ASTM E1751/E1751M-09e1

(Guide)Standard Guide for Temperature Electromotive Force (emf) Tables for Non-Letter Designated Thermocouple Combinations

Standard Guide for Temperature Electromotive Force (emf) Tables for Non-Letter Designated Thermocouple Combinations

SIGNIFICANCE AND USE

These thermocouple combinations have been developed for specific applications by the wire manufacturer(s). If additional information is required, consult ASTM MNL 12 or one of the following thermocouple manufacturers: Carpenter Technology, Engelhard Corp. Specialty Metals Div., Hoskins Mfg. Co., Johnson Matthey, Sigmund Cohn Corp.

SCOPE

1.1 This guide consists of reference tables that give temperature-electromotive force (emf) relationships for special purpose, limited use, thermocouple combinations that do not have a letter designation.

1.2 Extension wire or compensating extension wires are not covered by this guide. ASTM MNL 12 or thermocouple alloy suppliers should be consulted.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: E1751/E1751M − 09

StandardGuide for

Temperature Electromotive Force (emf) Tables for Non-

1

Letter Designated Thermocouple Combinations

ThisstandardisissuedunderthefixeddesignationE1751/E1751M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Units information and designation was corrected editorially in June 2009.

1. Scope 3.2.1 matched pairs, n—a set of positive and negative

thermoelementschosensothatathermocouplefabricatedfrom

1.1 This guide consists of reference tables that give

these thermoelements will match a specified temperature-

temperature-electromotiveforce(emf)relationshipsforspecial

elctromotive force relationship to within a specified tolerance,

purpose, limited use, thermocouple combinations that do not

at the time of first use.

have a letter designation.

1.2 Extension wire or compensating extension wires are not

4. Source of Data

2

covered by this guide.ASTM MNL12 or thermocouple alloy

4.1 The data in these tables are based on the SIVolt and the

suppliers should be consulted.

International Temperature Scale of 1990.

1.3 The values stated in either SI units or inch-pound units

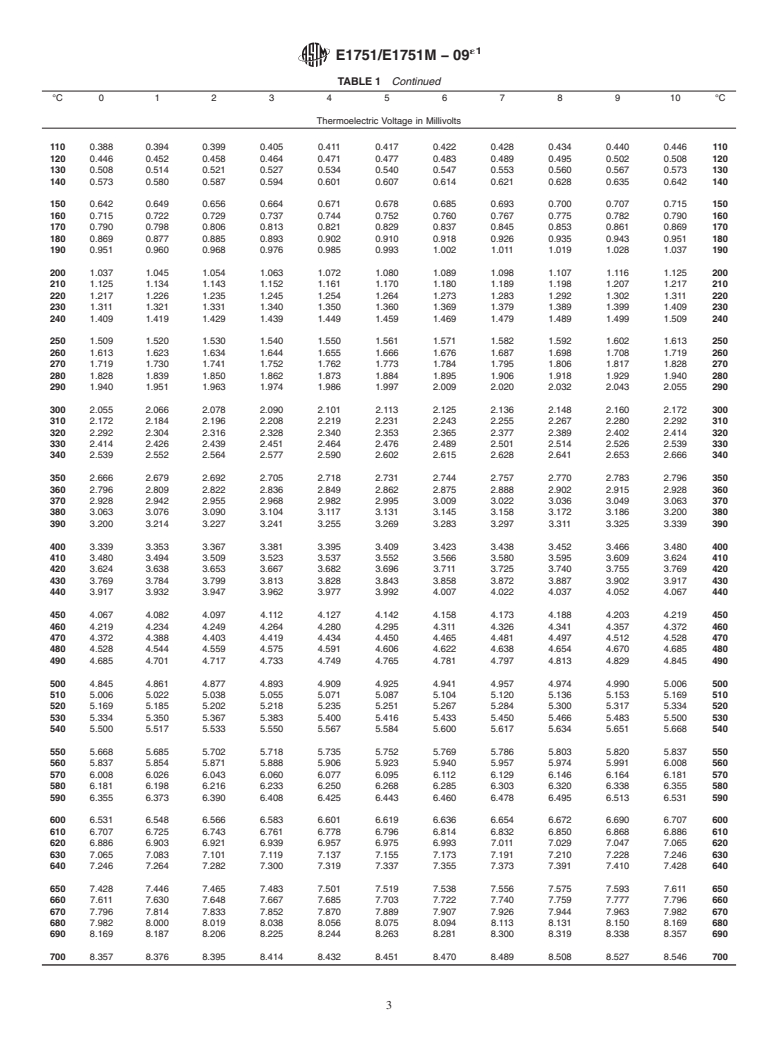

4.2 Alltemperature–electromotiveforcedatainTables1-20

are to be regarded separately as standard. The values stated in

have been developed from NIST, NRC, and wire manufactur-

each system may not be exact equivalents; therefore, each

ers’ data.

system shall be used independently of the other. Combining

4.3 Tables 1-16 give emf values in millivolts to three

values from the two systems may result in non-conformance

decimal places (1 µV) at 1°C or 1°F intervals. Tables 17-20

with the standard.

give emf values in microvolts to one decimal place (0.1 µV) at

1°C or 1°F intervals. If greater precision is required, refer to

2. Referenced Documents

the equation and coefficients listed for each thermocouple

3

2.1 ASTM Standards:

alloy.

E344Terminology Relating to Thermometry and Hydrom-

etry

5. Significance and Use

E696Specification for Tungsten-Rhenium Alloy Thermo-

5.1 These thermocouple combinations have been developed

couple Wire

for specific applications by the wire manufacturer(s). If addi-

tional information is required, consult ASTM MNL 12 or one

3. Terminology

of the following thermocouple manufacturers: Carpenter

3.1 Definitions:

Technology, Engelhard Corp. Specialty Metals Div., Hoskins

3.1.1 For definitions of terms used in this guide see Termi-

Mfg. Co., Johnson Matthey, Sigmund Cohn Corp.

nology E344.

3.2 Definitions of Terms Specific to This Standard:

6. Thermocouple Types

6.1 Letter symbols have not been assigned. Identification is

madebyalloycompositionwiththethermoelectricallypositive

1

This guide is under the jurisdiction ofASTM Committee E20 on Temperature

material listed first.

Measurement and is the direct responsibility of Subcommittee E20.04 on Thermo-

6.1.1 Tungsten versus tungsten−26% rhenium.

couples.

6.1.2 Tungsten−3% rhenium versus tungsten−25% rhe-

Current edition approved June 1, 2009. Published December 2009. Originally

approved in 1995. Last previous edition approved in 2000 as E1751–00, which

nium.

was withdrawn March 2009 and reinstated in June 2009. DOI: 10.1520/E1751_ 4

6.1.3 Platinel II.

E1751M-09E01.

5

2 6.1.4 KP versus gold−0.07% iron.

“Manual on the Use of Thermocouples in Temperature Measurement,” ASTM

Manual, 12, ASTM, 1993.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Trademark of Engelhard Corp., Specialty Metals Division.

5

Standards volume information, refer to the standard’s Document Summary page on Alloy compositions are expressed in percentages by mass, except for the

the ASTM website. gold−0.07% iron alloy, which is given in atomic percent.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

E1751/E1751M − 09

6.1.5 Platinum−5% molybdenum versus platinum−0.1%

Table 13 Nickel−18 % Molybdenum versus −50 °C to 1410 °C

Nickel−0.8 % Cobalt

molybdenum.

Table 14 Nickel−18 % Molybdenum versus −58 °F to 2570 °F

6.1.6 Platinum−40% rhodium versus platinum−20% rho-

Nickel−0.8 % Cobalt

dium. Table 15 Iridium 40 % Rhodium versus Iridium 0 °C to 2110 °C

Table 16 Iridium 40 % Rhodium versus Iridium 32 °F to 3830 °F

6.1.7 Nickel−18% molybdenum versus nickel−0.8% co-

6 Table 17 Gold versus Platinum 0 °C to 1000 °C

balt.

Table 18 Gold versus Platinum 32 °F to 1832 °F

6.1.8 Iridium−40% rhodium versus iridium.

Table 19 Platinum versus Palladium 0 °C to 1500 °C

Ta

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.