ASTM D2249-01

(Test Method)Standard Test Method for Predicting the Effect of Weathering on Face Glazing and Bedding Compounds on Metal Sash (Withdrawn 2002)

Standard Test Method for Predicting the Effect of Weathering on Face Glazing and Bedding Compounds on Metal Sash (Withdrawn 2002)

SCOPE

1.1 This test method covers an accelerated procedure for predicting the effect of weathering on adhesion, surface cracking and peeling, deep bead cracking, oil exudation, and wrinkling of face glazing or bedding compounds, or both, intended for exterior use on steel, aluminum, or other metal sash.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The committee with jurisdiction over this standard is not aware of any equivalent standard published by other ASTM committees, ISO or any other standards organizations.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 2249 – 01

Standard Test Method for

Predicting Effect of Weathering on Face Glazing and

1

Bedding Compounds on Metal Sash

This standard is issued under the fixed designation D 2249; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

1.1 This test method covers an accelerated procedure for 4.1 The test compound is pressed with a knife into a special

predicting the effect of weathering on adhesion, surface crack- aluminum muntin bar/glass assembly which simulates both

ing and peeling, deep bead cracking, oil exudation, and face glazing and bedding applications. Each test compound is

wrinkling of face glazing or bedding compounds, or both, run in duplicate. The compound is then exposed in an accel-

intended for exterior use on steel, aluminum, or other metal erated weathering unit for a period up to 300 h. Loss of

sash. adhesion, wrinkling, surface cracking and peeling, deep bead

1.2 The values stated in inch-pound units are to be regarded cracking, and oil exudation are observed and recorded.

as the standard. The values given in parentheses are for

5. Significance and Use

information only.

1.3 The committee with jurisdiction over this standard is not 5.1 The effect of accelerated weathering will assist in

judging the quality and predicting the performance of glazing

aware of any equivalent standard published by other ASTM

committees, ISO or any other standards organizations. compounds. Accelerated weathering devices should not, how-

ever, be used to predict the exact number of years of service

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the life, or the exact type of failure which will occur under all the

varied conditions encountered in actual use.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

6. Apparatus and Materials

bility of regulatory limitations prior to use.

6.1 Accelerated Weathering Unit—As described in Prac-

2. Referenced Documents

tices G 151 and G 153, equipped with water spray and an

un-insulated black panel thermometer. The instrument must

2.1 ASTM Standards:

2

C 717 Terminology of Building Seals and Sealants also be capable of being programmed for a repeating cycle of

102 minutes light followed by 18 minutes of light plus water

D 1730 Practices for Preparation of Aluminum and

3

Aluminum-Alloy Surfaces for Painting spray.

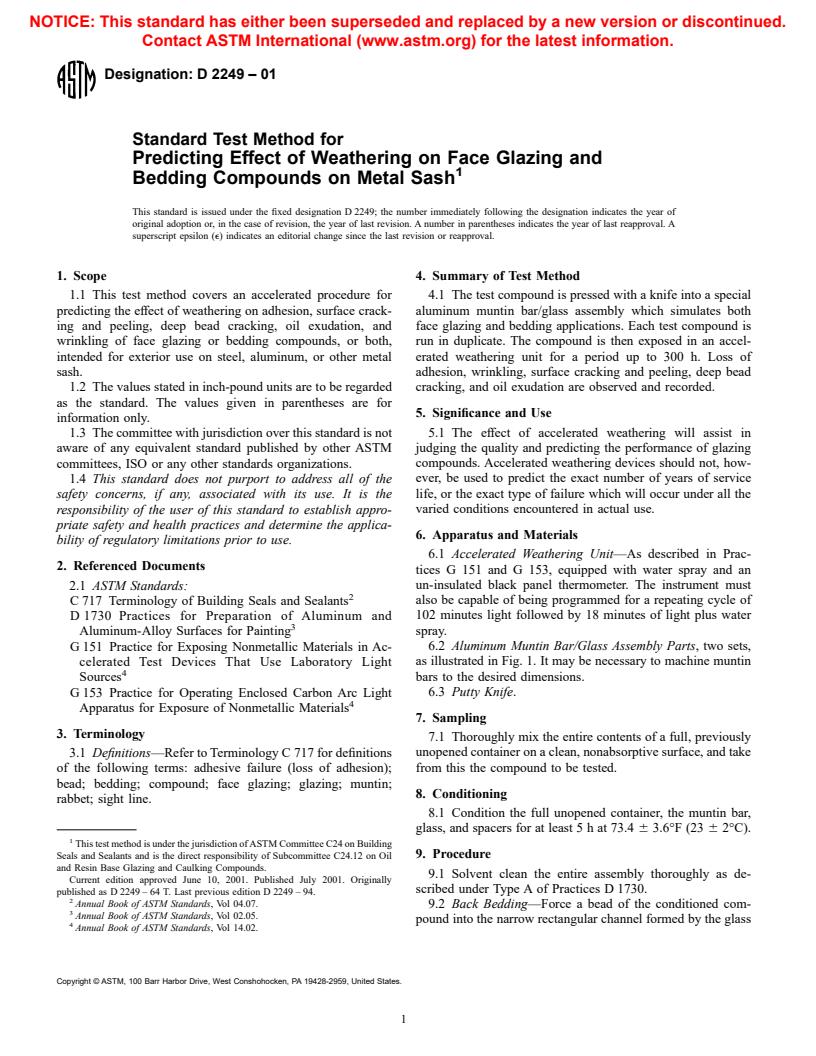

6.2 Aluminum Muntin Bar/Glass Assembly Parts, two sets,

G 151 Practice for Exposing Nonmetallic Materials in Ac-

as illustrated in Fig. 1. It may be necessary to machine muntin

celerated Test Devices That Use Laboratory Light

4

Sources bars to the desired dimensions.

6.3 Putty Knife.

G 153 Practice for Operating Enclosed Carbon Arc Light

4

Apparatus for Exposure of Nonmetallic Materials

7. Sampling

3. Terminology

7.1 Thoroughly mix the entire contents of a full, previously

3.1 Definitions—Refer to Terminology C 717 for definitions unopened container on a clean, nonabsorptive surface, and take

from this the compound to be tested.

of the following terms: adhesive failure (loss of adhesion);

bead; bedding; compound; face glazing; glazing; muntin;

8. Conditioning

rabbet; sight line.

8.1 Condition the full unopened container, the muntin bar,

glass, and spacers for at least5hat 73.4 6 3.6°F (23 6 2°C).

1

This test method is under the jurisdiction of ASTM Committee C24 on Building

9. Procedure

Seals and Sealants and is the direct responsibility of Subcommittee C24.12 on Oil

and Resin Base Glazing and Caulking Compounds.

9.1 Solvent clean the entire assembly thoroughly as de-

Current edition approved June 10, 2001. Published July 2001. Originally

scribed under Type A of Practices D 1730.

published as D 2249 – 64 T. Last previous edition D 2249 – 94.

2

Annual Book of ASTM Standards, Vol 04.07.

9.2 Back Bedding—Force a bead of the conditioned com-

3

Annual Book of ASTM Standards, Vol 02.05.

pound into the narrow rectangular channel formed by the glass

4

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 2249

TABLE 1 METRIC EQUIVALENTS

1 3 1 1 3 1 1

in. ⁄16 ⁄8 ⁄4 ⁄2 ⁄4 1 1 ⁄8 1 ⁄2 8 9

mm 1.6 3.2 6.4 12.7 19 25.4 28.6 38 203 229

FIG. 1 Aluminum Muntin Bar/Glass Assembly

and the aluminum as shown in Fig. 1, taking care to ensure that 9.6 After each exposure, remove the assemblies and exam-

the compound completely fills the space with no voids. ine

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.