ASTM C1517-02

(Test Method)Standard Test Method for Determination of Metallic Impurities in Uranium Metal or Compounds by DC-Arc Emission Spectroscopy

Standard Test Method for Determination of Metallic Impurities in Uranium Metal or Compounds by DC-Arc Emission Spectroscopy

SIGNIFICANCE AND USE

This test method is applicable to uranium metal, uranium oxides and compounds soluble in nitric or sulfuric acid, and uranium solutions which can be converted to uranium oxide (U3O8) in a muffle furnace. It may be used to determine the impurities in uranium compounds as listed in Specifications C 753, C 776, C 788, and C 967.

SCOPE

1.1 This test method describes the steps necessary for the preparation and determination of impurity metals in uranium metal and uranium compounds by DC arc emission spectroscopy.

1.2 The method is valid for those materials that can be dissolved in acid and/or converted to an oxide in a muffle furnace (see Practice C 1347).

1.3 This method uses the carrier distillation technique to selectively carry the impurities into the arc, leaving the uranium oxide in the electrode. If it is necessary to determine the carrier metal(usually a silver or strontium, or gallium compound) as an impurity, another technique must be chosen for that element.

1.4 This standard may involve hazardous materials, operations and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1517–02

Standard Test Method for

Determination of Metallic Impurities in Uranium Metal or

Compounds by DC-Arc Emission Spectroscopy

This standard is issued under the fixed designation C1517; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Emission Spectrographic Analysis

E116 Practice for Photographic Photometry in Spectro-

1.1 This test method describes the steps necessary for the

chemical Analysis

preparation and determination of impurity metals in uranium

E130 Practice for Designation of Shapes and Sizes of

metal and uranium compounds by DC arc emission spectros-

Graphite Electrode

copy.

E135 Terminology Relating to Analytical Chemistry for

1.2 The method is valid for those materials that can be

Metals, Ores and Related Materials

dissolved in acid and/or converted to an oxide in a muffle

E402 TestMethodforSpectrographicAnalysisofUranium

furnace (see Practice C1347).

Oxide (U O ) by Gallium Oxide Carrier Technique

3 8

1.3 This method uses the carrier distillation technique to

selectively carry the impurities into the arc, leaving the

3. Terminology

uranium oxide in the electrode. If it is necessary to determine

3.1 See definitions and terms in Terminologies C859 and

the carrier metal(usually a silver or strontium, or gallium

E135.

compound) as an impurity, another technique must be chosen

for that element.

4. Summary of Test Method

1.4 This standard may involve hazardous materials, opera-

4.1 Uranium metal, solutions and compounds are converted

tionsandequipment.Thisstandarddoesnotpurporttoaddress

to uranium oxide (U O ) in a muffle furnace. A weighed

3 8

all of the safety concerns, if any, associated with its use. It is

amount of the oxide is mixed with an appropriate spectro-

the responsibility of the user of this standard to establish

graphic carrier and loaded into a graphite electrode. The

appropriate safety and health practices and determine the

electrode is excited in a DC arc and the light is dispersed by a

applicability of regulatory limitations prior to use.

spectrograph or spectrometer. The resulting spectrum is mea-

sured electronically or photographed on photographic plates or

2. Referenced Documents

film sensitive to the proper regions. The line intensities are

2.1 ASTM Standards:

compared directly to standard plates or to calibration curves

C753 Specification for Nuclear Grade, Sinterable Uranium

2 derived from the arced standards.

Dioxide Pellets

C761 Test Methods for Chemical, Mass Spectrometric,

5. Significance and Use

Spectrochemical, Nuclear, and RadiochemicalAnalysis of

5.1 This test method is applicable to uranium metal, ura-

Uranium Hexafluoride

2 nium oxides and compounds soluble in nitric or sulfuric acid,

C776 Specification for Sintered Uranium Dioxide Pellets

and uranium solutions which can be converted to uranium

C788 Specification for Nuclear Grade Uranyl Nitrate So-

2 oxide (U O ) in a muffle furnace. It may be used to determine

3 8

lutions

theimpuritiesinuraniumcompoundsaslistedinSpecifications

C859 Terminology Relating to Nuclear Materials

2 C753, C776, C788, and C967.

C967 Specification for Uranium Ore Concentrate

C1347 PracticeforPreparationandDissolutionofUranium

6. Apparatus

Materials for Analysis

6.1 Spectrograph—Aspectrograph with sufficient resolving

E 115 Practice for Photographic Processing in Optical

power and linear dispersion to separate the analytical lines

from other lines in the spectrum of the sample in the spectral

region of 230.0 to 855.0 nm is required. Instruments with a

ThistestmethodisunderthejurisdictionofASTMCommitteeC26onNuclear

reciprocal linear dispersion in the first order of 0.5 nm/mm or

Fuel Cycle and is the direct responsibility of Subcommittee C26.05 on Test

Methods.

Current edition approved Jan. 10, 2002. Published May 2002.

2 3

Annual Book of ASTM Standards, Vol 12.01. Annual Book of ASTM Standards, Vol 03.05.

Annual Book of ASTM Standards, Vol 03.06.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

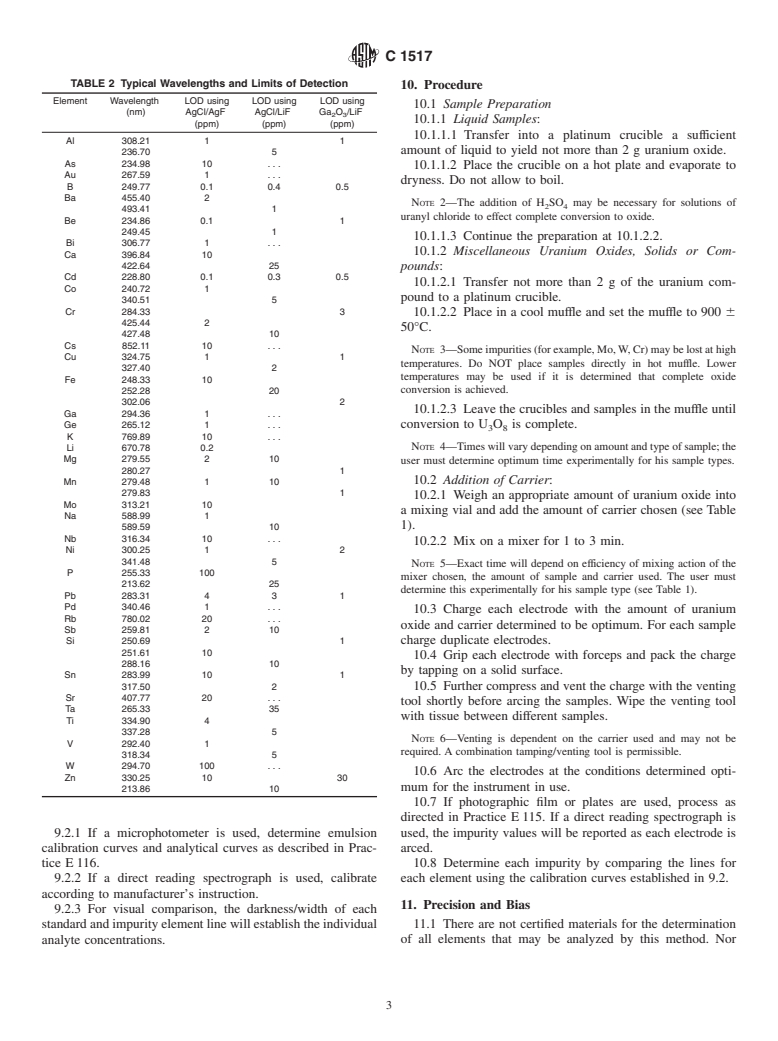

C1517

less are satisfactory. A direct-reading spectrometer of compa- 7.10 Standard Uranium Oxide (U O ) Diluent—Use NBL

3 8

rable quality may be substituted for equipment listed, in which CRM 129 (or its replacement or equivalent) of known impu-

case the directions given by the manufacturer should be rity level as a diluent.

substituted for those in this procedure.

8. Precautions

6.2 Excitation Source—Use an arc power source capable of

providing a dc arc of up to 14-A dc, depending on the carrier 8.1 Consult manufacturer’s Material Safety Data Sheets

used and electrode design.

(MSDS) for chemical incompatibilities, specific hazards, or

spill cleanup for any hazardous materials used in this method.

6.3 Excitation Stand—Conventional type with adjustable

water-cooled electrode holders (may be fitted with automatic 8.2 All mixing and weighing operations involving uranium

oxides should be carried out in properly functioning hoods or

sample changers if desired).

exhaust boxes.

6.4 Photographic Processing Equipment—Use developing,

fixing, washing and drying equipment conforming to Practice

9. Standardization and Calibration

E115.

9.1 Standards:

6.5 Microphotometer, having a precision of at least 61%

9.1.1 Standards may be synthesized by adding the impurity

for transmittances.

elementstopurifiedU O (NBLCRM129 ,orequivalent)and

6.6 Mixer, for dry materials.

3 8

homogenizing. Impurities in powder form, preferably as ox-

6.7 Platinum Crucible.

ides, may be blended in U O ; impurities in solution may be

3 8

6.8 Venting Tool, (see Fig. 1, Test Method E402 or Fig. 8,

addedtoU O andthemixturedried,blendedandreignited,or

3 8

Test Methods C761).

the impurities and uranium may be combined in solution and

6.9 Muffle Furnace, 1000°C capability.

reconverted to U O . The individual elements should grade in

3 8

such a ratio as to facilitate visual comparisons covering the

7. Reagents and Materials

desired analytical range for each.

7.1 Purity of Materials—Reagent grade chemicals shall be

9.1.2 The compounds used to make U O impurity stan-

3 8

used in all tests. Unless otherwise indicated, it is intended that

dards should be of the highest purity available.

all reagents conform to the specifications of the Committee of

9.1.3 Alternatively, commercially available uranium impu-

Analytical Reagents of theAmerican Chemical Society where

rity standards, such as NBL CRM 123 and 124 series

such specifications are available. Other grades may be used

standards,maybeused.(Otherstandardsmaybeavailable;the

provided it is first ascertained that the reagent is of sufficiently

usershoulddeterminequalityand/orapplicabilitypriortouse.)

high purity to permit its use without lessening the accuracy of

These may be supplemented by synthetic standards to extend

the determination.

calibration ranges, if necessary.

7.2 Electrodes—The anode and counter electrodes should

9.1.4 For each standard used, prepare in the same ratio of

beoftheS-2,S16andC-1typesasgiveninPracticeE130(or uranium oxide to carrier as for samples (seeTable 1 for further

equivalent).

details).

9.1.5 Charge the electrode and arc at the same conditions as

NOTE 1—Exact shapes and dimensions of the electrodes are not as

determined to be optimum for the instrument in use.

critical as given in Practice E130; however, dimensions of the electrodes

9.2 Calibration Curves:

used should be consistent and it is essential that the same dimension

electrodes be used for standards and samples.

7.3 Photographic Processing Solutions—Prepare solutions

as noted in Practice E115. 5

Available from the US Department of Energy, New Brunswick Laboratory, D

350,9800SouthCassAvenue,Argonne,IL60439,ATTN:ReferenceMaterialSales.

7.4 Photographic Film/Plates—Use photo emulsion SA-1

and 1-N or equivalent.

TABLE 1 Carrier—Sample Combinations

7.5 Powder Paper.

Carrier Carrier Wt, Oxide Wt, Electrode Mixing Time,

7.6 Nitric Acid (HNO )—concentrated (70%), electronic

Material (mg) (mg) Charge, (mg) (s)

grade, or equivalent.

Ag

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.