ASTM B231/B231M-16(2021)

(Specification)Standard Specification for Concentric-Lay-Stranded Aluminum 1350 Conductors

Standard Specification for Concentric-Lay-Stranded Aluminum 1350 Conductors

ABSTRACT

This specification covers aluminum 1350-H19, 1350-H16 or -H26, 1350-H14 or -H24, and 1350-H142 or -H242, bare concentric-lay-stranded conductors constructed with a straight round central wire surrounded by one or more layers of helically layered wires. Conductors are classified as Class AA for bare conductors usually used in overhead lines; Class A for conductors to be covered with weather resistant materials, and for bare conductors where greater flexibility than is afforded by Class AA is required; Class B for conductors to be insulated with various materials such as rubber, paper, varnished cloth, and so forth, and for the conductors indicated under Class A where greater flexibility is required; and Classes C and D for conductors where greater flexibility is required than is provided by Class B conductors. Aluminum wire employed in Classes AA and A conductors shall be 1350-H19, unless otherwise specified. The temper of conductors of Classes B, C and D shall be designated. The direction of lay of the outer layer shall be right-hand for Classes AA and A and left-hand for other classes. The various classes of concentric-lay-stranded conductors shall conform to the required areas of cross section, numbers, and diameters of wires. The rated strength of 1350-H19 conductors shall be taken as the percent of the sum of the strengths of the component wires, calculated using the nominal wire diameters and the specified minimum average tensile strength given in Specification B 230/B 230M for 1350-H19 wire.

SCOPE

1.1 This specification covers aluminum 1350-H19 (extra hard), 1350-H16 or -H26 (3/4 hard), 1350-H14 or -H24 (1/2 hard), and 1350-H142 or -H242 (1/2 hard), bare concentric-lay-stranded conductors constructed with a straight round central wire surrounded by one or more layers of helically layed wires. The conductors are for general use for electrical purposes (Explanatory Note 1 and Note 2).

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.2.1 For density, resistivity and temperature, the values stated in SI units are to be regarded as standard.

Note 1: Prior to 1975, aluminum 1350 was designated as EC aluminum.

Note 2: The aluminum and temper designations conform to ANSI Standard H35.1/H35.1M. Aluminum 1350 corresponds to Unified Numbering System A91350 in accordance with Practice E527.

Note 3: Sealed conductors that are intended to prevent longitudinal water propagation and are further covered/insulated are also permitted within the guidelines of this specification.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B231/B231M −16 (Reapproved 2021)

Standard Specification for

Concentric-Lay-Stranded Aluminum 1350 Conductors

This standard is issued under the fixed designation B231/B231M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2.2 ASTM Standards:

B193Test Method for Resistivity of Electrical Conductor

1.1 This specification covers aluminum 1350-H19 (extra

Materials

3 1

hard), 1350-H16 or -H26 ( ⁄4 hard), 1350-H14 or -H24 ( ⁄2

B230/B230MSpecification for Aluminum 1350–H19 Wire

hard), and 1350-H142 or -H242 ( ⁄2 hard), bare concentric-lay-

for Electrical Purposes

stranded conductors constructed with a straight round central

B263Test Method for Determination of Cross-Sectional

wiresurroundedbyoneormorelayersofhelicallylayedwires.

Area of Stranded Conductors

The conductors are for general use for electrical purposes

B354Terminology Relating to Uninsulated Metallic Electri-

(Explanatory Note 1 and Note 2).

cal Conductors

1.2 The values stated in either SI units or inch-pound units

B609/B609M Specification for Aluminum 1350 Round

are to be regarded separately as standard. The values stated in

Wire, Annealed and Intermediate Tempers, for Electrical

each system may not be exact equivalents; therefore, each

Purposes

system shall be used independently of the other. Combining

B682Specification for Standard Metric Sizes of Electrical

values from the two systems may result in non-conformance

Conductors

with the standard.

E29Practice for Using Significant Digits in Test Data to

1.2.1 For density, resistivity and temperature, the values

Determine Conformance with Specifications

stated in SI units are to be regarded as standard.

E527Practice for Numbering Metals and Alloys in the

Unified Numbering System (UNS)

NOTE 1—Prior to 1975, aluminum 1350 was designated as EC

aluminum.

2.3 ANSI Documents:

NOTE 2—The aluminum and temper designations conform to ANSI

ANSI H35.1American National StandardAlloy andTemper

Standard H35.1/H35.1M. Aluminum 1350 corresponds to Unified Num-

Designation System for Aluminum

bering System A91350 in accordance with Practice E527.

ANSI H35.1M American National Standard Alloy and

NOTE 3—Sealed conductors that are intended to prevent longitudinal

water propagation and are further covered/insulated are also permitted Temper Designation Systems for Aluminum [Metric]

within the guidelines of this specification. 4

2.4 NIST Document:

1.3 This international standard was developed in accor-

NBS Handbook 100—Copper Wire Tables

dance with internationally recognized principles on standard- 5

2.5 Aluminum Association Document:

ization established in the Decision on Principles for the

Publication 50 Code Words for Overhead Aluminum Elec-

Development of International Standards, Guides and Recom-

trical Conductors

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

3. Classification

3.1 For the purpose of this specification, conductors are

2. Referenced Documents

classified as follows (Explanatory Note 1 and Note 2):

2.1 The following documents of the issue in effect on date

of material purchase form a part of this specification to the

extent referenced herein:

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

1 3

This specification is under the jurisdiction of ASTM Committee B01 on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on 4th Floor, New York, NY 10036, http://www.ansi.org.

Conductors of Light Metals. Available from National Institute of Standards and Technology (NIST), 100

Current edition approved Oct. 1, 2021. Published October 2021. Originally Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

approved in 1948. Last previous edition approved in 2016 as B231/B231M–16. Available fromAluminumAssociation, 1400 Crystal Dr., Suite 430,Arlington,

DOI: 10.1520/B0231_B0231M-16R21. VA 22202, http://www.aluminum.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B231/B231M − 16 (2021)

3.1.1 Class AA—For bare conductors usually used in over- 6. Joints

head lines.

6.1 Only cold-pressure joints or electric-butt, cold-upset

3.1.2 Class A—For conductors to be covered with weather-

joints may be made in the six outer finished wires of (1) Class

resistant materials, and for bare conductors where greater

AA conductors composed of seven wires or (2) Class A

flexibilitythanisaffordedbyClassAAisrequired.Conductors

conductorscomposedofsevenwiresusedinoverheadlines.In

intendedforfurtherfabricationintotreewireortobeinsulated

other conductors, electric-butt welds, cold-pressure welds, or

and laid helically with or around aluminum or ACSR

electric-butt, cold-upset welds may be made in the finished

messengers, shall be regarded as Class A conductors with

wirescomposingconductors,butsuchweldsshallnotbecloser

respect to direction of lay only (see 7.4).

than prescribed in Table 5 (Explanatory Note 3).

3.1.3 Class B—For conductors to be insulated with various

materials such as rubber, paper, varnished cloth, and so forth,

7. Lay

and for the conductors indicated under Class A where greater

7.1 For Class AA conductors composed of seven wires or

flexibility is required.

more, the preferred lay of a layer of wires is 13.5 times the

3.1.4 Classes C and D—For conductors where greater

outside diameter of that layer, but the lay shall be not less than

flexibility is required than is provided by Class B conductors.

10 nor more than 16 times this diameter.

4. Ordering Information 7.2 For all other classes the lay of a layer of wires shall be

not less than 8 nor more than 16 times the outside diameter of

4.1 Ordersformaterialunderthisspecificationshallinclude

that layer, except that for conductors composed of 37 wires or

the following information:

more,thisrequirementshallapplyonlytothetwoouterlayers.

4.1.1 Quantity,

The lay of the layers other than the two outer layers shall be at

4.1.2 Conductor size: square millimetres, if cross-sectional

the option of the manufacturer, unless otherwise agreed upon.

area is specified as a requirement (Section 8 and Tables 1-4),

7.2.1 For conductors to be used in covered or insulated

4.1.2.1 Conductor size, number, and diameter of wires for

wiresorcables,thelaylengthofthewiresshallnotbelessthan

Class B, C, or D conductors, if cross-sectional area is not

8 nor more than 16 times the outer diameter of the finished

specified as a requirement (see 8.2),

conductor. For conductors of 37 wires or more, this require-

4.1.3 Class (see 3.1),

ment shall apply to the wires in the outer two layers. The lay

4.1.4 Temper (see 5.1),

of the layers other than the outer two layers shall be at the

4.1.5 Detailsofspecial-purposelays,whenrequired(see7.2

option of the manufacturer, unless otherwise agreed upon.

through 7.5),

7.3 Other lays for special purposes shall be furnished by

4.1.6 Special tension tests if required (see 14.1 and 15.1),

special agreement between the manufacturer and the purchaser

4.1.7 Package size and type (see 17.1 and Table 1 or Table

(Explanatory Note 4).

2),

4.1.8 Special package marking, if required (Section 19),

7.4 Thedirectionoflayoftheouterlayershallberight-hand

4.1.9 Heavy wood lagging, if required (see 18.2),

forClassesAAandAandleft-handforotherclasses,unlessthe

4.1.10 Place of inspection (Section 17), and

direction of lay is specified otherwise by the purchaser.

4.1.11 Method of cross-sectional area determination if not

7.5 The direction of lay for conductors having a nominal

optional (see 12.1).

cross-sectional area larger than No. 8 AWG (8 mm ) shall be

reversedinsuccessivelayers,unlessotherwisespecifiedbythe

5. Requirements for Wires

purchaser.

5.1 AluminumwireemployedinClassesAAandAconduc-

7.5.1 For conductors to be used in covered or insulated

tors shall be 1350-H19, unless otherwise specified. The pur-

wires or cables, the direction of lay of the outer layer shall be

chaser shall designate the temper of conductors of Classes B,

left hand and may be reversed or unidirectional/unilay in

C, and D.

successive layers, unless otherwise agreed upon with the

5.1.1 For conductor tempers other than 1350-H19, when purchaser.

temper designations are not more specific in the inquiry and

purchase order, the manufacturer shall have the following

8. Construction

options on manufacturing method:

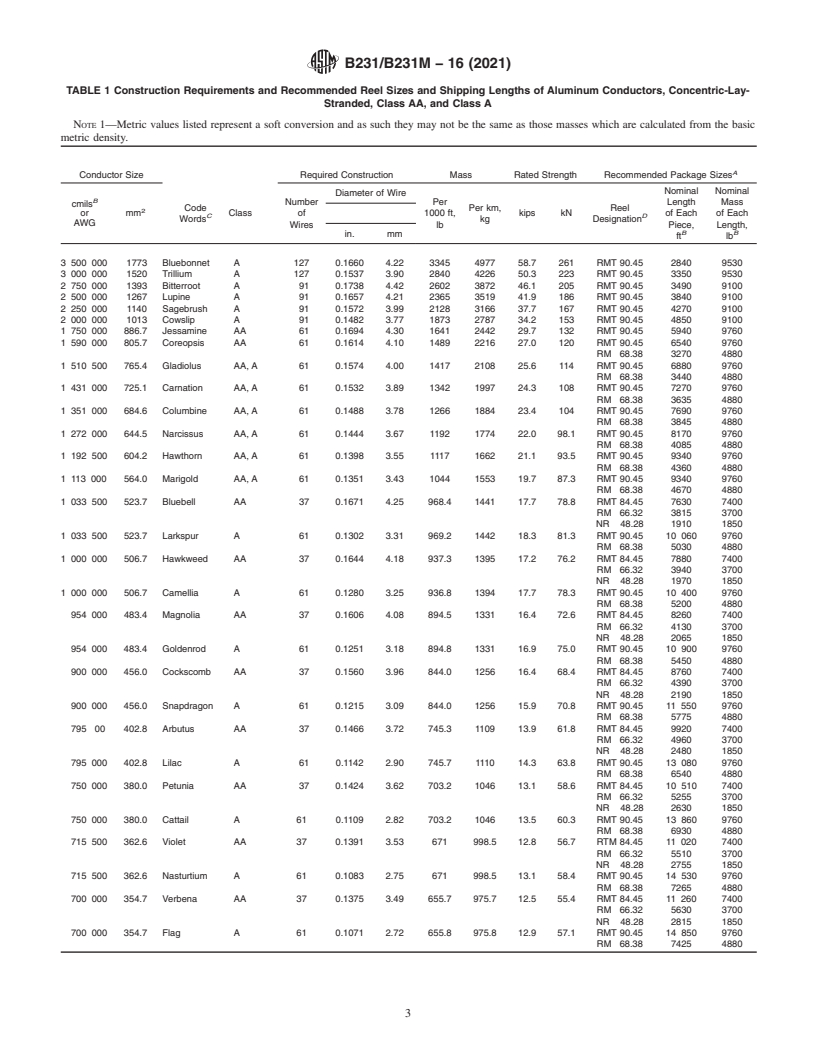

8.1 The areas of cross section, numbers, and diameters of

5.1.1.1 Strand the conductor from wires drawn to final

wires in the various classes of concentric-lay-stranded conduc-

temper;

torsshallconformtotherequirementsprescribedinTables1-4.

5.1.1.2 Strand the conductor from wires drawn to H19

Sizes 1100, 1200, and 1250 kcmil, Class B concentric-lay-

temper and annealed to final temper prior to stranding;

stranded conductors may have 61 wires subject to mutual

5.1.1.3 Strand the conductor from 1350-H19 wires and

agreement between the manufacturer and customer.

anneal the stranded conductor to final temper.

8.2 The diameters of the wires listed in Tables 3 and 4 are

5.2 Beforestranding,thealuminumwireusedshallmeetthe

nominal. Where “combination strand” is required in order to

requirements of Specifications B230/B230M or B609/B609M,

insulate the conductor properly, wires of different diameters

whichever is applicable.

may be used provided that the area of cross section after

5.3 All wires in the conductor shall be of the same temper. stranding is in accordance with Section 12.

B231/B231M − 16 (2021)

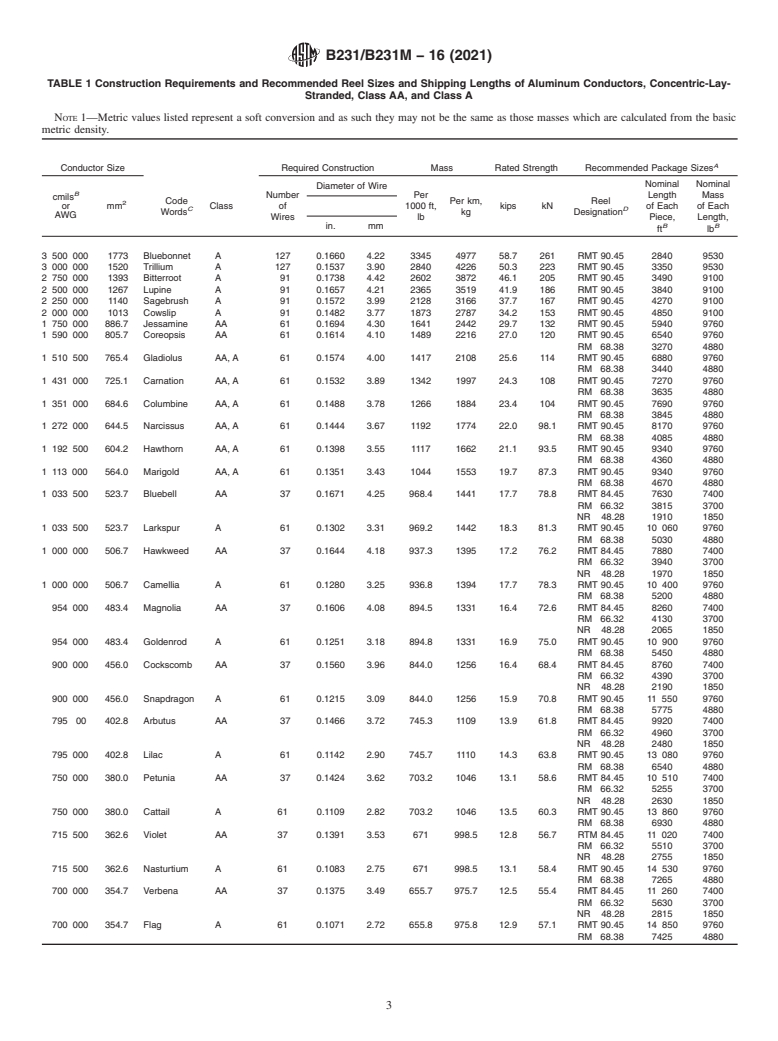

TABLE 1 Construction Requirements and Recommended Reel Sizes and Shipping Lengths of Aluminum Conductors, Concentric-Lay-

Stranded, Class AA, and Class A

NOTE 1—Metric values listed represent a soft conversion and as such they may not be the same as those masses which are calculated from the basic

metric density.

A

Conductor Size Required Construction Mass Rated Strength Recommended Package Sizes

Nominal Nominal

Diameter of Wire

B

Number Per Length Mass

cmils

Code Per km, Reel

or mm Class of 1000 ft, kips kN of Each of Each

C D

Words kg Designation

AWG

Wires lb Piece, Length,

B B

in. mm

ft lb

3 500 000 1773 Bluebonnet A 127 0.1660 4.22 3345 4977 58.7 261 RMT 90.45 2840 9530

3 000 000 1520 Trillium A 127 0.1537 3.90 2840 4226 50.3 223 RMT 90.45 3350 9530

2 750 000 1393 Bitterroot A 91 0.1738 4.42 2602 3872 46.1 205 RMT 90.45 3490 9100

2 500 000 1267 Lupine A 91 0.1657 4.21 2365 3519 41.9 186 RMT 90.45 3840 9100

2 250 000 1140 Sagebrush A 91 0.1572 3.99 2128 3166 37.7 167 RMT 90.45 4270 9100

2 000 000 1013 Cowslip A 91 0.1482 3.77 1873 2787 34.2 153 RMT 90.45 4850 9100

1 750 000 886.7 Jessamine AA 61 0.1694 4.30 1641 2442 29.7 132 RMT 90.45 5940 9760

1 590 000 805.7 Coreopsis AA 61 0.1614 4.10 1489 2216 27.0 120 RMT 90.45 6540 9760

RM 68.38 3270 4880

1 510 500 765.4 Gladiolus AA, A 61 0.1574 4.00 1417 2108 25.6 114 RMT 90.45 6880 9760

RM 68.38 3440 4880

1 431 000 725.1 Carnation AA, A 61 0.1532 3.89 1342 1997 24.3 108 RMT 90.45 7270 9760

RM 68.38 3635 4880

1 351 000 684.6 Columbine AA, A 61 0.1488 3.78 1266 1884 23.4 104 RMT 90.45 7690 9760

RM 68.38 3845 4880

1 272 000 644.5 Narcissus AA, A 61 0.1444 3.67 1192 1774 22.0 98.1 RMT 90.45 8170 9760

RM 68.38 4085 4880

1 192 500 604.2 Hawthorn AA, A 61 0.1398 3.55 1117 1662 21.1 93.5 RMT 90.45 9340 9760

RM 68.38 4360 4880

1 113 000 564.0 Marigold AA, A 61 0.1351 3.43 1044 1553 19.7 87.3 RMT 90.45 9340 9760

RM 68.38 4670 4880

1 033 500 523.7 Bluebell AA 37 0.1671 4.25 968.4 1441 17.7 78.8 RMT 84.45 7630 7400

RM 66.32 3815 3700

NR 48.28 1910 1850

1 033 500 523.7 Larkspur A 61 0.1302 3.31 969.2 1442 18.3 81.3 RMT 90.45 10 060 9760

RM 68.38 5030 4880

1 000 000 506.7 Hawkweed AA 37 0.1644 4.18 937.3 1395 17.2 76.2 RMT 84.45 7880 7400

RM 66.32 3940 3700

NR 48.28 1970 1850

1 000 000 506.7 Camellia A 61 0.1280 3.25 936.8 1394 17.7 78.3 RMT 90.45 10 400 9760

RM 68.38 5200 4880

954 000 483.4 Magnolia AA 37 0.1606 4.08 894.5 1331 16.4 72.6 RMT 84.45 8260 7400

RM 66.32 4130 3700

NR 48.28 2065 1850

954 000 483.4 Goldenrod A 61 0.1251 3.18 894.8 1331 16.9 75.0 RMT 90.45 10 900 9760

RM 68.38 5450 4880

900 000 456.0 Cockscomb AA 37 0.1560 3.96 844.0 1256 16.4 68.4 RMT 84.45 8760 7400

RM 66.32 4390 3700

NR 48.28 2190 1850

900 000 456.0 Snapdragon A 61 0.1215 3.09 844.0 1256 15.9 70.8 RMT 90.45 11 550 9760

RM 68.38 5775 4880

795 00 402.8 Arbutus AA 37 0.1466 3.72 745.3 1109 13.9 61.8 RMT 84.45 9920 7400

RM 66.32 4960 3700

NR 48.28 2480 1850

795 000 402.8 Lilac A 61 0.1142 2.90 745.7 1110 14.3 63.8 RMT 90.45 13 080 9760

RM 68.38 6540 4880

750 000 380.0 Petunia AA 37 0.1424 3.62 703.2 1046 13.1 58.6 RMT 84.45 10 510 7400

RM 66.32 5255 3700

NR 48.28 2630 1850

750 000 380.0 Cattail A 61 0.1109 2.82 703.2 1046 13.5 60.3 RMT 90.45 13 860 9760

RM 68.38 6930 4880

715 500 362.6 Violet AA 37 0.1391 3.53 671 998.5 12.8 56.7 RTM 84.45 11 020 7400

RM 66.32 5510 3700

NR 48.28 2755 1850

715 500 362.6 Nasturtium A 61 0.1083 2.75 671 998.5 13.1 58.4 RMT 90.45 14 530 9760

RM 68.38 7265 4880

700 000 354.7 Verbena AA 37 0.1375 3.49 655.7 975.7 12.5 55.4 RMT 84.45 11 260 7400

RM 66.32 5630 3700

NR 48.28 2815 1850

700 000 354.7 Flag A 61 0.1071 2.72 655.8 975.8 12.9 57.1 RMT 90.45 14 850 9760

RM 68.38 7425 4880

B231/B231M − 16 (2021)

TABLE 1 Continued

A

Conductor Size Required Construction Mass Rated Strength Recommended Package Sizes

Nominal Nominal

Diameter of Wire

B

Number Per Length Mass

cmils

Code Per km, Reel

or mm Class of 1000 ft, kips kN of Each of Each

C D

Words kg Designation

AWG

Wires lb Piece, Length,

B B

in. mm

ft lb

650 000 329.4 Heuchera AA 37 0.1326 3.37 609.8 907.4 11.6 51.7 RMT 84.45 12 130 7400

RM 66.32 6065 3700

NR 48.28 3035 1850

636 000 322.3 Orchid AA, A 37 0.1311 3.33 596.0 886.9 11.4 50.4 RMT 84.45 12 400 7400

RM 66.32 6200 3700

NR 48.28 3100 1850

600 000 304.0 Meadowsweet AA, A 37 0.1273 3.23 562.0 836.3 10.7 47.5 RMT 84.45 13 140 7400

RM 66.32 6570 3700

NR 48.28 3285 1850

556 500 282.0 Dahlia AA 19 0.1711 4.35 521.4 775.8 9.75 43.3 RM 66.32 7270

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B231/B231M − 16 (Reapproved 2021)

Standard Specification for

Concentric-Lay-Stranded Aluminum 1350 Conductors

This standard is issued under the fixed designation B231/B231M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2.2 ASTM Standards:

B193 Test Method for Resistivity of Electrical Conductor

1.1 This specification covers aluminum 1350-H19 (extra

Materials

3 1

hard), 1350-H16 or -H26 ( ⁄4 hard), 1350-H14 or -H24 ( ⁄2

B230/B230M Specification for Aluminum 1350–H19 Wire

hard), and 1350-H142 or -H242 ( ⁄2 hard), bare concentric-lay-

for Electrical Purposes

stranded conductors constructed with a straight round central

B263 Test Method for Determination of Cross-Sectional

wire surrounded by one or more layers of helically layed wires.

Area of Stranded Conductors

The conductors are for general use for electrical purposes

B354 Terminology Relating to Uninsulated Metallic Electri-

(Explanatory Note 1 and Note 2).

cal Conductors

1.2 The values stated in either SI units or inch-pound units

B609/B609M Specification for Aluminum 1350 Round

are to be regarded separately as standard. The values stated in

Wire, Annealed and Intermediate Tempers, for Electrical

each system may not be exact equivalents; therefore, each

Purposes

system shall be used independently of the other. Combining

B682 Specification for Standard Metric Sizes of Electrical

values from the two systems may result in non-conformance

Conductors

with the standard.

E29 Practice for Using Significant Digits in Test Data to

1.2.1 For density, resistivity and temperature, the values

Determine Conformance with Specifications

stated in SI units are to be regarded as standard.

E527 Practice for Numbering Metals and Alloys in the

Unified Numbering System (UNS)

NOTE 1—Prior to 1975, aluminum 1350 was designated as EC

aluminum.

2.3 ANSI Documents:

NOTE 2—The aluminum and temper designations conform to ANSI

ANSI H35.1 American National Standard Alloy and Temper

Standard H35.1/H35.1M. Aluminum 1350 corresponds to Unified Num-

Designation System for Aluminum

bering System A91350 in accordance with Practice E527.

ANSI H35.1M American National Standard Alloy and

NOTE 3—Sealed conductors that are intended to prevent longitudinal

water propagation and are further covered/insulated are also permitted Temper Designation Systems for Aluminum [Metric]

within the guidelines of this specification. 4

2.4 NIST Document:

1.3 This international standard was developed in accor-

NBS Handbook 100—Copper Wire Tables

dance with internationally recognized principles on standard- 5

2.5 Aluminum Association Document:

ization established in the Decision on Principles for the

Publication 50 Code Words for Overhead Aluminum Elec-

Development of International Standards, Guides and Recom-

trical Conductors

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

3. Classification

3.1 For the purpose of this specification, conductors are

2. Referenced Documents

classified as follows (Explanatory Note 1 and Note 2):

2.1 The following documents of the issue in effect on date

of material purchase form a part of this specification to the

extent referenced herein: 2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

1 3

This specification is under the jurisdiction of ASTM Committee B01 on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on 4th Floor, New York, NY 10036, http://www.ansi.org.

Conductors of Light Metals. Available from National Institute of Standards and Technology (NIST), 100

Current edition approved Oct. 1, 2021. Published October 2021. Originally Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

approved in 1948. Last previous edition approved in 2016 as B231/B231M – 16. Available from Aluminum Association, 1400 Crystal Dr., Suite 430, Arlington,

DOI: 10.1520/B0231_B0231M-16R21. VA 22202, http://www.aluminum.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B231/B231M − 16 (2021)

3.1.1 Class AA—For bare conductors usually used in over- 6. Joints

head lines.

6.1 Only cold-pressure joints or electric-butt, cold-upset

3.1.2 Class A—For conductors to be covered with weather-

joints may be made in the six outer finished wires of (1) Class

resistant materials, and for bare conductors where greater

AA conductors composed of seven wires or (2) Class A

flexibility than is afforded by Class AA is required. Conductors

conductors composed of seven wires used in overhead lines. In

intended for further fabrication into tree wire or to be insulated

other conductors, electric-butt welds, cold-pressure welds, or

and laid helically with or around aluminum or ACSR

electric-butt, cold-upset welds may be made in the finished

messengers, shall be regarded as Class A conductors with

wires composing conductors, but such welds shall not be closer

respect to direction of lay only (see 7.4).

than prescribed in Table 5 (Explanatory Note 3).

3.1.3 Class B—For conductors to be insulated with various

materials such as rubber, paper, varnished cloth, and so forth,

7. Lay

and for the conductors indicated under Class A where greater

7.1 For Class AA conductors composed of seven wires or

flexibility is required.

more, the preferred lay of a layer of wires is 13.5 times the

3.1.4 Classes C and D—For conductors where greater

outside diameter of that layer, but the lay shall be not less than

flexibility is required than is provided by Class B conductors.

10 nor more than 16 times this diameter.

4. Ordering Information 7.2 For all other classes the lay of a layer of wires shall be

not less than 8 nor more than 16 times the outside diameter of

4.1 Orders for material under this specification shall include

that layer, except that for conductors composed of 37 wires or

the following information:

more, this requirement shall apply only to the two outer layers.

4.1.1 Quantity,

The lay of the layers other than the two outer layers shall be at

4.1.2 Conductor size: square millimetres, if cross-sectional

the option of the manufacturer, unless otherwise agreed upon.

area is specified as a requirement (Section 8 and Tables 1-4),

7.2.1 For conductors to be used in covered or insulated

4.1.2.1 Conductor size, number, and diameter of wires for

wires or cables, the lay length of the wires shall not be less than

Class B, C, or D conductors, if cross-sectional area is not

8 nor more than 16 times the outer diameter of the finished

specified as a requirement (see 8.2),

conductor. For conductors of 37 wires or more, this require-

4.1.3 Class (see 3.1),

ment shall apply to the wires in the outer two layers. The lay

4.1.4 Temper (see 5.1),

of the layers other than the outer two layers shall be at the

4.1.5 Details of special-purpose lays, when required (see 7.2

option of the manufacturer, unless otherwise agreed upon.

through 7.5),

7.3 Other lays for special purposes shall be furnished by

4.1.6 Special tension tests if required (see 14.1 and 15.1),

special agreement between the manufacturer and the purchaser

4.1.7 Package size and type (see 17.1 and Table 1 or Table

(Explanatory Note 4).

2),

4.1.8 Special package marking, if required (Section 19),

7.4 The direction of lay of the outer layer shall be right-hand

4.1.9 Heavy wood lagging, if required (see 18.2),

for Classes AA and A and left-hand for other classes, unless the

4.1.10 Place of inspection (Section 17), and

direction of lay is specified otherwise by the purchaser.

4.1.11 Method of cross-sectional area determination if not

7.5 The direction of lay for conductors having a nominal

optional (see 12.1).

cross-sectional area larger than No. 8 AWG (8 mm ) shall be

reversed in successive layers, unless otherwise specified by the

5. Requirements for Wires

purchaser.

5.1 Aluminum wire employed in Classes AA and A conduc-

7.5.1 For conductors to be used in covered or insulated

tors shall be 1350-H19, unless otherwise specified. The pur-

wires or cables, the direction of lay of the outer layer shall be

chaser shall designate the temper of conductors of Classes B,

left hand and may be reversed or unidirectional/unilay in

C, and D.

successive layers, unless otherwise agreed upon with the

5.1.1 For conductor tempers other than 1350-H19, when

purchaser.

temper designations are not more specific in the inquiry and

purchase order, the manufacturer shall have the following

8. Construction

options on manufacturing method:

8.1 The areas of cross section, numbers, and diameters of

5.1.1.1 Strand the conductor from wires drawn to final

wires in the various classes of concentric-lay-stranded conduc-

temper;

tors shall conform to the requirements prescribed in Tables 1-4.

5.1.1.2 Strand the conductor from wires drawn to H19

Sizes 1100, 1200, and 1250 kcmil, Class B concentric-lay-

temper and annealed to final temper prior to stranding;

stranded conductors may have 61 wires subject to mutual

5.1.1.3 Strand the conductor from 1350-H19 wires and

agreement between the manufacturer and customer.

anneal the stranded conductor to final temper.

8.2 The diameters of the wires listed in Tables 3 and 4 are

5.2 Before stranding, the aluminum wire used shall meet the

nominal. Where “combination strand” is required in order to

requirements of Specifications B230/B230M or B609/B609M,

insulate the conductor properly, wires of different diameters

whichever is applicable.

may be used provided that the area of cross section after

5.3 All wires in the conductor shall be of the same temper. stranding is in accordance with Section 12.

B231/B231M − 16 (2021)

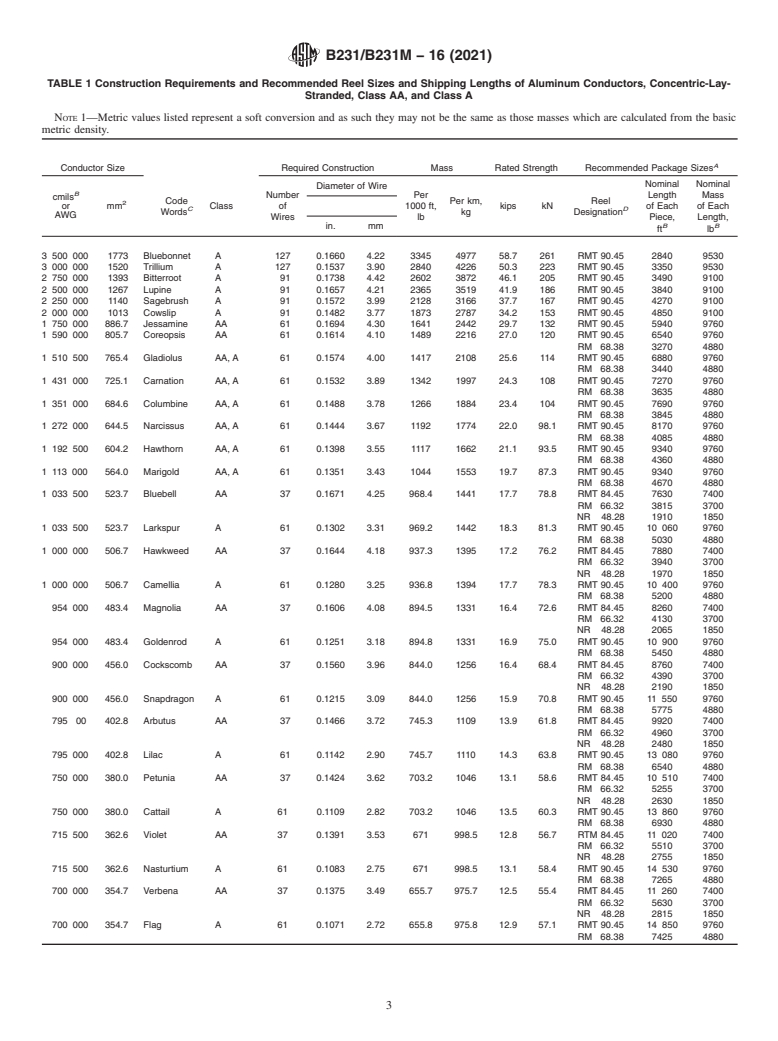

TABLE 1 Construction Requirements and Recommended Reel Sizes and Shipping Lengths of Aluminum Conductors, Concentric-Lay-

Stranded, Class AA, and Class A

NOTE 1—Metric values listed represent a soft conversion and as such they may not be the same as those masses which are calculated from the basic

metric density.

A

Conductor Size Required Construction Mass Rated Strength Recommended Package Sizes

Nominal Nominal

Diameter of Wire

B

Number Per Length Mass

cmils

Code Per km, Reel

or mm Class of 1000 ft, kips kN of Each of Each

C D

Words kg Designation

AWG

Wires lb Piece, Length,

B B

in. mm

ft lb

3 500 000 1773 Bluebonnet A 127 0.1660 4.22 3345 4977 58.7 261 RMT 90.45 2840 9530

3 000 000 1520 Trillium A 127 0.1537 3.90 2840 4226 50.3 223 RMT 90.45 3350 9530

2 750 000 1393 Bitterroot A 91 0.1738 4.42 2602 3872 46.1 205 RMT 90.45 3490 9100

2 500 000 1267 Lupine A 91 0.1657 4.21 2365 3519 41.9 186 RMT 90.45 3840 9100

2 250 000 1140 Sagebrush A 91 0.1572 3.99 2128 3166 37.7 167 RMT 90.45 4270 9100

2 000 000 1013 Cowslip A 91 0.1482 3.77 1873 2787 34.2 153 RMT 90.45 4850 9100

1 750 000 886.7 Jessamine AA 61 0.1694 4.30 1641 2442 29.7 132 RMT 90.45 5940 9760

1 590 000 805.7 Coreopsis AA 61 0.1614 4.10 1489 2216 27.0 120 RMT 90.45 6540 9760

RM 68.38 3270 4880

1 510 500 765.4 Gladiolus AA, A 61 0.1574 4.00 1417 2108 25.6 114 RMT 90.45 6880 9760

RM 68.38 3440 4880

1 431 000 725.1 Carnation AA, A 61 0.1532 3.89 1342 1997 24.3 108 RMT 90.45 7270 9760

RM 68.38 3635 4880

1 351 000 684.6 Columbine AA, A 61 0.1488 3.78 1266 1884 23.4 104 RMT 90.45 7690 9760

RM 68.38 3845 4880

1 272 000 644.5 Narcissus AA, A 61 0.1444 3.67 1192 1774 22.0 98.1 RMT 90.45 8170 9760

RM 68.38 4085 4880

1 192 500 604.2 Hawthorn AA, A 61 0.1398 3.55 1117 1662 21.1 93.5 RMT 90.45 9340 9760

RM 68.38 4360 4880

1 113 000 564.0 Marigold AA, A 61 0.1351 3.43 1044 1553 19.7 87.3 RMT 90.45 9340 9760

RM 68.38 4670 4880

1 033 500 523.7 Bluebell AA 37 0.1671 4.25 968.4 1441 17.7 78.8 RMT 84.45 7630 7400

RM 66.32 3815 3700

NR 48.28 1910 1850

1 033 500 523.7 Larkspur A 61 0.1302 3.31 969.2 1442 18.3 81.3 RMT 90.45 10 060 9760

RM 68.38 5030 4880

1 000 000 506.7 Hawkweed AA 37 0.1644 4.18 937.3 1395 17.2 76.2 RMT 84.45 7880 7400

RM 66.32 3940 3700

NR 48.28 1970 1850

1 000 000 506.7 Camellia A 61 0.1280 3.25 936.8 1394 17.7 78.3 RMT 90.45 10 400 9760

RM 68.38 5200 4880

954 000 483.4 Magnolia AA 37 0.1606 4.08 894.5 1331 16.4 72.6 RMT 84.45 8260 7400

RM 66.32 4130 3700

NR 48.28 2065 1850

954 000 483.4 Goldenrod A 61 0.1251 3.18 894.8 1331 16.9 75.0 RMT 90.45 10 900 9760

RM 68.38 5450 4880

900 000 456.0 Cockscomb AA 37 0.1560 3.96 844.0 1256 16.4 68.4 RMT 84.45 8760 7400

RM 66.32 4390 3700

NR 48.28 2190 1850

900 000 456.0 Snapdragon A 61 0.1215 3.09 844.0 1256 15.9 70.8 RMT 90.45 11 550 9760

RM 68.38 5775 4880

795 00 402.8 Arbutus AA 37 0.1466 3.72 745.3 1109 13.9 61.8 RMT 84.45 9920 7400

RM 66.32 4960 3700

NR 48.28 2480 1850

795 000 402.8 Lilac A 61 0.1142 2.90 745.7 1110 14.3 63.8 RMT 90.45 13 080 9760

RM 68.38 6540 4880

750 000 380.0 Petunia AA 37 0.1424 3.62 703.2 1046 13.1 58.6 RMT 84.45 10 510 7400

RM 66.32 5255 3700

NR 48.28 2630 1850

750 000 380.0 Cattail A 61 0.1109 2.82 703.2 1046 13.5 60.3 RMT 90.45 13 860 9760

RM 68.38 6930 4880

715 500 362.6 Violet AA 37 0.1391 3.53 671 998.5 12.8 56.7 RTM 84.45 11 020 7400

RM 66.32 5510 3700

NR 48.28 2755 1850

715 500 362.6 Nasturtium A 61 0.1083 2.75 671 998.5 13.1 58.4 RMT 90.45 14 530 9760

RM 68.38 7265 4880

700 000 354.7 Verbena AA 37 0.1375 3.49 655.7 975.7 12.5 55.4 RMT 84.45 11 260 7400

RM 66.32 5630 3700

NR 48.28 2815 1850

700 000 354.7 Flag A 61 0.1071 2.72 655.8 975.8 12.9 57.1 RMT 90.45 14 850 9760

RM 68.38 7425 4880

B231/B231M − 16 (2021)

TABLE 1 Continued

A

Conductor Size Required Construction Mass Rated Strength Recommended Package Sizes

Nominal Nominal

Diameter of Wire

B

Number Per Length Mass

cmils

Code Per km, Reel

or mm Class of 1000 ft, kips kN of Each of Each

C D

Words kg Designation

AWG

Wires lb Piece, Length,

B B

in. mm

ft lb

650 000 329.4 Heuchera AA 37 0.1326 3.37 609.8 907.4 11.6 51.7 RMT 84.45 12 130 7400

RM 66.32 6065 3700

NR 48.28 3035 1850

636 000 322.3 Orchid AA, A 37 0.1311 3.33 596.0 886.9 11.4 50.4 RMT 84.45 12 400 7400

RM 66.32 6200 3700

NR 48.28 3100 1850

600 000 304.0 Meadowsweet AA, A 37 0.1273 3.23 562.0 836.3 10.7 47.5 RMT 84.45 13 140 7400

RM 66.32 6570 3700

NR 48.28 3285 1850

556 500 282.0 Dahlia AA 19 0.1711 4.35 52

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B231/B231M − 16 B231/B231M − 16 (Reapproved 2021)

Standard Specification for

Concentric-Lay-Stranded Aluminum 1350 Conductors

This standard is issued under the fixed designation B231/B231M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

3 1

1.1 This specification covers aluminum 1350-H19 (extra hard), 1350-H16 or -H26 ( ⁄4 hard), 1350-H14 or -H24 ( ⁄2 hard), and

1350-H142 or -H242 ( ⁄2 hard), bare concentric-lay-stranded conductors constructed with a straight round central wire surrounded

by one or more layers of helically layed wires. The conductors are for general use for electrical purposes (Explanatory Note 1 and

Note 2).

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.2.1 For density, resistivity and temperature, the values stated in SI units are to be regarded as standard.

NOTE 1—Prior to 1975, aluminum 1350 was designated as EC aluminum.

NOTE 2—The aluminum and temper designations conform to ANSI Standard H35.1/H35.1M. Aluminum 1350 corresponds to Unified Numbering System

A91350 in accordance with Practice E527.

NOTE 3—Sealed conductors that are intended to prevent longitudinal water propagation and are further covered/insulated are also permitted within the

guidelines of this specification.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein:

2.2 ASTM Standards:

B193 Test Method for Resistivity of Electrical Conductor Materials

B230/B230M Specification for Aluminum 1350–H19 Wire for Electrical Purposes

This specification is under the jurisdiction of ASTM Committee B01 on Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on Conductors

of Light Metals.

Current edition approved Oct. 1, 2016Oct. 1, 2021. Published October 2016October 2021. Originally approved in 1948. Last previous edition approved in 20122016 as

B231/B231M – 12.B231/B231M – 16. DOI: 10.1520/B0231_B0231M-16.10.1520/B0231_B0231M-16R21.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B231/B231M − 16 (2021)

B263 Test Method for Determination of Cross-Sectional Area of Stranded Conductors

B354 Terminology Relating to Uninsulated Metallic Electrical Conductors

B609/B609M Specification for Aluminum 1350 Round Wire, Annealed and Intermediate Tempers, for Electrical Purposes

B682 Specification for Standard Metric Sizes of Electrical Conductors

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

2.3 ANSI Documents:

ANSI H35.1 American National Standard Alloy and Temper Designation System for Aluminum

ANSI H35.1M American National Standard Alloy and Temper Designation Systems for Aluminum [Metric]

2.4 NIST Document:

NBS Handbook 100—Copper Wire Tables

2.5 Aluminum Association Document:

Publication 50 Code Words for Overhead Aluminum Electrical Conductors

3. Classification

3.1 For the purpose of this specification, conductors are classified as follows (Explanatory Note 1 and Note 2):

3.1.1 Class AA—For bare conductors usually used in overhead lines.

3.1.2 Class A—For conductors to be covered with weather-resistant materials, and for bare conductors where greater flexibility

than is afforded by Class AA is required. Conductors intended for further fabrication into tree wire or to be insulated and laid

helically with or around aluminum or ACSR messengers, shall be regarded as Class A conductors with respect to direction of lay

only (see 7.4).

3.1.3 Class B—For conductors to be insulated with various materials such as rubber, paper, varnished cloth, and so forth, and for

the conductors indicated under Class A where greater flexibility is required.

3.1.4 Classes C and D—For conductors where greater flexibility is required than is provided by Class B conductors.

4. Ordering Information

4.1 Orders for material under this specification shall include the following information:

4.1.1 Quantity,

4.1.2 Conductor size: square millimetres, if cross-sectional area is specified as a requirement (Section 8 and Tables 1-4),

4.1.2.1 Conductor size, number, and diameter of wires for Class B, C, or D conductors, if cross-sectional area is not specified as

a requirement (see 8.2),

4.1.3 Class (see 3.1),

4.1.4 Temper (see 5.1),

4.1.5 Details of special-purpose lays, when required (see 7.2 through 7.5),

4.1.6 Special tension tests if required (see 14.1 and 15.1),

4.1.7 Package size and type (see 17.1 and Table 1 or Table 2),

4.1.8 Special package marking, if required (Section 19),

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036.10036, http://www.ansi.org.

Available from National Technical Information Service (NTIS), U.S. Department of Commerce, 5285 Port Royal Rd., Springfield, VA 22161.Institute of Standards and

Technology (NIST), 100 Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Available from the Aluminum Association, Inc., 900 19th Street, NW, Suite 300, Washington, DC 20006.1400 Crystal Dr., Suite 430, Arlington, VA 22202,

http://www.aluminum.org.

B231/B231M − 16 (2021)

TABLE 1 Construction Requirements and Recommended Reel Sizes and Shipping Lengths of Aluminum Conductors, Concentric-Lay-

Stranded, Class AA, and Class A

NOTE 1—Metric values listed represent a soft conversion and as such they may not be the same as those masses which are calculated from the basic

metric density.

A

Conductor Size Required Construction Mass Rated Strength Recommended Package Sizes

Nominal Nominal

Diameter of Wire

B

Number Per Length Mass

cmils

Code Per km, Reel

or mm Class of 1000 ft, kips kN of Each of Each

C D

Words kg Designation

AWG

Wires lb Piece, Length,

B B

in. mm

ft lb

3 500 000 1773 Bluebonnet A 127 0.1660 4.22 3345 4977 58.7 261 RMT 90.45 2840 9530

3 000 000 1520 Trillium A 127 0.1537 3.90 2840 4226 50.3 223 RMT 90.45 3350 9530

2 750 000 1393 Bitterroot A 91 0.1738 4.42 2602 3872 46.1 205 RMT 90.45 3490 9100

2 500 000 1267 Lupine A 91 0.1657 4.21 2365 3519 41.9 186 RMT 90.45 3840 9100

2 250 000 1140 Sagebrush A 91 0.1572 3.99 2128 3166 37.7 167 RMT 90.45 4270 9100

2 000 000 1013 Cowslip A 91 0.1482 3.77 1873 2787 34.2 153 RMT 90.45 4850 9100

1 750 000 886.7 Jessamine AA 61 0.1694 4.30 1641 2442 29.7 132 RMT 90.45 5940 9760

1 590 000 805.7 Coreopsis AA 61 0.1614 4.10 1489 2216 27.0 120 RMT 90.45 6540 9760

RM 68.38 3270 4880

1 510 500 765.4 Gladiolus AA, A 61 0.1574 4.00 1417 2108 25.6 114 RMT 90.45 6880 9760

RM 68.38 3440 4880

1 431 000 725.1 Carnation AA, A 61 0.1532 3.89 1342 1997 24.3 108 RMT 90.45 7270 9760

RM 68.38 3635 4880

1 351 000 684.6 Columbine AA, A 61 0.1488 3.78 1266 1884 23.4 104 RMT 90.45 7690 9760

RM 68.38 3845 4880

1 272 000 644.5 Narcissus AA, A 61 0.1444 3.67 1192 1774 22.0 98.1 RMT 90.45 8170 9760

RM 68.38 4085 4880

1 192 500 604.2 Hawthorn AA, A 61 0.1398 3.55 1117 1662 21.1 93.5 RMT 90.45 9340 9760

RM 68.38 4360 4880

1 113 000 564.0 Marigold AA, A 61 0.1351 3.43 1044 1553 19.7 87.3 RMT 90.45 9340 9760

RM 68.38 4670 4880

1 033 500 523.7 Bluebell AA 37 0.1671 4.25 968.4 1441 17.7 78.8 RMT 84.45 7630 7400

RM 66.32 3815 3700

NR 48.28 1910 1850

1 033 500 523.7 Larkspur A 61 0.1302 3.31 969.2 1442 18.3 81.3 RMT 90.45 10 060 9760

RM 68.38 5030 4880

1 000 000 506.7 Hawkweed AA 37 0.1644 4.18 937.3 1395 17.2 76.2 RMT 84.45 7880 7400

RM 66.32 3940 3700

NR 48.28 1970 1850

1 000 000 506.7 Camellia A 61 0.1280 3.25 936.8 1394 17.7 78.3 RMT 90.45 10 400 9760

RM 68.38 5200 4880

954 000 483.4 Magnolia AA 37 0.1606 4.08 894.5 1331 16.4 72.6 RMT 84.45 8260 7400

RM 66.32 4130 3700

NR 48.28 2065 1850

954 000 483.4 Goldenrod A 61 0.1251 3.18 894.8 1331 16.9 75.0 RMT 90.45 10 900 9760

RM 68.38 5450 4880

900 000 456.0 Cockscomb AA 37 0.1560 3.96 844.0 1256 16.4 68.4 RMT 84.45 8760 7400

RM 66.32 4390 3700

NR 48.28 2190 1850

900 000 456.0 Snapdragon A 61 0.1215 3.09 844.0 1256 15.9 70.8 RMT 90.45 11 550 9760

RM 68.38 5775 4880

795 00 402.8 Arbutus AA 37 0.1466 3.72 745.3 1109 13.9 61.8 RMT 84.45 9920 7400

RM 66.32 4960 3700

NR 48.28 2480 1850

795 000 402.8 Lilac A 61 0.1142 2.90 745.7 1110 14.3 63.8 RMT 90.45 13 080 9760

RM 68.38 6540 4880

750 000 380.0 Petunia AA 37 0.1424 3.62 703.2 1046 13.1 58.6 RMT 84.45 10 510 7400

RM 66.32 5255 3700

NR 48.28 2630 1850

750 000 380.0 Cattail A 61 0.1109 2.82 703.2 1046 13.5 60.3 RMT 90.45 13 860 9760

RM 68.38 6930 4880

715 500 362.6 Violet AA 37 0.1391 3.53 671 998.5 12.8 56.7 RTM 84.45 11 020 7400

RM 66.32 5510 3700

NR 48.28 2755 1850

715 500 362.6 Nasturtium A 61 0.1083 2.75 671 998.5 13.1 58.4 RMT 90.45 14 530 9760

RM 68.38 7265 4880

700 000 354.7 Verbena AA 37 0.1375 3.49 655.7 975.7 12.5 55.4 RMT 84.45 11 260 7400

RM 66.32 5630 3700

NR 48.28 2815 1850

700 000 354.7 Flag A 61 0.1071 2.72 655.8 975.8 12.9 57.1 RMT 90.45 14 850 9760

RM 68.38 7425 4880

B231/B231M − 16 (2021)

TABLE 1 Continued

A

Conductor Size Required Construction Mass Rated Strength Recommended Package Sizes

Nominal Nominal

Diameter of Wire

B

Number Per Length Mass

cmils

Code Per km, Reel

or mm Class of 1000 ft, kips kN of Each of Each

C D

Words kg Designation

AWG

Wires lb Piece, Length,

B B

in. mm

ft lb

650 000 329.4 Heuchera AA 37 0.1326 3.37 609.8 907.4 11.6 51.7 RMT 84.45 12 130 7400

RM 66.32 6065 3700

NR 48.28 3035 1850

636 000 322.3 Orchid AA, A 37 0.1311 3.33 596.0 886.9 11.4 50.4 RMT 84.45 12 400 7400

RM 66.32 6200 3700

NR 48.28 3100 1850

600 000 304.0 Meadowsweet AA, A 37 0.1273 3.23 562.0 836.3 10.7 47.5 RMT 84.45 13 140 7400

RM 66.32 6570 3700

NR 48.28 3285 1850

556 500 282.0 Dahlia AA 19 0.1711 4.35 521.4 775.8 9.75 43.3 RM 66.32 7270 3800

NR 48.28 3635 1900

NR 42.28 2425 1265

556 500 282.0 Mistletoe A 37 0.1226 3.12 521.3 775.7 9.94 44.3 RMT 84.45 14 170 7400

RM 66.32 7085 3700

NR 48.28 3545 1850

500 000 253.3 Zinnia AA 19 0.1622 4.12 468.5 697.1 8.76 38.9 RM 66.32 8100 3800

NR 48.28 4050 1900

NR 42.28 2700 1265

500 000 253.3 Hyacinth A 37 0.1162 2.95 468.3 696.8 9.11 40.5 RMT 84.45 15 760 7400

RM 66.32 7880 3700

NR 48.28 3940 1850

477 000 241.7 Cosmos AA 19 0.1584 4.02 446.8 664.8 8.36 37.0 RM 66.32 8490 3800

NR 48.28 4245 1900

NR 42.28 2830 1265

477 000 241.7 Syringa A 37 0.1135 2.88 446.8 664.8 8.69 38.6 RMT 84.45 16 530 7400

RM 66.32 8265 3700

NR 48.28 4135 1850

450 000 228.0 Goldentuft AA 19 0.1539 3.91 421.8 627.6 7.89 35.0 RM 66.32 9000 3800

NR 48.28 4500 1900

NR 42.28 3000 1265

397 500 201.4 Canna AA, A 19 0.1447 3.67 372.9 554.9 7.11 31.6 RM 66.32 10 180 3800

NR 48.28 5090 1900

NR 42.28 3395 1265

350 000 177.3 Daffodil A 19 0.1357 3.45 327.9 487.9 6.39 28.4 RM 66.32 11 560 3800

NR 48.28 5780 1900

NR 42.28 3855 1265

336 400 170.5 Tulip A 19 0.1331 3.38 315.5 469.5 6.15 27.3 RM 66.32 12 030 3800

NR 48.28 6015 1900

NR 42.28 4010 1265

300 000 152.0 Peony A 19 0.1257 3.19 281.4 418.3 5.48 24.3 RM 66.32 13 490 3800

NR 48.28 6745 1900

NR 42.28 4495 1265

266 800 135.2 Daisy AA 7 0.1953 4.96 250.2 372.3 4.83 21.4 NR 42.28 5590 1400

NR 36.22 2795 700

266 800 135.2 Laurel A 19 0.1185 3.01 250.1 372.2 4.97 22.1 RM 66.32 15 170 3800

NR 48.28 7585 1900

NR 42.28 5055 1265

250 000 126.7 Sneezewort AA 7 0.1890 4.80 234.4 348.8 4.52 20.1 NR 42.28 5970 1400

NR 36.22 2985 700

250 000 126.7 Valerian A 19 0.1147 2.91 234.3 348.6 4.66 20.7 RM 66.32 16 190 3800

NR 48.28 8095 1900

NR 42.28 5395 1265

4/0 107.2 Oxlip AA, A 7 0.1739 4.42 198.4 295.2 3.83 17.0 NR 42.28 7050 1400

NR 36.22 3525 700

3/0 85.0 Phlox AA, A 7 0.1548 3.93 157.2 233.9 3.04 13.5 NR 42.28 8890 1400

NR 36.22 4445 700

2/0 67.4 Aster AA, A 7 0.1379 3.50 124.8 185.7 2.51 11.1 NR 42.28 11 210 1400

NR 36.22 5605 700

1/0 53.5 Poppy AA, A 7 0.1228 3.12 98.9 147.2 1.99 8.84 NR 42.28 14 130 1400

NR 36.22 7065 700

1 42.4 Pansy AA, A 7 0.1093 2.78 78.4 116.6 1.64 7.30 NR 42.28 17 830 1400

NR 36.22 8915 700

2 33.6 Iris AA, A 7 0.0974 2.47 62.2 92.6 1.35 5.99 NR 42.28 22 470 1400

NR 36.22 11 235 700

4 21.1 Rose A 7 0.0772 1.96 39.1 58.2 0.881 3.91 NR 42.28 35 710 1400

NR 36.22 17 855 700

B231/B231M − 16 (2021)

TABLE 1 Continued

A

Conductor Size Required Construction Mass Rated Strength Recommended Package Sizes

Nominal Nominal

Diameter of Wire

B

Number Per Length Mass

cmils

Code Per km, Reel

or mm Class of 1000 ft, kips kN of Each of Each

C D

Words kg Designation

AWG

Wires lb Piece, Length,

B B

in. mm

ft lb

6 13.3 Peachbell A 7 0.0612 1.56 24.6 36.6 0.563 2.53 NR 42.28 56 910 1400

NR 36.22 28 455 700

A

For information only.

B 2

Conversion factors: 1 cmil = 5.067 E-04 mm , 1 mil + 2.54 E-02 mm, 1 lb/1000 ft = 1.488 E+00 kg/km, 1 ft = 3.048 E-01 m, l lb = 4.536 E-01 kg, 1 lbf = 4.448 E-03 kN.

C

Code words shown in this column are from, “Publication 50, Code Words for Overhead Aluminum Electrical Conductors,” by the Aluminum Association. They are provided

here for information only.

D

See Table 9 for dimensions of standard reels.

4.1.9 Heavy wood lagging, if required (see 18.2),

4.1.10 Place of inspection (Section 17), and

4.1.11 Method of cross-sectional area determination if not optional (see 12.1).

5. Requirements for Wires

5.1 Aluminum wire emp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.