ASTM D210-05(2019)

(Specification)Standard Specification for Bone Black Pigment

Standard Specification for Bone Black Pigment

ABSTRACT

This specification covers bone black, ivory black, or drop black pigment. The pigment may be in dry form or in aqueous dispersion. Dry pigment shall be made by the calcinations of bones, unmixed with any other substance. Dry pigment shall compose of ash, ash insoluble in acids, and coarse particles. Pigment in aqueous dispersion shall be made by grinding the pigment with water, dispersing agent, biocide, fungicide, pH stabilizer, and defoamer. ASTM test methods shall be conducted for coarse particles, pigment and linseed oil in paste in oil, and mass color and tinting strength.

SCOPE

1.1 This specification covers the pigment commercially known as bone black, ivory black, or drop black. The pigment may be purchased in the dry form or as an aqueous dispersion.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D210 − 05 (Reapproved 2019)

Standard Specification for

1

Bone Black Pigment

This standard is issued under the fixed designation D210; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

Ash (pigment dried at 105°C), max, % 88

Ash insoluble in acids, max, % 3.0

1.1 This specification covers the pigment commercially

Coarse particles (total residue retained on a No. 325 2.0

known as bone black, ivory black, or drop black. The pigment (45-µm) sieve), max, %

may be purchased in the dry form or as an aqueous dispersion.

3.2 Pigment in Aqueous Dispersion—The aqueous disper-

1.2 The values stated in SI units are to be regarded as sion shall be made by grinding the specified pigment with

water, dispersing agent, biocide, fungicide, pH stabilizer and

standard. The values given in parentheses are for information

only. defoamer using high speed dispersion equipment. The disper-

sion shall conform to the following requirements:

1.3 This international standard was developed in accor-

Pigment, min 38 %

dance with internationally recognized principles on standard-

Dispersing agent 14 %

ization established in the Decision on Principles for the

Biocide, max 1 %

Development of International Standards, Guides and Recom-

Fungicide, max 1 %

pH Stabilizer, max 1 %

mendations issued by the World Trade Organization Technical

Defoamer, max 1 %

Barriers to Trade (TBT) Committee.

Water 44 %

3.3 The mass color and character of the tint and the tinting

2. Referenced Documents

strength formed by a mixture with a white pigment shall be

2

2.1 ASTM Standards:

within mutually agreed upon limits of a standard acceptable to

D185 Test Methods for Coarse Particles in Pigments

both the purchaser and the seller.

D387 Test Method for Color and Strength of Chromatic

Pigments with a Mechanical Muller

4. Sampling

D1208 Test Methods for Common Properties of Certain

4.1 Two samples shall be taken at random from different

Pigments

packages from each 500 lb batch, consisting of one lot. At the

option of the purchaser, the samples may be tested separately

3. Composition and Properties

or after blending in equal quantities the samples from the same

3.1 Dry Pigment—The pigment shall be made by the calci-

production unit to form a composite sample.

nation of bones, shall be unmixed with any other substance,

and shall conform to the following requirements:

5. Test Methods

5.1 Tests shall be conducted in accordance with the fo

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D210 − 05 (Reapproved 2011) D210 − 05 (Reapproved 2019)

Standard Specification for

1

Bone Black Pigment

This standard is issued under the fixed designation D210; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the pigment commercially known as bone black, ivory black, or drop black. The pigment may be

purchased in the dry form or as an aqueous dispersion.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D185 Test Methods for Coarse Particles in Pigments

D387 Test Method for Color and Strength of Chromatic Pigments with a Mechanical Muller

D1208 Test Methods for Common Properties of Certain Pigments

3. Composition and Properties

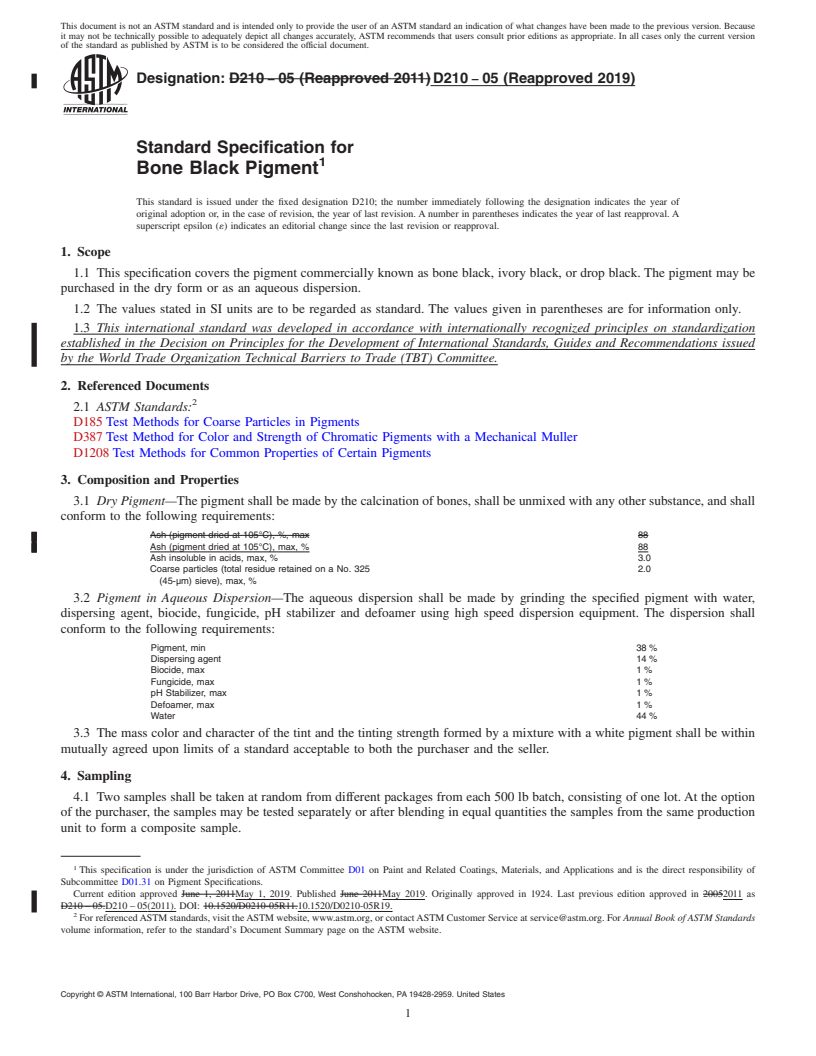

3.1 Dry Pigment—The pigment shall be made by the calcination of bones, shall be unmixed with any other substance, and shall

conform to the following requirements:

Ash (pigment dried at 105°C), %, max 88

Ash (pigment dried at 105°C), max, % 88

Ash insoluble in acids, max, % 3.0

Coarse particles (total residue retained on a No. 325 2.0

(45-μm) sieve), max, %

3.2 Pigment in Aqueous Dispersion—The aqueous dispersion shall be made by grinding the specified pigment with water,

dispersing agent, biocide, fungicide, pH stabilizer and defoamer using high speed dispersion equipment. The dispersion shall

conform to the following requirements:

Pigment, min 38 %

Dispersing agent 14 %

Biocide, max 1 %

Fungicide, max 1 %

pH Stabilizer, max 1 %

Defoamer, max 1 %

Water 44 %

3.3 The mass color and character of the tint and the tinting strength formed by a mixture with a white pigment shall be within

mutually agreed upon limits of a standard acceptable to both the purchaser and the seller.

4. Sampling

4.1 Two samples shall be taken at random from different packages from each 500 lb batch, consisting of one lot. At the option

of the purchaser, the samples may be tested sepa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.