ASTM B422-08a

(Specification)Standard Specification for Copper-Aluminum-Silicon-Cobalt Alloy, Copper-Nickel-Silicon-Magnesium Alloy, Copper-Nickel-Silicon Alloy, Copper-Nickel-Aluminum-Magnesium Alloy, and Copper-Nickel-Tin Alloy Sheet and Strip

Standard Specification for Copper-Aluminum-Silicon-Cobalt Alloy, Copper-Nickel-Silicon-Magnesium Alloy, Copper-Nickel-Silicon Alloy, Copper-Nickel-Aluminum-Magnesium Alloy, and Copper-Nickel-Tin Alloy Sheet and Strip

ABSTRACT

This specification establishes the requirements for sheets and strips of copper-aluminum-silicon-cobalt, copper-nickel-silicon-magnesium, copper-nickel-silicon, copper-nickel-aluminum-magnesium, and copper-nickel-tin alloys with Copper Alloy UNS Nos. C19010, C19020, C19025, C63800, C64725, C70250, C70260, and C70265. Materials shall be tested and shall conform to dimensional (thickness, width, length, straightness, and edges), mechanical (tensile and yield strength, elongation, and ductility or formability), electrical resistivity, chemical composition requirements.

SCOPE

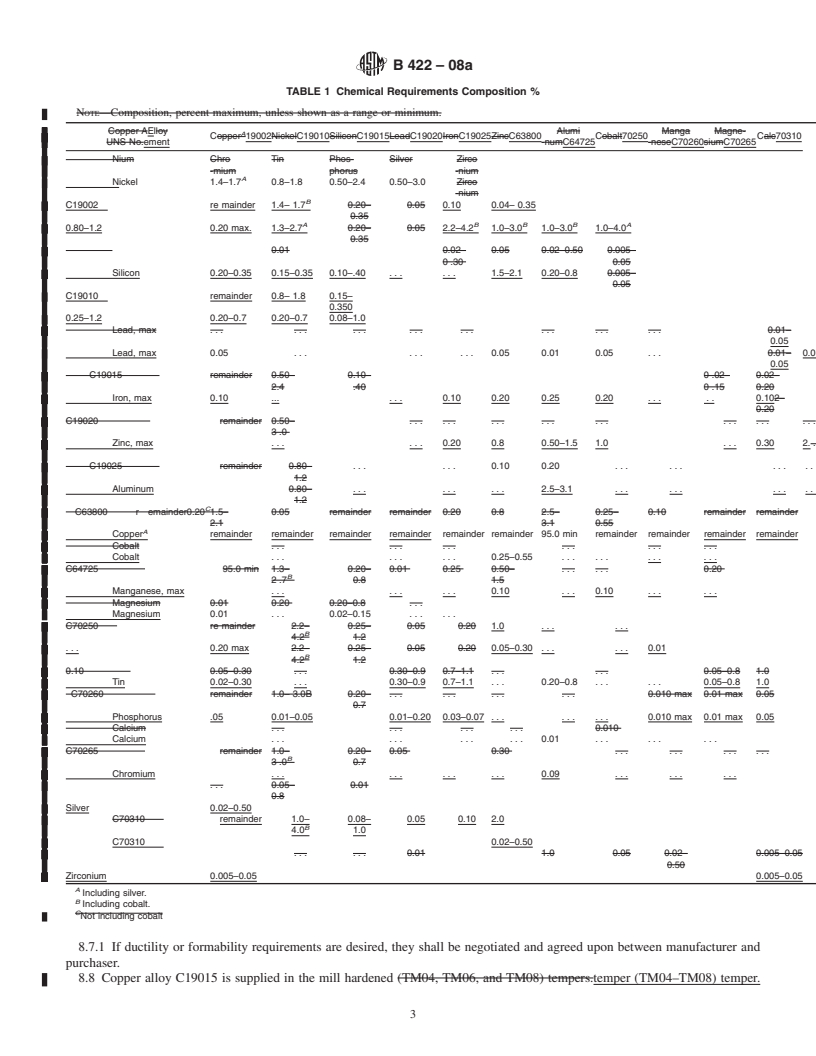

1.1 This specification establishes the requirements for Copper Alloy UNS Nos. C19002, C19010, C19015, ,C19020, C19025, C63800, C64725, C70250, C70260, C70265, and C70310 sheet and strip.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B422 – 08a

Standard Specification for

Copper-Aluminum-Silicon-Cobalt Alloy, Copper-Nickel-

Silicon-Magnesium Alloy, Copper-Nickel-Silicon Alloy,

Copper-Nickel-Aluminum-Magnesium Alloy, and Copper-

1

Nickel-Tin Alloy Sheet and Strip

This standard is issued under the fixed designation B422; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* B248 Specification for General Requirements for Wrought

2 Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled

1.1 Thisspecificationestablishestherequirementsfor Cop-

Bar

per Alloy UNS Nos. C19002, C19010, C19015, ,C19020,

B248M Specification for General Requirements for

C19025, C63800, C64725, C70250, C70260, C70265, and

Wrought Copper and Copper-Alloy Plate, Sheet, Strip, and

C70310 sheet and strip.

Rolled Bar (Metric)

1.2 The values stated in either SI units or inch-pound units

B846 Terminology for Copper and Copper Alloys

are to be regarded separately as standard. The values stated in

E527 Practice for Numbering Metals and Alloys in the

each system may not be exact equivalents; therefore, each

Unified Numbering System (UNS)

system shall be used independently of the other. Combining

values from the two systems may result in non-conformance

3. General Requirements

with the standard.

3.1 Material furnished to this specification shall be in

1.3 This standard does not purport to address all of the

accordance with the applicable requirements of the current

safety concerns, if any, associated with its use. It is the

edition of Specification B248.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Terminology

bility of regulatory limitations prior to use.

4.1 Definitions—For definitions of terms related to copper

2. Referenced Documents and copper alloys, refer to Terminology B846.

2.1 The following documents of the issue in effect on date

5. Ordering Information

of material purchase form a part of this specification to the

5.1 Orders for material under this specification should

extent referenced herein:

include the following information:

3

2.2 ASTM Standards:

5.1.1 Quantity (of each size),

5.1.2 Alloy: Copper Alloy UNS No. (Section 1),

5.1.3 Form of material (sheet or strip),

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

5.1.4 Temper (see 7.1),

andCopperAlloysandisthedirectresponsibilityofSubcommitteeB05.01onPlate,

5.1.5 Dimensions (thickness, width, length (if applicable),

Sheet, and Strip.

5.1.6 How furnished (rolls, specific lengths with or without

Current edition approved Oct. 1, 2008. Published November 2008. Originally

approved in 1965. Last previous edition approved in 2008 as B422 – 08. DOI:

ends, stock lengths with or without ends),

10.1520/B0422-08A.

5.1.7 Type of edge, if required (slit, sheared, sawed, square

2

The UNS system for copper and copper alloys (see Practice E527) is a simple

corners,roundedcorners,roundededges,orfull-roundededges

expansion of the former standard designation system accomplished by the addition

(see 10.6),

of a prefix “C” and a suffix “00.” The suffix can be used to accommodate

composition variations of the base alloy.

5.1.8 Type of width and straightness tolerances, if required

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

(slit-metal tolerances, square sheared-metal tolerances, sawed-

contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM

metal tolerances, straightened or edge-rolled-metal tolerances)

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. (Section 10), and

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B422 – 08a

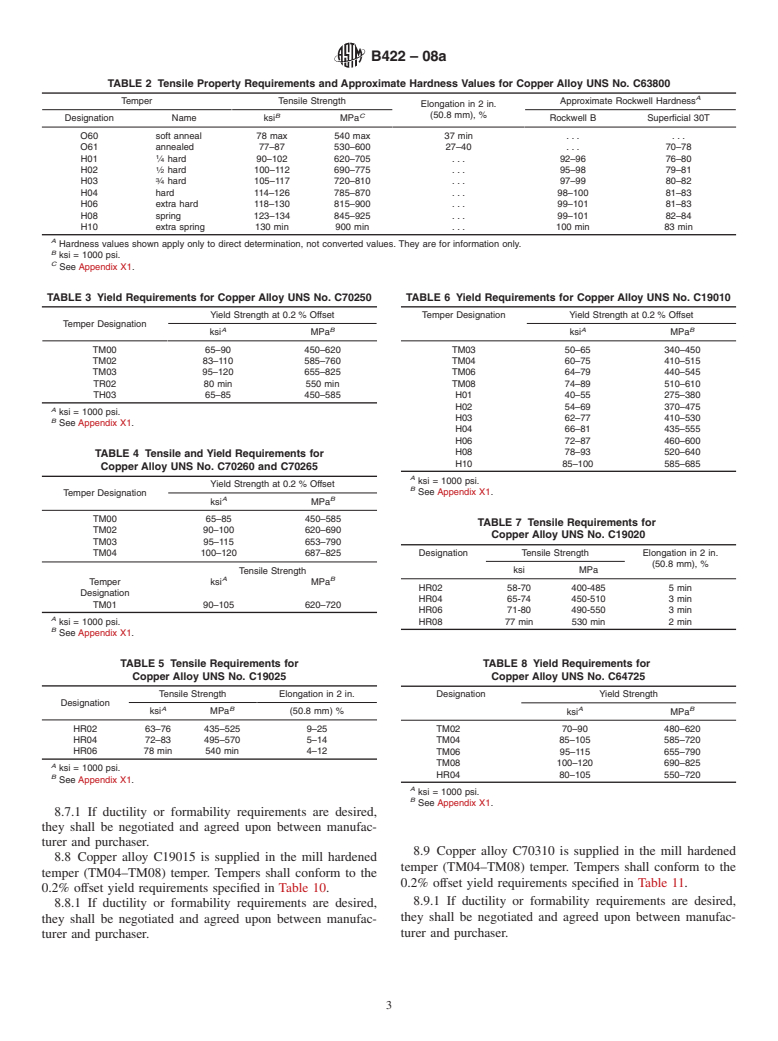

5.1.9 ASTM specification number and year of issue. 8.3 Copper Alloys UNS No. C70260 and C70265 are

5.2 In addition, when material is purchased for agencies of supplied in a mill-hardened temper. The 0.2 % offset yield

the U.S. government, it shall conform to the Supplementary

strengthshallbethestandardtestforthemill-hardenedtempers

Requirements as defined in Specification B248 when specified

TM00, TM02, TM03, and TM04 and shall conform to the

in the contract or purchase order.

requirements specified in Table 4. The tensile strength shall be

the standard test for the mill-hardened temper TM01 and shall

6. Chemical Composition

conform to the r

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B422–08 Designation: B 422 – 08a

Standard Specification for

Copper-Aluminum-Silicon-Cobalt Alloy, Copper-Nickel-

Silicon-Magnesium Alloy, Copper-Nickel-Silicon Alloy,

Copper-Nickel-Aluminum-Magnesium Alloy, and Copper-

1

Nickel-Tin Alloy Sheet and Strip

This standard is issued under the fixed designation B 422; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

2

1.1 This specification establishes the requirements for Copper Alloy UNS Nos. C19002, C19010, C19015, C19020, C19025,

C63800, C64725, C70250, C70260, C70265, and C70310 sheet and strip.

1.2The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard. CopperAlloy UNS Nos. C19002,

C19010, C19015, ,C19020, C19025, C63800, C64725, C70250, C70260, C70265, and C70310 sheet and strip.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein:

3

2.2 ASTM Standards:

B 248 Specification for General Requirements for Wrought Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled Bar

B 248M Specification for General Requirements for Wrought Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled Bar

(Metric)

B 846 Terminology for Copper and Copper Alloys

E 527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

3. General Requirements

3.1 Material furnished to this specification shall be in accordance with the applicable requirements of the current edition of

Specification B 248.

4. Terminology

4.1 Definitions— For definitions of terms related to copper and copper alloys, refer to Terminology B 846.

5. Ordering Information

5.1 Orders for material under this specification should include the following information:

5.1.1 Quantity (of each size),

5.1.2 Alloy: Copper Alloy UNS No. (Section 1),

1

This specification is under the jurisdiction of ASTM Committee B05 on Copper and Copper Alloys and is the direct responsibility of Subcommittee B05.01 on Plate,

Sheet, and Strip.

Current edition approved MayOct. 1, 2008. Published JuneNovember 2008. Originally approved in 1965. Last previous edition approved in 20062008 as B 422 – 068.

2

The UNS system for copper and copper alloys (see Practice E 527) is a simple expansion of the former standard designation system accomplished by the addition of

a prefix “C” and a suffix “00.” The suffix can be used to accommodate composition variations of the base alloy.

3

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B 422 – 08a

5.1.3 Form of material (sheet or strip),

5.1.4 Temper (see 7.1),

5.1.5 Dimensions (thickness, width, length (if applicable),

5.1.6 How furnished (rolls, specific lengths with or without ends, stock lengths with or without ends),

5.1.7 Type of edge, if required (slit, sheared, sawed, square corners, rounded corners, rounded edges, or full-rounded edges (see

10.6),

5.1.8 Type of width and straightness tolerances, if required (slit-metal tolerances, square sheared-metal tolerances, sawed-metal

tolerances, straightened or edge-rolled-metal tolerances) (Section

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.