueous solutions. These solu-

of trapping lubricants within the surface of the coated part.

tions contain either an alkylamineborane or sodium borohy-

1.8 This document describes only autocatalytic nickel boron

dride as a reducing agent, a source of nickel ions, a buffer,

coatings that have been produced without use of external

complexant, and control chemicals.

electric sources.

1.2 This standard describes the requirements for coatings of

1.9 The following hazards caveat pertains only to the Test

autocatalytic nickel boron deposited from aqueous solutions

Methods section of this specification: This standard does not

onto substrates for engineering use. The specification classifies

purport to address the safety problems associated with its use.

these coatings into two types:

It is the responsibility of the user of this standard to establish

1.2.1 Type 1 coatings have a boron content of 0.1 to less

appropriate safety and health practices and determine the

than 3.5 mass percent with the balance nickel.

applicability of regulatory limitations prior to use.

1.2.2 Type 2 coatings have a boron content of 3.5 to 6 mass

percent and a minimum of 90 mass percent nickel.

NOTE 1—The following AMS standards are not requirements. They are

1.3 The coatings are hard and uniform in thickness, even on

referenced for information only: AMS 2399 and AMS 2433.

irregular shaped parts, and used in a wide range of applications.

2. Referenced Documents

1.4 Process solutions formulated with an alkylamineborane

2.1 ASTM Standards:

usually produce coatings that contain 0.1 to 3.5 % boron. Thin

coatings of this type provide bondability and solderability on B 374 Terminology Relating to Electroplating

B 487 Test Method for Measurement of Metal and Oxide

electronic components such as lead frames, electrical contacts,

and headers. To maintain solderability, these coatings are Coating Thickness by Microscopical Examination of a

Cross Section

generally not heat treated.

1.5 Process solutions formulated with sodium borohydride B 567 Test Method for Measurement of Coating Thickness

by Beta Backscatter Method

are strongly alkaline and are frequently used to plate steel and

titanium parts to impart surface hardness and wear resistance B 568 Test Method for Measurement of Coating Thickness

by X-Ray Spectrometry

properties. Deposits produced from these processes can contain

B 571 Test Method for Adhesion of Metallic Coatings

3 to 5 % boron and thallium or other metals which are used to

stabilize the plating solution and modify the coating properties. B 578 Test Method for Microhardness of Electroplated

Coatings

1.6 The physical and mechanical properties of these depos-

its such as density, hardness, stress, and melting point will vary B 602 Test Method for Attribute Sampling of Metallic and

Inorganic Coatings

with the boron content. The variation of boron content also

affects the quantity and structure of nickel boride precipitated B 656 Guide for Autocatalytic (Electroless) Nickel-

Phosphorus Deposition on Metals for Engineering Use

during heat treatment. In the as-plated condition the deposit

consists of a predominantly amorphous mixture of nickel and B 667 Practice for Construction and Use of a Probe for

Measuring Electrical Contact Resistance

boron with a hardness of about 700 HKN. When the deposit is

heated above 300°C the nickel crystallizes, forming nickel B 678 Test Method for Solderability of Metallic-Coated

Products

clusters of Ni (111) and boron precipitates as nickel boride,

Ni B (211) and (311), increasing the hardness to greater than B 697 Guide for Selection of Sampling Plans for Inspection

of Electrodeposited Metallic and Inorganic Coatings

1000 HK for Type 2 coatings.

This specification is under the jurisdiction of ASTM Committee B-8 on

Metallic and Inorganic Coatingsand is the direct responsibility of Subcommittee

B08.08.01 on Engineering Coatings. Annual Book of ASTM Standards, Vol 02.05.

Current edition approved Feb. 22, 1991. Published May 1991. Annual Book of ASTM Standards, Vol 03.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B 607

B 762 Method of Variables Sampling of Metallic and Inor- 4.2.2 Class 2—Parts are heat treated after plating to increase

ganic Coatings hardness. The coating is heat treated at 365 to 385°C for 90

D 2670 Test Method for Measuring Wear Properties of min (see 7.2.4).

Fluid Lubricants (Falex Pin and Vee Block Method) 4.2.3 Class 3—Parts are heat treated after plating at 180 to

D 2714 Test Method for Calibration and Operation of the 200°C for 2 to 23 h to improve coating adhesion on steel and

Falex Block-on-Ring Friction and Wear Testing Machine for hydrogen embrittlement relief of steels (see 7.2.4).

E 39 Test Methods for Chemical Analysis of Nickel 4.2.4 Class 4—Parts are heat treated after plating at 120 to

F 519 Test Method for Mechanical Hydrogen Embrittle- 130°C for a minimum of1hto improve adhesion on

ment Testing of Plating Processes and Aircraft Mainte- heat-treatable (age-hardened) aluminum alloys and carburized

nance Chemicals steels (see 7.2.4).

2.2 Aerospace Materials Specifications: 4.2.5 Class 5—Parts are heat treated after plating at 365 to

AMS 2399 Electroless Nickel-Boron Plating 375°C for a minimum of4hto improve adhesion on titanium

AMS 2433 Electroless Nickel-Thallium-Boron Plating and titanium alloys (see 7.2.4).

2.3 U.S. Government Standards: 4.3 The classification by grade establishes the minimum

MIL-STD-105 Sampling Procedures and Tables for Inspec- thickness of the coating:

tion by Attributes 4.3.1 Grade A—Parts are plated to a minimum coating

MIL-STD-13165 Shot Peening of Metal Parts thickness of 0.5 μm.

4.3.2 Grade B—Parts are plated to a minimum coating

3. Terminology

thickness of 12 μm.

4.3.3 Grade C—Parts are plated to a minimum coating

3.1 Definitions—Many terms used in this standard are

thickness of 25 μm.

defined in Terminology B 374.

4.3.4 Grade D—Parts are plated to a minimum coating

3.2 Definitions of Terms Specific to This Standard:

thickness of 75 μm.

3.2.1 cold shut—a void on the surface which has been

closed by machining and then partially opened through clean-

5. Ordering Information

ing.

5.1 The purchaser should be aware of several processing

3.2.2 hot halide stress-corrosion cracking—a type of me-

considerations or options available to the processor and when

chanical failure produced by halogenated solvents that have

ordering should supply the information described in 5.1.1

been absorbed onto titanium and then in the presence of heat

through 5.1.15 in the purchase order and drawings.

cause microcracking, and the loss of mechanical strength.

5.1.1 Title, ASTM designation, and year of issue of this

3.2.3 lap cracks—a surface imperfection caused by cold

specification.

working of steels producing a void which can be duplicated in

5.1.2 Composition and metallurgical condition of the basis

the deposit.

metal, assemblies of dissimilar materials must be identified.

3.2.4 significant surface—those substrate surfaces which

5.1.3 Classification of the coating: type, class, and grade for

the coating must protect and that are essential to the appear-

this specification (see Section 4).

ance.

5.1.4 Minimum thickness required on the significant sur-

4. Classification face, and any maximum dimensions or tolerance requirements,

if any (see 7.2.2).

4.1 The classification by type of these coatings establishes

5.1.5 Method of adhesion testing from Test Method B 571

the amount of boron in the alloy.

to be used in acceptance requirements (see 8.3).

4.1.1 Type 1—Coatings shall contain 0.1 to less than 3.5

5.1.6 Requirements for certification and test reports (see

mass percent boron with the balance nickel.

Section 11).

4.1.2 Type 2—Coatings shall contain 3.5 to 6 mass percent

5.1.7 Requirements for heat treatment of the part(s) for

boron and a minimum of 90 mass percent nickel.

stress relief prior to plating (see 7.2.4).

4.2 The classification by class of these coatings establishes

5.1.8 Optional sampling plan for lot inspection of the part(s)

the post treatment to be performed on the part(s). The post

(see 9.1 and 13.1).

treatment steps are designed to reduce the potential for

5.1.9 Increased sampling frequency, if any, for qualification

hydrogen embrittlement, increase the adhesion of the coating

tests (see 7.3).

to the substrate, improve the fatigue properties of the part(s),

5.1.10 Supplemental requirements for shot peening of the

and increase the wear resistance and hardness of the coating:

part(s) (see 12.1).

4.2.1 Class 1—Parts are supplied as plated with no post heat

5.1.11 Supplemental requirements for wear testing (see 12.2

treatment.

and 12.3).

5.1.12 Supplemental requirements for heat treatment in

vacuum or inert or reducing atmosphere (see 7.2.1 & 12.4).

Annual Book of ASTM Standards, Vol 05.02.

5.1.13 Supplemental contact resistance requirements (see

Discontinued; see 1995 Annual Book of ASTM Standards, Vol 03.05.

Annual Book of ASTM Standards, Vol 15.03.

12.5).

Available from Society of Automotive Engineers, Inc. (SAE), 400 Common-

5.1.14 Supplemental solderability requirements (see 12.6).

wealth Drive, Warrendale, PA 15096.

8 5.1.15 Supplemental U.S. Government requirements, if any

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. (see Section 13).

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B 607

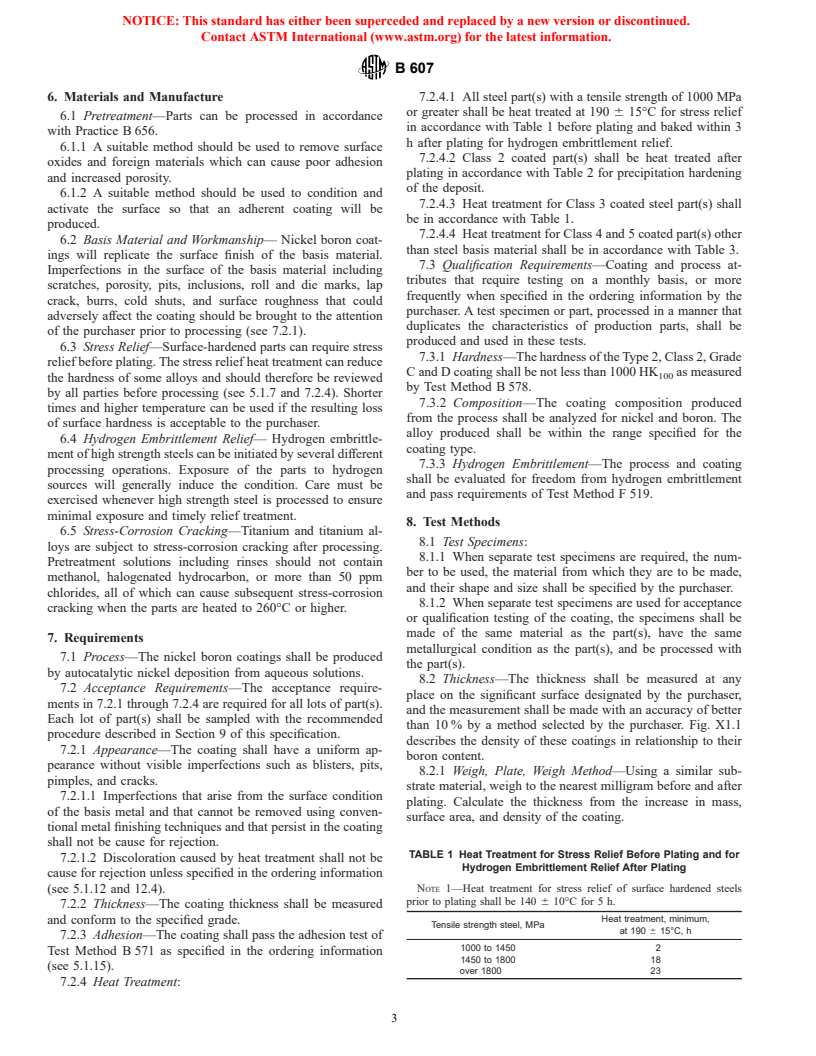

6. Materials and Manufacture 7.2.4.1 All steel part(s) with a tensile strength of 1000 MPa

or greater shall be heat treated at 190 6 15°C for stress relief

6.1 Pretreatment—Parts can be processed in accordance

in accordance with Table 1 before plating and baked within 3

with Practice B 656.

h after plating for hydrogen embrittlement relief.

6.1.1 A suitable method should be used to remove surface

7.2.4.2 Class 2 coated part(s) shall be heat treated after

oxides and foreign materials which can cause poor adhesion

plating in accordance with Table 2 for precipitation hardening

and increased porosity.

of the deposit.

6.1.2 A suitable method should be used to condition and

7.2.4.3 Heat treatment for Class 3 coated steel part(s) shall

activate the surface so that an adherent coating will be

be in accordance with Table 1.

produced.

7.2.4.4 Heat treatment for Class 4 and 5 coated part(s) other

6.2 Basis Material and Workmanship— Nickel boron coat-

than steel basis material shall be in accordance with Table 3.

ings will replicate the surface finish of the basis material.

7.3 Qualification Requirements—Coating and process at-

Imperfections in the surface of the basis material including

tributes that require testing on a monthly basis, or more

scratches, porosity, pits, inclusions, roll and die marks, lap

frequently when specified in the ordering information by the

crack, burrs, cold shuts, and surface roughness that could

purchaser. A test specimen or part, processed in a manner that

adversely affect the coating should be brought to the attention

duplicates the characteristics of production parts, shall be

of the purchaser prior to processing (see 7.2.1).

produced and used in these tests.

6.3 Stress Relief—Surface-hardened parts can require stress

7.3.1 Hardness—The hardness of the Type 2, Class 2, Grade

relief before plating. The stress relief heat treatment can reduce

C and D coating shall be not less than 1000 HK as measured

the hardness of some alloys and should therefore be reviewed

by Test Method B 578.

by all parties before processing (see 5.1.7 and 7.2.4). Shorter

7.3.2 Composition—The coating composition produced

times and higher temperature can be used if the resulting loss

from the process shall be analyzed for nickel and boron. The

of surface hardness is acceptable to the purchaser.

alloy produced shall be within the range specified for the

6.4 Hydrogen Embrittlement Relief— Hydrogen embrittle-

coating type.

ment of high strength steels can be initiated by several different

7.3.3 Hydrogen Embrittlement—The process and coating

processing operations. Exposure of the parts to hydrogen

shall be evaluated for freedom from hydrogen embrittlement

sources will generally induce the condition. Care must be

and pass requirements of Test Method F 519.

exercised whenever high strength steel is processed to ensure

minimal exposure and timely relief treatment.

8. Test Methods

6.5 Stress-Corrosion Cracking—Titanium and titanium al-

8.1 Test Specimens:

loys are subject to stress-corrosion cracking after processing.

8.1.1 When separate test specimens are required, the num-

Pretreatment solutions including rinses should not contain

ber to be used, the material from which they are to be made,

methanol, halogenated hydrocarbon, or more than 50 ppm

and their shape and size shall be specified by the purchaser.

chlorides, all of which can cause subsequent stress-corrosion

8.1.2 When separate test specimens are used for acceptance

cracking when the parts are heated to 260°C or higher.

or qualification testing of the coating, the specimens shall be

made of the same material as the part(s), have the same

7. Requirements

metallurgical condition as the part(s), and be processed with

7.1 Process—The nickel boron coatings shall be produced

the part(s).

by autocatalytic nickel deposition from aqueous solutions.

8.2 Thickness—The thickness shall be measured at any

7.2 Acceptance Requirements—The acceptance require-

place on the significant surface designated by the purchaser,

ments in 7.2.1 through 7.2.4 are required f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.