ASTM A970/A970M-04ae1

(Specification)Standard Specification for Headed Steel Bars for Concrete Reinforcement

Standard Specification for Headed Steel Bars for Concrete Reinforcement

SCOPE

1.1 This specification covers deformed and plain steel reinforcing bars in cut lengths, witha head(s) attached to one or both ends, for concrete reinforcement. Attachment can be accomplished through welding or forging of heads onto the bar ends, by internal threads in the head mating to threads on the bar end or by a separate threaded nut to secure the head to the bar. Heads are forge formed, machined from bar stock, or cut from plate.

Note 1—This specification is applicable for headed bars produced with welded, threaded, or forged heads and used for reinforcement of concrete structures. The requirements of this specification are not applicable to headed bars where the attachment of the head is accomplished by alternate means.

1.2 Grade—Headed bars are of a single minimum yield strength level of 420 MPa [60 000 psi], designated as Grade 420 [60].

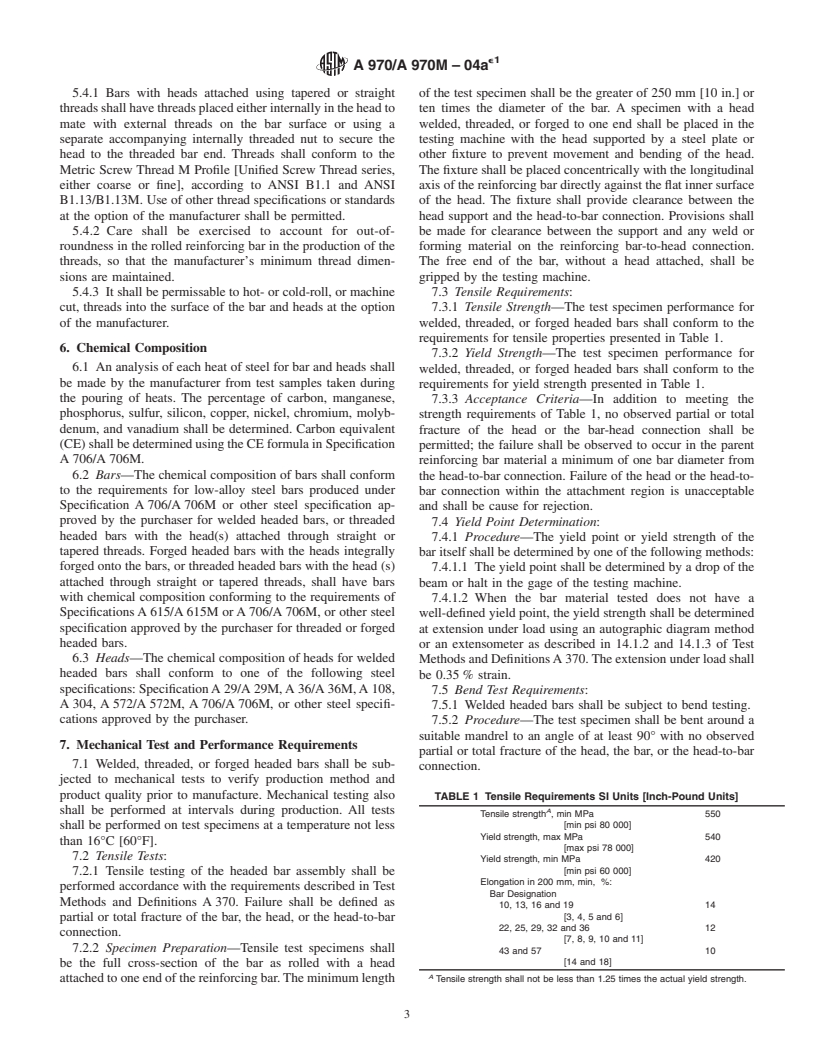

1.3 Controlled Mechanical Properties and Performance Requirements—This specification by use of tensile and bend tests and the specified minimum performance levels in Sections 7 and 8 provides the required performance properties for these assemblies.

1.4 Welding, Threading, and Forging

1.4.1 Welding of heads to the reinforcing steel shall be approached with care. A welding procedure conforming to ANSI/AWS D1.4 shall be used for all required production welding of the head to the bar, except for friction welding that shall conform to ANSI/AWS C6.1.

1.4.2 Forging—Integrally forged headed bars where the heads are produced by deforming the bar ends in a hot forging process also are acceptable.

1.4.3 Threading—It shall be permissable to attach the head(s) to the reinforcing bar using straight or tapered internal threads within the head or by securing the head to the threaded bar end with a separate internally threaded nut.

1.4.4 Low-Alloy Steel Bars—Low-alloy steel reinforcing bars conforming to Specification A 706/A 706M shall be used to manufacture welded headed bars. Specification A 706/A 706M limits chemical composition and carbon equivalence to enhance weldablity of the material.

1.4.5 Reinforcing bar material conforming to A 615/A 615M or A 706/A 706M is acceptable for the production of threaded or forged headed bars.

1.4.6 Other types of steel reinforcing bars shall be permitted: (1) providing they conform to the dimensional and weight requirements of the reinforcement as specified in 1.4.4 or 1.4.5, as applicable, and (2) when specified and agreed upon by the purchaser and the manufacturer and only when the suitability of the head and bar materials for the welding, threading, or forging process specified is demonstrated through successful application of the requirements for testing and frequency of testing in Sections 7 and 8 of this specification.

1.4.7 All reinforcing bars shall conform to the mechanical performance requirements of this specification.

1.5 This specification is applicable for orders in either SI or inch-pound units.

1.6 The values stated in either inch-pound units or SI units are to be regarded separately as the standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. The inch-pound units shall apply unless the "M" designation of this specification is specified in the order.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: A 970/A 970M – 04a

Standard Specification for

1

Headed Steel Bars for Concrete Reinforcement

This standard is issued under the fixed designationA 970/A 970M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

e NOTE—Editorial corrections were made throughout the standard in March 2004.

1. Scope* to manufacture welded headed bars. Specification A 706/

A 706M limits chemical composition and carbon equivalence

1.1 This specification covers deformed and plain steel

to enhance weldablity of the material.

reinforcing bars in cut lengths, with a head(s) attached to one

1.4.5 Reinforcing bar material conforming to A 615/A

or both ends, for concrete reinforcement. Attachment can be

615M or A 706/A 706M is acceptable for the production of

accomplished through welding or forging of heads onto the bar

threaded or forged headed bars.

ends, by internal threads in the head mating to threads on the

1.4.6 Other types of steel reinforcing bars shall be permit-

bar end or by a separate threaded nut to secure the head to the

ted: (1) providing they conform to the dimensional and weight

bar. Heads are forge formed, machined from bar stock, or cut

requirementsofthereinforcementasspecifiedin1.4.4or1.4.5,

from plate.

as applicable, and (2) when specified and agreed upon by the

NOTE 1—Thisspecificationisapplicableforheadedbarsproducedwith

purchaser and the manufacturer and only when the suitability

welded, threaded, or forged heads and used for reinforcement of concrete

of the head and bar materials for the welding, threading, or

structures. The requirements of this specification are not applicable to

forging process specified is demonstrated through successful

headedbarswheretheattachmentoftheheadisaccomplishedbyalternate

application of the requirements for testing and frequency of

means.

testing in Sections 7 and 8 of this specification.

1.2 Grade—Headed bars are of a single minimum yield

1.4.7 All reinforcing bars shall conform to the mechanical

strength level of 420 MPa [60 000 psi], designated as Grade

performance requirements of this specification.

420 [60].

1.5 This specification is applicable for orders in either SI or

1.3 Controlled Mechanical Properties and Performance

inch-pound units.

Requirements—This specification by use of tensile and bend

1.6 The values stated in either inch-pound units or SI units

testsandthespecifiedminimumperformancelevelsinSections

are to be regarded separately as the standard. Within the text,

7 and 8 provides the required performance properties for these

the SI units are shown in brackets. The values stated in each

assemblies.

system are not exact equivalents; therefore, each system shall

1.4 Welding, Threading, and Forging:

be used independently of the other. Combining values from the

1.4.1 Welding of heads to the reinforcing steel shall be

two systems may result in nonconformance with the specifi-

approached with care. A welding procedure conforming to

cation. The inch-pound units shall apply unless the “M”

ANSI/AWS D1.4 shall be used for all required production

designation of this specification is specified in the order.

welding of the head to the bar, except for friction welding that

1.7 This standard does not purport to address all of the

shall conform to ANSI/AWS C6.1.

safety concerns, if any, associated with its use. It is the

1.4.2 Forging—Integrally forged headed bars where the

responsibility of the user of this standard to establish appro-

heads are produced by deforming the bar ends in a hot forging

priate safety and health practices and determine the applica-

process also are acceptable.

bility of regulatory limitations prior to use.

1.4.3 Threading—It shall be permissible to attach the

head(s) to the reinforcing bar using straight or tapered internal

2. Referenced Documents

threads within the head or by securing the head to the threaded

2

2.1 ASTM Standards:

bar end with a separate internally threaded nut.

A 29/A 29M SpecificationforSteelBars,CarbonandAlloy,

1.4.4 Low-Alloy Steel Bars—Low-alloy steel reinforcing

Hot-Wrought and Cold-Finished, General Requirements

bars conforming to Specification A 706/A 706M shall be used

for

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

A01.05 on Steel Reinforcement.

contact ASTM customer service at service@astm.org. For Annual Book of ASTM

Current edition approved Feb. 1, 2004. Published February 2004. Originally

Standards volume information, refer to t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.