ASTM F1471-93(2001)

(Test Method)Standard Test Method for Air Cleaning Performance of a High-Efficiency Particulate Air- Filter System

Standard Test Method for Air Cleaning Performance of a High-Efficiency Particulate Air- Filter System

SIGNIFICANCE AND USE

This test method describes a procedure for determining the penetration of aerosols through a one- or twostage HEPA filter installation. Testing multiple filter stages as a single unit eliminates the need for: installation of auxiliary aerosol bypass ducts, installation of aerosol injection manifolds between filter stages, and entry of test personnel into contaminated areas. It provides for filter testing without interruption of plant processes and operation of ventilation systems.

The procedure is applicable for measuring penetrations requiring sensitivities to 0.1 μm.

A challenge concentration of 2.5 × 10 5 particles/cm3 (p/cm3), is required for evaluation of one-filter stage, and 2 × 106 p/cm 3, or about 30 μg/L (assuming unit density), is required to properly evaluate a two-stage HEPA filter system as one unit.

This test method can determine the penetration of HEPA filters in the particle-size range from 0.1 to 0.2 μm where the greatest penetration of particles is likely to occur.

SCOPE

1.1 This test method covers the procedure and equipment for measuring the penetration of test particles through high-efficiency particulate air (HEPA) filter systems using a laser aerosol spectrometer (LAS). This test method provides the capability of evaluating the overall effectiveness of HEPA filter systems consisting of one or two filter stages.

1.2 The aerosols used for testing have a heterodisperse size distribution in the submicrometer diameter range from 0.1 to 1.0 µm.

1.3 The purpose for conducting in-place filter testing by this test method is in the ability to determine penetration of multi-stage installations, without individual stage tests. Particle penetration as low as 10-8 can be measured by this test method. Also, the LAS provides a measure of penetration for discrete particle sizes.

1.4 Maximum penetration for an installed HEPA filter system is 5 X 10-4 for one filter stage, and 2.5 X 10-7 for two stages in series is recommended.

Note 1--Acceptance penetration criteria must be specified in the program, or owners specifications. The penetration criteria suggested in this test method is referenced in Ref (1).

1.5 The values stated in SI units are to be regarded as the standard.

1.6 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.Specific precautionary statements are given in 9.6.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1471–93 (Reapproved 2001)

Standard Test Method for

Air Cleaning Performance of a High-Efficiency Particulate

1

Air Filter System

This standard is issued under the fixed designation F1471; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope F328 Practice for Calibration of an Airborne Particle

Counter Using Monodisperse Spherical Particles

1.1 This test method covers the procedure and equipment

2.2 Military Standard:

for measuring the penetration of test particles through high-

MIL-STD 282 Military Standard Filter Units, Protective

efficiency particulate air (HEPA) filter systems using a laser

Clothing, Gas Mask Components, and Related Products:

aerosol spectrometer (LAS). This test method provides the

4

Performance Test Method

capabilityofevaluatingtheoveralleffectivenessofHEPAfilter

systems consisting of one or two filter stages.

3. Terminology

1.2 The aerosols used for testing have a heterodisperse size

3.1 Definitions of Terms Specific to This Standard:

distribution in the submicrometer diameter range from 0.1 to

3.1.1 diluter—a device used to reduce the aerosol particle

1.0 µm.

concentration to eliminate coincidence counting is in the LAS.

1.3 Thepurposeforconductingin-placefiltertestingbythis

3.1.2 dilution ratio—the ratio of the undiluted aerosol

test method is in the ability to determine penetration of

particleconcentrationenteringthedilutertothedilutedportion

multi-stageinstallations,withoutindividualstagetests.Particle

−8 of the particle concentration. Because diluters have inherent

penetrationaslowas10 canbemeasuredbythistestmethod.

particle losses that may vary according to the particle size, the

Also, the LAS provides a measure of penetration for discrete

dilution ratio may not be constant with respect to size.

particle sizes.

3.1.3 laser aerosol spectrometer (LAS)—aprecisionparticle

1.4 Maximum penetration for an installed HEPA filter

−4 −7 detector that allows single particle counting and sizing by the

system is 5 310 for one filter stage, and 2.5 310 for two

amount of scattered light from individual particles, where the

stages in series is recommended.

signals can be grouped into categories corresponding to par-

NOTE 1—Acceptance penetration criteria must be specified in the

ticle size.

program, or owners specifications. The penetration criteria suggested in

3.1.4 penetration—the number of particles passing through

2

this test method is referenced in Ref (1).

the filter stage, to the number of particles challenging the

1.5 The values stated in SI units are to be regarded as the

upstream side of the filter stage. The penetration, or the

standard.

challenge aerosol, may be associated for each particle size of

1.6 This standard does not purport to address all of the

interest.

safety problems, if any, associated with its use. It is the

4. Summary of Test Method

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

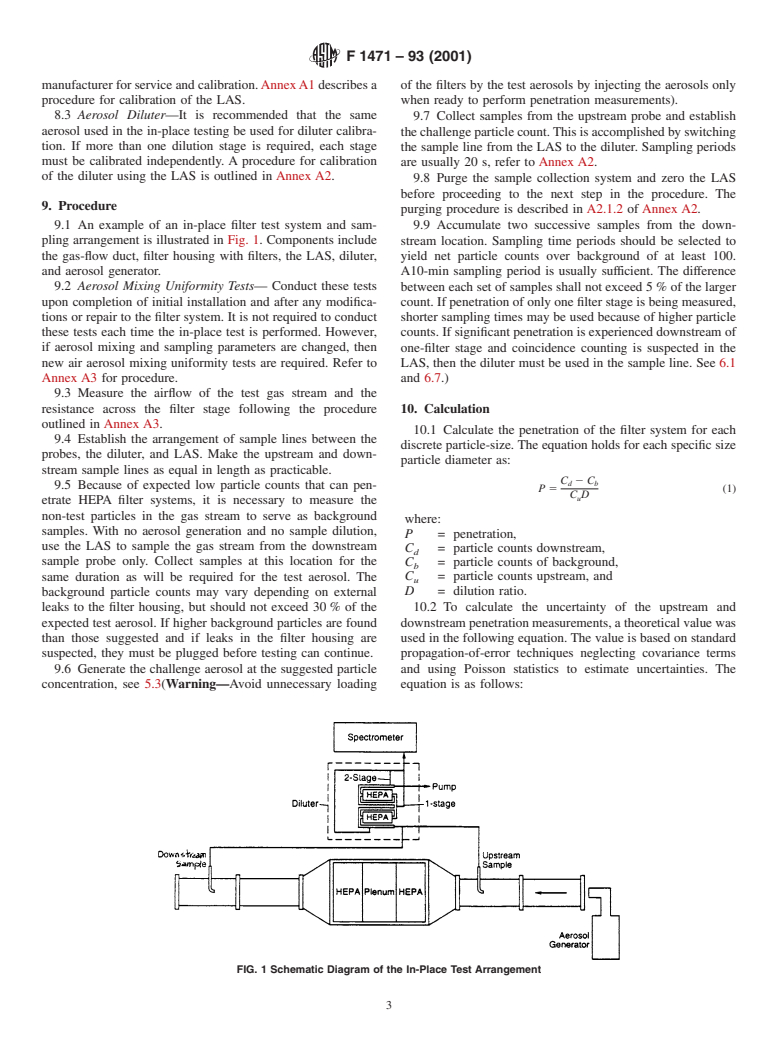

4.1 A challenge aerosol produced by Di(2-Ethylhexyl) Se-

bility of regulatory limitations prior to use. Specific precau-

bacate (DOS) or Di(2-Ethylhexyl) Phthalate (DOP) is injected

tionary statements are given in 9.6.

upstream of the filter system and allowed to mix with the

airstream. Using a LAS, samples of the aerosol are collected

2. Referenced Documents

from the airstream through probes, both upstream and down-

3

2.1 ASTM Standards:

stream of the filter system. With this test method, the penetra-

tion of the filter system can be calculated either as a function

of particle size, or in a particular size of interest. Due to high

1 particle concentrations that may be required to evaluate the

This test method is under the jurisdiction of ASTM Committee D22 on Air

performance of HEPAfilter systems, it may become necessary

Quality and is the direct responsibility of Subcommittee D22.05 on Indoor Air.

Current edition approved Feb. 15, 1993. Published April 1993.

to dilute the upstream sample to avoid errors due to coinci-

2

The boldface numbers in parentheses refer to a list of references at the end of

dence counting by the LAS.

this standard.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, Unit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.