ASTM A779/A779M-10

(Specification)Standard Specification for Steel Strand, Seven-Wire, Uncoated, Compacted, Stress-Relieved for Prestressed Concrete

Standard Specification for Steel Strand, Seven-Wire, Uncoated, Compacted, Stress-Relieved for Prestressed Concrete

ABSTRACT

This specification covers seven-wire, uncoated, compacted, stress-relieved steel strand for prestressed concrete. The chemical requirements, mechanical requirements, and dimensions and permissible variations are presented. The mechanical requirement includes breaking strength, load at 1% extension and elongation. Different test method shall be performed on the strand that includes dimension test, breaking strength test, load at 1% extension test, elongation test and workmanship.

SCOPE

1.1 This specification describes three grades of compacted, seven-wire, uncoated, stress-relieved strand for use in pre-tensioned and post-tensioned prestressed concrete construction.

1.2 Supplement I describes low-relaxation strand and low-relaxation testing.

1.3 The values stated in either inch-pound or SI units are to be regarded as standard. Within the text, the inch-pound units are shown in parentheses. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other, without combining values in any way.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A779/A779M −10

StandardSpecification for

Steel Strand, Seven-Wire, Uncoated, Compacted, Stress-

1

Relieved for Prestressed Concrete

This standard is issued under the fixed designationA779/A779M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* uniform pitch of not less than 14 and not more than 18 times

the nominal diameter of the strand.

1.1 This specification describes three grades of compacted,

seven-wire, uncoated, stress-relieved strand for use in pre-

4. Classification

tensioned and post-tensioned prestressed concrete construc-

4.1 Grade 1700 (245)—Nominal diameter of 18.0 mm (0.7

tion.

in.) with tensile failure stress of 1705 MPa (247 ksi) based on

1.2 Supplement I describes low-relaxation strand and low-

nominal area of the strand.

relaxation testing.

4.2 Grade 1800 (260)—Nominal diameter of 15.2 mm (0.6

1.3 The values stated in either inch-pound or SI units are to

in.) with tensile failure stress of 1815 MPa (263 ksi) based on

be regarded as standard. Within the text, the inch-pound units

nominal area of the strand.

are shown in parentheses. The values stated in each system are

4.3 Grade 1860 (270)—Nominal diameter of 12.7 mm (0.5

not exact equivalents; therefore, each system shall be used

independently of the other, without combining values in any in.) with tensile failure stress of 1860 MPa (270 ksi) based on

nominal area of the strand.

way.

2. Referenced Documents

5. Ordering Information

2

2.1 ASTM Standards:

5.1 It shall be the responsibility of the purchaser to specify

A751 Test Methods, Practices, and Terminology for Chemi-

all requirements that are necessary for material ordered to this

cal Analysis of Steel Products

specification. Such requirements shall include, but are not

A1061/A1061M Test Methods for Testing Multi-Wire Steel

limited to, the following:

Strand

5.1.1 Quantity (meters (feet)),

5.1.2 Grade of strand (Section 4),

3. Terminology

5.1.3 Special inspection requirements, if desired (see Sec-

3.1 Definitions of Terms Specific to This Standard:

tion 13),

3.1.1 compacted strand—strand that has been compacted by

5.1.4 Packaging,

drawing through a die or a similar compacting process and

5.1.5 ASTM designation and date of issue, and

subsequently stress-relieved prior to winding into coils or

5.1.6 Special requirements, if any.

reelless packs.

NOTE 1—Atypical ordering description is as follows: 100 000 m Grade

3.1.2 lot—all of the compacted strand of the same grade and

260 compacted low-relaxation strand in approximately 3700 m reelless

package size produced on the same production equipment and packs to ASTM A779/A779M (328 000 ft Grade 1800 compacted

low-relaxation strand in approximately 12 000 ft-reelless packs toASTM

submitted for inspection at the same time.

A779/A779M.)

3.1.3 strand—a group of wires having a center wire en-

closed tightly by six helically placed outer wires with a

6. Materials and Manufacture

6.1 The steel shall be of such quality that, when processed,

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

the finished wire shall be free of detrimental flaws and undue

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

segregation.

A01.05 on Steel Reinforcement.

Current edition approved April 1, 2010. Published July 2010. Originally

6.2 Wire from which the strand is to be fabricated shall be

approved in 1980. Last previous edition approved in 2005 as A779/A779M – 05.

in the cold-drawn condition and have a common dry-drawn

DOI: 10.1520/A0779_A0779M-10.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or finish.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.3 After stranding and compacting, all strand shall be

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. subjected to a stress-relieving continuous thermal treatment to

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A779/A779M−10

TABLE 1 Breaking Strength Requirements

Nominal Diameter of Strand Specified Minimum Nominal Steel Area of Strand Nominal Mass (Weight) of

Breaking Strength Strands kg/1000 m (lb/1000 ft)

2 2

mm (in.) mm (in.)

of Strand, kN (lbf)

Grade 1860 (270)

12.7 (0.5) 209 (47 000) 112 (0.174) 890 (600)

Grade 1800 (260)

15.2 (0.6) 300 (67 440) 165 (0.256) 1295 (873)

Grade 1700 (245)

18.0 (0.7) 380 (85 430) 223 (0.346) 1750 (1176)

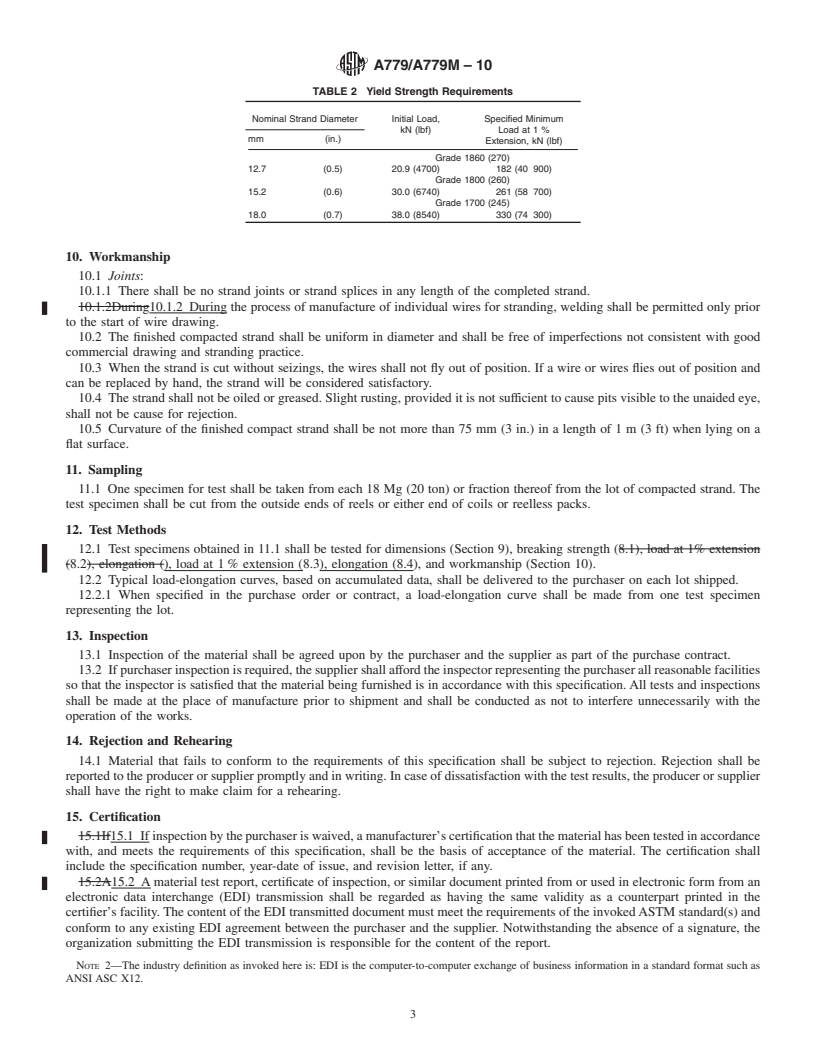

TABLE 2 Y

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A779/A779M–05 Designation: A779/A779M – 10

Standard Specification for

Steel Strand, Seven-Wire, Uncoated, Compacted, Stress-

1

Relieved for Prestressed Concrete

This standard is issued under the fixed designationA779/A779M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification describes three grades of compacted, seven-wire, uncoated, stress-relieved strand for use in pre-tensioned

and post-tensioned prestressed concrete construction.

1.2 Supplement I describes low-relaxation strand and low-relaxation testing.

1.3 The values stated in either inch-pound or SI units are to be regarded as standard. Within the text, the inch-pound units are

shown in parentheses. The values stated in each system are not exact equivalents; therefore, each system shall be used

independently of the other, without combining values in any way.

2. Referenced Documents

2

2.1 ASTM Standards: A370Test Methods and Definitions for Mechanical Testing of Steel Products

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products E328Test Methods for Stress

Relaxation for Materials and

Structures

A1061/A1061M Test Methods for Testing Multi-Wire Steel Strand

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 compacted strand—strand that has been compacted by drawing through a die or a similar compacting process and

subsequently stress-relieved prior to winding into coils or reelless packs.

3.1.2 lot—all of the compacted strand of the same grade and package size produced on the same production equipment and

submitted for inspection at the same time.

3.1.3 strand—a group of wires having a center wire enclosed tightly by six helically placed outer wires with a uniform pitch

of not less than 14 and not more than 18 times the nominal diameter of the strand.

4. Classification

4.1 Grade 1700 (245)—Nominal diameter of 18.0 mm (0.7 in.) with tensile failure stress of 1705 MPa (247 ksi) based on

nominal area of the strand.

4.2 Grade 1800 (260)—Nominal diameter of 15.2 mm (0.6 in.) with tensile failure stress of 1815 MPa (263 ksi) based on

nominal area of the strand.

4.3 Grade 1860 (270)—Nominal diameter of 12.7 mm (0.5 in.) with tensile failure stress of 1860 MPa (270 ksi) based on

nominal area of the strand.

5. Ordering Information

5.1It5.1 It shall be the responsibility of the purchaser to specify all requirements that are necessary for material ordered to this

specification. Such requirements shall include, but are not limited to, the following:

5.1.1 Quantity (meters (feet)),

5.1.2 Grade of strand (Section 4),

5.1.3 Special inspection requirements, if desired (see Section 13),

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility of SubcommitteeA01.05

on Steel Reinforcement.

Current edition approved MarchApril 1, 2005.2010. Published March 2005.July 2010. Originally approved in 1980. Last previous edition approved in 20002005 as

A779/A779M – 005. DOI: 10.1520/A0779_A0779M-105.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A779/A779M – 10

5.1.4 Packaging,

5.1.5 ASTM designation and date of issue, and

5.1.6 Special requirements, if any.

NOTE 1—Atypical ordering description is as follows: 100 000 m Grade 260 compacted low-relaxation strand in approximately 3700 m reelless packs

to ASTM A779/A779M (328 000 ft Grade 1800 compacted low-relaxation strand in approximately 12 000 ft-reelless packs to ASTM A779/A779M.)

6. Materials and Manufacture

6.1 The steel shall be of such quality that, when processed, the finished wire shall be free of detrimental flaws and undue

segregation.

6.2 Wire from which the strand is to be fabricated shall be in the cold-drawn condition and have a common dry-drawn finish.

6.3 After stranding and compacting, all strand shall be subjected to a stress-re

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.