ASTM F1176-01e1

(Practice)Standard Practice for Design and Installation of Underground Thermoplastic Irrigation Systems With Maximum Working Pressure of 125 psi (Withdrawn 2010)

Standard Practice for Design and Installation of Underground Thermoplastic Irrigation Systems With Maximum Working Pressure of 125 psi (Withdrawn 2010)

ABSTRACT

This practice establishes the basic design and proper installation procedures for flexible thermoplastic piping systems for underground irrigation systems that operate at maximum working pressures of 125 psi. The thermoplastic pipes shall be made of poly(vinyl chloride) (PVC) or polyethylene (PE), and shall be assembled to withstand the design working pressure for the pipeline without leakage, internal restriction, or obstruction that could reduce line capacity below design requirements. The piping system shall conform to requirements for the working pressure, service factor, system capacity, friction losses, flow velocity, outlets, check valves, pressure-relief valves, and air-release and vacuum-relief valves. The procedures for trench and joints preparation, thrust block construction, line charging, and backfilling are also detailed thoroughly.

SCOPE

1.1 This practice establishes procedures for the design and installation of thermoplastic flexible piping systems, for underground irrigation systems. Because there is considerable variability in end-use requirements, soil conditions, and thermoplastic piping characteristics, the intent of this practice is to outline general objectives and basics of systems design, proper installation procedures, and to provide pertinent references.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are mathematical conversions to SI units which are for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This practice establishes procedures for the design and installation of thermoplastic flexible piping systems, for underground irrigation systems. Because there is considerable variability in end-use requirements, soil conditions, and thermoplastic piping characteristics, the intent of this practice is to outline general objectives and basics of systems design, proper installation procedures, and to provide pertinent references.

Formerly under the jurisdiction of Committee F17 on Plastic Piping Systems, this practice was withdrawn in February 2010 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

´1

Designation: F1176 – 01

Standard Practice for

Design and Installation of Underground Thermoplastic

Irrigation Systems With Maximum Working Pressure of 125

1

psi

This standard is issued under the fixed designation F1176; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Keywords added editorially in November 2003.

1. Scope D2657 Practice for Heat Fusion Joining of Polyolefin Pipe

and Fittings

1.1 This practice establishes procedures for the design and

D2749 Symbols for Dimensions of Plastic Pipe Fittings

installation of thermoplastic flexible piping systems, for under-

F402 Practice for Safe Handling of Solvent Cements, Prim-

ground irrigation systems. Because there is considerable vari-

ers, and Cleaners Used for Joining Thermoplastic Pipe and

ability in end-use requirements, soil conditions, and thermo-

Fittings

plastic piping characteristics, the intent of this practice is to

F412 Terminology Relating to Plastic Piping Systems

outline general objectives and basics of systems design, proper

F690 Practice for Underground Installation of Thermoplas-

installation procedures, and to provide pertinent references.

tic Pressure Piping Irrigation Systems

1.2 The values stated in inch-pound units are to be regarded

F714 Specification for Polyethylene (PE) Plastic Pipe

asthestandard.Thevaluesgiveninparenthesesaremathemati-

(SDR-PR) Based on Outside Diameter

cal conversions to SI units which are for information only and

F771 Specification for Polyethylene (PE) Thermoplastic

are not considered standard.

High-Pressure Irrigation Pipeline Systems

1.3 This standard does not purport to address all of the

F1290 Practice for Electrofusion Joining Polyolefin Pipe

safety concerns, if any, associated with its use. It is the

and Fittings

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3. Terminology

bility of regulatory limitations prior to use.

3.1 The terminology used in this practice is in accordance

2. Referenced Documents with Terminology F412, Terminology D1600, and Symbols

2 D2749, unless otherwise specified.

2.1 ASTM Standards:

D1600 Terminology for Abbreviated Terms Relating to

4. Summary of Practice

Plastics

4.1 This practice gives standardized criteria and procedures

D2241 Specification for Poly(Vinyl Chloride) (PVC)

for underground installation of thermoplastic pipe in pressure

Pressure-Rated Pipe (SDR Series)

irrigation systems.

D2487 Practice for Classification of Soils for Engineering

4.2 Thermoplastic pipe used in this practice is made of

Purposes (Unified Soil Classification System)

poly(vinyl chloride) (PVC) or polyethylene (PE) and shall be

D2488 Practice for Description and Identification of Soils

assembled to withstand the design working pressure for the

(Visual-Manual Procedure)

pipeline without leakage, internal restriction, or obstruction

that could reduce line capacity below design requirements.

4.3 Joining materials shall be of composition that will not

1

This practice is under the jurisdiction of ASTM Committee F17 on Plastic

damage the pipe and shall be recommended for use at the

Piping Systems and is the direct responsibility of Subcommittee F17.61 on Water.

design pressure for the pipeline. Consult the manufacturer for

Current edition approved Aug. 10, 2001. Published October 2001. Originally

design and installation recommendations.

published as F1176 – 88. Last previous edition F1176 – 93. DOI: 10.1520/F1176-

01E01.

4.4 When materials subject to corrosion are used in the line,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

they shall be adequately protected by wrapping or coating with

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

high-quality corrosion preventatives. Wrappings or coatings

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. applied to metallic surfaces should not be applied on plastic

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

F1176 – 01

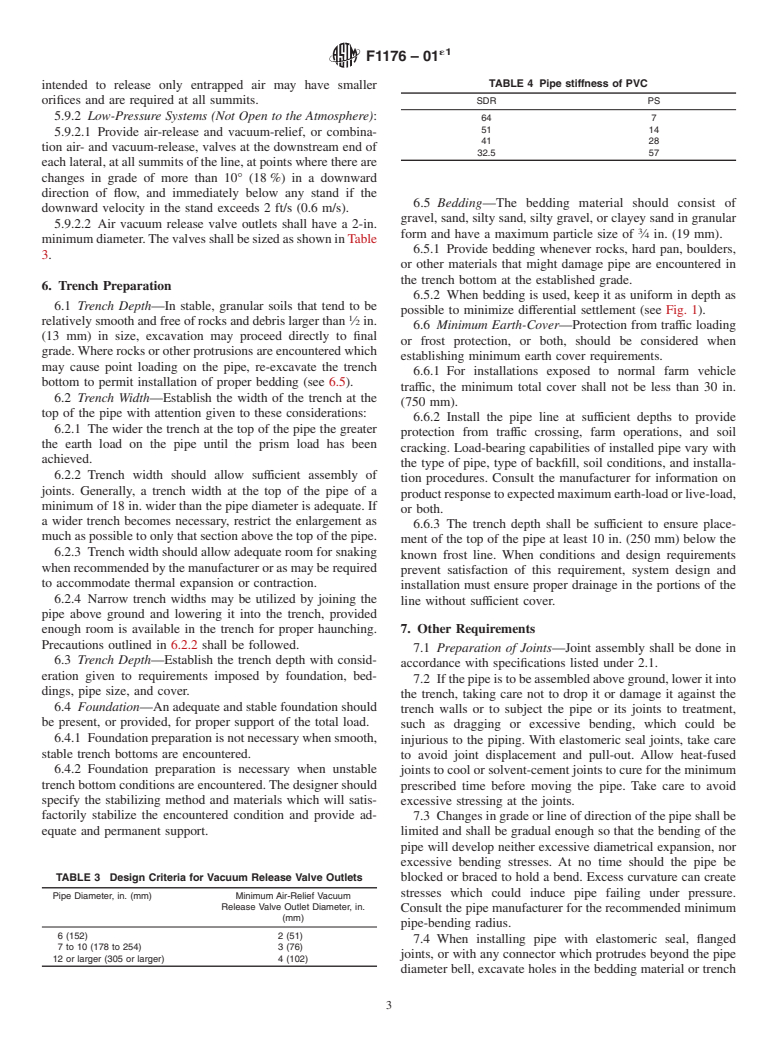

TABLE 2 Pressure Rating Service Factors for Temperatures

pipe or fittings unless it is first established by consulting the

from 73.4 to 140°F (23 to 60°C) for PVC and PE Pipes

piping manufacturer so that they have no detrimental effect on

Temperature, PVC Factor PE Factor

the plastic.

°F °C

5. Requirements 73.4 23 1.00 1.00

80 26.7 0.88 0.92

5.1 Working Pressure—The pipe line shall have a pressure

90 3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.