ASTM B171/B171M-12

(Specification)Standard Specification for Copper-Alloy Plate and Sheet for Pressure Vessels, Condensers, and Heat Exchangers

Standard Specification for Copper-Alloy Plate and Sheet for Pressure Vessels, Condensers, and Heat Exchangers

ABSTRACT

This specification establishes the requirements for plates, sheets, and circles cut from plates and sheets made of UNS C36500, C44300, C44400, C44500, C46400, C46500, C61300, C61400, C63000, C63200, C70600, C70620, C71500, C71520, or C72200 copper alloy. These materials are recommended for use in pressure vessels, condensers, and heat exchangers. The materials are manufactured by either hot rolling or forging and finished by such cold working and annealing to produce products of the required dimensions and properties. Tempers available under this specification are as hot rolled and hot rolled and annealed. The products manufactured for ASME Boiler and Pressure Vessel code applications must be certified to the hot rolled and annealed temper while all other products can either have hot rolled or hot rolled and annealed temper. This specification also contains information on the required material chemical compositions, densities, and tensile properties.

SCOPE

1.1 This specification2 establishes the requirements for copper-alloy plate, sheet, and circles cut from plate and sheet for pressure vessels, condensers, and heat exchangers. The following alloys are covered:

Copper Alloy

Previously Used Designation

C36500

Leaded Muntz Metal

C44300

Admirality, Arsenical

C44400

Admirality, Antimonial

C44500

Admirality, Phosphorized

C46400

Naval Brass, Uninhibited

C46500

Naval Brass, Arsenical

C61300

Aluminum Bronze

C61400

Aluminum Bronze D

C63000

10 % Aluminum-Nickel Bronze

C63200

9 % Aluminum-Nickel Bronze

C70600

90-10 Copper Nickel

C70620

90-10 Copper Nickel -(modified for welding)

C71500

70-30 Copper Nickel

C71520

70-30 Copper Nickel-(modified for welding)

C72200

. . .

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B171/B171M −12

Standard Specification for

Copper-Alloy Plate and Sheet for Pressure Vessels,

1

Condensers, and Heat Exchangers

This standard is issued under the fixed designation B171/B171M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* B248M SpecificationforGeneralRequirementsforWrought

2 Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled

1.1 This specification establishes the requirements for

Bar (Metric)

copper-alloy plate, sheet, and circles cut from plate and sheet

B601 Classification forTemper Designations for Copper and

for pressure vessels, condensers, and heat exchangers. The

Copper Alloys—Wrought and Cast

following alloys are covered:

B846 Terminology for Copper and Copper Alloys

Copper Alloy Previously Used Designation

E8/E8M Test Methods for Tension Testing of Metallic Ma-

C36500 Leaded Muntz Metal terials

C44300 Admirality, Arsenical

E29 Practice for Using Significant Digits in Test Data to

C44400 Admirality, Antimonial

Determine Conformance with Specifications

C44500 Admirality, Phosphorized

C46400 Naval Brass, Uninhibited E54 Test Methods for ChemicalAnalysis of Special Brasses

4

C46500 Naval Brass, Arsenical

and Bronzes (Withdrawn 2002)

C61300 Aluminum Bronze

E62 Test Methods for Chemical Analysis of Copper and

C61400 Aluminum Bronze D

4

C63000 10 % Aluminum-Nickel Bronze CopperAlloys (Photometric Methods) (Withdrawn 2010)

C63200 9 % Aluminum-Nickel Bronze

E255 Practice for Sampling Copper and Copper Alloys for

C70600 90-10 Copper Nickel

the Determination of Chemical Composition

C70620 90-10 Copper Nickel -(modified for welding)

C71500 70-30 Copper Nickel

E478 Test Methods for ChemicalAnalysis of CopperAlloys

C71520 70-30 Copper Nickel-(modified for welding)

E527 Practice for Numbering Metals and Alloys in the

C72200 . . .

Unified Numbering System (UNS)

1.2 Units—The values stated in either SI units or inch-

pound units are to be regarded separately as standard. The

3. Terminology

values stated in each system may not be exact equivalents;

3.1 For definitions of terms related to copper and copper

therefore,eachsystemshallbeusedindependentlyoftheother.

alloys, refer to Terminology B846.

Combining values from the two systems may result in non-

conformance with the standard.

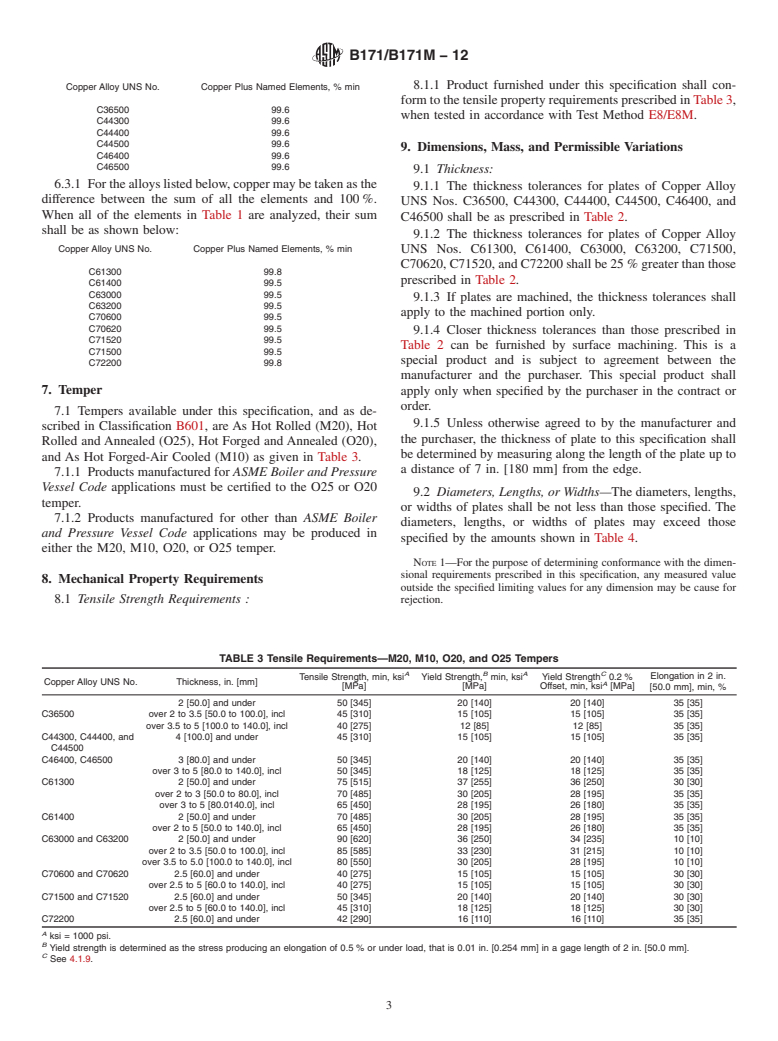

4. Ordering Information

4.1 Include the following information when placing orders

2. Referenced Documents

for product under this specification, as applicable:

3

2.1 ASTM Standards:

4.1.1 ASTM designation and year of issue,

B248 Specification for General Requirements for Wrought

4.1.2 Whether inch-pound or SI units are applicable (see

Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled

1.2),

Bar

4.1.3 Copper Alloy UNS. No. (see Section 6, Table 1),

4.1.4 Whether the alloy ordered will be used in applications

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

requiring it to be welded (see Table 1, footnotes B and C for

andCopperAlloysandisthedirectresponsibilityofSubcommitteeB05.01onPlate,

UNS Nos. C61300 and C72200, respectively, and UNS Nos.

Sheet, and Strip.

C70620 and C71520 in place of UNS Nos. C70600 and

Current edition approved Oct. 15, 2012. Published November 2012. Originally

ε1

approved in 1942. Last previous edition approved in 2011 as B171/B171M – 11 .

C71500),

DOI: 10.1520/B0171_B0171M-12.

4.1.5 Whether plate is to be machined (see 9.1.3),

2

For ASME Boiler and Pressure Vessel Code applications, see related Specifi-

4.1.6 How tolerance is specified (Table 2 Footnote A),

cation SB-171 in Section II of that Code.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B171/B171M−12

TABLE 1 Chemical Requirements

Composition, % max (Unless Shown as a Range)

Copper Alloy

A Copper, incl Manganese, Other Named

UNS No.

Tin Nickel, incl Cobalt Lead Iron Zinc Aluminum Chromium

Silver max Elements

C36500 58.0-61.0 0.25 . . . . . . 0.25-0.7 0.15 remainder . . . . . . . . .

C44300 70.0-73.0 0.8-1.2 . . . . . . 0.07 0.06 remainder . . . . . . 0.02-0.06 As

C44400 70.0-73.0 0.8-1.2 . . . . . . 0.

...

´1

Designation: B171/B171M − 11 B171/B171M − 12

Standard Specification for

Copper-Alloy Plate and Sheet for Pressure Vessels,

1

Condensers, and Heat Exchangers

This standard is issued under the fixed designation B171/B171M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon («) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

εNOTE—Table 1 Cr editorially corrected in March 2011.

1. Scope*

2

1.1 This specification establishes the requirements for copper-alloy plate, sheet, and circles cut from plate and sheet for

pressure vessels, condensers, and heat exchangers. The following alloys are covered:

Copper Alloy Previously Used Designation

C36500 Leaded Muntz Metal

C44300 Admirality, Arsenical

C44400 Admirality, Antimonial

C44500 Admirality, Phosphorized

C46400 Naval Brass, Uninhibited

C46500 Naval Brass, Arsenical

C61300 Aluminum Bronze

C61400 Aluminum Bronze D

C63000 10 % Aluminum-Nickel Bronze

C63200 9 % Aluminum-Nickel Bronze

C70600 90-10 Copper Nickel

C70620 90-10 Copper Nickel -(modified for welding)

C71500 70-30 Copper Nickel

C71520 70-30 Copper Nickel-(modified for welding)

C72200 . . .

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated

in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values

from the two systems may result in non-conformance with the standard.

2. Referenced Documents

3

2.1 ASTM Standards:

B248 Specification for General Requirements for Wrought Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled Bar

B248M Specification for General Requirements for Wrought Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled Bar

(Metric)

B601 Classification for Temper Designations for Copper and Copper Alloys—Wrought and Cast

B846 Terminology for Copper and Copper Alloys

E8/E8M Test Methods for Tension Testing of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

4

E54 Test Methods for Chemical Analysis of Special Brasses and Bronzes (Withdrawn 2002)

4

E62 Test Methods for Chemical Analysis of Copper and Copper Alloys (Photometric Methods) (Withdrawn 2010)

E255 Practice for Sampling Copper and Copper Alloys for the Determination of Chemical Composition

E478 Test Methods for Chemical Analysis of Copper Alloys

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

3. Terminology

3.1 For definitions of terms related to copper and copper alloys, refer to Terminology B846.

4. Ordering Information

4.1 Include the following information when placing orders for product under this specification, as applicable:

4.1.1 ASTM designation and year of issue,

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B171/B171M − 12

4.1.2 Whether inch-pound or SI units are applicable (see 1.2),

4.1.3 Copper Alloy UNS. No. (see Section 6, Table 1),

4.1.4 Whether the alloy ordered will be used in applications requiring it to be welded (see Table 1, footnotes B and C for UNS

Nos. C61300 and C72200, respectively, and UNS Nos. C70620 and C71520 in place of UNS Nos. C70600 and C71500),

4.1.5 Whether plate is to be machined (see 9.1.3),

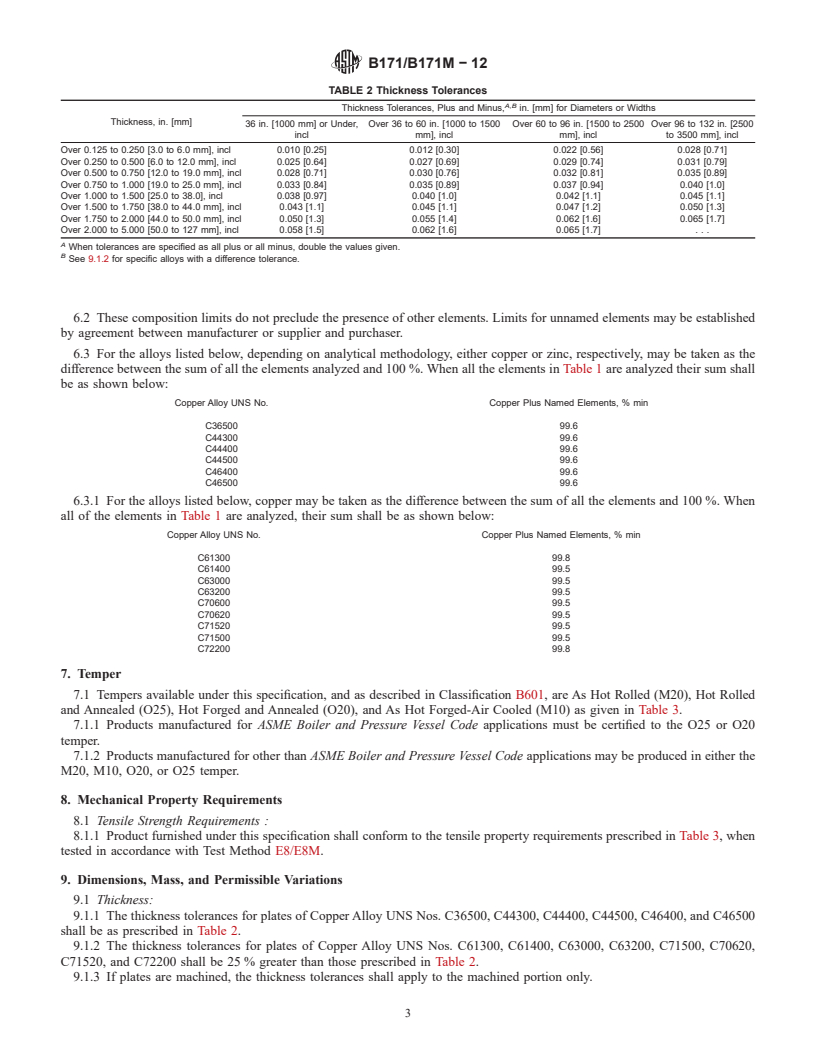

4.1.6 How tolerance is specified (Table 2 Footnote A),

4.1.7 Certification, if required (Section 17),

4.1.8 Weight (total for each size),

4.1.9 Mill test report, if required (Section 18),

4.1.10 Special marking, if required (Section 19), and

4.1.11 Whether 0.2 yield offset strength is required.

5. Materials and Manufacture

5.1 Material—The material and manufacture shall be cast cake of the Copper Alloy UNS No. specified in the purchase order

and shall be of such shape and soundness so as to be suitable for processing into the final product.

5.2 Manufacture—The product shall be manufactured by hot rolling or forging and finished by such cold working and annealing

as may be necessary to achieve the required dimensions and properties.

6. Chemical Composition

6.1 The materials shall conform to the chemical compositional requirements specified in Table 1 for the copper alloy UNS

designations specified in the ordering information.

1

This specification is under the jurisdiction of ASTM Committee B05 on Copper and Copper Alloys and is the direct responsibility of Subcommittee B05.01 on Plate,

Sheet, and Strip.

Current edition approved Jan. 1, 2011Oct. 15, 2012. Published February 2011November 2012. Originally approved in 1942. Last previous edition approved in 20092011

ε1

as B171/B171M – 09a.B171/B171M – 11 . DOI: 10.15

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.