ASTM E1636-10

(Practice)Standard Practice for Analytically Describing Depth-Profile and Linescan-Profile Data by an Extended Logistic Function (Withdrawn 2019)

Standard Practice for Analytically Describing Depth-Profile and Linescan-Profile Data by an Extended Logistic Function (Withdrawn 2019)

SIGNIFICANCE AND USE

Information on interface composition is frequently obtained by measuring surface composition while the specimen material is gradually removed by ion bombardment (see Guide E1127 and Practice E1162). In this way, interfaces are revealed and characterized by the measurement of composition versus depth to obtain a sputter-depth profile. The shape of such interface profiles contains information about the physical and chemical properties of the interface region. In order to accurately and unambiguously describe this interface region and to determine its width (see Guide E1438), it is helpful to define the shape of the entire interface profile with a single analytic function.

Interfaces in depth profiles from one semi-infinite medium to another generally have a sigmoidal shape characteristic of the cumulative logistic distribution. Use of such a logistic function is physically appropriate and is superior to other functions (for example, polynomials) that have heretofore been used for interface-profile analysis in that it contains the minimum number of parameters for describing interface shapes.

Measurements of variations in signal intensity or surface composition as a function of position on a surface give information on the shape of a step or topographic feature on a surface or on the sharpness of an interface at a phase boundary. The shapes of steps or other features on a surface can give information on the lateral resolution of a surface-analysis technique if the sample being measured has sufficiently sharp edges (see ISO 18516). Similarly, the shapes of compositional variations across a surface can give information on the physical and chemical properties of the interface region (for example, the extent of mixing or diffusion across the interface). It is convenient in these applications to describe the measured linescan profile with an appropriate analytic function.

Although the logistic distribution is not the only function that could be used to describe measure...

SCOPE

1.1 This practice describes a systematic method for analyzing depth-profile and linescan data and for accurately characterizing the shape of an interface region or topographic feature. The profile data are described with an appropriate analytic function, and the parameters of this function define the position, width, and any asymmetry of the interface or feature. The use of this practice is recommended in order that the shapes of composition profiles of interfaces or of linescans of topographic features acquired with different instruments or techniques can be unambiguously compared and interpreted.

1.2 This practice is intended to be used for two purposes. First, it can be used to describe the shape of depth-profiles obtained at an interface between two dissimilar materials that might be measured by common surface-analysis techniques such as Auger electron spectroscopy, secondary-ion mass spectrometry, and X-ray photoelectron spectroscopy. Second, it can be used to describe the shape of linescans across a detectable topographic feature such as a step or a feature on a surface that might be measured by a surface-analysis technique, scanning electron microscopy, or scanning probe microscopy. The practice is particularly valuable for determining the position and width of an interface in a depth profile or of a feature on a surface and in assessments of the width as an indication of the sharpness of the interface or feature (a characteristic of the material system being measured) or of the achieved depth resolution of the profile or the lateral resolution of the linescan (a characteristic of the particular analytical technique and instrumentation).

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of t...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1636 −10

Standard Practice for

Analytically Describing Depth-Profile and Linescan-Profile

1

Data by an Extended Logistic Function

This standard is issued under the fixed designation E1636; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This practice describes a systematic method for analyz-

ing depth-profile and linescan data and for accurately charac-

2. Referenced Documents

terizingtheshapeofaninterfaceregionortopographicfeature.

2

The profile data are described with an appropriate analytic

2.1 ASTM Standards:

function, and the parameters of this function define the

E673TerminologyRelatingtoSurfaceAnalysis(Withdrawn

3

position, width, and any asymmetry of the interface or feature.

2012)

The use of this practice is recommended in order that the

E1127Guide for Depth Profiling in Auger Electron Spec-

shapes of composition profiles of interfaces or of linescans of

troscopy

topographic features acquired with different instruments or

E1162Practice for Reporting Sputter Depth Profile Data in

techniques can be unambiguously compared and interpreted.

Secondary Ion Mass Spectrometry (SIMS)

E1438Guide for Measuring Widths of Interfaces in Sputter

1.2 This practice is intended to be used for two purposes.

Depth Profiling Using SIMS

First, it can be used to describe the shape of depth-profiles

4

obtained at an interface between two dissimilar materials that

2.2 ISO Standards:

might be measured by common surface-analysis techniques

ISO18115Surface Chemical Snalysis – Vocabulary, 2001;

such as Auger electron spectroscopy, secondary-ion mass

Amd. 1:2006, Amd. 2:2007

spectrometry,andX-rayphotoelectronspectroscopy.Second,it

ISO18516 Surface Chemical Analysis – Auger Electron

can be used to describe the shape of linescans across a

Spectroscopy and X-Ray Photoelectron Spectroscopy –

detectable topographic feature such as a step or a feature on a

Determination of Lateral Resolution, 2006

surface that might be measured by a surface-analysis

technique, scanning electron microscopy, or scanning probe

3. Terminology

microscopy.The practice is particularly valuable for determin-

3.1 Definitions—For definitions of terms used in this

ing the position and width of an interface in a depth profile or

practice, see Terminology E673 and ISO18115.

of a feature on a surface and in assessments of the width as an

3.2 Definitions of Terms Specific to This Standard:

indication of the sharpness of the interface or feature (a

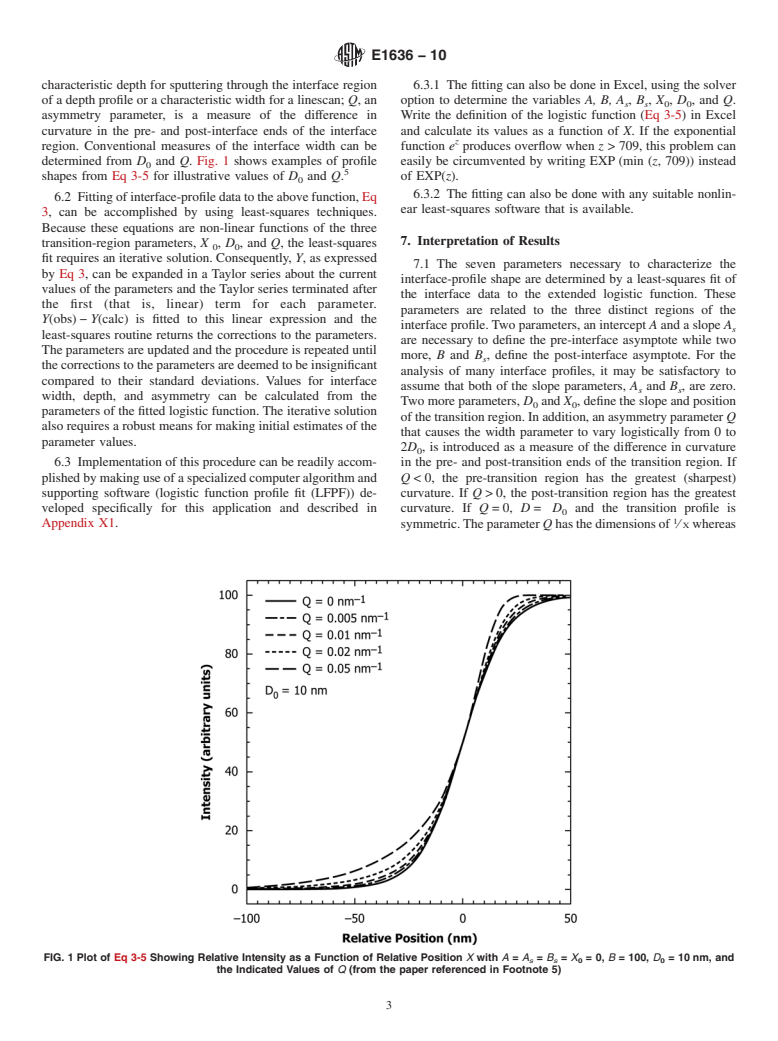

3.2.1 Throughout this practice, three regions of a sigmoidal

characteristic of the material system being measured) or of the

profile will be referred to as the pre-interface, interface, and

achieveddepthresolutionoftheprofileorthelateralresolution

post-interface regions. These terms are not dependent on

of the linescan (a characteristic of the particular analytical

whether a particular interface or feature profile is a growth or

technique and instrumentation).

a decay curve. The terms pre- and post- are taken in the sense

1.3 The values stated in SI units are to be regarded as

of increasing values of the independent variable X, the depth

standard. No other units of measurement are included in this

(for a depth profile) or the lateral position on the surface (for a

standard.

linescan).

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

1

This practice is under the jurisdiction of ASTM Committee E42 on Surface the ASTM website.

3

Analysis and is the direct responsibility of Subcommittee E42.08 on Ion Beam The last approved version of this historical standard is referenced on

Sputtering. www.astm.org.

4

Current edition approved Jan. 1, 2010. Published March 2010. Originally Available from International Organization for Standardization (ISO), 1, ch. de

approved in 1999. Last previous version approved in 2004 as E1636–04. DOI: la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

10.1520/E1636-10. www.iso.ch.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1636−10

4. Summary of Practice 5.5 Manyattemptshavebeen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.