ASTM F1115-95(2001)

(Test Method)Standard Test Method for Determining the Carbon Dioxide Loss of Beverage Containers

Standard Test Method for Determining the Carbon Dioxide Loss of Beverage Containers

SIGNIFICANCE AND USE

Two procedures, A and B, are outlined in this test method. Procedure A is used most often for development of various beverage container designs to determine the functional characteristics of the package in regard to shelf life. Procedure B is recommended for use in beverage filling operations as a quality control tool in maintaining the desired CO2 fill pressure. A loss of CO2 will affect product taste.

5.1.1 Procedure A involves the use of sensitive pressure and temperature monitoring equipment where a high degree of accuracy is essential, for example, a micro-pressure transducer and thermocouple for measuring pressure and temperature of the package in a closed system. Alternatively, this procedure may also use bottles closed with roll-on aluminum caps containing rubber septums. The septum is pierced with a hypodermic needle attached to a pressure transducer to obtain pressure readings. This procedure should be confined to laboratories that are practiced in this type of analytical testing.

5.1.2 Procedure B is more widely used when measuring the carbonation level of the package due to the simplicity of the technique. A simple Zahm-Nagle pressure assembly or Terris CO2 Analyzer is utilized.

SCOPE

1.1 The objective of this test method is to determine the carbon dioxide (CO2) loss from plastic beverage containers after a specified period of storage time.

1.2 Factors contributing to this pressure loss are volume expansion and the gas transport characteristics of the package including permeation and leakage.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 1115 – 95 (Reapproved 2001)

Standard Test Method for

Determining the Carbon Dioxide Loss of Beverage

Containers

This standard is issued under the fixed designation F 1115; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.1 carbonation volume—the volume of CO (at 0°C, 1

atm pressure) that is dissolved in the carbonated water, divided

1.1 The objective of this test method is to determine the

by the volume of the liquid (based on water volume at 3.98°C

carbon dioxide (CO ) loss from plastic beverage containers

equals1.000g/cm ).Theconversionofpressuretocarbonation

after a specified period of storage time.

volumes should be made using a carbonation volumes table.A

1.2 Factors contributing to this pressure loss are volume

table for carbonated water would not necessarily apply to

expansion and the gas transport characteristics of the package

liquids containing additional substances, such as carbonated

including permeation and leakage.

beverages containing sugar.

1.3 This standard does not purport to address all of the

3.2.2 initial pressure—the equilibrium pressure in the test

safety concerns, if any, associated with its use. It is the

bottles as measured at 24 h after filling with carbonated water.

responsibility of the user of this standard to establish appro-

(The filled bottles are allowed to stand for 24 h to obtain

priate safety and health practices and determine the applica-

temperatureequilibriumwiththetestenvironmentandtoallow

bility of regulatory limitations prior to use.

time for pressure adjustment and equilibration of the CO in

2. Referenced Documents the headspace and liquid.)

3.2.3 sample—a set of bottles produced on the same equip-

2.1 ASTM Standards:

ment in a single run and using the same material and process

D 1129 Terminology Relating to Water

conditions. Bottles should represent normal thickness distribu-

D 1193 Specification for Reagent Water

tion.

E 177 Practice for Use of the Terms Precision and Bias in

3.2.4 shelf life—thenumberofweeksasamplesetofbottles

ASTM Test Methods

retain a specified carbonation level, or a percent of the initial

E 380 Practice for the Use of International System of Units

level.

(SI) (the Modernized Metric System)

3.2.5 pressure monitoring device—a pressure gage or trans-

E 691 Practice for Conducting an Interlaboratory Study to

ducer assembly with support electronics for indicating internal

Determine the Precision of a Test Method

pressure level of the bottle. This device is used with brass

3. Terminology

closure fitting-equipped bottles.

3.2.5.1 temperature monitoring device—a thermocouple

3.1 Units, symbols, and abbreviations used in this test

with support electronics (same equipment as described in

method are those recommended by Practice E 380.

7.2.2). A precision glass thermometer may be used provided a

3.2 Definitions of Terms Specific to This Standard:

bottle filled with noncarbonated water is used as a control in

each sample set (Procedure A).

This test method is under the jurisdiction ofASTM Committee F2 on Flexible

3.2.6 Terriss CO Analyzer—an electronic unit that will

Barrier Materials and is the direct responsibility of Subcommittee F02.10 on

pierce the roll-on closure and automatically read pressure,

Permeation.

temperature, and volume of gas (Procedure B).

Current edition approved Sept. 10, 1995. Published March 1996. Originally

published as F 1115 – 87. Last previous edition F 1115 – 87. 3.2.7 Zahm-Nagle Pressure Tester—a unit that manually

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

pierces the closure and measures container pressure; an at-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

tached thermometer is then used to measure temperature

Standards volume information, refer to the standard’s Document Summary page on

(Procedure B).

the ASTM website.

Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1115 – 95 (2001)

3.2.8 support ring—a protrusion below the bottle finish

which is used to support or stabilize the bottle during filling

and capping.

3.2.9 finish—the threaded part of the bottle which receives

the cap.

3.3 For other terms used in this test method, refer to

Terminology D 1129.

4. Summary of Test Method

4.1 Test bottles are filled with carbonated water or beverage

and, after closure application, are exposed to test environments

forspecifiedtimeperiods.Byperiodicallymeasuringtheinitial

and final carbonation levels in the container, the loss and rate

can be calculated.

5. Significance and Use

5.1 Two procedures, A and B, are outlined in this test

method. Procedure A is used most often for development of

various beverage container designs to determine the functional

characteristics of the package in regard to shelf life. Procedure

B is recommended for use in beverage filling operations as a

quality control tool in maintaining the desired CO fill pres-

sure. A loss of CO will affect product taste.

5.1.1 ProcedureAinvolves the use of sensitive pressure and

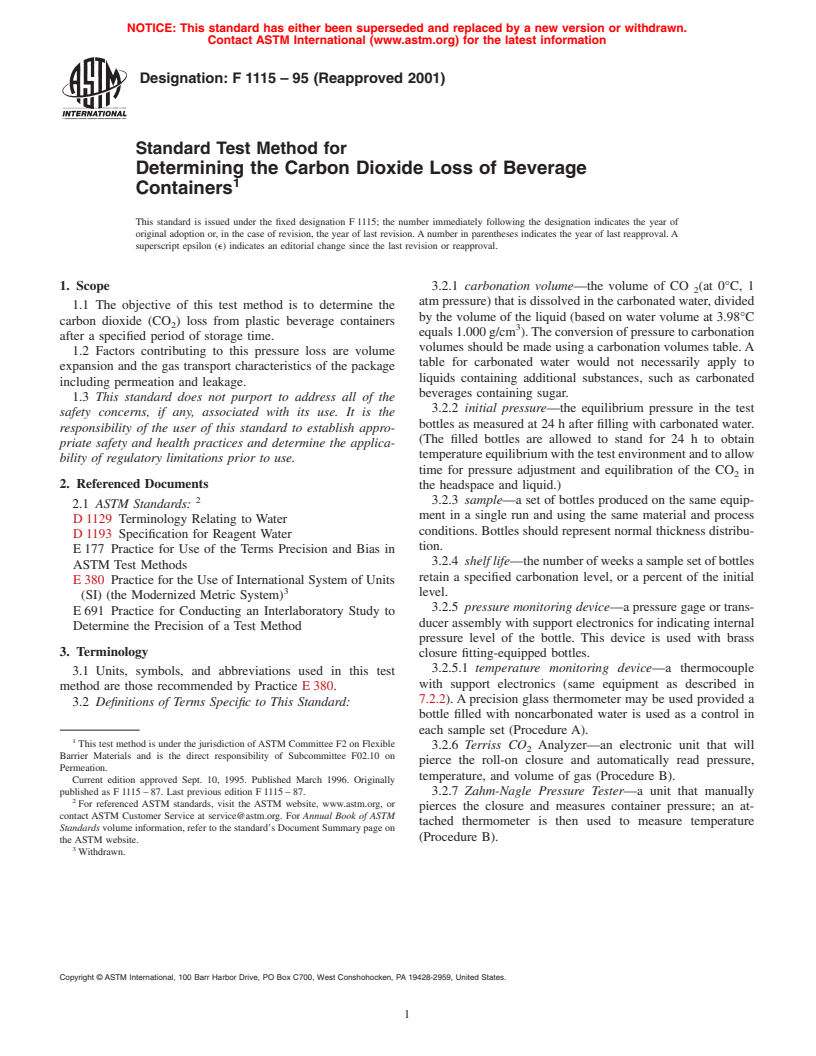

NOTE 1—Break sharp edges. All dimensions are inches unless other-

temperature monitoring equipment where a high degree of

wise stated. If conversion of dimension is desired, use standard equiva-

accuracy is essential, for example, a micro-pressure transducer

lence table.

and thermocouple for measuring pressure and temperature of

Material: Brass.

the package in a closed system. Alternatively, this procedure

FIG. 1 Machined Metal Cap for PET Beverage Bottle Testing

may also use bottles closed with roll-on aluminum caps

containing rubber septums. The septum is pierced with a

7. Apparatus

hypodermic needle attached to a pressure transducer to obtain

pressure readings. This procedure should be confined to

7.1 Procedures A and B:

laboratories that are practiced in this type of analytical testing.

7.1.1 Bottle Stand, optional.

5.1.2 Procedure B is more widely used when measuring the

7.1.2 Height Measuring Device, capable of measuring to

carbonation level of the package due to the simplicity of the

within 0.001 in. (optional).

technique. A simple Zahm-Nagle pressure assembly or Terris

7.1.3 Top Loading Balance, capable of weighing to 2500 g

CO Analyzer is utilized.

with an accuracy of 60.01 g (optional).

7.1.4 OutsideDiameterMeasuringDevice, ptapeorsimilar

6. Interferences device (optional).

7.1.5 Carbonated Water or Beverage Dispensing Equip-

6.1 The following conditions can interfere with the test

ment.

results:

7.1.6 Micrometer or Ultrasonic Thickness Gage, capable of

6.1.1 CO leakageatclosureduetodefectivebottlefinishor

measuring to within 0.001 in. or less (optional).

improper sealing of closure apparatus,

7.2 Procedure A:

6.1.2 CO leakage due to improper equipment set-up,

7.2.1 Machined Metal Cap (see Fig. 1).

6.1.3 Change in ambient temperature, upsetting the equilib-

7.2.2 Temperature-Measuring Device, capable of accurately

rium of the headspace and dissolved CO gas,

measuring temperature in increments of 0.1°C or less in a

6.1.4 Measurement of pressure before the bottle and liquid

range from 18 to 32°C (65 to 100°F).

have reached ambient temperature,

6.1.5 Inaccurate thermocouple device used for measuring

the liquid temperature,

Tape 57399, available from PI Company, Box 397, Lemon Grove, CA 92045,

6.1.6 Excessive air in the bottle headspace or dissolved in

has been found satisfactory for this purpose.

the liquid,

Doric Trendicator 410 with copper constantan thermocouple, available from

6.1.7 Inaccurate or erratic pressure monitoring device,

DoricScientificDiv.,EmersonElectricCo.,3883RuffinRd.,SanDiego,CA 92123,

6.1.8 Ambient humidity in the test area,

has been found satisfactory for this purpose.

6.1.9 Age of bottles, and

6.1.10 Excessive bottle-to-bottle variation in the material

distribution,whichmayresultinawidevariationfrombottleto

bottle within the sample population.

F 1115 – 95 (2001)

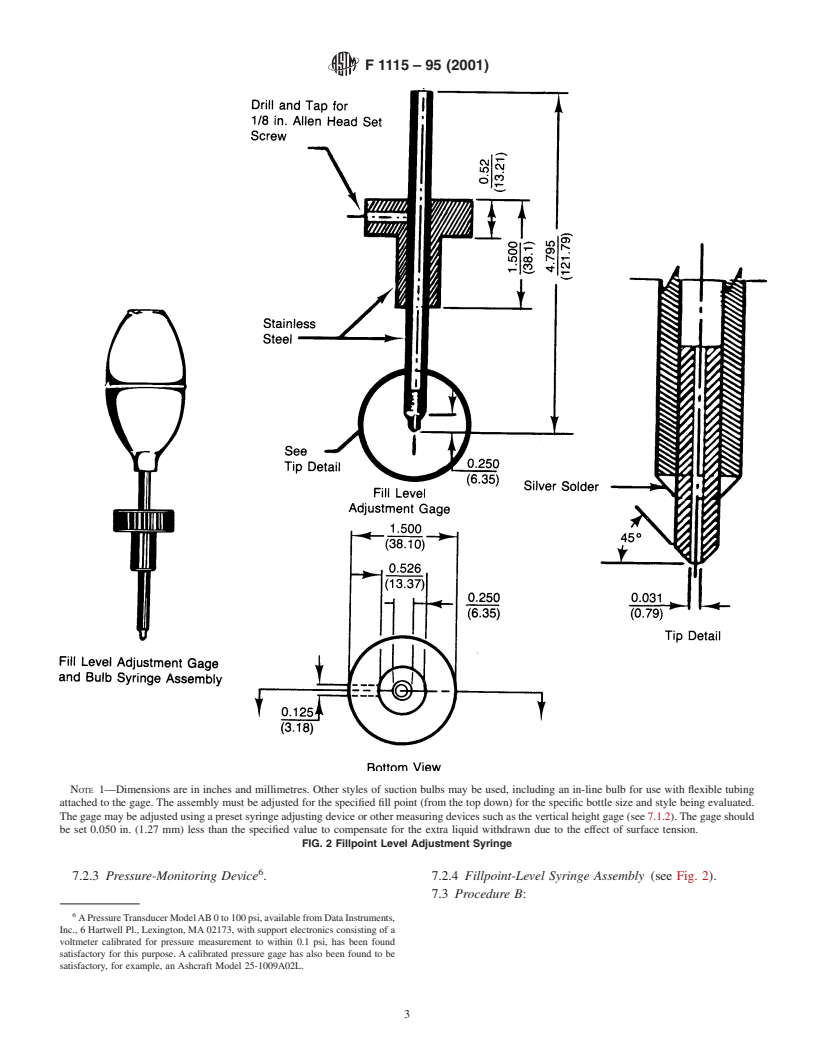

NOTE 1—Dimensions are in inches and millimetres. Other styles of suction bulbs may be used, including an in-line bulb for use with flexible tubing

attached to the gage. The assembly must be adjusted for the specified fill point (from the top down) for the specific bottle size and style being evaluated.

The gage may be adjusted using a preset syringe adjusting device or other measuring devices such as the vertical height gage (see 7.1.2).The gage should

be set 0.050 in. (1.27 mm) less than the specified value to compensate for the extra liquid withdrawn due to the effect of surface tension.

FIG. 2 Fillpoint Level Adjustment Syringe

7.2.3 Pressure-Monitoring Device . 7.2.4 Fillpoint-Level Syringe Assembly (see Fig. 2).

7.3 Procedure B:

APressureTransducerModelAB0to100psi,availablefromDataInstruments,

Inc., 6 Hartwell Pl., Lexington, MA 02173, with support electronics consisting of a

voltmeter calibrated for pressure measurement to within 0.1 psi, has been found

satisfactory for this purpose. A calibrated pressure gage has also been found to be

satisfactory, for example, an Ashcraft Model 25-1009A02L.

F 1115 – 95 (2001)

7.3.1 Pressure- and Temperature-Measuring Device . 10.3.5 Ifthetestingdeviceuseddoesnothaveatemperature

sensing probe inside the bottle, fill another bottle with cold

8. Reagents and Materials

noncarbonatedwatertouseasatemperaturecontrolforthisset

8.1 Water carbonated to a level sufficient to ensure a of bottles. This bottle should be kept with this set during

minimum carbonation level of 4.5 volumes in the filled bottles. storage, agitation, and testing. Its temperature shall be used for

ReagentwaterconformingtoTypeIVofSpecificationsD 1193 the temperature of each bottle in the set when determining

or better shall be used. carbonation level.

8.2 Carbon Dioxide, compressed (CO ).

10.4 Pressure Adjustment and Equilibration of Filled

8.3 Leak-Detecting Solution.

Bottles:

10.4.1 Allow filled bottles to come to ambient storage

9. Conditioning

temperature, and let stand for 24 h in the test environment.

9.1 Test bottles must be conditioned for at least 72 h and

10.4.2 After bottles have equilibrated for 22 h at ambient

tested at 23°C (73.4°F) 6 2°C, and 50 6 5 % relative

temperature, agitate the bottles for at least one min using hand

humidity, unless other conditions are agreed upon by the

shaking or mechanical agitation to ensure proper equilibration

parties involved.

ofheadspaceanddissolvedCO .SniftpressureoraddCO gas

2 2

9.2 Bottles may be tested with or without base cup attached.

as required to adjust the carbonation level to 4.0 volumes 6

0.05 volumes according to a carbonation volumes table. The

10. Procedure A

starting CO level is critical.

10.1 Apparatus Preparation:

10.4.3 After a total of 24-h equilibration, again agitate the

10.1.1 Assemble and calibrate pressure- and temperature-

test bottles and determine their carbonation level. If any bottle

monitoring equipment.

has a carbonation level of 3.95 volumes or less, discontinue

10.1.2 Pressure test assembly at 60 psi using leak detecting

testing of that bottle.

solution.

10.5 Measurements:

10.1.3 Check calibration of monitoring equipment.

10.5.1 Before filling bottles for the carbonation level test,

10.2 Record weight and dimensions of empty and filled

measure wall thickness profile using suitable equipment to

bottles (optional).

determine the quality of the material distribution (optional).

10.2.1 Weigh each empty bottle to at least 0.01 g.

10.5.2 Twenty-four hours after filling, agitate each test

10.2.2 Measure the outside diameter of each empty bottle

bottle to equilibrium pressure for at least 1 min to obtain the

usinga ptape.Measureatthecenterofthelabelpanel,orother

initial values as outlined below:

previously agreed upon location(s).

10.5.2.1 Equilibrium pressure of each bottle,

10.2.3 Measure the height of each empty bottle to the

10.5.2.2 Temperature of each bottle or the control bottles,

bottom of the support ring using a vertical height gage or

10.5.2.3 Carbonation level (from a carbonation volumes

similar equipment.

table),

10.3 Filling Bottles:

10.5.2.4 Bottle height to the bottom of the support ring

10.3.1 Using a carbonating unit or similar equipment, fill

(optional),

containers to the nominal fill level with carbonated water

cooled to 5°C (41°F) or below, preferably 1°C (34°F). Samples 10.5.2.5 Bottle outside diameter (optional).

must be carbonated to no less than 4.5 volumes CO . Use

10.5.3 Repeatmeasurements,andagitatebottleforatleast1

Tables X1.1-X1.4 or another table agreed upon by the parties

min prior to measuring pressure and temperature at 3 days, 1

involved to determine CO content by measuring pressure and

week, 3 weeks, 6 weeks, 8 weeks, 12 weeks, and 16 weeks. If

temperature with the equipment described in Section 7.

attached pressure transducers or gages are used, pressure and

10.3.2 Using a fillpoint-level syringe, draw liquid level

temperature may be measured more frequently (for example,

down to the specified fillpoint. weekly)eithertoallowearlypredictionofshelflifeortoobtain

10.3.3 Immediately after the fillpoint-level adjustment, ap-

a more precise measure of the end point.

ply the pressure monitoring apparatus tightly to the bottle. DO

10.5.4 If the attached septum method is used, a set of six

NOT AGITATE THE BOTTLE. A brass closure fitted with a

glass control bottles of the same capacity must be tested along

micropressure transducer or pressure gage (see Fig. 3) and a

with the plastic bottles. Average loss of these bottles must be

thermocouple capable of reading within increments of 0.1°C

subtractedfromthelossoftheplasticbottlestocompensatefor

and 1.0 psi, respectively, or a roll-on aluminum closure fitted

CO lost from the septum.

with a rubber septum have been found satisfactory for this

purpose.

11. Procedure B

10.3.4 Fill a minimum set of five bottles for each sample.

11.1 Apparatus Preparation:

11.1.1 Ensure proper calibration of the Terris Unit or

7 Zahm-Nagle Apparatus using appropriate manufacturer’s

A Terriss Unit, available from Terriss-Consolidated Industries, Box 110B,

Asbury Park, NJ 07712, and a Zahm-Nagel apparatus, available from Zahm and guidelines.

Nagel Co., Inc., 74 Hewett Ave., Buffalo, NY 14214, have been found satisfactory

11.1.2 Pressure test assembly to ensure no pressure leakage

for this purpose.

8 will occur.

Snoop Leak Detector, available from Nupro Company, 15635 Saramac Rd.,

Cleveland, OH 44110, has been found sati

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.