ASTM F319-91a(1997)e1

(Practice)Standard Practice for Polarized Light Detection of Flaws in Aerospace Transparency Heating Elements

Standard Practice for Polarized Light Detection of Flaws in Aerospace Transparency Heating Elements

SCOPE

1.1 This practice describes a standard procedure for detecting flaws in the conductive coating (heater element) by the observation of polarized light patterns.

1.2 This practice applies to coatings on surfaces of monolithic transparencies as well as to coatings imbedded in laminated structures.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 6.

1.4 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: F 319 – 91a (Reapproved 1997)

Standard Practice for

Polarized Light Detection of Flaws in Aerospace

Transparency Heating Elements

This standard is issued under the fixed designation F 319; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Keywords were added editorially in April 1997.

INTRODUCTION

Electrically conductive coatings used in aerospace transparencies for heating purposes may contain

flaws resulting from imperfections of materials, imperfections of manufacturing techniques, handling

damage, or contamination. Flaws may develop before, during, or after coating and processing and

usually appear as hairline cracks, scratches, or pin holes. When these flaws are of sufficient size, hot

spots can occur as a result of disruption and concentration of the flow of electrical current adjacent to

the flaws. These hot spots may result in reduced service life of the transparency. Hot spot flaws in the

transparency may also produce undesirable temporary distortion of vision during powered operation

of the heater and permanent vision distortion after repeated cycling of the heater.

Polarized light is widely used to detect electrically conductive coating flaws during aerospace

transparency processing.

1. Scope discontinuity in the coating, caused generally by coating

cracks, pin holes, fine threads, scratches, etc.

1.1 This practice describes a standard procedure for detect-

ing flaws in the conductive coating (heater element) by the

3. Summary of Practice

observation of polarized light patterns.

3.1 Flaws in electrically powered conductive coatings pro-

1.2 This practice applies to coatings on surfaces of mono-

duce local concentrations of current which result in tempera-

lithic transparencies as well as to coatings imbedded in

ture gradients and stresses. Since glass and plastic transparen-

laminated structures.

cies are birefringent when stressed, flaws can be detected by

1.3 This standard does not purport to address all of the

optical methods, and in this case by the use of polarized light.

safety concerns, if any, associated with its use. It is the

3.2 This practice consists of directing polarized light

responsibility of the user of this standard to establish appro-

through a heated transparent test specimen and reading the

priate safety and health practices and determine the applica-

transmitted light with a polarizing screen or filter. Diffracted

bility of regulatory limitations prior to use. For specific

light from the region of the flaw will become visible, in the

precautionary statements see Section 6.

form of a brighter or more intense local image, usually shaped

1.4 The values stated in SI units are to be regarded as the

like a butterfly.

standard. The values in parentheses are for information only.

4. Significance and Use

2. Terminology

4.1 This practice is useful as a screening basis for accep-

2.1 Definitions:

tance or rejection of transparencies during manufacturing so

2.1.1 transparent conductive coating—a transparent thin

that units with identifiable flaws will not be carried to final

film of electrically conductive material such as gold, stannous

inspection for rejection at that time.

oxide, or indium oxide applied to plastic or glass which, when

4.2 This practice may also be employed as a go-no go

bounded by connecting bus-bars energized by electricity,

technique for acceptance or rejection of the finished product.

becomes a resistance type heating element.

4.3 This practice is simple, inexpensive, and effective.

2.1.2 electrically conductive coating flaw—an electrical

Flaws identified by this practice, as with other optical methods,

are limited to those which produce temperature gradients when

This practice is under the jurisdiction of ASTM Committee F-7 on Aerospace

electrically powered. Any other type of flaw, such as minor

and Aircraft and is the direct responsibility of Subcommittee F07.08 on Transparent

scratches parallel to the direction of electrical flow, are not

Enclosures and Materials.

detectable.

Current edition approved Dec. 15, 1991. Published February 1992. Originally

published as F 319 – 77. Last previous edition F 319 – 91. 4.4 If another method (equally suitable for flaw detection) is

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 319

designated for final optical inspection of the laminated part 5.2.1 Uniform Light Source, such as a bank of fluorescent

under power, the polarized light practice will not be required lamps.

for the final inspection. 5.2.2 Translucent Light Diffusion Plate, such as milk-white

glass located so as to provide a uniform light distribution.

5. Apparatus

5.2.3 Polarizing Screen, which converts the diffused light to

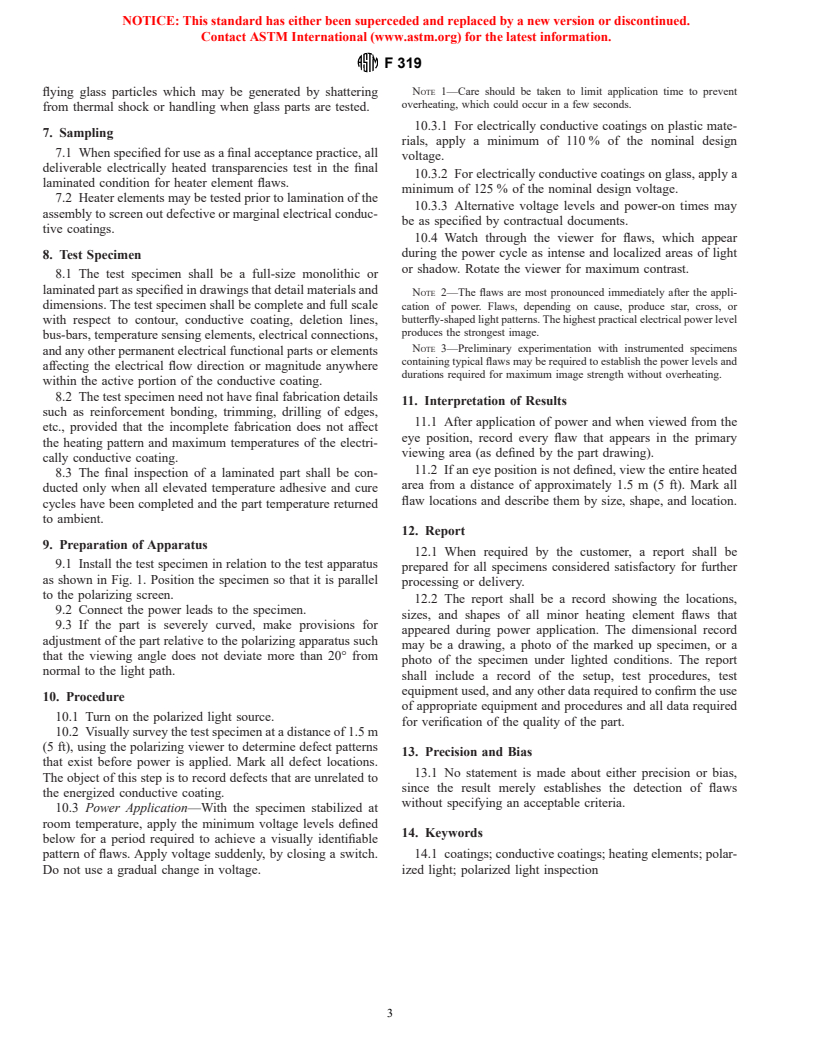

5.1 The elements of the apparatus are detailed below in their

polarized light.

physical relationship as shown in Fig. 1. The minimum size

5.2.4 Transparent Dust Shield (optional).

and spacing of the elements of the apparatus are determined by

5.2.5 Support for the specimen.

the size and curvature of the part. The size of light source, light

5.2.6 Polarizing Viewer, hand-held or mounted so it can be

diffuser, and polarizing screen shall be large enough so that

rotated to give maximum contrast as an analyzer.

every portion of the electrically coated area of the test

5.2.7 Electrical Power Supply, regulated.

specimen is in the light path and is uniformly back lighted. If

5.2.8 Timer, for controlling power application.

the test specimen is curved severely, its position may have to

5.2.9 Meters, for measuring power input to heater element.

be adjusted during inspection so that the light path is within

6. Safety Precautions

20° of normal to the location being viewed. Since specimen

size and curvature vary considerably, a dimensionally fixed 6.1 This practice requires application of high voltages.

standard is not given. Exercise precautions to prevent direct or indirect exposure of

5.2 The apparatus, in the order of assembly, consists of the test personnel to terminals, test leads, etc.

following: 6.2 Wear protective glasses to prevent damage to eyes by

FIG. 1 Typical Arrangement for Polar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.