ASTM B829-04A(2009)e1

(Specification)Standard Specification for General Requirements for Nickel and Nickel Alloys Seamless Pipe and Tube

Standard Specification for General Requirements for Nickel and Nickel Alloys Seamless Pipe and Tube

ABSTRACT

This general specification contains the mandatory requirements to the ASTM standards listed herein for seamless pipes and tubes made from nickel and nickel alloys. In case of conflict, the requirements listed in the particular product specification takes precedence over those listed here.

SCOPE

1.1 This specification contains various requirements that, with the exception of Sections 5 and 10, are mandatory requirements to the following ASTM nickel and nickel alloy, seamless pipe and tube specifications:

Title of Specification

ASTM

Designation2

Nickel Seamless Pipe and Tube

B161

Seamless Nickel and Nickel Alloy, Condenser and Heat Ex-

changer Tubes

B163

Nickel-Copper Alloy (UNS N04400) Seamless Pipe and Tube

B165

Nickel-Chromium-Iron Alloys (UNS N06600, N06601, and

N06690) Seamless Pipe and Tube

B167

Nickel-Iron-Chromium Alloy Seamless Pipe and Tube

B407

Nickel-Iron-Chromium-Molybdenum-Copper Alloy (UNS N08825

and N08221) Seamless Pipe and Tube

B423

Nickel-Chromium-Molybdenum-Columbium Alloys (UNS

N06625) Pipe and Tube

B444

Nickel-Chromium-Iron-Columbium-Molybdenum-Tungsten Alloy

(UNS N06102) Seamless Pipe and Tube

B445

Nickel-Iron-Chromium-Silicon Alloys (UNS N08330 and UNS

N08332) Seamless Pipe

B535

Copper-Beryllium Alloy Forgings and Extrusion

B570

Seamless Nickel and Nickel-Cobalt Alloy Pipe and Tube

B622

UNS N08028 Seamless Tubes

B668

UNS N08904, UNS N08925 and UNS N08926 Seamless Pipe

and Tube

B677

Iron-Nickel-Chromium-Molybdenum Alloys (UNS N08366 and

UNS N08367) Seamless Pipe and Tube

B690

Ni-Cr-Mo-Co-W-Fe-Si Alloy (UNS N06333) Seamless Pipe and

Tube

B722

Seamless UNS N08020, UNS N08026, and UNS N08024

Nickel-Alloy Pipe and Tube

B729

1.2 One or more of the test requirements of Section 5 apply only if specifically stated in the product specification or in the purchase order.

1.3 In case of conflict between a requirement of the product specification and a requirement of this general specification, only the requirement of the product specification needs to be satisfied.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 The following safety hazards caveat pertains only to the test requirements portion, Section 5, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:B829 −04a(Reapproved 2009)

Standard Specification for

General Requirements for Nickel and Nickel Alloys

Seamless Pipe and Tube

This standard is issued under the fixed designation B829; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Table 4 was corrected editorially in November 2012.

1. Scope* 1.3 In case of conflict between a requirement of the product

specification and a requirement of this general specification,

1.1 This specification contains various requirements that,

only the requirement of the product specification needs to be

with the exception of Sections 5 and 10, are mandatory

satisfied.

requirements to the following ASTM nickel and nickel alloy,

seamless pipe and tube specifications: 1.4 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

ASTM

Title of Specification

Designation

conversions to SI units that are provided for information only

Nickel Seamless Pipe and Tube B161

and are not considered standard.

Seamless Nickel and Nickel Alloy, Condenser and Heat Ex- B163

changer Tubes

1.5 The following safety hazards caveat pertains only to the

Nickel-Copper Alloy (UNS N04400) Seamless Pipe and Tube B165

test requirements portion, Section 5, of this specification: This

Nickel-Chromium-Iron Alloys (UNS N06600, N06601, and B167

standard does not purport to address all of the safety concerns,

N06690) Seamless Pipe and Tube

Nickel-Iron-Chromium Alloy Seamless Pipe and Tube B407

if any, associated with its use. It is the responsibility of the user

Nickel-Iron-Chromium-Molybdenum-Copper Alloy (UNS N08825 B423

of this standard to become familiar with all hazards including

and N08221) Seamless Pipe and Tube

those identified in the appropriate Material Safety Data Sheet

Nickel-Chromium-Molybdenum-Columbium Alloys (UNS B444

N06625) Pipe and Tube

(MSDS) for this product/material as provided by the

Nickel-Chromium-Iron-Columbium-Molybdenum-Tungsten Alloy B445

manufacturer, to establish appropriate safety and health

(UNS N06102) Seamless Pipe and Tube

Nickel-Iron-Chromium-Silicon Alloys (UNS N08330 and UNS B535 practices, and determine the applicability of regulatory limi-

N08332) Seamless Pipe

tations prior to use.

Copper-Beryllium Alloy Forgings and Extrusion B570

Seamless Nickel and Nickel-Cobalt Alloy Pipe and Tube B622

2. Referenced Documents

UNS N08028 Seamless Tubes B668

UNS N08904, UNS N08925 and UNS N08926 Seamless Pipe B677

2.1 ASTM Standards:

and Tube

B880 Specification for General Requirements for Chemical

Iron-Nickel-Chromium-Molybdenum Alloys (UNS N08366 and B690

UNS N08367) Seamless Pipe and Tube

Check Analysis Limits for Nickel, Nickel Alloys and

Ni-Cr-Mo-Co-W-Fe-Si Alloy (UNS N06333) Seamless Pipe and B722

Cobalt Alloys

Tube

E8/E8M Test Methods for Tension Testing of Metallic Ma-

Seamless UNS N08020, UNS N08026, and UNS N08024 B729

Nickel-Alloy Pipe and Tube

terials

E18 Test Methods for Rockwell Hardness of Metallic Ma-

1.2 One or more of the test requirements of Section 5 apply

terials

only if specifically stated in the product specification or in the

E29 Practice for Using Significant Digits in Test Data to

purchase order.

Determine Conformance with Specifications

E39 Methods for Chemical Analysis of Nickel (Withdrawn

This specification is under the jurisdiction of ASTM Committee B02 on

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee 1995)

B02.07 on Refined Nickel and Cobalt and Their Alloys.

E76 Test Methods for Chemical Analysis of Nickel-Copper

Current edition approved April 15, 2009. Published April 2009. Originally 3

Alloys (Withdrawn 2003)

approved in 1992. Last previous edition approved in 2004 as B829 – 04a. DOI:

E112 Test Methods for Determining Average Grain Size

10.1520/B0829-04AR09E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

B829−04a(2009)

E213 Practice for Ultrasonic Testing of Metal Pipe and (6.9 MPa) provided that the fiber stress, calculated from the

Tubing following equation, does not exceed the allowable fiber stress

E426 PracticeforElectromagnetic(Eddy-Current)Examina- for the material:

tion of Seamless and Welded Tubular Products, Titanium,

P 5 2St/D (1)

Austenitic Stainless Steel and Similar Alloys

where:

E571 PracticeforElectromagnetic(Eddy-Current)Examina-

tion of Nickel and Nickel Alloy Tubular Products P = hydrostatic test pressure, psi (MPa),

S = allowable fiber stress, for material in the condition

E1473 Test Methods for Chemical Analysis of Nickel,

(temper) furnished as specified in the product specifi-

Cobalt, and High-Temperature Alloys

4 cation (S is calculated as the lower of ⁄3 of the specified

2.2 ANSI Standards:

minimum 0.2 % offset yield strength or ⁄4 of the

B1.20.1 Pipe Threads

specified minimum ultimate strength for the material),

B36.10 Welded and Seamless Wrought Steel Pipe

t = minimum wall thickness permitted, in. (mm), including

B36.19 Stainless Steel Pipe

minus tolerance, if any, and

D = nominal outside diameter of the pipe or tube, in. (mm).

3. Terminology

5.2.1 The test pressure must be held for a minimum of 5 s.

3.1 Definitions:

NOTE 1—Testing at a pressure greater than 1000 psi may be performed

3.1.1 average diameter, n—theaverageofthemaximumand

upon agreement between purchaser and manufacturer provided that the

minimum outside diameters, as determined at any one cross

allowable fiber stress is not exceeded.

section of the pipe or tube.

5.2.2 If any pipe or tube shows leaks during hydrostatic

3.1.2 nominal wall, n—aspecifiedwallthicknesswithaplus

testing, it shall be rejected.

or minus tolerance from the specified thickness.

5.3 Nondestructive Electric Test:

3.1.3 seamless pipe, n—a round hollow produced with a

5.3.1 Eddy Current Testing—Testing shall be conducted in

continuous periphery in all stages of manufacture, and pro-

accordance with Practices E426 or E571. The eddy current

duced to the particular dimensions commercially known as

examination reference in this specification has the capability of

pipe sizes (NPS).

detecting significant discontinuities, especially of the short,

3.1.4 seamless tube, n—a tube produced with a continuous

abrupt type.

periphery in all stages of the operation.

5.3.1.1 Unless otherwise specified by the purchaser, the

3.1.5 thin wall tube, n—tube with specified wall thickness

calibration standard shall contain, at the option of the

3 % or less of the specified outside diameter.

manufacturer, any one of the following discontinuities to

establish a minimum sensitivity level for rejection.

4. Chemical Composition

5.3.1.2 Drill Hole—A hole not larger than 0.031 in. (0.79

mm) diameter shall be drilled radially and completely through

4.1 In case of disagreement, the chemical composition shall

the wall, care being taken to avoid distortion of the material

be determined in accordance with the following methods.

while drilling.

UNS No. Prefixes ASTM Method

5.3.1.3 Transverse Tangential Notch—Using a round file or

N02 E39

N04 E76

tool with a ⁄4 in. (6 mm) diameter, a notch shall be filed or

N06, N08 E1473

milled on the tube or pipe outside diameter tangential to the

4.2 The ladle analysis of the material shall conform to the

surface and transverse to the longitudinal axis of the material.

chemical requirements prescribed by the individual product

Said notch shall have a depth not exceeding 12.5 % of the

specification.

specifiedwallthicknessofthematerial,or0.004in.(0.10mm),

whichever is greater.

4.3 The product (check) analysis of the material shall meet

5.3.2 Ultrasonic Testing—Testing shall be conducted in

the requirements for the ladle analysis within the tolerance

accordance with Practice E213. The ultrasonic examination

limits prescribed in Specification B880.

referred to in this specification is intended to detect longitudi-

nal discontinuities having a reflective area similar to or larger

5. Test Requirements

than the calibration reference notches specified in 5.3.2.1. The

5.1 Flare Test—The flare test shall consist of flaring a test

examination may not detect circumferentially oriented imper-

specimen with an expanding tool having an included angle of

fections or short, deep defects.

60° until the specified outside diameter has been increased by

5.3.2.1 For ultrasonic testing, longitudinal calibration

30 %. The flared specimen shall not exhibit cracking through

notches shall be machined on the outside and inside diameter

the wall.

surfaces. The depth of the notches shall not exceed 12.5 % of

5.2 Hydrostatic Test—Each pipe or tube shall be tested by

the specified wall thickness or 0.004 in. (0.10 mm), whichever

themanufacturertoaninternalhydrostaticpressureof1000psi

is greater.

5.3.3 Calibration Frequency—The frequency of calibration

checks shall be as follows:

5.3.3.1 At the beginning of each production run or lot.

Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. 5.3.3.2 At least every four hours during testing.

´1

B829−04a(2009)

5.3.3.3 At the end of each production run or lot. 5.5 Tension Test—Tension testing shall be conducted in

5.3.3.4 After any suspected equipment malfunction or work accordance with Test Methods E8/E8M.

stoppage.

5.5.1 The material shall conform to the tensile properties

5.3.3.5 If, during any check, the equipment fails to detect

prescribed in the individual product specification.

the calibration defects, the instrument must be recalibrated and

5.6 Hardness Test—Hardness testing shall be conducted in

all material tested since the last satisfactory check shall be

accordance with Test Methods E18.

retested.

5.3.4 Acceptance and Rejection—Material producing a sig-

5.7 Grain Size—The measurement of average grain size

nal equal to or greater than the calibration defect shall be

may be carried out by the planimetric method, the comparison

subject to rejection.

method, or the intercept method described in Test Methods

5.3.4.1 Test signals produced by imperfections that cannot

E112. In case of dispute, the “referee” method for determining

be identified or produced by cracks or crack-like imperfections

average grain size shall be the intercept method.

shall result in rejection of the pipe or tube, subject to rework

5.8 For purposes of determining compliance with the speci-

and retest.

fied limits for requirements of the properties listed in the

5.3.4.2 If the imperfection is judged as not fit for use, the

following table, an observed value or a calculated value shall

tube shall be rejected, but may be reconditioned and retested

beroundedinaccordancewiththeroundingmethodofPractice

providing the wall thickness requirements are met. To be

E29:

accepted, retested material shall meet the original electric test

requirements. Requirements Rounded Unit for Observed

or Calculated Value

5.3.4.3 If the imperfection is explored to the extent that it

Chemical composition and nearest unit in the last right-hand place

canbeidentified,andthepipeortubeisdeterminedtobefitfor

tolerances of figures of the specified limit

use, the material may be accepted without further testing, Tensile strength and yield strength nearest 1000 psi (7 MPa)

Elongation nearest 1 %

providing the imperfection does not encroach on minimum

Grain size

wall thickness requirements.

0.0024 in. (0.060 mm) or larger nearest multiple of 0.0002 in. (0.005 mm)

Less than 0.0024 in. (0.060 mm) nearest multiple of 0.0001 in. (0.002 mm)

5.4 When specified by the purchaser, a nondestructive

electrictest,inaccordancewithPracticesE213,E426,orE571,

6. Dimensions and Permissible Variations

may be used for seamless pipe or tube, instead of the

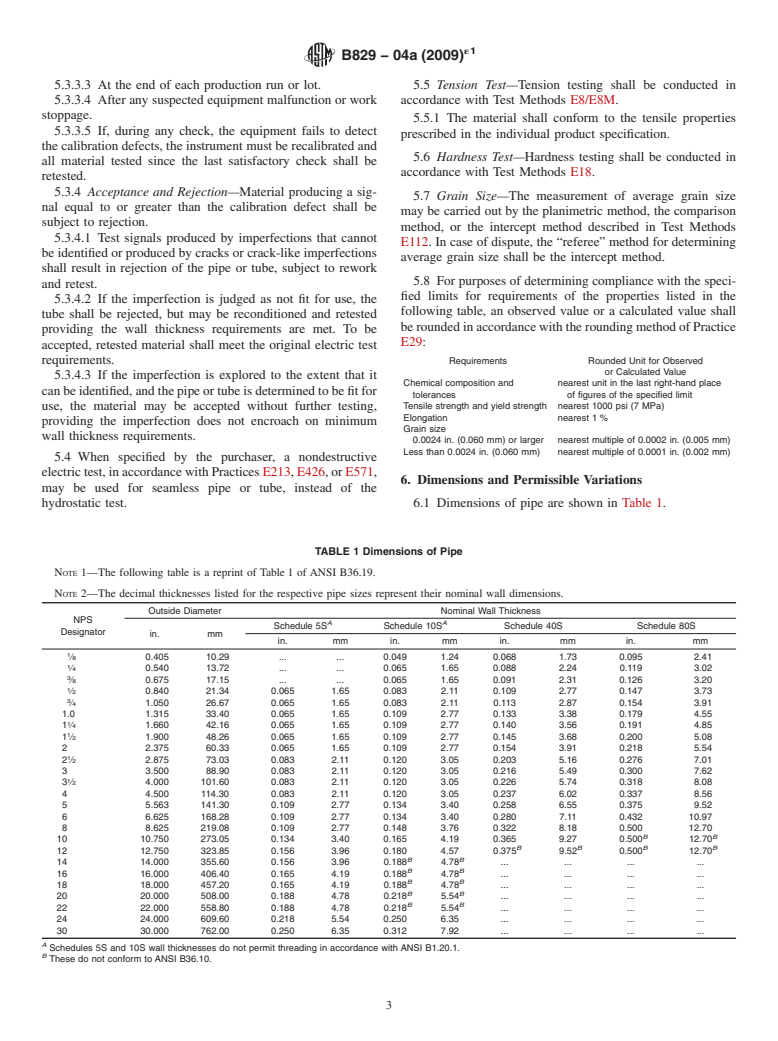

hydrostatic test. 6.1 Dimensions of pipe are shown in Table 1.

TABLE 1 Dimensions of Pipe

NOTE 1—The following table is a reprint of Table 1 of ANSI B36.19.

NOTE 2—The decimal thicknesses listed for the respective pipe sizes represent their nominal wall dimensions.

Outside Diameter Nominal Wall Thickness

NPS

A A

Schedule 5S Schedule 10S Schedule 40S Schedule 80S

Designator

in. mm

in. mm in. mm in. mm in. mm

⁄8 0.405 10.29 . . 0.049 1.24 0.068 1.73 0.095 2.41

⁄4 0.540 13.72 . . 0.065 1.65 0.088 2.24 0.119 3.02

⁄8 0.675 17.15 . . 0.065 1.65 0.091 2.31 0.126 3.20

⁄2 0.840 21.34 0.065 1.65 0.083 2.11 0.109 2.77 0.147 3.73

⁄4 1.050 26.67 0.065 1.65 0.083 2.11 0.113 2.87 0.154 3.91

1.0 1.315 33.40 0.065 1.65 0.109 2.77 0.133 3.38 0.179 4.55

1 ⁄4 1.660 42.16 0.065 1.65 0.109 2.77 0.140 3.56 0.191 4.85

1 ⁄2 1.900 48.26 0.065 1.65 0.109 2.77 0.145 3.68 0.200 5.08

2 2.375 60.33 0.065 1.65 0.109 2.77 0.154 3.91 0.218 5.54

2 ⁄2 2.875 73.03 0.083 2.11 0.120 3.05 0.203 5.16 0.276 7.01

3 3.500 88.90 0.083 2.11 0.120 3.05 0.216 5.49 0.300 7.62

3 ⁄2 4.000 101.60 0.083 2.11 0.120 3.05 0.226 5.74 0.318 8.08

4 4.500 114.30 0.083 2.11 0.120 3.05 0.237 6.02 0.337 8.56

5 5.563 141.30 0.109 2.77 0.134 3.40 0.258 6.55 0.375 9.52

6 6.625 168.28 0.109 2.77 0.134 3.40 0.280 7.11 0.432 10.97

8 8.625 219.08 0.109 2.77 0.148 3.76 0.322 8.18 0.500 12.70

B B

10 10.750 273.05 0.134 3.40 0.165 4.19 0.365 9.27 0.500 12.70

B B B B

12 12.750 323.85 0.156 3.96 0.180 4.57 0.375 9.52 0.500 12.70

B B

14 14.000 355.60 0.156 3.96 0.188 4.78 . . . .

B B

16 16.000 406.40 0.165 4.19 0.188 4.78 . . . .

B B

18 18.000 457.20 0.165 4.19 0.188 4.78 . . . .

B B

20 20.000 508.00 0.188 4.78 0.218 5.54 . . . .

B B

22 22.000 558.80 0.188 4.78 0.218 5.54 . . . .

24 24.000 609.60 0.218 5.54 0.250 6.35 . . . .

30 30.000 762.00 0.250 6.35 0.312 7.92 . . . .

A

Schedules 5S and 10S wall thicknesses do not permit threading in accordance with ANSI B1.20.1.

B

These do not conform to ANSI B36.10.

´1

B829−04a(2009)

6.1.1 Permissible variations in outside diameter and wall 8.2.1 Chemical Analysis—Representative samples from

thickness are shown in Table 2, Table 3, and Table 4. each lot shall be taken during pouring or subsequent process-

ing.

6.2 Length—When material is ordered as cut-to-length, the

8.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.