ASTM A795/A795M-08(2012)

(Specification)Standard Specification for Black and Hot-Dipped Zinc-Coated (Galvanized) Welded and Seamless Steel Pipe for Fire Protection Use

Standard Specification for Black and Hot-Dipped Zinc-Coated (Galvanized) Welded and Seamless Steel Pipe for Fire Protection Use

ABSTRACT

This specification covers black and hot-dipped zinc-coated (galvanized) welded and seamless steel pipe for fire protection use. The pipe may be bent, but it is not intended for bending made at ambient temperature wherein the inside diameter of the bend is less than twelve times the outside diameter of the pipe being bent. The steel shall conform to the required chemical composition. Each length of pipe shall be subjected to a hydrostatic test without leakage through the pipe wall. As an alternative to the hydrostatic test, and when accepted by the purchaser, each pipe shall be tested with a non-destructive electrical method. Finally, flattening test shall be performed on the pipe in accordance with, electric-resistance-welded pipe, and furnace-welded pipe.

SCOPE

1.1 This specification covers black and hot-dipped galvanized welded and seamless steel pipe in NPS 1/2 to NPS 10, inclusive [DN 15 to DN 250, inclusive] (Note 1), with wall thicknesses as given in Table 1 and Table 2. Pipe having other wall thicknesses may be furnished provided such pipe complies with all other requirements of this specification and the outside diameter is as given in Table 2. Pipe ordered under this specification is intended for use in fire protection systems. The pipe may be bent, but it is not intended for bending made at ambient temperature wherein the inside diameter of the bend is less than twelve times the outside diameter of the pipe being bent (Note 2). Note 1—The dimensionless designators NPS (nominal pipe size) and DN (nominal diameter) have been substituted in this standard for such traditional terms as “nominal diameter,” “size,” and “nominal size.” TABLE 1 Dimensions, Weights, and Test Pressure For Light-Weight Fire Protection Pipe—Schedule 10A

NPS

Designator

DN

Designator

Outside Diameter

Nominal Wall Thickness

Weight Plain End

Test Pressure

Furnace-Welded

Seamless and

Electric-Resistance-Welded

in.

mm

in.

mm

lb/ft

kg/m

psi

kPa

psi

kPa

3/4

20

1.050

[26.7]

0.083

[2.11]

0.86

[1.28]

500

[3400]

700

[4800]

1

25

1.315

[33.4]

0.109

[2.77]

1.41

[2.09]

500

[3400]

700

[4800]

11/4

32

1.660

[42.2]

0.109

[2.77]

1.81

[2.69]

500

[3400]

1000

[6900]

11/2

40

1.900

[48.3]

0.109

[2.77]

2.09

[3.11]

500

[3400]

1000

[6900]

2

50

2.375

[60.3]

0.109

[2.77]

2.64

[3.93]

500

[3400]

1000

[6900]

21/2

65

2.875

[73.0]

0.120

[3.05]

3.53

[5.26]

500

[3400]

1000

[6900]

3

80

3.500

[88.9]

0.120

[3.05]

4.34

[6.46]

500

[3400]

1000

[6900]

31/2

90

4.000

[101.6]

0.120

[3.05]

4.98

[7.41]

500

[3400]

1200

[8300]

4

100

4.500

[114.3]

0.120

[3.05]

5.62

[8.37]

500

[3400]

1200

[8300]

5

125

5.563

[141.3]

0.134

[3.40]

7.78

[11.58]

B

B

1200

[8300]

6

150

6.625

[168.3]

0.134

[3.40]

9.30

[13.85]

B

B

1000

[6900]

8

200

8.625

[219.1]

0.188C

[4.78]

16.96

[25.26]

B

B

800

[5500]

10

250

10.750

[273.1]

0.188C

[4.78]

21.23

[31.62]

B

B

700

[4800] A Schedule 10 corresponds to Schedule 10S as listed in ANSI B36.19 for NPS 3/4 through 6 [DN 20 through 150] only. B Furnace-welded pipe is not made in sizes larger than NPS 4 [DN 100]. C Not Schedule 10. TABLE 2 Dimensions, Weights, Test Pressures For Standard-Weight Fire Protection Pipe—Schedule 30 and Schedule 40

NPS

Designator

DN

Designator

Specified Outside

Diameter

Nominal Wall

ThicknessA

Weight Plain End

Weight Threaded

and CoupledB

Test Pressure

Furnace-Welded

Seamless and

Electric-Resistance-Welded

...

General Information

Relations

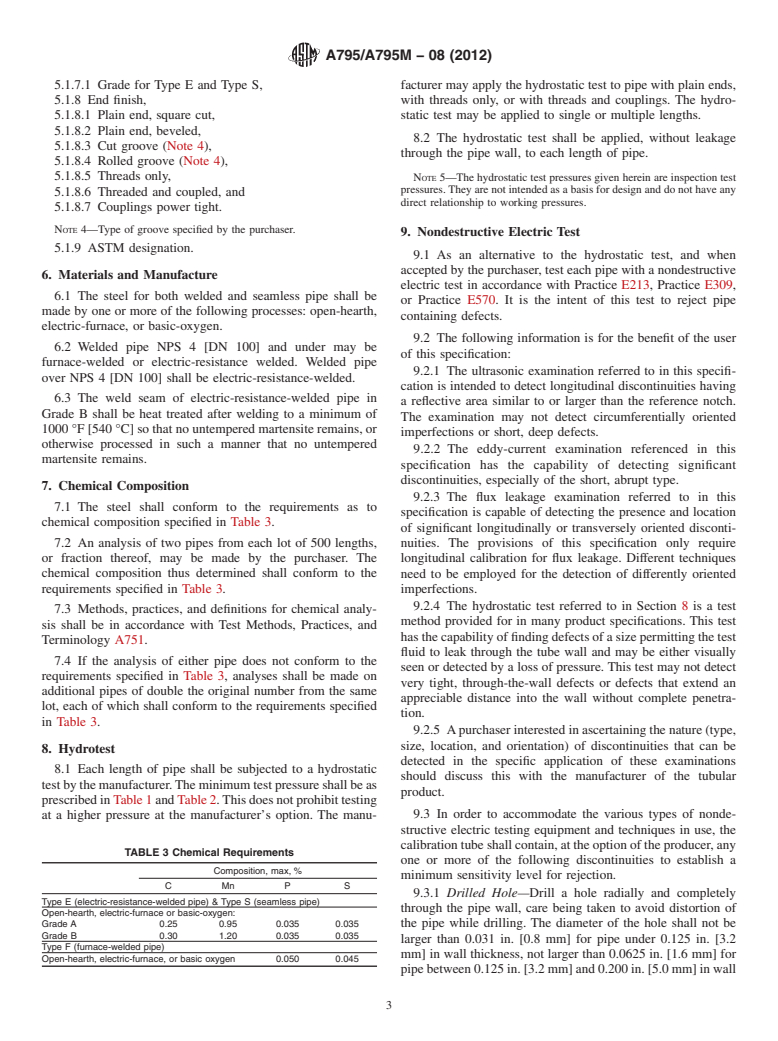

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A795/A795M −08(Reapproved 2012)

Standard Specification for

Black and Hot-Dipped Zinc-Coated (Galvanized) Welded and

1

Seamless Steel Pipe for Fire Protection Use

This standard is issued under the fixed designationA795/A795M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* health practices and determine the applicability of regulatory

limitations prior to use.

1.1 This specification covers black and hot-dipped galva-

1.4 The values stated in either SI units or inch-pound units

nized welded and seamless steel pipe in NPS 1/2 to NPS 10,

are to be regarded separately as standard. Within the text, the

inclusive [DN 15 to DN 250, inclusive] (Note 1), with wall

SI units are shown in brackets. The values stated in each

thicknesses as given in Table 1 and Table 2. Pipe having other

system may not be exact equivalents; therefore, each system

wallthicknessesmaybefurnishedprovidedsuchpipecomplies

shall be used independently of the other. Combining values

with all other requirements of this specification and the outside

from the two systems may result in non-conformance with the

diameter is as given in Table 2. Pipe ordered under this

standard.

specification is intended for use in fire protection systems. The

pipe may be bent, but it is not intended for bending made at

2. Referenced Documents

ambient temperature wherein the inside diameter of the bend is

2

2.1 ASTM Standards:

less than twelve times the outside diameter of the pipe being

A90/A90M Test Method for Weight [Mass] of Coating on

bent (Note 2).

Iron and Steel Articles with Zinc or Zinc-Alloy Coatings

NOTE 1—The dimensionless designators NPS (nominal pipe size) and

A700 Practices for Packaging, Marking, and Loading Meth-

DN (nominal diameter) have been substituted in this standard for such

ods for Steel Products for Shipment

traditional terms as “nominal diameter,” “size,” and “nominal size.”

A751 Test Methods, Practices, and Terminology for Chemi-

NOTE 2—Successful bending of pipe is a function of equipment and

technique as well as pipe properties. cal Analysis of Steel Products

A865 Specification for Threaded Couplings, Steel, Black or

1.2 This pipe is suitable for joining by the following

Zinc-Coated (Galvanized)Welded or Seamless, for Use in

methods:

Steel Pipe Joints

1.2.1 Light-Weight Fire Protection Pipe— Rolled groove,

B6 Specification for Zinc

welding, and fittings for plain end pipe. See Table 1 for

E213 Practice for Ultrasonic Testing of Metal Pipe and

dimensions.

Tubing

1.2.2 Standard-Weight Fire Protection Pipe—Cut or rolled

E309 Practice for Eddy-Current Examination of Steel Tubu-

groove, threading, welding, and fittings for plain end pipe. See

lar Products Using Magnetic Saturation

Table 2 for dimensions.

E570 Practice for Flux Leakage Examination of Ferromag-

1.2.3 For pipe having dimensions other than those of Table

netic Steel Tubular Products

1 and Table 2, the joining method must be compatible with the

2.2 ASME Standards:

pipe dimensions. A complete listing of standard light weight

3

B1.20.1 Pipe Threads, General Purpose, Inch

dimensions appears in ASME B36.10 and B36.19.

3

B36.10 Welded and Seamless Wrought Steel Pipe

1.3 The following safety hazards caveat pertains only to the

3

B36.19 Stainless Steel Pipe

test method portion, Sections 8, 9, and 10, of this specification:

2.3 Federal Standard:

This standard does not purport to address all of the safety

4

Fed. Std. No. 123 Marking for Shipments (Civil Agencies)

concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, the ASTM website.

3

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee Available from American Society of Mechanical Engineers (ASME), ASME

A01.09 on Carbon Steel Tubular Products. International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

Current edition approved Sept. 1, 2012. Published November 2012. Originally www.asme.org.

4

approved in 1982. Last previous edition approved in 2008 as A795/A795M–08. AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

DOI: 10.1520/A0795_A0795M-08R12. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

*A Summary of Changes section appears at the end of this standard

Copyright ©

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.