ASTM F1037-10(2016)e1

(Test Method)Standard Test Method for Visual Rating of Appearance of Resilient Floors After In-Service Exposure to Foot Traffic

Standard Test Method for Visual Rating of Appearance of Resilient Floors After In-Service Exposure to Foot Traffic

SIGNIFICANCE AND USE

4.1 Ratings are developed by subjective, comparative, evaluation of exposed samples to original unexposed specimens of those parameters experience has shown to be the most important in the consumers' minds in evaluating the performance of a walking surface. These parameters are a change in gloss, color, surface texture, alterations to pattern and restorability of appearance with normal maintenance procedures, including the use of finishes or buffing. Rating is done by a panel of qualified observers under specified lighting conditions in accordance with prescribed procedures.

SCOPE

1.1 This test method is intended to provide a numerical rating system for classification of resilient floors during the various stages of their wear life in relation to their condition, as perceived by a knowledgeable user.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F1037 − 10 (Reapproved 2016)

Standard Test Method for

Visual Rating of Appearance of Resilient Floors After In-

Service Exposure to Foot Traffic

This standard is issued under the fixed designation F1037; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorial changes were made in June 2016.

1. Scope mance of a walking surface. These parameters are a change in

gloss, color, surface texture, alterations to pattern and restor-

1.1 This test method is intended to provide a numerical

ability of appearance with normal maintenance procedures,

rating system for classification of resilient floors during the

including the use of finishes or buffing. Rating is done by a

variousstagesoftheirwearlifeinrelationtotheircondition,as

panelofqualifiedobserversunderspecifiedlightingconditions

perceived by a knowledgeable user.

in accordance with prescribed procedures.

1.2 This standard does not purport to address all of the

safety problems, if any, associated with its use. It is the

5. Apparatus

responsibility of the user of this standard to establish appro-

5.1 Buffıng Machine, residential, equipped with single or

priate safety and health practices and determine the applica-

double brush (pad), soft fiber polishing brushes, and lamb’s

bility of regulatory limitations prior to use.

wool pads. When equipped with polishing brushes, the unit

1.3 The values stated in inch-pound units are to be regarded

should deliver a nominal lineal velocity (loaded) of 1100 to

as standard. The values given in parentheses are mathematical

1400ft/min(eachbrush)andaDwellratioof190to210ft (17

conversions to SI units that are provided for information only

to 19 m ) per min at a pressure of 0.40 to 0.50 psi. When

and are not considered standard.

equipped with buffing pads, the unit shall deliver a nominal

lineal velocity (loaded) of 1100 to 1400 lineal fpm (each pad)

2. Referenced Documents

2 2

and a Dwell ratio of 500 to 550 ft (45 to 50 m ) per min at a

2.1 ASTM Standards:

pressure of 0.15 to 0.20 psi (see note).

D1436Test Methods for Application of Emulsion Floor

5.2 Scrub Brush, approximately 2½by7 in. (63by178

Polishes to Substrates for Testing Purposes

mm) with nylon bristles approximately 1 ⁄4in. (32 mm) long.

F141Terminology Relating to Resilient Floor Coverings

5.3 Cellulose Sponge, approximate dry dimension

3. Terminology

8by4 ⁄4by1 in. (203by108 mm).

3.1 Definitions of Terms Specific to This Standard:

6. Reagent

3.1.1 surface texture—surface imperfections such as deep

scratches, indents, or changes in embossing texture.

6.1 Cleaning Solution, shall be as recommended by the

flooring manufacturer and shall be prepared in sufficient

4. Significance and Use

quantity in accordance with the manufacturer’s instructions.

4.1 Ratings are developed by subjective, comparative,

NOTE 1—For flooring test specimens maintained with polish, the

evaluation of exposed samples to original unexposed speci-

cleaning solution shall be capable of removing the polish.

mens of those parameters experience has shown to be the most

important in the consumers’ minds in evaluating the perfor-

7. Sampling, Test Specimens, and Test Units

7.1 Specimen size can vary as desired. A typical size panel

ThistestmethodisunderthejurisdictionofASTMCommitteeF06onResilient

would be 24by24 in. (610by610 mm) and contain four

Floor Coverings and is the direct responsibility of Subcommittee F06.30 on Test

12by12 in. (305by305 mm) similar or different panels to be

Methods - Performance.

tested.Inaddition,acompanionspecimenmustberetainedand

Current edition approved Dec. 1, 2010. Published May 2016. Originally

stored in a location where its appearance will not be altered.

approved in 1987. Last previous edition approved in 2010 as F1037–10. DOI:

10.1520/F1037-10R15E01.

This specimen will be used for comparison purposes through-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

out the test cycle. Each sample is to be cleaned in accordance

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

with the washing procedure in 8.1. The finish procedure shall

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. be followed on all resilient flooring samples designed to be

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F1037 − 10 (2016)

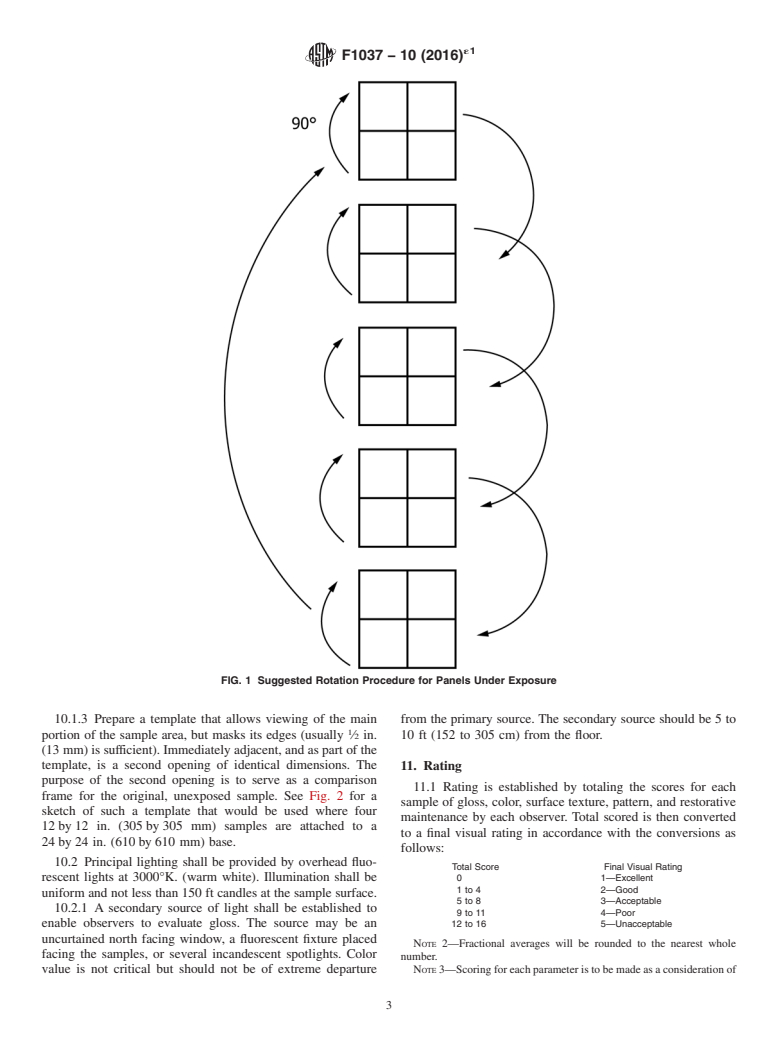

maintained with finish before each rating session. The original 8.3.2 Repeat 8.3.1, using an overlapping top to bottom to

unexposed samples of these products shall be finished also. top motion, covering the entire sample fully from left to right

Those no-finish floors whose appearance, through exposure to to left in 1 min.

traffic,hasdeterioratedtoanoverallratingof“3”ormoreshall 8.3.3 Repeat the bidirectional buffing technique above, us-

berestoredwitheitherthefinishprocedure(nosamplesreceive ing lamb’s wool pads on the buffer.

double-finish) (see 8.2) or the buffing procedure (see 8.3). The 8.3.4 Washing Lamb’s Wool Pads—Forpurposesofthistest,

choice of restorative maintenance is determined by the manu- thelamb’swoolpadswillbewashedeverytimetheequivalent

2 2

facturer’s recommended procedure. All cleaning and restor- of 2016 in. (13104 cm ) samples are buffed according to this

ative maintenance procedures shall be performed on the entire procedure.

sample. 8.3.4.1 Pads are to be washed in a mild detergent and cold

water (2 heaping teaspoons (10.0 g) per gallon (3.8 L) of

7.2 Before evaluation, each sample shall be prepared using

water), rinsed in cold water and air dried (do not “wring out”

the procedure given in Section 8.This procedure is intended to

pads).

remove all dirt and finish (if present).

9. Observer Panel

8. Procedure

9.1 The panel of observers shall consist of at least three

8.1 Mix the cleaning solution and stir thoroughly.

people. One-third of the panel shall consist of a person(s)

8.1.1 Soak brush in solution for 1 min.

technically trained in the composition and use of household

8.1.2 Apply enough solution so that the panel is covered

cleaning products, such as a home economist or chemist.

with a thin coat of solution. Allow the solution to remain

One-thirdofthepanelshallconsistofaperson(s)trainedinthe

undisturbed for 3 min.

technical characteristics and testing procedures used on resil-

8.1.3 Dip brush in solution, then scrub the panel 30 times in

ient flooring, such as an engineer or chemist. One-third of the

each direction with enough pressure to slightly bend the

panel shall be a non-technically trained person(s) who regu-

bristles. Localized, abnormal stains such as chewing gum,

larly maintains resilient floors in a home. No panel member

ground-out cigarettes, tar, or other spots considered abnormal

shall be color blind. The maintenance person shall not be

in residential environment may be given special attention.

included in the observer panel. Members shall be carefully

Overall stains, discoloration, or soil that lodges in deep

instructed on the scoring procedure and shall have had prior

embossments should not be given special treatment.

experience of at least a complete rating of one sample before

8.1.4 With the cellulose sponge wrung out in clear, luke-

establishing a valid scored rating.

warm water, remove the cleaning solution. Rinse sponge in

9.2 Individual panel observers are provided with separate

clear, lukewarm water, wring sponge out lightly, then go over

data sheets and are to separately rate gloss, color, surface

the panel to rewet the surface. Rinse out sponge again in clear

texture, pattern change and restorative effects of maintenance.

water. Wring out tightly and remove as much rinse water as

They may do their rating simultaneously, but should not

possible.

discuss or compare ratings. If any sample requires restorative

8.1.5 Allow surface to air dry for 1 h.

maintenance, all panels are returned to the exp

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: F1037 − 10 F1037 − 10 (Reapproved 2016)

Standard Test Method for

Visual Rating of Appearance of Resilient Floors After In-

Service Exposure to Foot Traffic

This standard is issued under the fixed designation F1037; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorial changes were made in June 2016.

1. Scope

1.1 This test method is intended to provide a numerical rating system for classification of resilient floors during the various

stages of their wear life in relation to their condition, as perceived by a knowledgeable user.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

2.1 ASTM Standards:

D1436 Test Methods for Application of Emulsion Floor Polishes to Substrates for Testing Purposes

F141 Terminology Relating to Resilient Floor Coverings

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 surface texture—surface imperfections such as deep scratches, indents, or changes in embossing texture.

4. Significance and Use

4.1 Ratings are developed by subjective, comparative, evaluation of exposed samples to original unexposed specimens of those

parameters experience has shown to be the most important in the consumers’ minds in evaluating the performance of a walking

surface. These parameters are a change in gloss, color, surface texture, alterations to pattern and restorability of appearance with

normal maintenance procedures, including the use of waxes, finishes, finishes or buffing. Rating is done by a panel of qualified

observers under specified lighting conditions in accordance with prescribed procedures.

5. Apparatus

5.1 Buffıng Machine, residential, equipped with single or double brush (pad), soft fiber polishing brushes, and lamb’s wool pads.

When equipped with polishing brushes, the unit should deliver a nominal lineal velocity (loaded) of 1100 to 1400 ft/min (each

2 2

brush) and a Dwell ratio of 190 to 210 ft (17 to 19 m ) per min at a pressure of 0.40 to 0.50 psi. When equipped with buffing

pads, the unit shall deliver a nominal lineal velocity (loaded) of 1100 to 1400 lineal fpm (each pad) and a Dwell ratio of 500 to

2 2

550 ft (45 to 50 m ) per min at a pressure of 0.15 to 0.20 psi (see note).

5.2 Scrub Brush, approximately 2½ by 7 in. (63 by 178 mm) with nylon bristles approximately 1 ⁄4 in. (32 mm) long.

5.3 Cellulose Sponge, approximate dry dimension 8 by 4 ⁄4 by 1 in. (203 by 108 mm).

This test method is under the jurisdiction of ASTM Committee F06 on Resilient Floor Coverings and is the direct responsibility of Subcommittee F06.30 on Test Methods

- Performance.

Current edition approved Dec. 1, 2010. Published January 2011May 2016. Originally approved in 1987. Last previous edition approved in 20052010 as F1037–05.–10.

DOI: 10.1520/F1037-10.10.1520/F1037-10R15E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F1037 − 10 (2016)

6. Reagent

6.1 Cleaning Solution, shall be as recommended by the flooring manufacturer and shall be prepared in sufficient quantity in

accordance with the manufacturer’s instructions.

NOTE 1—For flooring test specimens maintained with polish, the cleaning solution shall be capable of removing the polish.

7. Sampling, Test Specimens, and Test Units

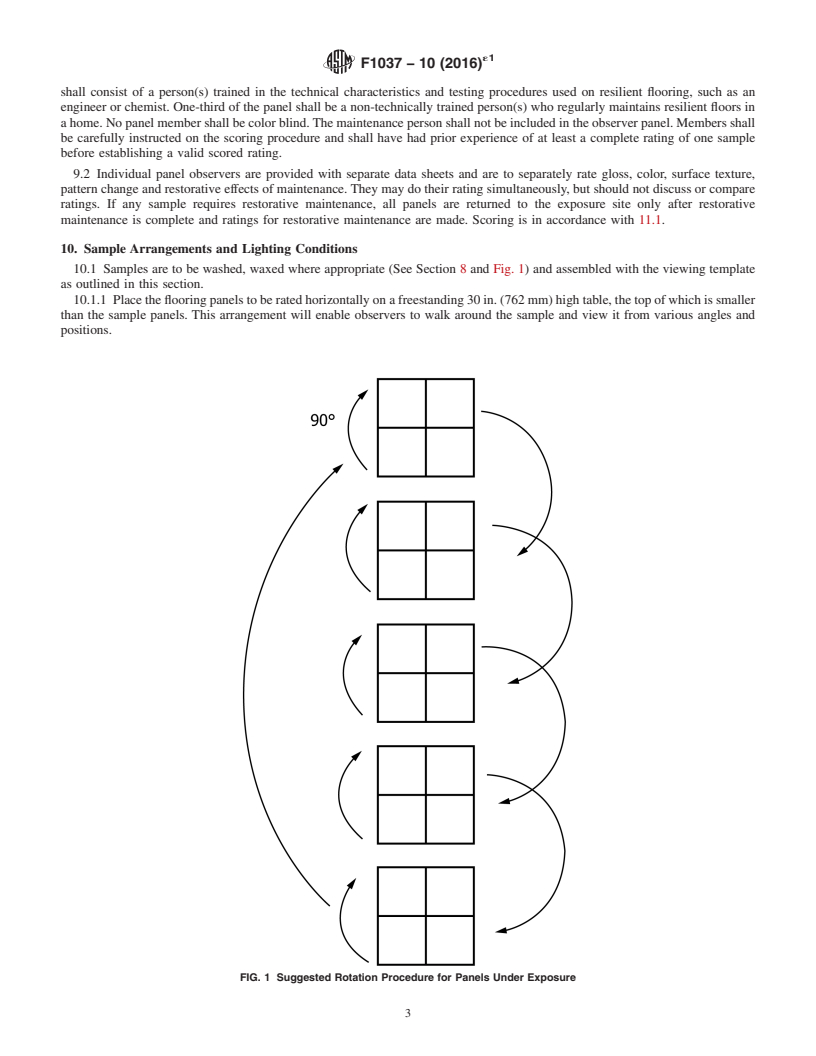

7.1 Specimen size can vary as desired. A typical size panel would be 24 by 24 in. (610 by 610 mm) and contain four 12 by 12

in. (305 by 305 mm) similar or different panels to be tested. In addition, a companion specimen must be retained and stored in a

location where its appearance will not be altered. This specimen will be used for comparison purposes throughout the test cycle.

Each sample is to be cleaned in accordance with the washing procedure in 8.1. The waxingfinish procedure shall be followed on

all resilient flooring samples designed to be maintained with waxfinish before each rating session. The original unexposed samples

of these products shall be waxedfinished also. Those no-waxno-finish floors whose appearance, through exposure to traffic, has

deteriorated to an overall rating of “3” or more shall be restored with either the waxingfinish procedure (no samples receive

double-waxing)double-finish) (see 8.2) or the buffing procedure (see 8.3). The choice of restorative maintenance is determined by

the manufacturer’s recommended procedure. All cleaning and restorative maintenance procedures shall be performed on the entire

sample.

7.2 Before evaluation, each sample shall be prepared using the procedure given in Section 8. This procedure is intended to

remove all dirt and waxfinish (if present).

8. Procedure

8.1 Mix the cleaning solution and stir thoroughly.

8.1.1 Soak brush in solution for 1 min.

8.1.2 Apply enough solution so that the panel is covered with a thin coat of solution. Allow the solution to remain undisturbed

for 3 min.

8.1.3 Dip brush in solution, then scrub the panel 30 times in each direction with enough pressure to slightly bend the bristles.

Localized, abnormal stains such as chewing gum, ground-out cigarettes, tar, or other spots considered abnormal in residential

environment may be given special attention. Overall stains, discoloration, or soil that lodges in deep embossments should not be

given special treatment.

8.1.4 With the cellulose sponge wrung out in clear, lukewarm water, remove the cleaning solution. Rinse sponge in clear,

lukewarm water, wring sponge out lightly, then go over the panel to rewet the surface. Rinse out sponge again in clear water. Wring

out tightly and remove as much rinse water as possible.

8.1.5 Allow surface to air dry for 1 h.

8.2 Finish Procedure—After washing, apply to each individual sample to receive finish, a wax or finish in the following manner.

Use a fresh supply of an acrylic floor finish or an equivalent material appropriate for the specific type of floor. Apply the waxfinish

in accordance with Method B of Test Methods D1436.

8.3 Buffıng Procedure—Following the washing procedure outlined in 8.2, samples of resilient floor coverings whose

manufacturers’ recommend buffing as the restorative maintenance should be treated according to the following buffing procedure.

8.3.1 Buff each sample with the polishing brushes, using a left to right to left motion covering the entire sample from top to

bottom to top again, using overlapping strokes, in 1 min. No excess pressure or weight should be used on the buffer.

8.3.2 Repeat 8.3.1, using an overlapping top to bottom to top motion, covering the entire sample fully from left to right to left

in 1 min.

8.3.3 Repeat the bidirectional buffing technique above, using lamb’s wool pads on the buffer.

8.3.4 Washing Lamb’s Wool Pads—For purposes of this test, the lamb’s wool pads will be washed every time the equivalent

2 2

of 2016 in. (13 104 cm ) samples are buffed according to this procedure.

8.3.4.1 Pads are to be washed in a mild detergent and cold water (2 heaping teaspoons (10.0 g) per gallon (3.8 L) of water),

rinsed in cold water and air dried (do not “wring out” pads).

9. Observer Panel

9.1 The panel of observers shall consist of at least three people. One-third of the panel shall consist of a person(s) technically

trained in the composition and use of household cleaning products, such as a home economist or chemist. One-third of the panel

A sponge with scrubbing capabilities may be substituted for the scrub brush and cellulose sponge.

Future floor polish, a trademark of S.C. Johnson, or its equivalent, has been fou

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.