ASTM E402-95

(Test Method)Standard Test Method for Spectrographic Analysis of Uranium Oxide (U3O8)by Gallium Oxide-Carrier Technique

Standard Test Method for Spectrographic Analysis of Uranium Oxide (U<sub>3</sub>O<sub>8</sub>)by Gallium Oxide-Carrier Technique

SCOPE

1.1 This test method covers the semiquantitative spectrographic analysis of high-purity U O for the 32 elements in the ranges indicated in Table 1. (Quantitative analyses of boron, chromium, iron, magnesium, manganese, nickel, and other impurities can be performed using densitometric methods.)

1.2 The test method can be applied to those samples of uranium and uranium compounds, or both, which can be converted to the black oxide (U O ) and which are of approximately 99.5% purity or better.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

Designation: E 402 – 95

Standard Test Method for

Spectrographic Analysis of Uranium Oxide (U O )by

3 8

Gallium Oxide-Carrier Technique

This standard is issued under the fixed designation E402; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope gallium sesquioxide (Ga O ) in the ratio of 98 parts U O to 2

2 3 3 8

parts Ga O . If densitometric determinations are desired, the

1.1 This test method covers the semiquantitative spectro- 2 3

Ga O used in the mixture contains 1% chromium or 1%

2 3

graphicanalysisofhigh-purityU O forthe32elementsinthe

3 8

cobaltbyweight.Thechromiumorcobaltisusedasaninternal

ranges indicated in Table 1. (Quantitative analyses of boron,

standard element in the spectrochemical analysis. The U O -

3 8

chromium, iron, magnesium, manganese, nickel, and other

Ga O mixture is placed in a special cupped electrode and

impurities can be performed using densitometric methods.) 2 3

excited in a d-c arc. Varying amounts of impurities either in

1.2 The test method can be applied to those samples of

vapor form or as solid particles are carried up into the arc

uranium and uranium compounds, or both, which can be

stream, along with the vaporized Ga O , for excitation. The

2 3

converted to the black oxide (U O ) and which are of approxi-

3 8

spectrum is recorded on a photographic plate and the selected

mately 99.5% purity or better.

lines are either visually compared with standard plates or

1.3 This standard does not purport to address all of the

photometrically measured and compared with synthetically

safety concerns, if any, associated with its use. It is the

prepared standards according to standard spectrochemical

responsibility of the user of this standard to establish appro-

procedures.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5. Significance and Use

2. Referenced Documents 5.1 Impurities in the uranium used as fuel for nuclear

reactors may affect the nuclear chain reaction. Their concen-

2.1 ASTM Standards:

trations must be closely controlled. This method provides a

E115 Practice for Photographic Processing in Optical

technique for their determination.

Emission Spectrographic Analysis

E116 Practice for Photographic Photometry in Spectro-

6. Apparatus

chemical Analysis

6.1 Sample Preparation Equipment:

E130 Practice for Designation of Shapes and Sizes of

2 6.1.1 Sample-Carrier Mixers, either a highly polished agate

Graphite Electrodes

mortar and pestle, or a clean plastic capsule with a plastic ball

E135 Terminology Relating to Analytical Chemistry for

2 and a mechanical mixer.

Metals, Ores, and Related Materials

6.2 Balances, torsion type, with capacities up to 1000 mg,

3. Terminology capable of weighing 60.1 mg accurately. When samples are

hand ground it may be necessary to have a balance capacity of

3.1 Fordefinitionsoftermsusedinthistestmethod,referto

2.500 g.

Terminology E135E135.

6.3 Muffle Furnace, capable of 1000°C.

4. Summary of Test Method

6.4 Excitation Source, capable of providing a 14-A d-c arc

(short-circuit).

4.1 The as-received sample is ignited to U O . It is impor-

3 8

6.5 Excitation Stand, conventional type with adjustable

tant that the sample be in the same physical oxide form as are

water cooled electrode holders.

the comparison standards. The sample is mixed with pure

6.6 Spectrograph,grating,providingpreexposureandexpo-

˚

sure timers, wavelength coverage from 2250 to 8650 A,a

This test method is under the jurisdiction of ASTM Committee E-1 on

˚

reciprocal linear dispersion of at least 5 A/mm and sufficient

Analytical Chemistry for Metals, Ores and Related Materials and is the direct

˚

resolving power to separate cadmium 2288.02 A from arsenic

responsibility of Subcommittee E01.05 on Zn, Sn, Pb, Cd, Be, and Other Metals.

˚

Current edition approved Jan. 15, 1995. Published March 1995. Originally 2288.12 A.

published as E402–70. Last previous edition E402–70(1989).

Annual Book of ASTM Standards, Vol 03.05.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

E402–95

A

TABLE 1 Elements and Analytical Ranges

Concentration Range, Concentration Range, Concentration Range,

Element Element Element

ppm ppm ppm

Antimony 1 to 200 Arsenic 10 to 200 Gold 1 to 100

Beryllium 1 to 200 Barium 10 to 200 Indium 1 to 100

Chromium 1 to 200 Cesium 10 to 200 Manganese 1 to 100

Cobalt 1 to 200 Phosphorus 10 to 200 Rubidium 1 to 100

Lead 1 to 200 Vanadium 10 to 200 Tin 1 to 100

Nickel 1 to 200 Zinc 10 to 200 Molybdenum 2 to 100

Potassium 1 to 200 Lithium 0.5 to 100 Thallium 5 to 100

Sodium 1 to 200 Magnesium 0.5 to 100 Silver 0.1 to 50

Aluminum 5 to 200 Copper 0.5 to 100 Cadmium 0.1 to 10

Iron 5 to 200 Bismuth 1 to 100 Boron 0.2 to 10

Silicon 5 to 200 Germanium 1 to 100

A

ppm on uranium basis.

6.7 Photographic Processing Equipment, to provide devel- to facilitate visual comparisons, such a ratio as 10–5–2–1

oping, fixing, washing, and drying operations, and conforming covering the desired analytical range for each. No single

to the requirements of Practices E115E115. standard should have a total concentration of impurities ex-

6.8 Comparator-Microphotometer, as a comparator to pro- ceeding 2000 ppm.The bulk densities of the standards and the

vide sufficient magnification and facility to compare spectral sample U O should be as nearly identical as possible. Similar

3 8

line densities of the sample and a reference standard plate or element responses should be obtained with U O standards

3 8

film; as a microphotometer having a precision of 61.0% or with similar bulk densities, regardless of the method used to

better for transmittance values between 5 and 90%. make the standards. The sample and comparison standards

6.9 Calculating Equipment, capable of transposing percent should have the same physical oxide form and oxide prepara-

transmission values into intensity or density values. tion, if possible. Wherever possible an independent analytical

method should be used to verify the established concentrations

7. Reagents and Materials

in the standards.

8.2 The elements or compounds used to synthesize U O

7.1 Carrier:

3 8

standardsshouldbeofthehighestpurity.Referto(1, 2,and 3)

7.1.1 For visual comparison analysis, use a 99.99% pure

for sources of such materials.

Ga O .

2 3

8.3 If U O of suitable purity is not available for the base

7.1.2 Fordensitometricanalysisexceptforchromium,usea

3 8

material of the standards, the uranium may be purified by

mixture containing 98.54 parts of Ga O and 1.46 parts of

2 3

followingqualitativelysteps1through10ofSectionF,Method

chromium sesquioxide (Cr O ). This is equivalent to 1%

2 3

A of Ref (4).

chromium in this mix or to 200 ppm chromium in the final

U O -Ga O mixture.

3 8 2 3

9. Preparation of Samples

7.1.3 For densitometric analysis except for cobalt, use a

mixture of 98.53 parts of Ga O and 1.47 parts of cobalt oxide 9.1 Ignite sample as received in a muffle furnace at 950°C

2 3

(Co O ). This is equivalent to 1% cobalt in this mix or to 200 for 30 min.

2 3

ppm cobalt in the final U O -Ga O mixture. 9.2 Combine 980 mg of the U O sample and 20 mg of the

3 8

3 8 2 3

7.2 Electrodes—The anode, pedestal and the counter elec- proper Ga O carrier by thoroughly grinding with an agate

2 3

trodes should be respectively of the S-1, S-2 and C-1 types as mortar and pestle. Weigh quadruplicate 100-mg U O -Ga O

3 8 2 3

given in Practice E130E130. The graphite should be a charges into anode electrodes held in a plastic electrode board.

high-purity type with an average density near 1.85 g/cm and Gently tap the electrode board to settle the electrode charges.

−4

a specific electrical resistance near 4.5 310 V-in. Compress the charges and introduce center vent hole in the

7.3 Photographic Emulsion, Eastman Kodak, Type SA No. charge with a venting tool similar to the one shown in Fig. 1.

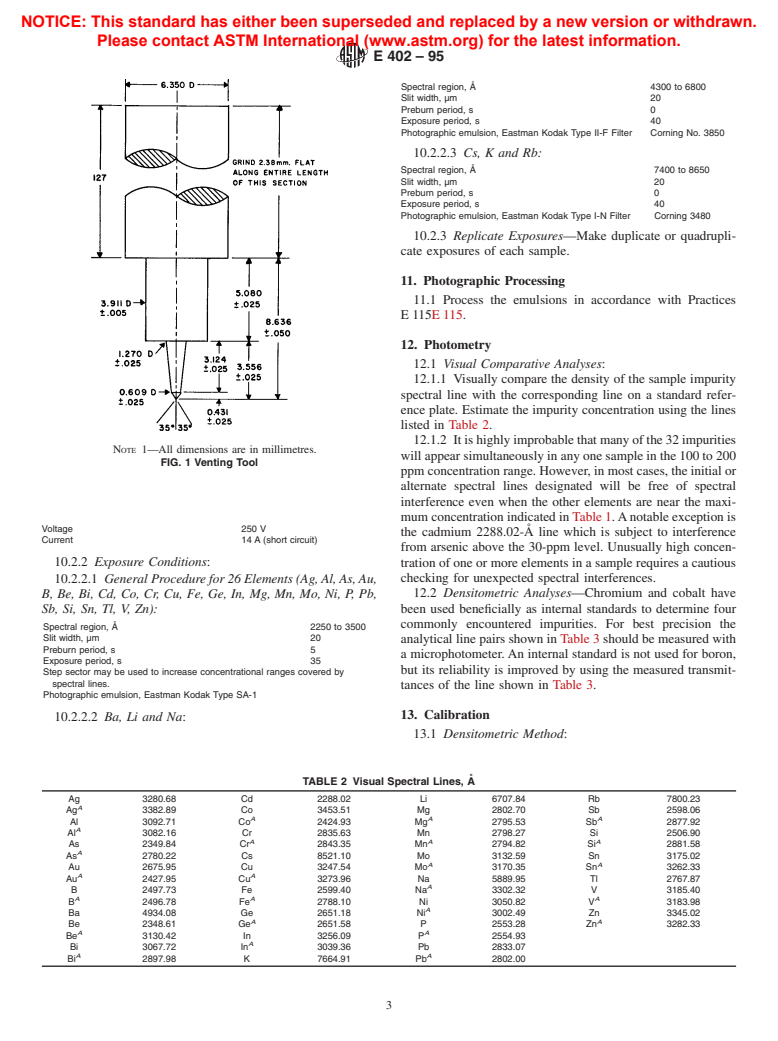

1, II-F and I-N plates or film, or equivalent.

10. Preparation of Apparatus

NOTE 1—TypeII-Fplatesarenotavailable.Comparableresultsmaybe

10.1 Electrode System—Insert a ⁄8-in. counter electrode in

obtained for Ba on SA No. 1 and Li and Na on I-N plates.

the upper holder. Mount a ⁄8-in. pedestal electrode so as to

7.4 Photographic Processing Solutions, Formulas for pro-

extend ⁄2in.abovethelowerelectrodeholder.Inserttheanode

cessing solutions are given in Practices E115E115.

electrode, with its charge, firmly on the pedestal. Adjust to an

analytical gap of 4 mm, with its center aligned with the optical

8. Standards

axis of the spectrograph. The sample is electrically positive.

8.1 Standards can be synthesized by adding the impurity

10.2 Excitation and Exposure—Produce and record the

elements to purified U O and homogenizing. Impurities in a

3 8

spectra in accordance with the following conditions:

solid or powder form, preferably as oxides, may be blended

10.2.1 Electrical Parameters:

with U O ; impurities in solution may be added to U O , and

3 8 3 8

themixturedried,blended,andreignited;ortheimpuritiesand

uranium may be combined in solution and reconverted to

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

U O . The individual elements should grade in such a ratio as this method.

3 8

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.