ASTM C1041-85(2007)

(Practice)Standard Practice for In-Situ Measurements of Heat Flux in Industrial Thermal Insulation Using Heat Flux Transducers

Standard Practice for In-Situ Measurements of Heat Flux in Industrial Thermal Insulation Using Heat Flux Transducers

SIGNIFICANCE AND USE

The major contribution of this practice is that it enables a measurement of the real-time energy loss or gain through a chosen surface of an existing process insulation with minimal disturbance to the heat flux through the insulating body.

The primary use of this practice will be for the in-situ estimation of thermal transport properties of industrial insulation such as used on pipes, tanks, ovens, and boilers, operating under normal process conditions.

Errors attributable to heat flow measurements over a small area or short term testing can be misleading and this practice is intended to minimize such errors.

Insulation processes with large temperature differences across the insulation are best suited to HFT measurements because modest changes in ambient conditions have but minimal effects on HFT output.

While it would be ideal for the HFT and attachment system to have zero thermal resistance, this factor is insignificant to the measured result if kept to 5 % or less of the resistance of the insulating section being tested.

SCOPE

1.1 This practice covers the in-situ measurement of heat flux through industrial thermal insulation using a heat flux transducer (HFT).

1.2 This practice estimates the thermal transport properties of thermal insulation materials in-situ in field applications under pseudo steady-state conditions. It is not intended that this practice should be used as a substitute for more precise laboratory procedures such as Test Methods C 177, C 335, or C 518.

1.3 This practice is limited by the relatively small area that can be covered by an HFT and by the transient effects of environmental conditions.

1.4 Temperature limitations shall be as specified by the manufacturer of the HFT.

1.5 While accurate values of heat flux are highly depend-ent upon proper calibrations under the conditions of use, manufacturer's calibrations may be used with confidence for comparative work between similar materials, aging, or other conditions of use. Note 1 - Further information may be found in the literature (1-6).

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1041–85(Reapproved2007)

Standard Practice for

In-Situ Measurements of Heat Flux in Industrial Thermal

Insulation Using Heat Flux Transducers

This standard is issued under the fixed designation C1041; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C335 Test Method for Steady-State Heat Transfer Proper-

ties of Pipe Insulation

1.1 Thispracticecoversthein-situmeasurementofheatflux

C518 Test Method for Steady-State Thermal Transmission

through industrial thermal insulation using a heat flux trans-

Properties by Means of the Heat Flow Meter Apparatus

ducer (HFT).

E220 Test Method for Calibration of Thermocouples By

1.2 This practice estimates the thermal transport properties

Comparison Techniques

of thermal insulation materials in-situ in field applications

E230 Specification and Temperature-Electromotive Force

underpseudosteady-stateconditions.Itisnotintendedthatthis

(EMF) Tables for Standardized Thermocouples

practice should be used as a substitute for more precise

laboratory procedures such as Test Methods C177, C335,or

3. Terminology

C518.

3.1 Definitions:

1.3 This practice is limited by the relatively small area that

3.1.1 heat flux transducer (HFT)—a rigid or flexible trans-

can be covered by an HFT and by the transient effects of

ducer in a durable housing comprised of a thermopile or

environmental conditions.

equivalent for sensing the temperature drop across a thin

1.4 Temperature limitations shall be as specified by the

thermal resistance layer which gives a voltage output propor-

manufacturer of the HFT.

tional to the heat flux through the transducer.

1.5 While accurate values of heat flux are highly depend-ent

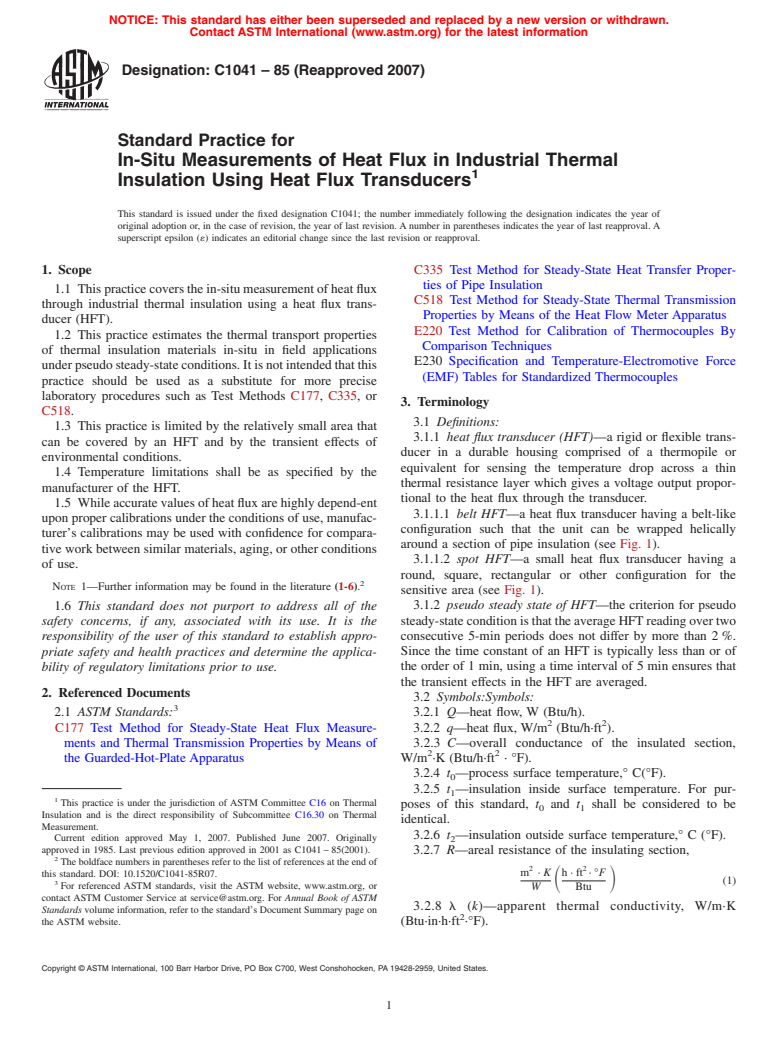

3.1.1.1 belt HFT—a heat flux transducer having a belt-like

upon proper calibrations under the conditions of use, manufac-

configuration such that the unit can be wrapped helically

turer’s calibrations may be used with confidence for compara-

around a section of pipe insulation (see Fig. 1).

tive work between similar materials, aging, or other conditions

3.1.1.2 spot HFT—a small heat flux transducer having a

of use.

round, square, rectangular or other configuration for the

NOTE 1—Further information may be found in the literature (1-6).

sensitive area (see Fig. 1).

1.6 This standard does not purport to address all of the 3.1.2 pseudo steady state of HFT—the criterion for pseudo

steady-stateconditionisthattheaverageHFTreadingovertwo

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- consecutive 5-min periods does not differ by more than 2 %.

Since the time constant of an HFT is typically less than or of

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. the order of 1 min, using a time interval of 5 min ensures that

the transient effects in the HFT are averaged.

2. Referenced Documents

3.2 Symbols:Symbols:

2.1 ASTM Standards: 3.2.1 Q—heat flow, W (Btu/h).

2 2

C177 Test Method for Steady-State Heat Flux Measure- 3.2.2 q—heat flux, W/m (Btu/h·ft ).

ments and Thermal Transmission Properties by Means of 3.2.3 C—overall conductance of the insulated section,

2 2

the Guarded-Hot-Plate Apparatus W/m ·K (Btu/h·ft · °F).

3.2.4 t —process surface temperature,° C(°F).

3.2.5 t —insulation inside surface temperature. For pur-

This practice is under the jurisdiction of ASTM Committee C16 on Thermal

poses of this standard, t and t shall be considered to be

0 1

Insulation and is the direct responsibility of Subcommittee C16.30 on Thermal

identical.

Measurement.

3.2.6 t —insulation outside surface temperature,° C (°F).

Current edition approved May 1, 2007. Published June 2007. Originally 2

approved in 1985. Last previous edition approved in 2001 as C1041 – 85(2001).

3.2.7 R—areal resistance of the insulating section,

The boldface numbers in parentheses refer to the list of references at the end of

2 2

m · K h·ft ·°F

this standard. DOI: 10.1520/C1041-85R07.

(1)

3 S D

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

W Btu

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.2.8 l (k)—apparent thermal conductivity, W/m·K

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. (Btu·in·h·ft ·°F).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1041–85 (2007)

6.2 Voltmeter/Recorder—A voltage-measuring recording

instrument accurate to within 0.5 % of the lowest HFT output

anticipated during the test. An integrating voltmeter is even

more appropriate for reading the output of the HFT.

6.3 Temperature Sensor—A thermocouple or other device

of a type suitable for the temperatures being measured.

6.3.1 For measuring the temperature of an insulated surface,

such as a pipe under insulation, a 1.5-mm diameter or smaller,

flexible ungrounded thermocouple probe 500 mm long is

recommended.

6.3.2 For measuring the temperature of surfaces that can be

easily accessed, 24 gage or smaller, bare bead thermocouples

or equivalent shall be used.

6.4 Attachment Materials—Pressure-sensitive adhesive

tape, elastic bands, straps, mastic, grease, or other means may

be used to hold the HFT in place on the test surface.

6.5 Thermal Contact Materials—Patching cement, silicone

grease, heat sink grease, silicone sealant, room temperature

vulcanizing elastomer, thermally conducting epoxy, or con-

formable pads may be used to provide maximum contact

NOTE 1—Belt wraps around exterior; shim slips under jacketing (spot

between the test surface and the HFT where applicable. The

HFT).

FIG. 1 Flexible Heat Flux Transducers for Pipes thermal coupler should not add to or reduce the resistance of

the system such that the temperature patterns of heat flows are

significantly changed. This could be measured by surface

3.2.9 D—thickness of test section, m (in.).

temperature probes or infrared measurement devices.

3.2.10 r —outer radius of pipe insulation, m (in.).

6.6 Surfacing Materials—Coating, films, or foils to adjust

3.2.11 r —inner radius of pipe insulation, m (in.).

the surface emittance of the HFT to match the radiant charac-

3.2.12 r —outer radius of pipe, m (in.).

teristics of the test surface.

3.2.13 V—HFT output in millivolts or other chosen unit.

4. Summary of Practice

7. Calibrations

4.1 This practice is a guide to the proper use of heat flux

7.1 HFT must be calibrated under the conditions of use; for

transducers for estimating the thermal transport properties of

example, a calibration under aluminum jacketing on a test

thermal insulation in-situ in field applications under pseudo

setup in accordance with Test Method C335, would be proper

steady-state conditions.

for calibration of an HFT for subsequent testing under similar

conditions.

5. Significance and Use

7.2 Calibrate HFT to national reference standards in accor-

5.1 The major contribution of this practice is that it enables

dance with Test Methods C177, C335,or C518. A calibration

a measurement of the real-time energy loss or gain through a

curve showing q/V versus insulation surface temperature (ex-

chosen surface of an existing process insulation with minimal

pected to be the HFTtemperature) shall be developed covering

disturbance to the heat flux through the insulating body.

the intended range of operating temperatures and heat fluxes.

5.2 The primary use of this practice will be for the in-situ

7.2.1 The following is an example of calibration under use

estimation of thermal transport properties of industrial insula-

conditions (pipe insulated with preformed insulation and jack-

tion such as used on pipes, tanks, ovens, and boilers, operating

eted with aluminum):

under normal process conditions.

7.2.1.1 SetuptheapparatusinaccordancewithTestMethod

5.3 Errors attributable to heat flow measurements over a

C335 with preformed insulation, jacketed with aluminum

small area or short term testing can be misleading and this

jacket in the same condition as that to be tested.

practice is intended to minimize such errors.

7.2.1.2 Establish steady-state at test temperature (3.1.2).

5.4 Insulation processes with large temperature differences

across the insulation are best suited to HFT measurements 7.2.1.3 Insert flexible HFT under jacket, near the center of

the insulation section. The jacket should be lifted enough to

because modest changes in ambient conditions have but

minimal effects on HFT output. provideguidanceinplacingtheHFTawayfromalljointsinthe

insulation section. (When a belt HFT is being calibrated, it

5.5 While it would be ideal for the HFT and attachment

system to have zero thermal resistance, this factor is insignifi- must be wrapped in a tight helix around the center of the

cant to the measured result if kept to 5 % or less of the insulation section with the appropriate side, foil or gray to

resistance of the insulating section being tested. match emittance, exposed. Attach the strap to the belt, pulling

and rubbing the belt into close contact with the insulation

6. Apparatus

section, making sure that the lap of the belt is on the side of the

6.1 Heat Flux Transducer, as described in 3.1.1. pipe.)

C1041–85 (2007)

7.2.1.4 Insert a bare temperature sensor about 50 mm away 8.3.1 Measure the process surface temperature by inserting

from the HFT. After calibrating the belt HFT, place the sensor a thermocouple probe as described in 6.3.1 such that the probe

between the belt and the insulation surface to measure surface lies against the process surface for 150 mm (6 in.) or more. For

temperature. purposes of inserting the probe, pierce the insulation with an

7.2.1.5 Read pseudo steady-state electrical output of HFT ice pick or other means at an angle of 30° or less to the plane

and temperature at both surfaces of the insulation. Since the of the surface to be measured. The correct insertion of the

output of the HFT will fluctuate under most conditions, a probe should show the maximum DT across the insulation.

graphical or integrated average of the output of the HFT must

8.3.1.1 If the process system has built-in temperature-

be made.

measuring capabilities in good repair and calibration the output

7.2.1.6 Utilizing q, as may be calculated from Test Method

from such devices may be usable in place of a temperature

C335 data, determine the calibration value for the HFT in q/V

probe.

for at least 3 insulation surface temperatures.

8.3.2 A bare bead thermocouple should be inserted under

7.2.1.7 Plot calibration value (q/V) versus insulation surface

the jacket to measure the surface temperature of the insulation

temperature (7.2.1.6).

near the HFT (see 7.2.1.4).

7.3 Calibrate the thermocouple in accordance with Test

8.3.3 When the HFT is installed on a surface rather than

Method E220.

under a jacket (or other cover), measure the surface tempera-

ture of the insulation near the HFT by taping a bare bead

8. Test Section and HFT and Temperature Sensor

thermocouple to the insulation surface (6.3.2) such that at least

Placement Guidelines

100 mm of the thermocouple is in contact with the surface.The

8.1 Test Section:

emittance of the tape should match that of the insulation

8.1.1 Selection of the test sections must be appropriate and

surface within 60.2 (see 8.2.2).

consistent with the test objectives. Several test sections may be

needed.

9. HFT and Temperature Data Points

8.1.2 Infrared scanning is an appropriate way to identify

9.1 The output from the HFT shall be recorded with a

relative surface uniformity conditions so that the HFT may be

suitable recorder such that pseudo steady-state (3.1.2) may be

placed to measure the thermal transport properties of a repre-

observed when attained. Depending on exact environmental

sentative area.

conditions, the recorder usually traces a “band” of data which

8.1.3 Test sections must be amenable to attachment of the

must be averaged graphically.

HFTwithgoodthermalcouplingandwithminimaldisturbance

9.2 As an alternative to recording the output of the HFT, an

of normal heat transfer.

integrating voltmeter may be used. While the exact conditions

8.2 HFT Placement:

to be utilized will depend upon the capabilities of the voltmeter

8.2.1 Where block or pipe insulation is being tested, place a

at hand, it is suggested that short integration periods be

spot HFT preferably under the jacketing material near the

averaged over sequential 5-min intervals to determine when

center of a formed section of material. Avoid placement on

pseudo steady-state (3.1.2) is achieved.

joints in insulation or laps in jacketing unless joint loss is being

9.3 Temperature readings shall be taken when the HFT

evaluated.

reading comes to pseudo steady-state as defined in 3.1.2.

8.2.2 When a spot HFT is surface-mounted, it may be

attached by using an adhesive two-sided tape, heat transfer 9.4 Multiple location data points must be taken and aver-

grease, or other appropriate means. The emittance of the HFT aged.

must match the surface as closely as possible. With one

transducer an error of 0.01 at the 0.05 emittance level displaces 10. Procedure

the reading by 3.5 %.An error of 0.1 at the 0.5 emittance level

10.1 Select an appropriate test area and install HFT and

displaces the reading by 3.5 %.

temperature sensors in accordance with Section 8.

8.2.3 Use a belt HFT for obtaining system thermal perfor-

10.2 Shield the HFT from direct solar radiation unless solar

mance data of block or pipe insulation, including heat loss

gain is intended as a factor in the study.

from large joints. When the belt HFT is mounted on reflective

10.3 Connect the HFT to the recorder or integrating volt-

insulation jacketing, it should have the foil side exposed; when

meterandtakereadingsuntilpseudosteady-stateisachievedin

it is mounted on a surface with high emittance, the gray side

accordance with Section 9.

must be exposed. Wrap the belt HFT around the insulation test

10.4 Measure the surface temperature of the insulation near

section in a tight helix with no overlap, with the belt pulled and

the HFT in accordance with 8.3.2, 8.3.3, and 9.3.

rubbed to achieve close contact with the test surface. For full

10.5 Measure the temperature of the process surface in

circumferential integration, a minimum of one complete wrap

accordance with 8.3.1 and 9.3.

must be made. If the HFT is not long enough to wrap

10.6 If appropriate, measure ambient weather conditions

completely around the test section, connect additiona

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.