ASTM F1471-93(2001)

(Test Method)Standard Test Method for Air Cleaning Performance of a High-Efficiency Particulate Air- Filter System

Standard Test Method for Air Cleaning Performance of a High-Efficiency Particulate Air- Filter System

SIGNIFICANCE AND USE

This test method describes a procedure for determining the penetration of aerosols through a one- or twostage HEPA filter installation. Testing multiple filter stages as a single unit eliminates the need for: installation of auxiliary aerosol bypass ducts, installation of aerosol injection manifolds between filter stages, and entry of test personnel into contaminated areas. It provides for filter testing without interruption of plant processes and operation of ventilation systems.

The procedure is applicable for measuring penetrations requiring sensitivities to 0.1 μm.

A challenge concentration of 2.5 × 10 5 particles/cm3 (p/cm3), is required for evaluation of one-filter stage, and 2 × 106 p/cm 3, or about 30 μg/L (assuming unit density), is required to properly evaluate a two-stage HEPA filter system as one unit.

This test method can determine the penetration of HEPA filters in the particle-size range from 0.1 to 0.2 μm where the greatest penetration of particles is likely to occur.

SCOPE

1.1 This test method covers the procedure and equipment for measuring the penetration of test particles through high-efficiency particulate air (HEPA) filter systems using a laser aerosol spectrometer (LAS). This test method provides the capability of evaluating the overall effectiveness of HEPA filter systems consisting of one or two filter stages.

1.2 The aerosols used for testing have a heterodisperse size distribution in the submicrometer diameter range from 0.1 to 1.0 µm.

1.3 The purpose for conducting in-place filter testing by this test method is in the ability to determine penetration of multi-stage installations, without individual stage tests. Particle penetration as low as 10-8 can be measured by this test method. Also, the LAS provides a measure of penetration for discrete particle sizes.

1.4 Maximum penetration for an installed HEPA filter system is 5 X 10-4 for one filter stage, and 2.5 X 10-7 for two stages in series is recommended.

Note 1--Acceptance penetration criteria must be specified in the program, or owners specifications. The penetration criteria suggested in this test method is referenced in Ref (1).

1.5 The values stated in SI units are to be regarded as the standard.

1.6 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.Specific precautionary statements are given in 9.6.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1471–93 (Reapproved 2001)

Standard Test Method for

Air Cleaning Performance of a High-Efficiency Particulate

Air Filter System

This standard is issued under the fixed designation F1471; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope F328 Practice for Calibration of an Airborne Particle

Counter Using Monodisperse Spherical Particles

1.1 This test method covers the procedure and equipment

2.2 Military Standard:

for measuring the penetration of test particles through high-

MIL-STD 282 Military Standard Filter Units, Protective

efficiency particulate air (HEPA) filter systems using a laser

Clothing, Gas Mask Components, and Related Products:

aerosol spectrometer (LAS). This test method provides the

Performance Test Method

capabilityofevaluatingtheoveralleffectivenessofHEPAfilter

systems consisting of one or two filter stages.

3. Terminology

1.2 The aerosols used for testing have a heterodisperse size

3.1 Definitions of Terms Specific to This Standard:

distribution in the submicrometer diameter range from 0.1 to

3.1.1 diluter—a device used to reduce the aerosol particle

1.0 µm.

concentration to eliminate coincidence counting is in the LAS.

1.3 Thepurposeforconductingin-placefiltertestingbythis

3.1.2 dilution ratio—the ratio of the undiluted aerosol

test method is in the ability to determine penetration of

particleconcentrationenteringthedilutertothedilutedportion

multi-stageinstallations,withoutindividualstagetests.Particle

−8 of the particle concentration. Because diluters have inherent

penetrationaslowas10 canbemeasuredbythistestmethod.

particle losses that may vary according to the particle size, the

Also, the LAS provides a measure of penetration for discrete

dilution ratio may not be constant with respect to size.

particle sizes.

3.1.3 laser aerosol spectrometer (LAS)—aprecisionparticle

1.4 Maximum penetration for an installed HEPA filter

−4 −7 detector that allows single particle counting and sizing by the

system is 5 310 for one filter stage, and 2.5 310 for two

amount of scattered light from individual particles, where the

stages in series is recommended.

signals can be grouped into categories corresponding to par-

NOTE 1—Acceptance penetration criteria must be specified in the

ticle size.

program, or owners specifications. The penetration criteria suggested in

3.1.4 penetration—the number of particles passing through

this test method is referenced in Ref (1).

the filter stage, to the number of particles challenging the

1.5 The values stated in SI units are to be regarded as the

upstream side of the filter stage. The penetration, or the

standard.

challenge aerosol, may be associated for each particle size of

1.6 This standard does not purport to address all of the

interest.

safety problems, if any, associated with its use. It is the

4. Summary of Test Method

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4.1 A challenge aerosol produced by Di(2-Ethylhexyl) Se-

bility of regulatory limitations prior to use. Specific precau-

bacate (DOS) or Di(2-Ethylhexyl) Phthalate (DOP) is injected

tionary statements are given in 9.6.

upstream of the filter system and allowed to mix with the

airstream. Using a LAS, samples of the aerosol are collected

2. Referenced Documents

from the airstream through probes, both upstream and down-

2.1 ASTM Standards:

stream of the filter system. With this test method, the penetra-

tion of the filter system can be calculated either as a function

of particle size, or in a particular size of interest. Due to high

1 particle concentrations that may be required to evaluate the

This test method is under the jurisdiction of ASTM Committee D22 on Air

performance of HEPAfilter systems, it may become necessary

Quality and is the direct responsibility of Subcommittee D22.05 on Indoor Air.

Current edition approved Feb. 15, 1993. Published April 1993.

to dilute the upstream sample to avoid errors due to coinci-

The boldface numbers in parentheses refer to a list of references at the end of

dence counting by the LAS.

this standard.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1471–93 (2001)

4.2 If a diluter is required, the diluter system is calibrated 6.7 An aerosol diluter is required to reduce the number of

using lower particle counts of the same aerosol and using the particles of the upstream sample to avoid significant coinci-

LAS for the measurements (refer toAnnexA1 for calibration). dence counting losses in the LAS. The diluter must have

4.3 Heterodisperse submicrometer aerosols spanning the minimumparticlelossesoverthesizerangeofinterestandthat

diameter range from 0.1 to 1.0 µm are used in the testing. the losses are constant with particle size. Calibration of the

diluter is done with the LAS.The diluter calibration procedure

5. Significance and Use

isindicatedinAnnexA2.Aschematicdiagramofthediluterin

5.1 This test method describes a procedure for determining

calibration mode is shown in Fig.A2.1.The diluter calibration

the penetration of aerosols through a one- or twostage HEPA

plotispresentedinFig.A2.2.Atypicaldiluterwithdimensions

filter installation. Testing multiple filter stages as a single unit

is illustrated in Fig. A2.3.

eliminatestheneedfor:installationofauxiliaryaerosolbypass

6.8 Aerosol Generation —It is required that the generator

ducts, installation of aerosol injection manifolds between filter

produceaparticle-sizedistributioncoveringthediameterrange

stages, and entry of test personnel into contaminated areas. It

from0.1to1.0µm.Itmusthavethecapabilityofachievingup

provides for filter testing without interruption of plant pro-

to 3000 p/s in gas streams when testing multiple-stage HEPA

cesses and operation of ventilation systems.

filter systems.

5.2 The procedure is applicable for measuring penetrations 6.9 For streams where large volumes of aerosol are not

requiring sensitivities to 0.1 µm.

required, an air-operated or small gas-thermal generator may

5 3

5.3 Achallengeconcentrationof2.5 310 particles/cm (p/ be used.

3 6

cm ),isrequiredforevaluationofone-filterstage,and2 310

6.10 Injection ports, or manifolds, must be provided for

p/cm ,orabout30µg/L(assumingunitdensity),isrequiredto distributing the aerosol uniformly with the gas stream. Up-

properly evaluate a two-stage HEPA filter system as one unit.

stream and downstream probes are required to extract aerosol

5.4 ThistestmethodcandeterminethepenetrationofHEPA samplesfrominsidethefilterhousing.Thelocationofinjection

filters in the particle-size range from 0.1 to 0.2 µm where the

ports and sample collection probes or manifolds must be

greatest penetration of particles is likely to occur.

located in accordance with the requirements in Annex A3.

6.11 It is recommended that sample lines between the LAS,

6. Apparatus

diluter, and the upstream and downstream probes be the same

6.1 LAS —TheLASisaparticledetectorforthepurposeof

size and material, and the same length as practicable.

sizingandcountingsingleparticlesinagasstream.Upto3000

particles per second (p/s) can be counted with less than 10%

7. Reagent and Materials

coincidence, or electronic loss at its maximum flow rate. The 8

7.1 DOP or DOS is used as the liquid material to form test

quantitative particle size distribution shall be a distribution by

aerosols.

number, not mass, volume, or surface area.

7.2 Polystyrene Latex Spheres.

6.2 The test aerosol should be in the diameter range from

0.1 to 1.0 µm.

8. Calibration and Standardization

6.3 The primary particle-size calibration of the LAS by the

8.1 Perform the primary calibration of the LAS by the

manufacturer shall be based on at least three sizes of mono-

instrument manufacturer or by qualified personnel using ac-

disperse polystyrene latex spheres (PSLs), covering the dy-

ceptablestandardmethodsinaccordancewithRef(2).Perform

namic range of the LAS. Calibration standards must be

calibrations at regular twelve-month intervals and following

traceabletotheNationalInstituteofStandardsandTechnology

any repair or modification of the instrument. Place a label

(NIST).

showing the due date of the next calibration on the instrument.

6.4 Sample flow accuracy through the LAS of 65% is

8.2 A check calibration by the operator is recommended

required, based on the manufacturer’s specifications. (Refer to

periodically if the instrument is used continuously or is moved

manufacturer’s guide for altitude adjustments of the sample

to a new test location requiring vehicle transportation or rough

volume.)

handling. The calibration check consists of testing the LAS

6.5 The LAS must have the capability for producing a

with at least two sizes of PSLs. The LAS must correctly size

listing of the particle size distribution over the LAS range. A

the calibration aerosols and reproduce the spectral peak to

standard RS-232C interface signal for line printers, tape

within 0.05 µm. If the instrument cannot be adjusted to within

recorders, and computers is usually provided with the instru-

those calibration limits, then it must be returned to the

ment.

6.6 For calibration aerosol having a median size two times

the minimum detectable size of the LAS, the relative standard

AvailablefromTSIIncorporatedParticleInstrumentGroup,P.O.Box64394St.

deviationoftheparticlesizedistributionindicatedbytheLAS,

Paul, MN 55164.

shall not be increased more than 10% over the actual relative

Aerosol generators are available from the following sources: Air Techniques

standard deviation of the calibration aerosol.

Division of Hamilton Associates, Inc., Baltimore, MD 21207, Particle Measure-

ments Systems, Inc., 1815 South 57th Court, Boulder, CO 80301 (Calibration), and

Nuclear Consulting Services, Inc., P.O. Box 29151, Columbus, OH 43229.

5 8

Laser aerosol spectrometers are available from the following sources: Particle Di(2-Ethylhexyl) Phthalate (DOP) and Sebacate (DOS) are available from C.P.

Measuring Systems, Inc., 1815 South 57th Court, Boulder, CO 80301, TSI Hall Co., Chicago, IL 60635, and Nuclear Consulting Services, Inc., P.O. Box

Incorporated Particle Instruments Group, P.O. Box 64394, St. Paul, MN 55164, and 29151, Columbus, OH 43229.

Met One, Inc., 481 California Avenue, Grants Pass, OR 97526. Available from Duke Scientific Corp., Palo Alto, CA 94303.

F1471–93 (2001)

manufacturerforserviceandcalibration.AnnexA1describesa of the filters by the test aerosols by injecting the aerosols only

procedure for calibration of the LAS. when ready to perform penetration measurements).

8.3 Aerosol Diluter—It is recommended that the same

9.7 Collect samples from the upstream probe and establish

aerosol used in the in-place testing be used for diluter calibra- thechallengeparticlecount.Thisisaccomplishedbyswitching

tion. If more than one dilution stage is required, each stage

the sample line from the LAS to the diluter. Sampling periods

must be calibrated independently. A procedure for calibration are usually 20 s, refer to Annex A2.

of the diluter using the LAS is outlined in Annex A2.

9.8 Purge the sample collection system and zero the LAS

before proceeding to the next step in the procedure. The

9. Procedure

purging procedure is described in A2.1.2 of Annex A2.

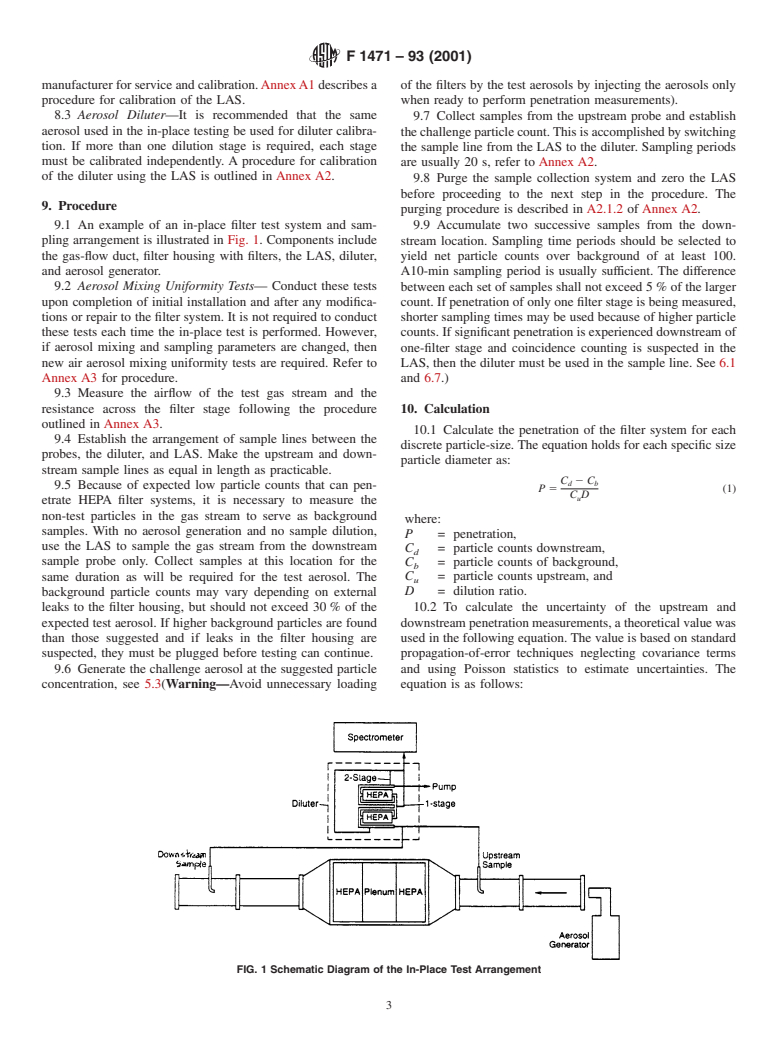

9.1 An example of an in-place filter test system and sam- 9.9 Accumulate two successive samples from the down-

pling arrangement is illustrated in Fig. 1. Components include stream location. Sampling time periods should be selected to

the gas-flow duct, filter housing with filters, the LAS, diluter, yield net particle counts over background of at least 100.

and aerosol generator. A10-min sampling period is usually sufficient. The difference

9.2 Aerosol Mixing Uniformity Tests— Conduct these tests between each set of samples shall not exceed 5% of the larger

upon completion of initial installation and after any modifica- count.Ifpenetrationofonlyonefilterstageisbeingmeasured,

tions or repair to the filter system. It is not required to conduct shorter sampling times may be used because of higher particle

these tests each time the in-place test is performed. However, counts.Ifsignificantpenetrationisexperienceddownstreamof

if aerosol mixing and sampling parameters are changed, then

one-filter stage and coincidence counting is suspected in the

new air aerosol mixing uniformity tests are required. Refer to LAS, then the diluter must be used in the sample line. See 6.1

Annex A3 for procedure.

and 6.7.)

9.3 Measure the airflow of the test gas stream and the

resistance across the filter stage following the procedure

10. Calculation

outlined in Annex A3.

10.1 Calculate the penetration of the filter system for each

9.4 Establish the arrangement of sample lines between the

discrete particle-size.The equation holds for each specific size

probes, the diluter, and LAS. Make the upstream and down-

particle diameter as:

stream sample lines as equal in length as practicable.

C 2 C

d b

9.5 Because of expected low particle counts that can pen-

P 5 (1)

C D

u

etrate HEPA filter systems, it is necessary to measure the

non-test particles in the gas stream to serve as background

where:

samples. With no aerosol generation and no sample dilution,

P = penetration,

use the LAS to sample the gas stream from the downstream

C = particle counts downstream,

d

sample probe only. Collect samples at this location for the

C = particle counts of background,

b

C = particle counts upstream, and

same duration as will be required for the test aerosol. The

u

D = dilution ratio.

background particle counts may vary depending on external

leaks to the filter housing, but should not exceed 30% of the 10.2 To calculate the uncertainty of the upstream and

expected test aerosol. If higher background particles are found downstreampenetrationmeasurements,atheoreticalvaluewas

than those suggested and if leaks in the filter housing are used in the following equation.The value is based on standard

suspected, they must be plugged before testing can continue. propagation-of-error techniques neglecting covariance terms

9.6 Generate the challenge aeros

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.