ASTM F320-21

(Test Method)Standard Test Method for Hail Impact Resistance of Aerospace Transparent Enclosures

Standard Test Method for Hail Impact Resistance of Aerospace Transparent Enclosures

SIGNIFICANCE AND USE

4.1 This test method shall be used to determine the hail impact resistance of windshields for acceptance, design, service, or research purposes. By using this method with the installed windshield angle and velocity of a specific aerospace vehicle, design allowables, criteria, and tolerances can be established for that vehicle's windshield.

SCOPE

1.1 This test method covers the determination of the impact resistance of an aerospace transparent enclosure (windshield, canopy, window, lens cover, etc.), hereinafter called windshield, during hailstorm conditions using simulated hailstones consisting of ice balls molded under tightly controlled conditions. This test shall also be used to meet hail test or performance requirements that are specified by design or contract.

1.2 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 7.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F320 −21

Standard Test Method for

Hail Impact Resistance of Aerospace Transparent

1

Enclosures

ThisstandardisissuedunderthefixeddesignationF320;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2.1.3 impact angle, n—the angle between the ice ball flight

path and the target normal.

1.1 This test method covers the determination of the impact

2.1.4 sabot, n—a plastic carrier used to carry the ice ball

resistance of an aerospace transparent enclosure (windshield,

down the launch tube. One type of sabot (see Fig. 1) consists

canopy, window, lens cover, etc.), hereinafter called

of a split polycarbonate rod containing a central cavity for

windshield, during hailstorm conditions using simulated hail-

holding the ice ball. Each sabot half is designed to assure

stones consisting of ice balls molded under tightly controlled

aerodynamic separation from the ice ball after exiting from the

conditions. This test shall also be used to meet hail test or

launch tube.

performance requirements that are specified by design or

contract.

3. Summary of Test Method

1.2 Units—The values stated in inch-pound units are to be

3.1 The test method involves launching a series of ice balls

regarded as standard. The values given in parentheses are

of specified sizes at a sample windshield at a designated

mathematical conversions to SI units that are provided for

velocity and angle and in a specified pattern. Requirements are

information only and are not considered standard.

specified for the ice ball, test specimen, procedure, and data

1.3 This standard does not purport to address all of the

acquisition. The ice ball is photographed in flight to verify its

safety concerns, if any, associated with its use. It is the

integrity.

responsibility of the user of this standard to establish appro-

3.2 Requirements are specified for an example apparatus

priate safety, health, and environmental practices and deter-

andtestprocedure,butoptionsarepermitted.However,itmust

mine the applicability of regulatory limitations prior to use.

be demonstrated that the options used result in an ice ball

For specific hazard statements, see Section 7.

impacting the test panel with the same size, consistency, and

1.4 This international standard was developed in accor-

velocity as with the specified apparatus and procedure. Fol-

dance with internationally recognized principles on standard-

lowing are areas where options are allowed:

ization established in the Decision on Principles for the

3.2.1 Ice Ball Mold Material.

Development of International Standards, Guides and Recom-

3.2.2 Launcher—Any type of launcher is allowable as long

mendations issued by the World Trade Organization Technical

as the ice ball reaches the test specimen intact at the correct

Barriers to Trade (TBT) Committee.

speed. The use of sabots and sabot material and geometry are

2. Terminology optional.

3.2.3 Method of Determining Ice Ball Integrity.

2.1 Definitions:

3.2.4 Ice Ball Speed Measurement, as long as accuracy

2.1.1 damage, n—any modification in visual properties or

standards are met.

integrity of a windshield as a result of hail impact including

3.2.5 Test Specimen Sizes—Those given are minimum.

scratches, crazing, delamination, cracks, penetration, or shat-

3.2.6 Safety—Safety must satisfy the safety standards of the

tering.

test facility being used.

2.1.2 ice ball, n—a frozen sphere of water, with filler, that

simulates a natural hailstone in weight, size, and toughness. 4. Significance and Use

4.1 This test method shall be used to determine the hail

1

impact resistance of windshields for acceptance, design,

This test method is under the jurisdiction of ASTM Committee F07 on

Aerospace andAircraft and is the direct responsibility of Subcommittee F07.08 on

service, or research purposes. By using this method with the

Transparent Enclosures and Materials.

installed windshield angle and velocity of a specific aerospace

Current edition approved May 1, 2021. Published June 2021. Originally

vehicle, design allowables, criteria, and tolerances can be

approved in 1978. Last previous edition approved in 2016 as F320–16. DOI:

10.1520/F0320-21. established for that vehicle’s windshield.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

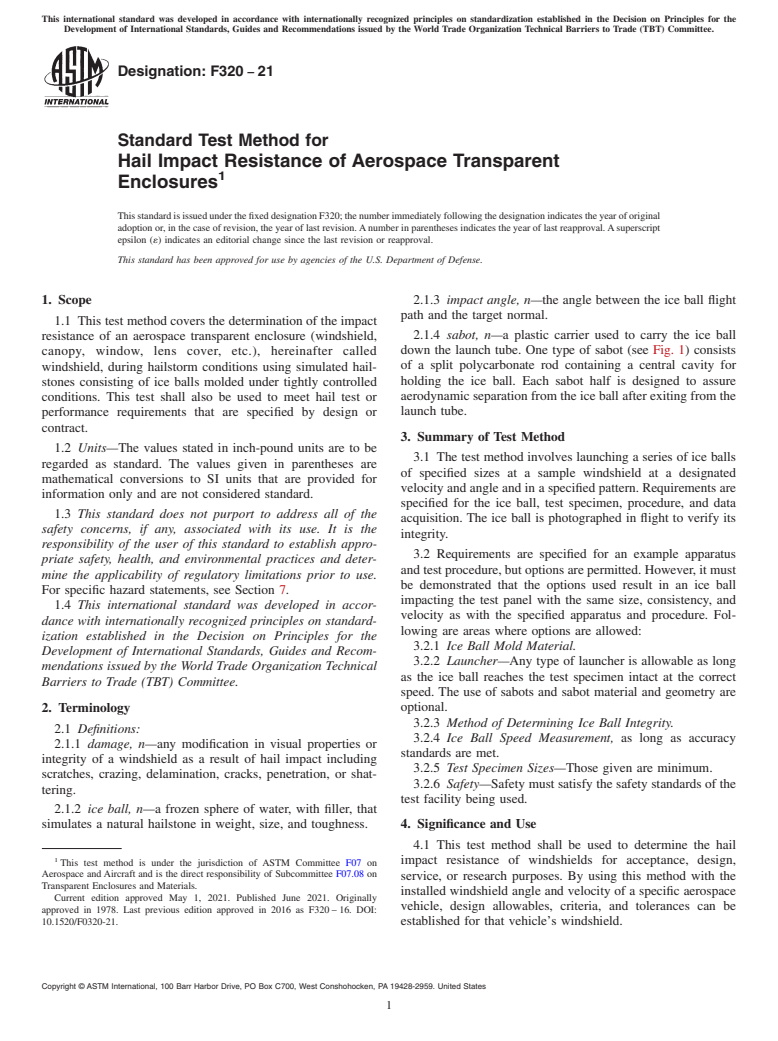

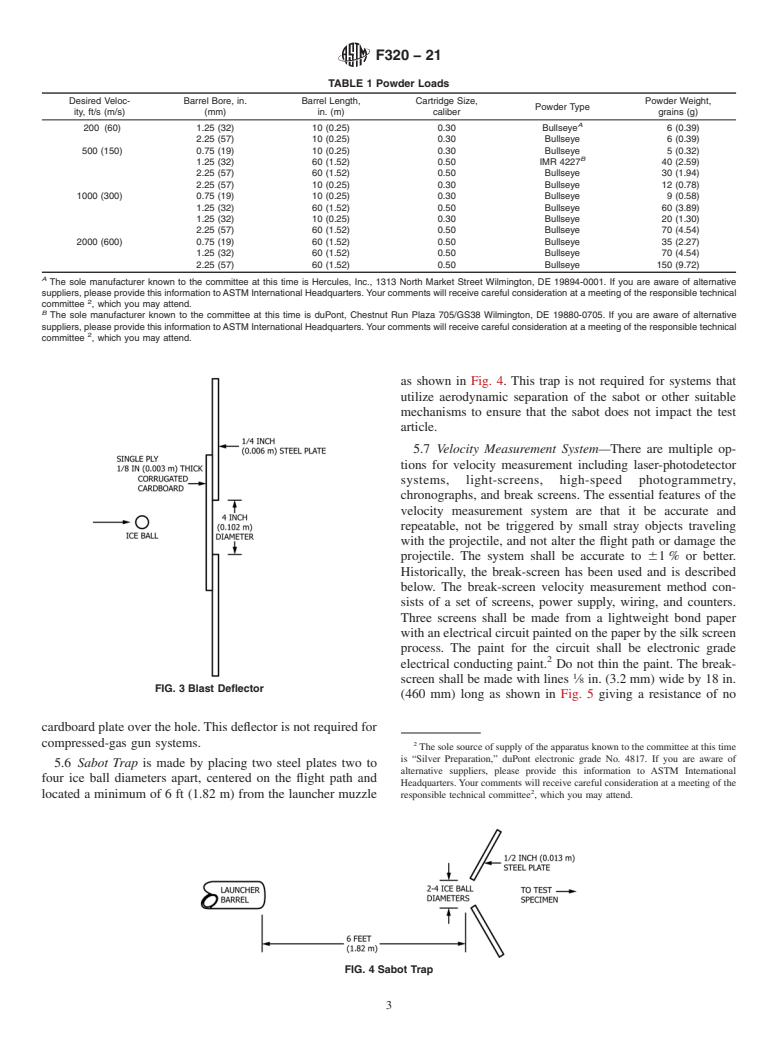

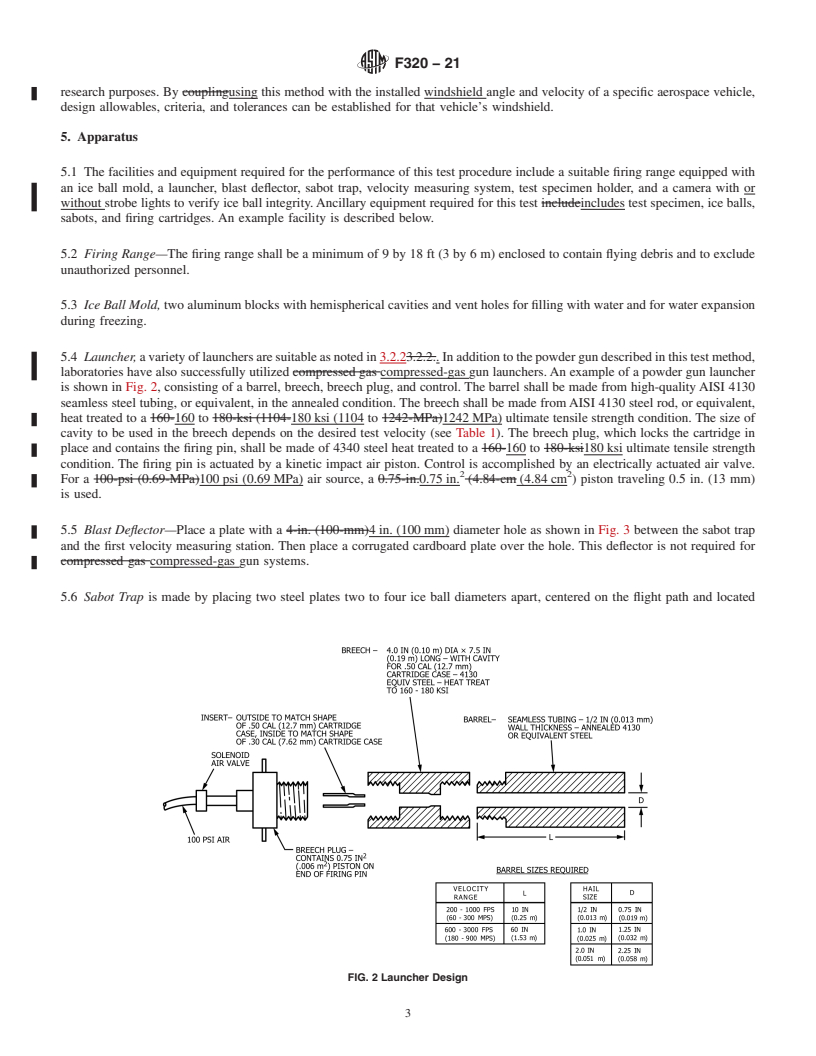

---------------------- Page: 1 ----------------------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F320 − 16 F320 − 21

Standard Test Method for

Hail Impact Resistance of Aerospace Transparent

1

Enclosures

This standard is issued under the fixed designation F320; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This test method covers the determination of the impact resistance of an aerospace transparent enclosure, enclosure

(windshield, canopy, window, lens cover, etc.), hereinafter called windshield, during hailstorm conditions using simulated

hailstones consisting of ice balls molded under tightly controlled conditions. This test shall also be used to meet hail test or

performance requirements that are specified by design or contract.

1.2 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. For specific hazard statements, see Section 7.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Terminology

2.1 Definitions:

2.1.1 damage, n—any modification in visual properties or integrity of a windshield as a result of hail impact including scratches,

crazing, delamination, cracks, penetration, or shattering.

2.1.2 ice ball, n—a frozen masssphere of water, with filler, that simulates a natural hailstone in weight, size, and toughness.

2.1.3 impact angle, n—the angle between the ice ball flight path and the target normal.

2.1.4 sabot, n—a plastic device for protecting carrier used to carry the ice ball while in down the launch tube. One type of sabot

(see Fig. 1) consists of a split polycarbonate rod containing a central cavity for holding the ice ball. Each sabot half is designed

to assure aerodynamic separation from the ice ball after ejectionexiting from the launch tube.

1

This test method is under the jurisdiction of ASTM Committee F07 on Aerospace and Aircraft and is the direct responsibility of Subcommittee F07.08 on Transparent

Enclosures and Materials.

Current edition approved April 1, 2016May 1, 2021. Published April 2016June 2021. Originally approved in 1978. Last previous edition approved in 20102016 as

F320 – 10.F320 – 16. DOI: 10.1520/F0320-16.10.1520/F0320-21.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F320 − 21

FIG. 1 Sabot Configuration

3. Summary of Test Method

3.1 The test method involves launching a series of ice balls of specified sizes at a sample windshield at a designated velocity and

angle and in a specified pattern. Requirements are specified for the ice ball, test specimen, procedure, and data acquisition. The

ice ball is photographed in flight to verify its integrity.

3.2 Requirements are specified for a particularan example apparatus and test procedure, but options are permitted for certain areas.

permitted. However, it must be possible to demonstrate demonstrated that the options used result in an ice ball impacting the test

panel with the same size, consistency, and velocity as with the specified apparatus and procedure. Following are areas where

options are allowed:

3.2.1 Ice Ball Mold Material.

3.2.2 Launcher—Any type of launcher is allowable as long as the iceball ice ball reaches the test specimen intact at the correct

speed. The use of sabots and sabot material and geometry are optional.

3.2.3 Method of Determining Ice Ball Integrity.

3.2.4 Ice Ball Speed Measurement, optional as long as accuracy standards are met.

3.2.5 Test Specimen Sizes—Those given are minimum.

3.2.6 Safety—Safety must satisfy the safety standards of th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.