ASTM F1564-95(2006)

(Specification)Standard Specification for Structure-Mounted Insulating Work Platforms for Electrical Workers

Standard Specification for Structure-Mounted Insulating Work Platforms for Electrical Workers

ABSTRACT

This specification covers the design testing of mechanical and electrical characteristics of structure-mounted insulating work platforms for electrical workers in conjunction with personal protective equipment while working on energized circuits. This shall include, but not limited to, insulating gloves with protectors or insulating and insulated hotsticks, or both and a fall protection device that does not compromise the electrical insulating protection of the platform. The platforms shall be subjected to electrical test to determine the leakage current and the ability of the specimen to withstand certain alternating-current potential without flashover between electrodes. Mechanical test shall also be conducted to allow deflection measurement under controlled loading and to determine the ability of the platform to withstand this loading without visible damages such as cracks, delamination, permanent deformation, or discoloration.

SCOPE

1.1 This specification covers the design testing of mechanical and electrical characteristics of structure-mounted insulating work platforms used by electrical workers.

1.2 Platforms covered by this specification are singleworker platforms not exceeding 9 ft (2.75 m) in length. Platforms designed to support more than one worker at a time are beyond the scope of this specification.

1.3 Non-insulating platforms are not within the scope of this specification.

1.4 The use and maintenance of this equipment are beyond the scope of this specification.

1.5 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

The following safety hazards caveat pertains only to the test method portion, Section 9 of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1564 −95(Reapproved 2006)

Standard Specification for

Structure-Mounted Insulating Work Platforms for Electrical

Workers

This standard is issued under the fixed designation F1564; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 Refer to Definitions F819 for definitions of terms

specific to this specification.

1.1 This specification covers the design testing of mechani-

3.2 Definitions of Terms Specific to This Standard:

cal and electrical characteristics of structure-mounted insulat-

3.2.1 design test—a type of test made on a sample treated as

ing work platforms used by electrical workers.

representative of an industrial product. These tests will not be

1.2 Platforms covered by this specification are singleworker

repeated in quantity production.

platforms not exceeding 9 ft (2.75 m) in length. Platforms

3.2.2 discontinuities—abrupt changes in surface that may

designed to support more than one worker at a time are beyond

trip an electrical worker or otherwise introduce a hazard to the

the scope of this specification.

worker (see 8.1).

1.3 Non-insulatingplatformsarenotwithinthescopeofthis

3.2.3 insulating distance—the distance from the structure

specification.

attachment point to the beginning of the work area of the

1.4 The use and maintenance of this equipment are beyond

platform.

the scope of this specification.

4. Significance and Use

1.5 The values stated in inch-pound units are to be regarded

as the standard. The SI units given in parentheses are for

4.1 Insulating work platforms covered by this specification

information only.

are designed to be used by electrical workers in conjunction

1.6 The following safety hazards caveat pertains only to the

with personal protective equipment while working on ener-

test method portion, Section 9 of this specification:This stan- gized circuits. This shall include, but not be limited to:

dard does not purport to address all of the safety concerns, if

4.1.1 Insulating gloves with protectors or insulating and

any, associated with its use. It is the responsibility of the user

insulated hotsticks, or both.

of this standard to establish appropriate safety and health

4.1.2 A fall protection device that does not compromise the

practices and determine the applicability of regulatory limita-

electrical insulating protection of the platform.

tions prior to use.

4.2 The test procedures in this specification provide an

2. Referenced Documents objective means of determining if a platform meets minimum

2 electrical and mechanical specifications. The methods permit

2.1 ASTM Standards:

testing of major components of the platform under controlled

F711 Specification for Fiberglass-Reinforced Plastic (FRP)

conditions.

Rod and Tube Used in Live Line Tools

F819 Terminology Relating to Electrical Protective Equip- 4.3 The test procedures utilize objective criteria for evalu-

ment for Workers

ation and may be discontinued at any time defects are found.

3. Terminology

5. Ordering Information

3.1 Definitions:

5.1 Orders for platforms under this specification should

include the following information:

This specification is under the jurisdiction of ASTM Committee F18 on

5.1.1 Length,

Electrical Protective Equipment for Workers and is the direct responsibility of

Subcommittee F18.35 on Tools & Equipment. 5.1.2 Pivot or non-pivot attachment, and

Current edition approved Nov. 1, 2006. Published January 2007. Originally

5.1.3 Single-point or rail-type attachment for worker.

approved in 1994. Last previous edition approved in 2000 as F1564 – 95(00). DOI:

10.1520/F1564-95R06.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 6. Manufacture and Marking

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.1 Each platform covered by this specification shall be

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. marked clearly and permanently with the maximum working

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1564−95(Reapproved 2006)

load in the position used as well as the name of the

manufacturer, month and year of assembly, and the ASTM

designation.

F1564−95 (2006)

6.2 Each platform shall have a durable nonskid finish 8.2 All insulated surface areas providing electrical insula-

applied to the area of the platform on which the worker stands. tion and isolation of the work area from the structure shall be

This coating shall be nonconductive and shall permanently smooth for ease of cleaning.

adhere to the surface.

9. Test Methods

7. Other Requirements

9.1 Test each design of insulating work platform covered by

7.1 Each platform shall be free of areas that will trap water this specification dielectrically and mechanically in accordance

anddebristhatmayimpairtheinsulatingeffectivenessbetween

with the following procedures:

the worker location and the structure attachment. 9.1.1 Electrical Test:

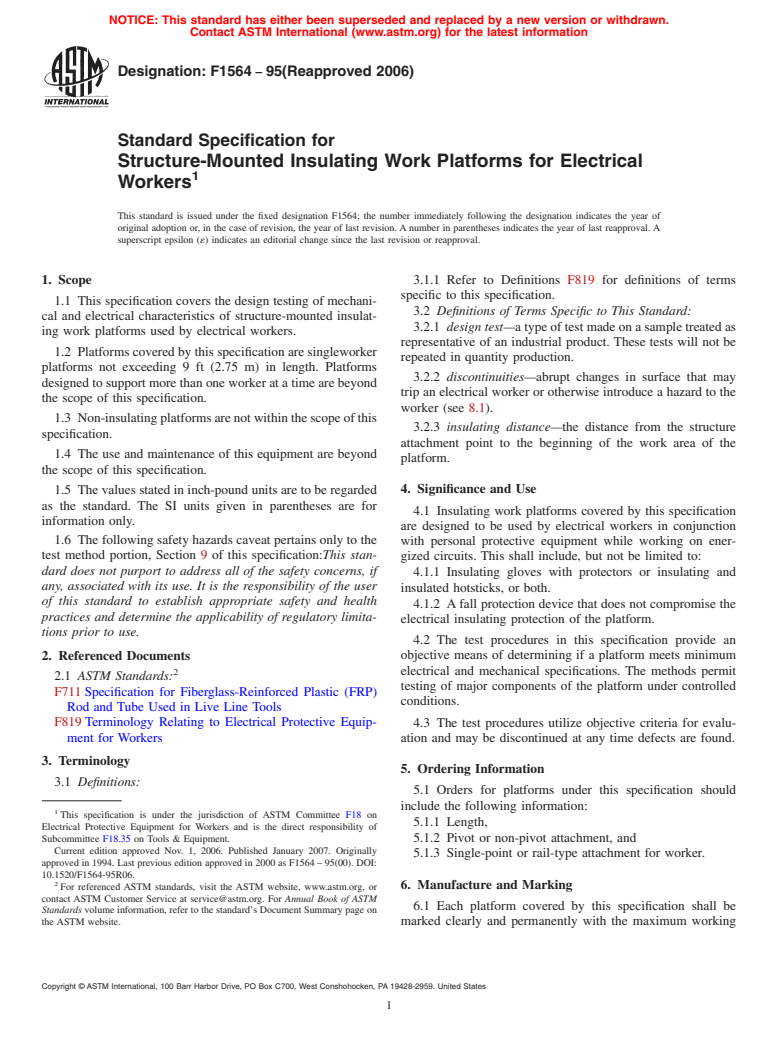

7.2 Each platform shall have a minimum overall length of

NOTE 1—Equivalent direct-current (DC) test voltages are under con-

sideration at this time and will be inserted at a later date.

38 in. (96.52 cm) and an insulating distance of at least 12 in.

(30.48 cm) from the structure attachment to the kick board or

9.1.1.1 As shown in Fig. 2, the 12-in. (30.48-cm) insulating

other suitable barrier. See Fig. 1 for details.

segment of the assembled platform shall withstand a 100-kV

7.2.1 Anybracepolesorattachmentsbridgingtheinsulating

alternating-current (ac) potential for 5 min. Passing this test is

section of the platform shall have a minimum of 12 in. (30.48

indicated by the following: no flashover between electrodes;

cm) of insulating distance. (See Fig. 1.)

the surf

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.