ASTM B250/B250M-01e1

(Specification)Standard Specification for General Requirements for Wrought Copper Alloy Wire

Standard Specification for General Requirements for Wrought Copper Alloy Wire

SCOPE

1.1 This specification establishes requirements common to wrought copper alloy wire and shall apply to Specifications B 16/B 16M, B 99/B 99M, B 134/B 134M, B 159/B 159M, B 197/B 197M, B 206/B 206M, B 272, and B 301/B 301M to the extent referenced therein.

1.2 The chemical composition, physical and mechanical properties, and all other requirements not included in this specification shall be prescribed in the product specification.

1.3 UnitsThe values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: B 250/B 250M – 01

Standard Specification for

1

General Requirements for Wrought Copper Alloy Wire

This standard is issued under the fixed designation B 250/B 250M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

e NOTE—Table 2 was editorially corrected in April 2005.

1. Scope* B 272 Specification for Copper Flat Products with Finished

(Rolled or Drawn) Edges (Flat Wire and Strip)

1.1 This specification establishes requirements common to

B 301/B 301M Specification for Free-Cutting Copper Rod

wrought copper alloy wire and shall apply to Specifications

and Bar and Shapes

B 16/B 16M, B 99/B 99M, B 134/B 134M, B 159/B 159M,

B 846 Terminology for Copper and Copper Alloys

B 197/B 197M, B 206/B 206M, B 272, and B 301/B 301M to

E3 Practice for Preparation of Metallographic Specimens

the extent referenced therein.

E8 Test Methods for Tension Testing of Metallic Materials

1.2 The chemical composition, physical and mechanical

E8M Test Methods for Tension Testing of Metallic Mate-

properties, and all other requirements not included in this

rials [Metric]

specification shall be prescribed in the product specification.

E18 Test Methods for Rockwell Hardness and Rockwell

1.3 Units—The values stated in either SI units or inch-

Superficial Hardness of Metallic Materials

pound units are to be regarded separately as standard. The

E 18M Test Methods for Rockwell Hardness and Rockwell

values stated in each system may not be exact equivalents;

3

Superficial Hardness of Metallic Materials [Metric]

therefore,eachsystemshallbeusedindependentlyoftheother.

E29 Practice for Using Significant Digits in Test Data to

Combining values from the two systems may result in non-

Determine Conformance with Specifications

conformance with the standard.

E54 Test Methods for Chemical Analysis of Special

3

2. Referenced Documents

Brasses and Bronzes

2

E62 Test Methods for Chemical Analysis of Copper and

2.1 ASTM Standards:

Copper Alloys (Photometric Methods)

B 16/B 16M Specification for Free-Cutting Brass Rod, Bar,

E75 Test Methods for ChemicalAnalysis of Copper-Nickel

and Shapes for Use in Screw Machines

and Copper-Nickel-Zinc Alloys

B 99/B 99M Specification for Copper-Silicon Alloy Wire

E112 Test Methods for Determining Average Grain Size

for General Applications

E118 Test Methods for Chemical Analysis of Copper-

B 134/B 134M Specification for Brass Wire

Chromium Alloys

B 159/B 159M Specification for Phosphor Bronze Wire

E 121 Test Methods for Chemical Analysis of Copper-

B 193 Test Method for Resistivity of Electrical Conductor

Tellurium Alloys

Materials

E 255 Practice for Sampling Copper and CopperAlloys for

B 194 Copper-Beryllium Alloy Plate, Strip, Sheet, and

the Determination of Chemical Composition

Rolled Bar

E 478 Test Methods for Chemical Analysis of Copper

B 197/B 197M Specification for Copper-Beryllium Alloy

Alloys

Wire

E 581 Test Methods for Chemical Analysis of Manganese-

B 206/B 206M Specification for Copper-Nickel-Zinc Alloy

Copper Alloys

(Nickel Silver) Wire and Copper-Nickel Alloy Wire

3. Terminology

3.1 For definitions of terms related to copper and copper

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

alloys, refer to Terminology B 846.

and CopperAlloys and is the direct responsibility of Subcommittee B05.02 on Rod,

Bar, Wire, Shapes, and Forgings.

4. Materials and Manufacture

Current edition approved April 15, 2005. Published February 2002. Originally

approved in 1951. Last previous edition approved in 1995 as B 250 – 95.

4.1 Materials:

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

3

the ASTM website. Withdrawn.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

e1

B 250/B 250M – 01

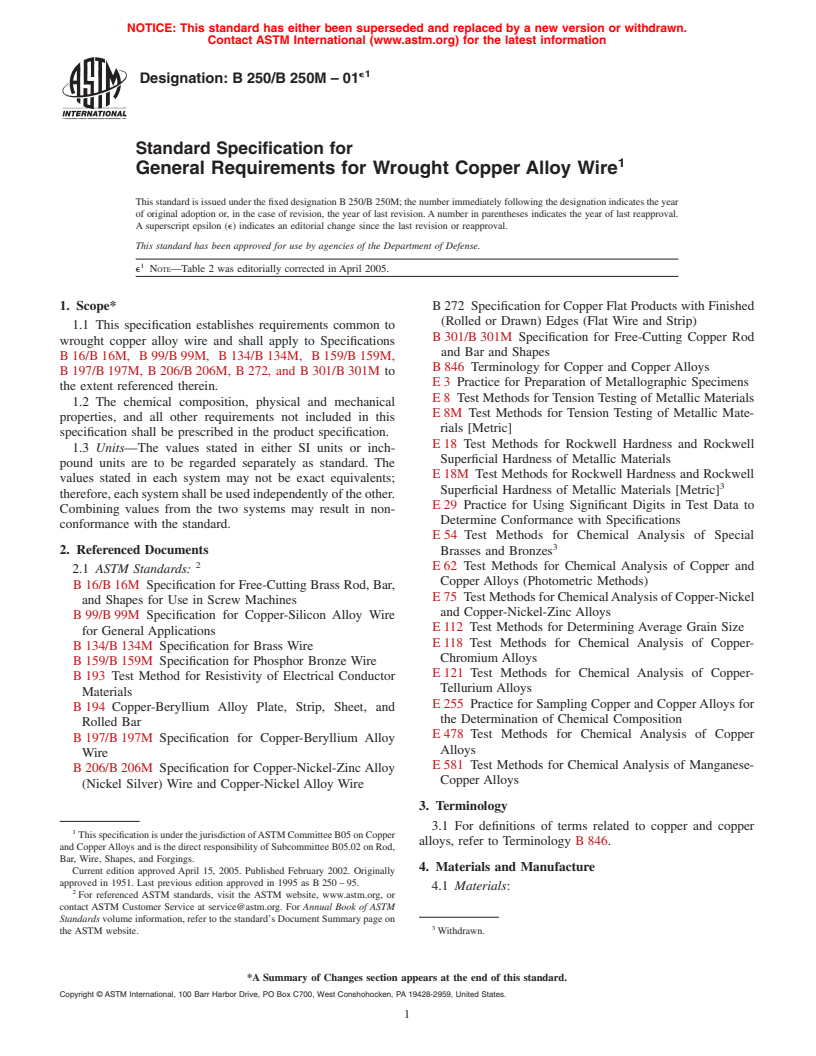

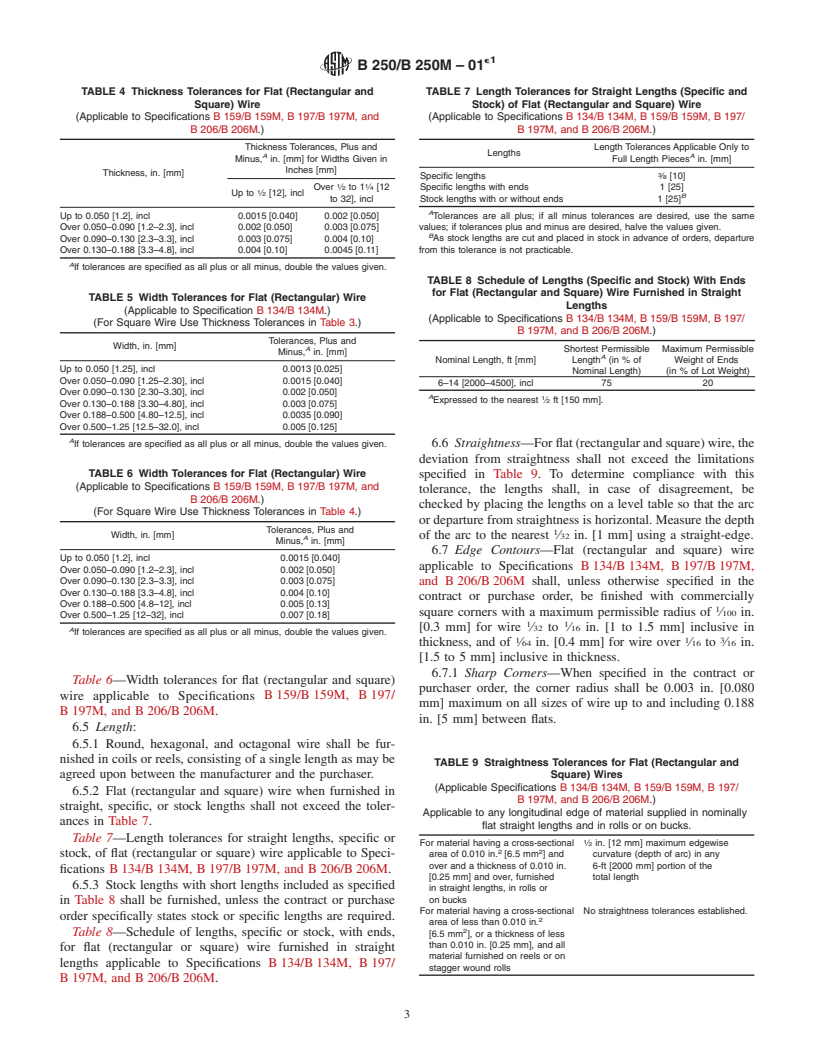

TABLE 1 Tolerances for Diameter or Distance Between Parallel

4.1.1 The materials shall conform to the published compo-

Surfaces of Wire

sitional requirements of the Copper Alloy UNS No. designa-

(Applicable to Specifications B 16/B 16M, B 99/B 99M Copper Alloy

tion specified in the ordering information.

UNS No. C65100, B 134/B 134M, and B 301/B 301M.)

4.1.2 In the event heat identification or traceability is

A

Diameter or Distance

Tolerances, Plus and Minus

required, the purch

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.