ASTM C1219-92(1997)

(Test Method)Standard Test Methods for Arsenic in Uranium Hexafluoride

Standard Test Methods for Arsenic in Uranium Hexafluoride

SCOPE

1.1 These test methods are applicable to the determination of total arsenic in uranium hexafluoride (UF6) by atomic absorption spectrometry. Two test methods are given: Test Method A-Arsine Generation-Atomic Absorption (Sections 5 to 10), and Test Method B-Graphite Furnace Atomic Absorption (Sections 11 to 16).

1.2 The test methods are equivalent. The limit of detection for each test method is 0.1 [mu]g As/g U when using a sample containing 0.5 to 1.0 g U.

1.3 Test Method A covers the measurement of arsenic in uranyl fluoride (UO2F2) solutions by converting arsenic to arsine and measuring the arsine vapor by flame atomic absorption spectrometry.

1.4 Test Method B utilizes a solvent extraction to remove the uranium from the UO2F2 solution prior to measurement of the arsenic by graphite furnace atomic absorption spectrometry.

1.5 Both insoluble and soluble arsenic are measured when UF6 is prepared according to Test Method C761.

1.6 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 1219 – 92 (Reapproved 1997)

Standard Test Methods for

Arsenic in Uranium Hexafluoride

This standard is issued under the fixed designation C 1219; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope solution is fumed with sulfuric acid in the presence of boric

acid to complex the fluoride. Potassium iodide is used to

1.1 These test methods are applicable to the determination

reduce arsenic(V) to arsenic(III). Sodium borohydride is used

of total arsenic in uranium hexafluoride (UF ) by atomic

togeneratearsinevaporinahydridegeneratorwithsubsequent

absorption spectrometry. Two test methods are given: Test

measurement by flame atomic absorption spectrometry.

Method A—Arsine Generation-Atomic Absorption (Sections

3.2 Graphite Furnace Atomic Absorption Spectrometry

5-10), and Test Method B—Graphite FurnaceAtomicAbsorp-

Method—ThesampleofUF ishydrolyzed,andtheuraniumin

tion (Sections 11-16).

the UO F solution is removed by extraction with tri(2-ethyl-

1.2 The test methods are equivalent. The limit of detection 2 2

hexyl)phosphate/heptane. The aqueous phase containing the

for each test method is 0.1 µg As/g U when using a sample

arsenic is analyzed by graphite furnace atomic absorption.

containing 0.5 to 1.0 g U.

1.3 Test Method A covers the measurement of arsenic in

4. Significance and Use

uranyl fluoride (UO F ) solutions by converting arsenic to

2 2

4.1 Arsenic compounds are suspected to cause corrosion in

arsine and measuring the arsine vapor by flame atomic absorp-

some materials used in UF handling equipment. Arsenic

tion spectrometry.

originates as a contaminant in fluorspar (CaF ) used to produce

1.4 Test Method B utilizes a solvent extraction to remove

anhydrous hydrogen fluoride which is used subsequently in the

the uranium from the UO F solution prior to measurement of

2 2

production of UF .

the arsenic by graphite furnace atomic absorption spectrom-

4.2 These test methods are used to measure the arsenic

etry.

content in UO F solutions prepared from the hydrolysis of

2 2

1.5 Both insoluble and soluble arsenic are measured when

UF for determination of conformance to Specification C 787.

UF is prepared according to Test Method C 761.

1.6 This standard does not purport to address all of the

TEST METHOD A—ARSINE GENERATION-ATOMIC

safety concerns, if any, associated with its use. It is the

ABSORPTION SPECTROMETRY

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5. Interferences

bility of regulatory limitations prior to use.

5.1 The presence of hydrofluoric acid in the sample sup-

presses arsine generation when using sodium borohydride.

2. Referenced Documents

Boric acid is added to complex the fluoride present at a molar

2.1 ASTM Standards:

excess of 250 %.

C 761 Test Methods for Chemical, Mass Spectrometric,

5.2 Arsenic(V) must be reduced to arsenic(III) otherwise

Spectrochemical, Nuclear, and Radiochemical Analysis of

arsine will not be generated using sodium borohydride and

Uranium Hexafluoride

hydrochloric acid.

C 787 Specification for Uranium Hexafluoride for Enrich-

5.3 The reduction of arsenic(V) by potassium iodide is time

ment

dependentatroomtemperaturerequiringstrictadherencetothe

D 1193 Specification for Reagent Water

procedure.

5.4 Do not use platinum labware.

3. Summary of Test Methods

3.1 Arsine Generation-Atomic Absorption Spectromety

Method—The sample of UF is hydrolyzed and the UO F

6 2 2

This test methods are under the jurisdiction of ASTM Committee C-26 on

Nuclear Fuel Cycle and are the direct responsibility of Subcommittee C26.05 on

Methods of Tests. Petrik, K., and Krivan, V., “Radiotracer Investigation of the Interference of

Current edition approved Nov. 15, 1992. Published July 1993. Hydrofluoric Acid in the Determination of Arsenic and Antimony by Hydride

Annual Book of ASTM Standards, Vol 12.01. GenerationAtomicAbsorption Spectroscopy,”AnalyticalChemistry,Vol 59, No. 20

Annual Book of ASTM Standards, Vol 11.01. (1987), pp. 2426–2427.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

C 1219

6. Apparatus 7.1.13 Sodium Borohydride Solution (6.0 g/L)—Dissolve

3.0 g of sodium borohydride (NaBH ) and 2.5 g of sodium

6.1 Atomic Absorption Spectrometer, equipped with an

hydroxide (NaOH) in water and dilute to 500 mL in a

air-acetylene burner, arsenic hollow cathode lamp and hydride

volumetric flask. This solution should be prepared weekly.

generator, gas/liquid separator, and hydride absorption cell.

7.1.14 Sulfuric Acid (sp gr 1.84)—Concentrated sulfuric

6.2 Hot Plate, capable of reaching a surface temperature of

acid (H SO ).

2 4

500°C.

8. Calibration and Standardization

7. Reagents and Materials

8.1 Instrument Parameters—A set of suggested atomic

7.1 Reagents:

absorption operating parameters is listed in Table 1 and Table

7.1.1 PurityofReagents—Reagent grade chemicals shall be

2. The parameters may vary with the type of instrument used

used in all tests. Unless otherwise indicated, it is intended that

and the manufacturer’s instructions.

all reagents conform to the specifications of the Committee on

8.2 Preparation of Calibration Solutions:

Analytical Reagents of theAmerican Chemical Society, where

8.2.1 Aliquot 0, 2, 5, 10, 20, and 30 mLof the 0.10 mgAs/L

such specifications are available. Other grades may be used,

solution into 100-mL volumetric flasks. Add 2 mL concen-

provided it is first ascertained that the reagent is of sufficiently

trated H SO and 10 mL concentrated HCl to each flask.

2 4

high purity to permit its use without lessening the accuracy of

8.2.2 Add 2 mL of 50 % potassium iodide solution and

the determination.

dilute to volume with water 75 min before running the

7.1.2 Purity of Water— Unless otherwise indicated, refer-

calibration solutions.

ences to water shall mean reagent water Type II conforming to

8.3 Calibration:

Specification D 1193.

8.3.1 Follow the manufacturer’s directions to calibrate the

7.1.3 Acetylene (C H ), 99.6 % minimum purity.

2 2

instrument. Use the following arsenic calibration solutions

7.1.4 Air—compressed breathing air or equivalent.

with a 30-s water rinse between each solution: 0, 0.002, 0.005,

7.1.5 Arsenic Standard Stock Solution (1000 mg As/L)—

0.010, 0.020, and 0.030 mg As/L. If the AA is manually

Dissolve 1.320 g of arsenic trioxide (As O ) in 100 mL of

2 3

controlled, record the absorbances.

hydrochloric acid (1 + 2) and dilute to 1 L. Commercially

8.3.2 Withamicroprocessor-controlledinstrument,generate

available stock solutions traceable to NIST primary standards

the calibration curve using the manufacturer’s directions. The

may be used.

calibration curve can also be generated manually by graphing

7.1.6 Arsenic Standard Solution (0.10 mg As/L)—Pipet 10

the absorbance of the calibration solutions on the ordinate and

mL of 1000 mg/L arsenic stock solution into a 1-L volumetric

the corresponding concentration on the abscissa.

flask containing 500 mL of water. Add 20 mL of concentrated

8.3.3 Verify the calibration by running the mid-range 0.010

hydrochloric acid, dilute to volume with water and mix. This

mgAs/L calibration solution. If the value differs by more than

(10 mg/L) solution should be kept no longer than one month.

5 %, repeat the calibration.

Pipet 2 mL of the 10 mg/L arsenic solution into a 200-mL

volumetric flask containing 100 mL of water. Add 4 mL of

9. Procedure

concentrated hydrochloric acid and dilute to volume with

9.1 Sample Preparation:

water.

9.1.1 Prepare a hydrolyzed UF solution within a concen-

NOTE 1—The 0.10-mg As/L solution must not be kept longer than one

tration range of 50 to 250 g/LU using the appropriate sections

day.

of Test Method C 761.

7.1.7 Boric Acid (H BO ). 9.1.2 Transfer an aliquot of UO F solution containing

2 2

3 3

7.1.8 Hydrochloric Acid (sp gr 1.18)—Concentrated hydro- approximately 0.5 g of uranium into a 125-mL Erlenmeyer

chloric acid (HCl). flask.

7.1.9 Hydrochloric Acid (1 + 1)—Add one volume of con- 9.1.3 Add 0.5 g of H BO and 2 mLof concentrated H SO

3 3 2 4

centrated hydrochloric acid to one volume of water. to the sample.

7.1.10 HydrochloricAcid (1 + 2)—Add one volume of con- 9.1.4 Heat the sample at 325°C until the acid starts to fume.

centrated hydrochloric acid to two volumes of water. Increase the hot plate temperature to 385°C. When the sample

7.1.11 Nitrogen (N ), 99.9 % minimum purity. fumes vigorously, increase the temperature to 500°C and heat

7.1.12 Potassium Iodide Solution (50 % w/v)—Dissolve 50 until the acid fumes lift above the solution.

g of potassium iodide in water and dilute to 100 mL in a

volumetric flask. Store in a brown bottle.

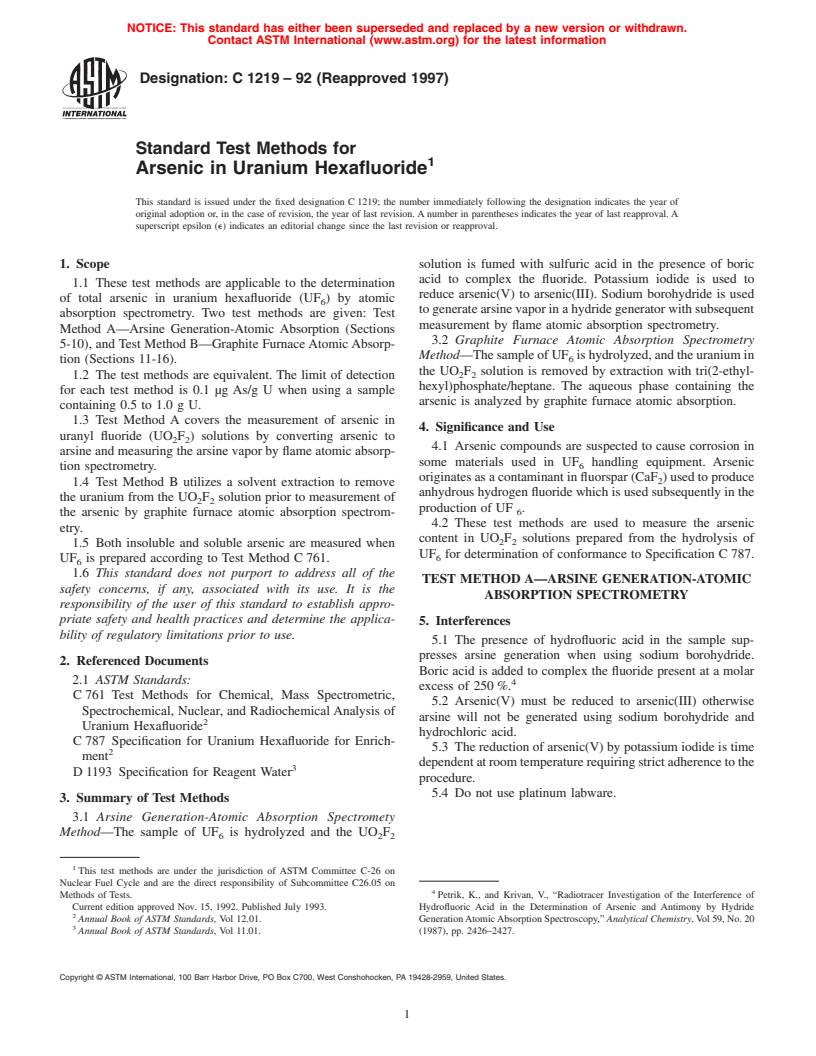

TABLE 1 Atomic Absorption Operating Parameters

Element arsenic

NOTE 2—The colorless solution is stable for two days. A yellow tinge

Wavelength, nm 193.7

indicates the solution has deteriorated.

Lamp current, mA 10

Slit width, nm 0.5

Gas C H /air

2 2

Acetylene, psig 9

“Reagent Chemicals, American Chemical Society Specifications,” American

Air, psig 40

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

Argon, psig 50

listed by the American Chemical Society, see “Reagent Chemicals and Standards,”

Fuel flow, L/min 1.5

by Joseph Rosin, D. Van Nostrand Company, Inc., New York, New York, and the Oxidant flow, L/min 4.0

“United States Pharmacopeia.”

C 1219

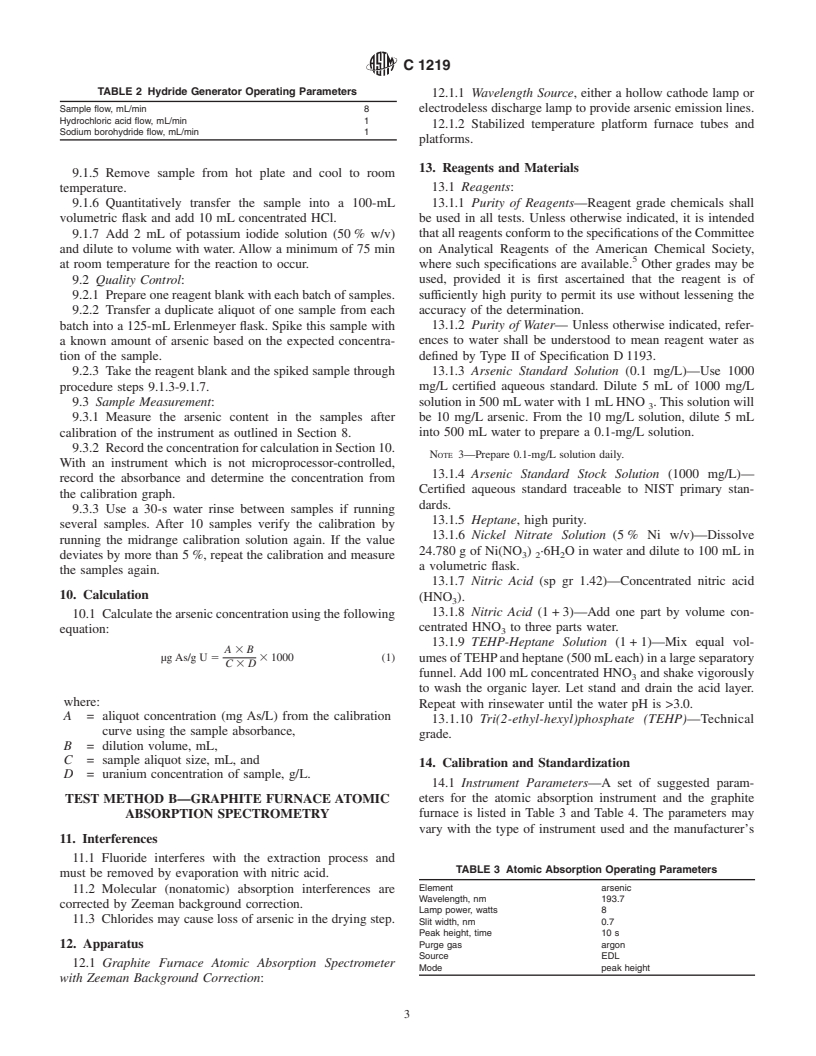

TABLE 2 Hydride Generator Operating Parameters

12.1.1 Wavelength Source, either a hollow cathode lamp or

Sample flow, mL/min 8 electrodeless discharge lamp to provide arsenic emission lines.

Hydrochloric acid flow, mL/min 1

12.1.2 Stabilized temperature platform furnace tubes and

Sodium borohydride flow, mL/min 1

platforms.

13. Reagents and Materials

9.1.5 Remove sample from hot plate and cool to room

temperature. 13.1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.