ASTM F1760-97

(Specification)Standard Specification for Coextruded Poly(Vinyl Chloride) (PVC) Non-Pressure Plastic Pipe Having Reprocessed-Recycled Content

Standard Specification for Coextruded Poly(Vinyl Chloride) (PVC) Non-Pressure Plastic Pipe Having Reprocessed-Recycled Content

SCOPE

1.1 This specification has been published in response to the special circumstance of regulatory requirements regarding federal procurement guidelines for plastic pipe having recycled content.

1.2 This specification covers coextruded Poly(Vinyl Chloride) (PVC) plastic pipe with a center layer and concentric inner and outer solid layers. The pipe is produced using a multi-layer coextrusion die. The inner and outer layers are made of virgin PVC compound and the center layer has reprocessed-recycled PVC content. The pipe is for non-pressure use in three series:

1.2.1 Sewer-Drain series with a sewer-pipe outside diameter and a pipe stiffness of 46 psi (320 kPa),

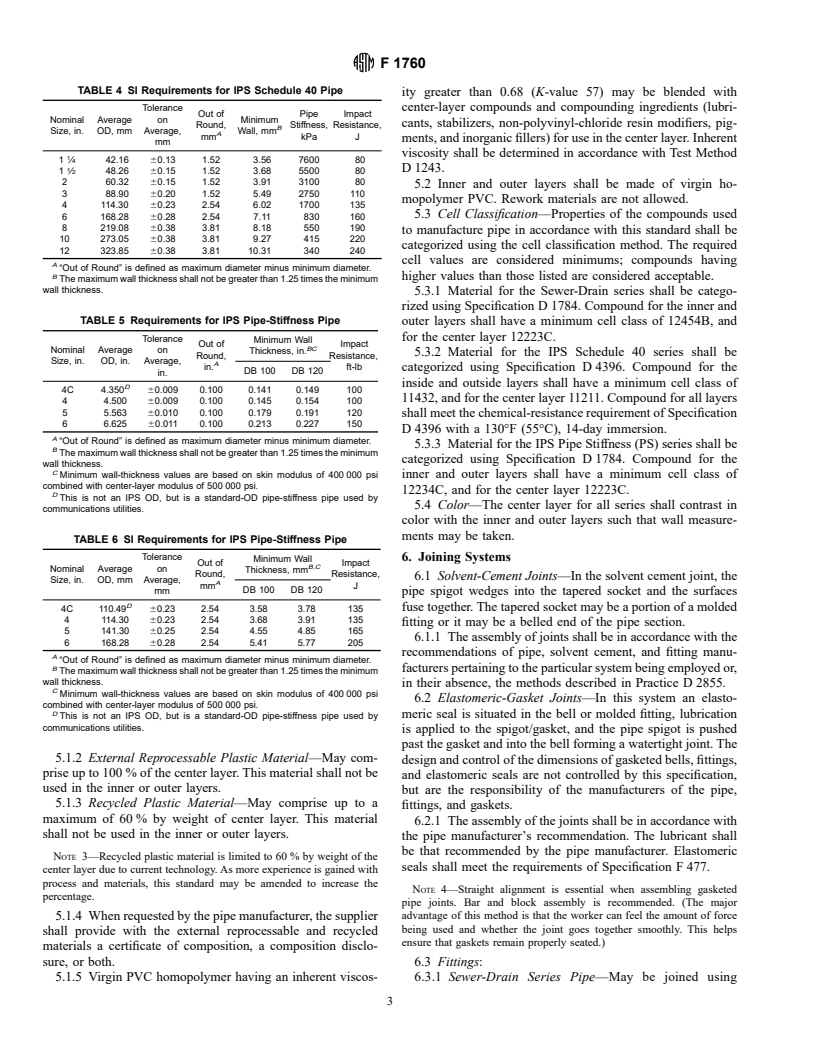

1.2.2 IPS Schedule 40 series, and

1.2.3 IPS Pipe Stiffness (PS) series with pipe stiffnesses of 100 psi (690 kPa) and 120 psi (830 kPa).

1.3 Pipe that is outside-diameter controlled does not necessarily have an inside diameter suitable for use as a fitting socket.

1.4 All series may be perforated.

1.5 The values stated in inch-pound units are to be regarded as the standard. The SI values are provided for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1760 – 97 An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Coextruded Poly(Vinyl Chloride) (PVC) Non-Pressure Plastic

1

Pipe Having Reprocessed-Recycled Content

This standard is issued under the fixed designation F 1760; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope pounds and Chlorinated Poly(Vinyl Chloride) (CPVC)

2

Compounds

1.1 This specification has been published in response to the

D 2122 Test Method for Determining Dimensions of Ther-

special circumstance of regulatory requirements regarding

3

moplastic Pipe and Fittings

federal procurement guidelines for plastic pipe having recycled

D 2412 Test Method for Determination of External Loading

content.

3

Characteristics of Plastic Pipe by Parallel-Plate Loading

1.2 This specification covers coextruded Poly(Vinyl Chlo-

D 2444 Test Method for Impact Resistance of Thermoplas-

ride) (PVC) plastic pipe with a center layer and concentric

3

tic Pipe and Fittings by Means of a Tup (Falling Weight)

inner and outer solid layers. The pipe is produced using a

D 2466 Specification for Poly(Vinyl Chloride) (PVC) Plas-

multi-layer coextrusion die. The inner and outer layers are

3

tic Pipe Fittings, Schedule 40

made of virgin PVC compound and the center layer has

D 2665 Specification for Poly(Vinyl Chloride) (PVC) Plas-

reprocessed-recycled PVC content. The pipe is for non-

3

tic Drain, Waste, and Vent Pipe and Fittings

pressure use in three series:

D 2855 Practice for Making Solvent-Cemented Joints with

1.2.1 Sewer-Drain series with a sewer-pipe outside diameter

3

Poly(Vinyl Chloride) (PVC) Pipe and Fittings

and a pipe stiffness of 46 psi (320 kPa),

D 3034 Specification for Type PSM Poly(Vinyl Chloride)

1.2.2 IPS Schedule 40 series, and

3

(PVC) Sewer Pipe and Fittings

1.2.3 IPS Pipe Stiffness (PS) series with pipe stiffnesses of

D 3212 Specification for Joints for Drain and Sewer Plastic

100 psi (690 kPa) and 120 psi (830 kPa).

3

Pipes Using Flexible Elastomeric Seals

1.3 Pipe that is outside-diameter controlled does not neces-

D 4396 Specification for Rigid Poly(Vinyl Chloride) (PVC)

sarily have an inside diameter suitable for use as a fitting

Compounds and Chlorinated Poly(Vinyl Chloride) (PVC)

socket.

Compounds for Plastic Pipe and Fittings Used in Nonpres-

1.4 All series may be perforated.

4

sure Applications

1.5 The values stated in inch-pound units are to be regarded

3

F 412 Terminology Relating to Plastic Piping Systems

as the standard. The SI values are provided for information

F 477 Specification for Elastomeric Seals (Gaskets) for

only.

3

Joining Plastic Pipe

1.6 This standard does not purport to address all of the

F 512 Specification for Smooth-Wall Poly(Vinyl Chloride)

safety concerns, if any, associated with its use. It is the

3

(PVC) Conduit and Fittings for Underground Installation

responsibility of the user of this standard to establish appro-

F 1336 Specification for Poly(Vinyl Chloride) (PVC) Gas-

priate safety and health practices and determine the applica-

3

keted Sewer Fittings

bility of regulatory limitations prior to use.

F 1365 Test Method for Water Infiltration Resistance of

2. Referenced Documents Plastic Underground Conduit Joints Which Use Flexible

3

Elastomeric Seals

2.1 ASTM Standards:

5

2

2.2 Plastic Pipe Institute Technical Report:

D 883 Terminology Relating to Plastics

PPI-TR-7 Recommended Method for Calculation of Nomi-

D 1243 Test Method for Dilute Solution Viscosity for Vinyl

2

nal Weight of Plastic Pipe

Chloride Polymers

D 1600 Terminology for Abbreviated Terms Relating to

3. Terminology

2

Plastics

3.1 Definitions—Definitions are in accordance with Termi-

D 1784 Specification for Rigid Poly(Vinyl Chloride) Com-

nologies D 883, D 1600, and F 412, unless otherwise indicated.

3.1.1 coextrusion—a process whereby two or more plastic

1

This specification is under the jurisdiction of ASTM Committee F-17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.25 on Vinyl

3

Based Pipe. Annual Book of ASTM Standards, Vol 08.04.

4

Current edition approved October 10, 1997. Published October 1998. Originally Annual Book of ASTM Standards, Vol 08.03.

5

published as F 1760–96. Last previous edition F 1760–96e1. Available from Plastic Pipe Institute, 1275 K Street NW, Suite 400, Washing-

2

Annual Book of ASTM Standards, Vol 08.01. ton, DC 20005.

1

---------------------- Page: 1 ----------------------

F 1760

TABLE 2 SI Requirements for Sewe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.