ASTM A851-96

(Specification)Standard Specification for High-Frequency Induction Welded, Unannealed, Austenitic Steel Condenser Tubes (Withdrawn 2002)

Standard Specification for High-Frequency Induction Welded, Unannealed, Austenitic Steel Condenser Tubes (Withdrawn 2002)

SCOPE

1.1 This specification covers nominal-wall-thickness tubes intended for use as steam surface condenser tubes. These tubes are made from the austenitic steels listed in Table 1 using a high-frequency induction welding process where post-weld solution heat treatment is not necessary for corrosion resistance.

1.2 The tubing sizes and thickness usually furnished to this specification are 5/8 in. (15.9 mm) to 3 1/8 in. (79.4 mm) in outside diameter and 0.015 to 0.109 in. (0.40 to 2.8 mm), inclusive, in wall thickness. Tubing having other dimensions may be furnished, provided such tubes comply with all other requirements of this specification.

1.3 Optional supplementary requirements are provided in this specification and, when one or more of these are desired, each shall be so stated in the order.

1.4 The values stated in inch-pound units are to be regarded as the standard.

General Information

Standards Content (Sample)

Designation: A 851 – 96 An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

High-Frequency Induction Welded, Unannealed, Austenitic

1

Steel Condenser Tubes

This standard is issued under the fixed designation A 851; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

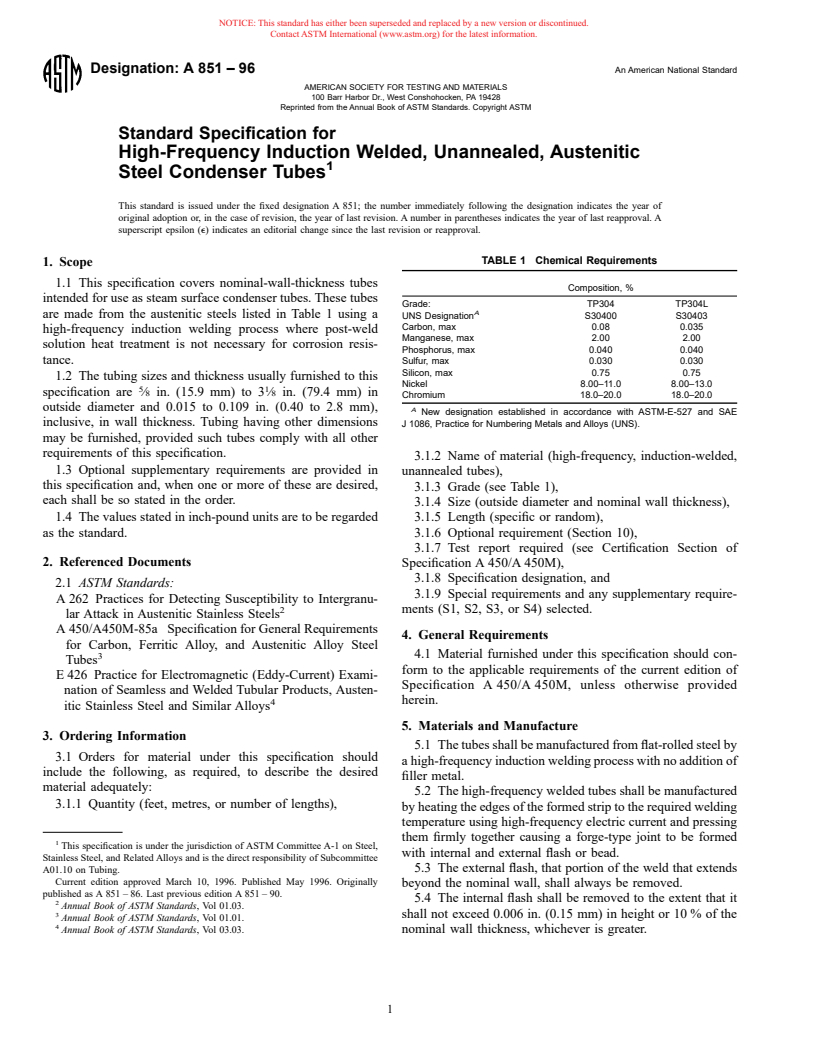

TABLE 1 Chemical Requirements

1. Scope

1.1 This specification covers nominal-wall-thickness tubes

Composition, %

intended for use as steam surface condenser tubes. These tubes

Grade: TP304 TP304L

A

are made from the austenitic steels listed in Table 1 using a UNS Designation S30400 S30403

Carbon, max 0.08 0.035

high-frequency induction welding process where post-weld

Manganese, max 2.00 2.00

solution heat treatment is not necessary for corrosion resis-

Phosphorus, max 0.040 0.040

tance.

Sulfur, max 0.030 0.030

Silicon, max 0.75 0.75

1.2 The tubing sizes and thickness usually furnished to this

Nickel 8.00–11.0 8.00–13.0

5 1

specification are ⁄8 in. (15.9 mm) to 3 ⁄8 in. (79.4 mm) in

Chromium 18.0–20.0 18.0–20.0

outside diameter and 0.015 to 0.109 in. (0.40 to 2.8 mm), A

New designation established in accordance with ASTM-E-527 and SAE

inclusive, in wall thickness. Tubing having other dimensions

J 1086, Practice for Numbering Metals and Alloys (UNS).

may be furnished, provided such tubes comply with all other

requirements of this specification.

3.1.2 Name of material (high-frequency, induction-welded,

1.3 Optional supplementary requirements are provided in

unannealed tubes),

this specification and, when one or more of these are desired,

3.1.3 Grade (see Table 1),

each shall be so stated in the order.

3.1.4 Size (outside diameter and nominal wall thickness),

1.4 The values stated in inch-pound units are to be regarded 3.1.5 Length (specific or random),

as the standard. 3.1.6 Optional requirement (Section 10),

3.1.7 Test report required (see Certification Section of

2. Referenced Documents

Specification A 450/A 450M),

3.1.8 Specification designation, and

2.1 ASTM Standards:

3.1.9 Special requirements and any supplementary require-

A 262 Practices for Detecting Susceptibility to Intergranu-

2 ments (S1, S2, S3, or S4) selected.

lar Attack in Austenitic Stainless Steels

A 450/A450M-85a Specification for General Requirements

4. General Requirements

for Carbon, Ferritic Alloy, and Austenitic Alloy Steel

4.1 Material furnished under this specification should con-

3

Tubes

form to the applicable requirements of the current edition of

E 426 Practice for Electromagnetic (Eddy-Current) Exami-

Specification A 450/A 450M, unless otherwise provided

nation of Seamless and Welded Tubular Products, Austen-

4 herein.

itic Stainless Steel and Similar Alloys

5. Materials and Manufacture

3. Ordering Information

5.1 The tubes shall be manufactured from flat-rolled steel by

3.1 Orders for material under this specification should

a high-frequency induction welding process with no addition of

include the following, as required, to describe the desired

filler metal.

material adequately:

5.2 The high-frequency welded tubes shall be manufactured

3.1.1 Quantity (feet, metres, or number of lengths),

by heating the edges of the formed strip to the required welding

temperature using high-frequency electric current and pressing

them firmly together causing a forge-type joint to be formed

1

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

with internal and external flash or bead.

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

5.3 The external flash, that portion of the weld that extends

A01.10 on Tubing.

Current edition approved March 10, 1996. Published May 1996. Originally

beyond the nominal wall, shall always be removed.

published as A 851 – 86. Last previous edition A 851 – 90.

5.4 The internal flash shall be removed to the extent that it

2

Annual Book of ASTM Standards, Vol 01.03.

3

shall not exceed 0.006 in. (0.15 mm) in height or 10 % of the

Annual Book of ASTM Standards, Vol 01.01.

4

Annual Book of ASTM Standards, Vol 03.03. nominal wall thickness, whichever is greater.

1

---------------------- Page: 1 ----------------------

A 851

5.5 There shall be no evidence of cracks or lack of penetra- 13. Surface Condition

tion or overlaps resulting from flash removal in the weld.

13.1 The tubes shall be furnished clean and free of scale.

6. Strip Heat Treatment 14. Mechanical Tests

14.1 Tension Test—Two tubes shall be selected from each

6.1 The tubes shall be manufactured from strip solution heat

lot (Note 2) and subjected to the tension test.

treated by heating the material to a minimum temperature of

14.2 Flattening Test—One flat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.