ASTM F1335-04

(Specification)Standard Specification for Pressure-Rated Composite Pipe and Fittings for Elevated Temperature Service (Withdrawn 2011)

Standard Specification for Pressure-Rated Composite Pipe and Fittings for Elevated Temperature Service (Withdrawn 2011)

ABSTRACT

This specification covers pressure-rated composite pipe and fittings for the transport of hot or cold liquids, beverages, or gases that are compatible with the composite pipe and fittings. Composite pipe is produced using a butt welded aluminum pipe as a core, with an extruded inside layer of cross-linked polyethylene (PEX) or polyethylene (PE). An adhesive layer is used to bond the inside layer to the wall of the aluminum pipe. An outer layer of polyethylene (PE) and an adhesive layer are extruded to the outer wall of the aluminum pipe. The following test shall be performed to conform with the specified requirements: composite pipe and fittings qualification test; hydrostatic sustained pressure test; vacuum depression test; hot and cold pressure cycling; water hammer test; delamination; fusion line test; and gel content.

SCOPE

1.1 This specification covers pressure-rated composite pipe and fittings for the transport of hot or cold liquids, beverages, or gases that are compatible with the composite pipe and fittings.

1.2 Composite pipe is produced using a butt welded aluminum pipe as a core, with an extruded inside layer of crosslinked polyethylene (PEX) or polyethylene (PE). An adhesive layer is used to bond the inside layer to the wall of the aluminum pipe. An outer layer of polyethylene (PE) and an adhesive layer are extruded to the outer wall of the aluminum pipe.

1.3 Composite pipe is produced in four configurations and referenced in Fig. 1, as Classes 1, 2, 3, and 4 composite pipe.

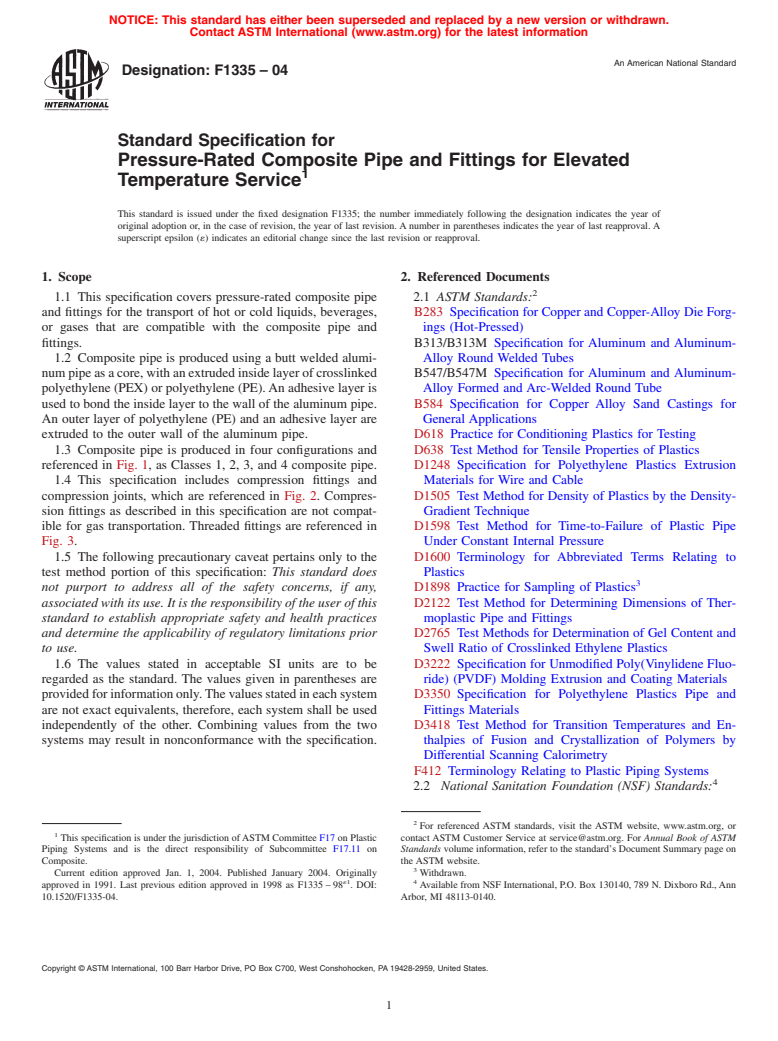

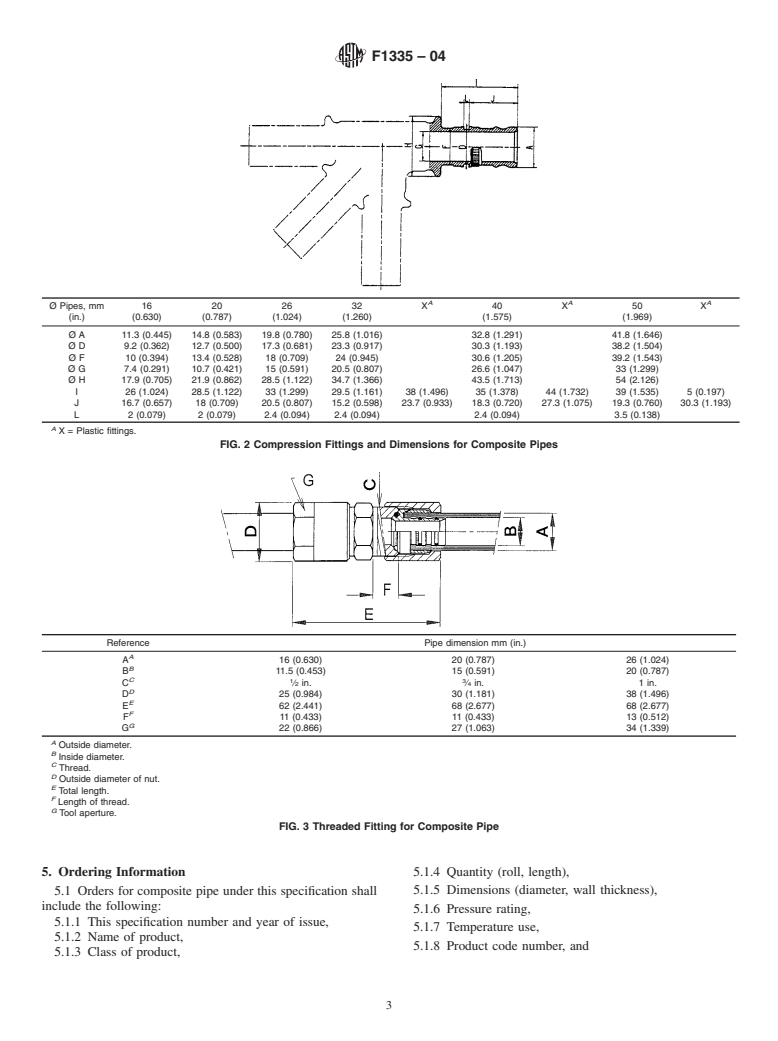

1.4 This specification includes compression fittings and compression joints, which are referenced in . Compression fittings as described in this specification are not compatible for gas transportation. Threaded fittings are referenced in .

1.5 The following precautionary caveat pertains only to the test method portion of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.6 The values stated in acceptable SI units are to be regarded as the standard. The values given in parentheses are provided for information only. The values stated in each system are not exact equivalents, therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

WITHDRAWN RATIONALE

This specification covers pressure-rated composite pipe and fittings for the transport of hot or cold liquids, beverages, or gases that are compatible with the composite pipe and fittings.

Formerly under the jurisdiction of Committee F17 on Plastic Piping Systems, this specification was withdrawn in November 2011 because there is no known product being manufactured per Specification F1335.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F1335 – 04

Standard Specification for

Pressure-Rated Composite Pipe and Fittings for Elevated

1

Temperature Service

This standard is issued under the fixed designation F1335; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This specification covers pressure-rated composite pipe 2.1 ASTM Standards:

and fittings for the transport of hot or cold liquids, beverages, B283 SpecificationforCopperandCopper-AlloyDieForg-

or gases that are compatible with the composite pipe and ings (Hot-Pressed)

fittings. B313/B313M Specification for Aluminum and Aluminum-

1.2 Composite pipe is produced using a butt welded alumi- Alloy Round Welded Tubes

numpipeasacore,withanextrudedinsidelayerofcrosslinked B547/B547M Specification for Aluminum and Aluminum-

polyethylene(PEX)orpolyethylene(PE).Anadhesivelayeris Alloy Formed and Arc-Welded Round Tube

usedto bond the insidelayertothewallofthealuminumpipe. B584 Specification for Copper Alloy Sand Castings for

An outer layer of polyethylene (PE) and an adhesive layer are General Applications

extruded to the outer wall of the aluminum pipe. D618 Practice for Conditioning Plastics for Testing

1.3 Composite pipe is produced in four configurations and D638 Test Method for Tensile Properties of Plastics

referenced in Fig. 1, as Classes 1, 2, 3, and 4 composite pipe. D1248 Specification for Polyethylene Plastics Extrusion

1.4 This specification includes compression fittings and Materials for Wire and Cable

compression joints, which are referenced in Fig. 2. Compres- D1505 Test Method for Density of Plastics by the Density-

sion fittings as described in this specification are not compat- Gradient Technique

ible for gas transportation. Threaded fittings are referenced in D1598 Test Method for Time-to-Failure of Plastic Pipe

Fig. 3. Under Constant Internal Pressure

1.5 The following precautionary caveat pertains only to the D1600 Terminology for Abbreviated Terms Relating to

test method portion of this specification: This standard does Plastics

3

not purport to address all of the safety concerns, if any, D1898 Practice for Sampling of Plastics

associated with its use. It is the responsibility of the user of this D2122 Test Method for Determining Dimensions of Ther-

standard to establish appropriate safety and health practices moplastic Pipe and Fittings

and determine the applicability of regulatory limitations prior D2765 Test Methods for Determination of Gel Content and

to use. Swell Ratio of Crosslinked Ethylene Plastics

1.6 The values stated in acceptable SI units are to be D3222 Specification for Unmodified Poly(Vinylidene Fluo-

regarded as the standard. The values given in parentheses are ride) (PVDF) Molding Extrusion and Coating Materials

providedforinformationonly.Thevaluesstatedineachsystem D3350 Specification for Polyethylene Plastics Pipe and

are not exact equivalents, therefore, each system shall be used Fittings Materials

independently of the other. Combining values from the two D3418 Test Method for Transition Temperatures and En-

systems may result in nonconformance with the specification. thalpies of Fusion and Crystallization of Polymers by

Differential Scanning Calorimetry

F412 Terminology Relating to Plastic Piping Systems

4

2.2 National Sanitation Foundation (NSF) Standards:

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Piping Systems and is the direct responsibility of Subcommittee F17.11 on Standards volume information, refer to the standard’s Document Summary page on

Composite. the ASTM website.

3

Current edition approved Jan. 1, 2004. Published January 2004. Originally Withdrawn.

´1 4

approved in 1991. Last previous edition approved in 1998 as F1335–98 . DOI: Available from NSF International, P.O. Box 130140, 789 N. Dixboro Rd.,Ann

10.1520/F1335-04. Arbor, MI 48113-0140.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F1335 – 04

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

7

2.6 Military Standard:

MIL-STD-129 Marking for Shipment and Storage

3. Terminology

3.1 Definitions—Definitions are in accordance with Termi-

nology F412, and abbreviations are in accordance with Termi-

nology D1600, unless otherwise specified.

3.1.1 composite pipe—pipe consisting of two or more

differentmaterialsarrangedwi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.